Contents

Manufacturing Insight: Custom Sheet Metal Bending

Precision Custom Sheet Metal Bending: Engineered for Your Application

Honyo Prototype delivers advanced custom sheet metal bending solutions designed to meet the exacting demands of complex prototyping and low-to-mid volume production. Our expertise centers on achieving tight tolerances and intricate geometries using state-of-the-art CNC press brakes, ensuring consistent repeatability and structural integrity across diverse materials including aluminum, stainless steel, cold-rolled steel, and specialty alloys. We understand that precision bending is not merely a forming step but a critical determinant of final assembly fit, function, and performance, directly impacting your product’s success.

Our comprehensive Sheet Metal Fabrication services extend seamlessly beyond bending to encompass the entire manufacturing workflow. From initial laser cutting and precision punching to welding, finishing, and final assembly, Honyo provides a single-source solution. This integrated approach, managed by experienced manufacturing engineers, minimizes lead times, reduces potential errors from supplier handoffs, and guarantees that every bent component adheres to rigorous quality standards throughout the fabrication process. We specialize in transforming complex 2D flat patterns into accurately formed 3D parts, regardless of geometric complexity or material thickness requirements.

Accelerate your project timeline with Honyo’s Online Instant Quote system. Gain immediate, accurate pricing and manufacturability feedback for your custom bending and fabrication needs directly through our web portal. Simply upload your CAD file, specify materials and quantities, and receive a detailed quote within minutes—no waiting for manual RFQ processing. This transparent, efficient tool empowers engineering and procurement teams to make faster design and sourcing decisions, moving your critical hardware from concept to physical prototype or production with unprecedented speed. Leverage Honyo’s engineering-driven fabrication and instant quoting to optimize your supply chain.

Technical Capabilities

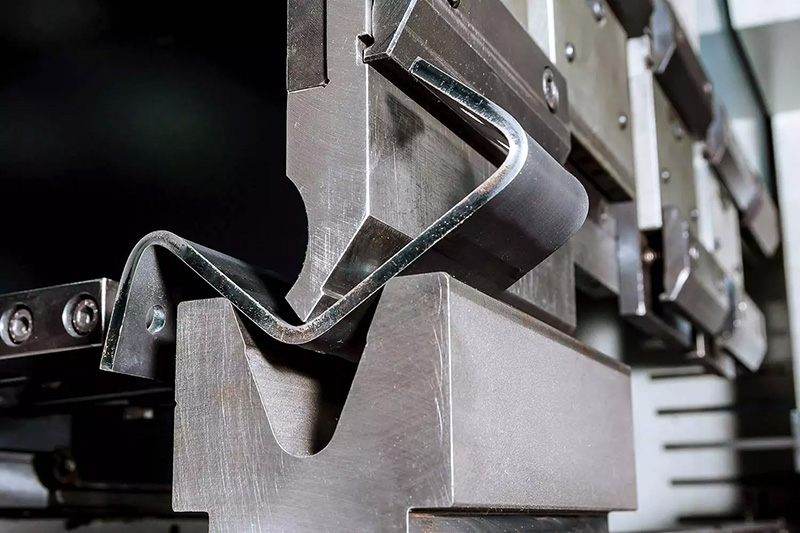

Custom sheet metal bending involves a series of precision fabrication processes including laser cutting, bending, and welding. These operations are performed to transform flat sheet materials into complex structural components according to engineering specifications. The process begins with laser cutting for accurate profile definition, followed by CNC press braking for precise angular bends, and completed with welding when assemblies require permanent joints. Below are the technical specifications for each process, including compatible materials such as aluminum, steel, ABS, and nylon.

Laser Cutting Specifications

| Parameter | Specification |

|---|---|

| Cutting Method | Fiber laser cutting (for metals); CO₂ laser (for plastics) |

| Maximum Cutting Thickness | Aluminum: 20 mm, Steel: 25 mm, ABS: 10 mm, Nylon: 8 mm |

| Positional Accuracy | ±0.1 mm |

| Kerf Width | 0.1 – 0.3 mm (material and thickness dependent) |

| Edge Quality | Burr-minimized, oxidation-free (especially on stainless and aluminum) |

| Supported Materials | Aluminum (5052, 6061, 7075), Mild Steel (CRS, HRMS), Stainless Steel (304, 316), ABS, Nylon (PA6, PA66) |

CNC Bending Specifications

| Parameter | Specification |

|---|---|

| Bending Method | CNC press brake with hydraulic or electric servo drive |

| Maximum Sheet Size | 3000 mm × 1500 mm |

| Maximum Material Thickness | Aluminum: 6 mm, Steel: 6 mm, ABS: 3 mm, Nylon: 3 mm |

| Minimum Flange Length | 2.5 × material thickness + bend radius |

| Bend Radius | Typically 0.8 mm to 5 mm (tooling and material dependent) |

| Angular Accuracy | ±0.25° |

| Tooling | Standard V-dies and punches; custom tooling available for special geometries |

| Materials Supported | Aluminum alloys, Cold Rolled Steel, Stainless Steel, ABS (limited), Nylon (limited, requires preheating) |

Welding Specifications

| Parameter | Specification |

|---|---|

| Welding Process | TIG (preferred for aluminum and stainless), MIG (for carbon steel), Spot Welding |

| Joint Types | Butt, fillet, edge, corner, and lap joints |

| Penetration Control | Adjustable current and pulse settings for thin to thick materials |

| Heat Input | Minimized to reduce warping; back purging used for critical stainless joints |

| Post-Weld Treatment | Grinding, polishing, or passivation (for stainless); inspection per ISO 5817 |

| Filler Materials | ER4043/ER5356 (Aluminum), ER70S-2 (Steel), no filler for resistance welding |

| Materials Supported | Aluminum, Mild Steel, Stainless Steel (weldable grades); ABS and Nylon – not weldable via arc processes; may use ultrasonic or hot plate welding separately |

Material Compatibility Summary

| Material | Laser Cuttable | Bendable | Weldable (Arc) | Notes |

|---|---|---|---|---|

| Aluminum | Yes | Yes | Yes | Excellent for TIG welding; reflective, requires high-power fiber laser |

| Steel (Mild/Stainless) | Yes | Yes | Yes | Mild steel easily welded; stainless requires proper shielding gas |

| ABS | Yes (CO₂) | Yes (limited) | No (arc) | Thermoplastic; can be glued or ultrasonically welded; prone to melting |

| Nylon | Yes (CO₂) | Yes (limited, with preheating) | No (arc) | Hygroscopic; requires drying; welding via hot gas or ultrasonic methods only |

These technical parameters ensure high repeatability, dimensional accuracy, and structural integrity in custom sheet metal fabrication projects at Honyo Prototype. Process selection is optimized based on material type, part geometry, and end-use requirements.

From CAD to Part: The Process

Honyo Prototype Custom Sheet Metal Bending Process Overview

Honyo Prototype delivers precision custom sheet metal bending through a streamlined, technology-driven workflow designed for speed, accuracy, and manufacturability. Our process begins with seamless digital integration and concludes with certified delivery, ensuring client requirements are met without compromise.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, DXF, DWG, SLDPRT) via our secure online portal. Our system performs immediate automated validation checks for file integrity, unit consistency, and geometric completeness. Invalid or ambiguous submissions trigger an instant notification with specific error details, minimizing initial delays. Validated files proceed directly into the quoting engine without manual intervention.

AI-Powered Instant Quote

Leveraging proprietary AI algorithms trained on 15+ years of production data, our system analyzes the CAD geometry, material specifications, and tolerances to generate a comprehensive quote within 90 seconds. The AI evaluates bend sequences, tooling requirements, secondary operations, and material utilization to calculate accurate material costs, machine time, and labor. Critical parameters like minimum flange lengths, internal radii, and proximity to edges are cross-referenced against machine capabilities. The output includes a detailed cost breakdown, lead time estimate, and preliminary feasibility flag.

Engineered DFM Analysis

All quotes undergo mandatory Design for Manufacturability (DFM) review by our senior manufacturing engineering team. Unlike automated-only systems, this phase combines AI insights with human expertise to identify potential issues such as:

Excessive bend counts requiring secondary operations

Non-standard tooling needs impacting cost

Critical dimension conflicts with achievable tolerances (±0.1mm typical for bends)

Material grain direction implications for strength

Our engineers provide specific, actionable recommendations via annotated 3D models and written reports. Clients receive alternative solutions—not just problem notifications—to maintain design intent while optimizing cost and lead time. Client approval of the DFM report is required before production release.

Precision Production Execution

Approved designs move to our CNC press brake cells featuring Amada HG and Bystronic machines with 100-300 ton capacity and 0.05mm repeatability. Each job includes:

First-article inspection against all critical dimensions using calibrated CMMs

In-process checks at 50% and 100% completion for multi-part runs

Real-time machine monitoring for tonnage, angle consistency, and backgauge positioning

Material traceability maintained via barcoded work orders from raw stock to finished part

Secondary operations like deburring, tapping, or welding are sequenced within the same workflow to prevent handling damage.

Certified Delivery

Final parts undergo full dimensional verification against the approved drawing. Components are cleaned, passivated (if stainless), and packaged using anti-static materials with custom foam cradling to prevent deformation during transit. Every shipment includes:

Certificate of Conformance with material mill test reports

FAI report documenting all inspected characteristics

As-built dimensional data package

Traceable job documentation for audit compliance

Standard lead time is 5-7 business days from DFM approval, with expedited options available.

Process Efficiency Comparison

Our integrated workflow eliminates traditional handoffs between quoting, engineering, and production teams. This reduces typical industry quoting-to-approval cycles by 65% while maintaining rigorous quality control.

| Phase | Traditional Manual Process | Honyo Prototype Process |

|---|---|---|

| Quote Generation | 2-5 business days | <90 seconds |

| DFM Resolution | 3-7 days (multiple iterations) | 24 hours (single iteration) |

| First-Article Approval | Post-production | Pre-series production |

| Tolerance Adherence Risk | High (reactive correction) | Low (proactive DFM mitigation) |

Start Your Project

Looking for precision custom sheet metal bending services? Partner with Honyo Prototype for high-quality, on-demand fabrication from our modern facility in Shenzhen. From prototyping to low-volume production, we deliver accurate bends, tight tolerances, and fast turnaround for a wide range of industrial applications.

Contact Susan Leo today to discuss your project requirements or request a quote.

Email: [email protected]

Leverage our localized manufacturing expertise and streamlined processes to accelerate your product development cycle.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.