Contents

Manufacturing Insight: Custom Precision Metal Stamping

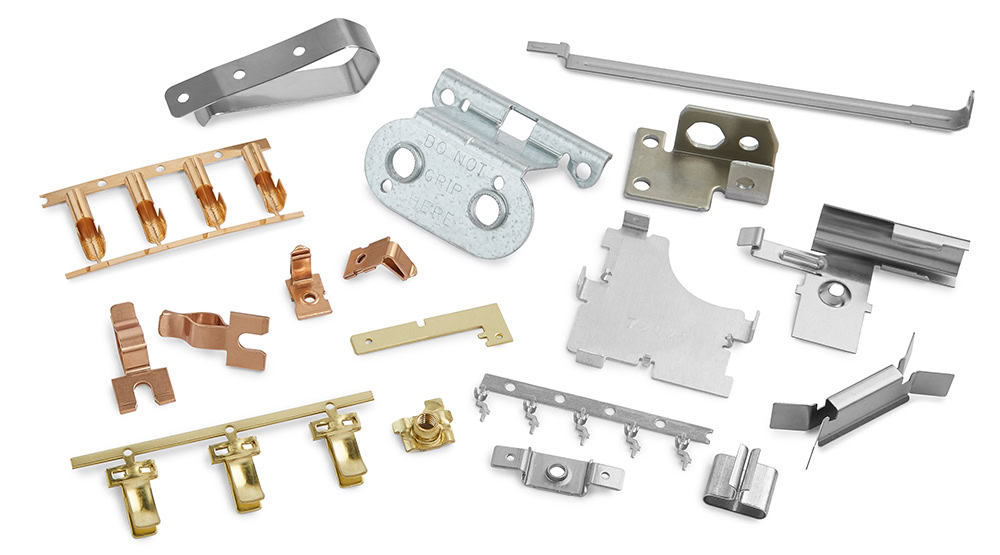

Honyo Prototype: Precision Metal Stamping and Sheet Metal Fabrication Engineered for Your Success

In the demanding landscape of modern manufacturing, achieving exceptional part accuracy, material integrity, and rapid time-to-market for metal components is non-negotiable. Honyo Prototype stands as your strategic partner for custom precision metal stamping and comprehensive Sheet Metal Fabrication services, delivering the exacting quality and engineering support your critical applications demand. We specialize in transforming complex designs into high-fidelity metal components, leveraging advanced stamping presses, CNC turret and laser cutting, precision bending, and expert welding techniques. Our commitment extends beyond mere production; we integrate deep metallurgical knowledge and process optimization to ensure your parts meet stringent tolerance requirements while minimizing material waste and maximizing structural performance, whether for prototyping, low-volume production, or high-mix manufacturing.

Our end-to-end Sheet Metal Fabrication capabilities encompass every stage of the metal component lifecycle. From initial design for manufacturability (DFM) analysis and material selection guidance through precision cutting, forming, assembly, and finishing, Honyo provides the technical expertise and flexible capacity required for demanding applications across aerospace, medical devices, electronics, and industrial equipment. We handle a wide range of materials, including stainless steel, aluminum, copper alloys, and specialty metals, consistently achieving tight tolerances and superior surface finishes. The table below highlights key aspects of our precision stamping and fabrication capacity:

| Capability | Typical Range/Specification | Application Benefit |

|---|---|---|

| Tolerance Control | ±0.005 mm (±0.0002″) | Ensures perfect fit and function |

| Material Thickness | 0.05 mm – 3.0 mm (0.002″ – 0.125″) | Supports diverse component requirements |

| Press Capacity | Up to 100 Ton | Handles intricate stamping dies |

| Prototype to Production | Seamless transition | Accelerates product development cycles |

Eliminating procurement friction is critical to your project velocity. Honyo Prototype significantly streamlines your sourcing process with our Online Instant Quote system. Upload your STEP, DWG, or DXF file directly to our platform, specify material and quantity requirements, and receive a detailed, accurate manufacturing quotation within hours – not days. This transparent, data-driven approach provides immediate cost visibility and manufacturability feedback, empowering your engineering and procurement teams to make faster, more informed decisions and accelerate your entire product development timeline. Partner with Honyo Prototype for precision metal stamping and fabrication where engineering excellence meets operational efficiency.

Technical Capabilities

Custom Precision Metal Stamping – Technical Specifications

Custom precision metal stamping at Honyo Prototype integrates advanced laser cutting, CNC bending, and precision welding to deliver high-tolerance components for demanding industrial applications. While stamping traditionally refers to die-based forming of sheet metal, our process combines stamping with subtractive and joining technologies to achieve complex geometries and superior repeatability. Below are the technical capabilities and material specifications for key fabrication stages.

| Process | Capability | Tolerance | Max Workpiece Size | Compatible Materials (Primary) |

|---|---|---|---|---|

| Laser Cutting | Fiber laser cutting for intricate 2D profiles and detailed apertures | ±0.05 mm | 1500 mm × 3000 mm | Aluminum (5052, 6061, 7075), Cold Rolled Steel (CRS), Stainless Steel (304, 316) |

| CNC Bending | High-precision air bending using CNC press brakes with tooling selection | ±0.2° angular, ±0.1 mm linear | 2500 mm length, up to 3 mm aluminum / 2 mm steel | Aluminum, CRS, Stainless Steel |

| Precision Welding | TIG and spot welding for clean, high-integrity joints; robotic MIG available | ±0.3 mm positional | Full-part assembly up to 1200 × 800 mm | Aluminum, Mild Steel, Stainless Steel |

Material Notes:

Aluminum and steel are primary candidates for laser cutting, stamping, bending, and welding due to their formability, strength, and weldability. ABS and Nylon, while used in hybrid assemblies, are non-metallic thermoplastics and are not compatible with stamping or laser cutting in the same manner as metals. These polymers are typically machined, molded, or ultrasonically welded and may be integrated into sub-assemblies post-metal fabrication.

ABS and Nylon are included in design considerations for insulative or wear-resistant components but require secondary attachment methods such as fasteners, adhesives, or overmolding when combined with stamped metal parts. They cannot undergo laser cutting or bending in a metal fabrication line and are excluded from welding processes involving metal fusion.

For full electromechanical assemblies, Honyo Prototype supports hybrid builds where precision-stamped metal components interface with polymer elements, ensuring tight integration and functional reliability.

From CAD to Part: The Process

Honyo Prototype Custom Precision Metal Stamping Process Overview

Honyo Prototype executes custom precision metal stamping through a rigorously integrated workflow designed for accuracy, speed, and manufacturability. This closed-loop process begins with client-provided CAD data and culminates in certified part delivery, with embedded quality checks at every phase. Below is the detailed sequence:

Upload CAD

Clients initiate the process by uploading native 3D CAD files (STEP, IGES, or Parasolid formats preferred) via our secure customer portal. We require geometrically complete models with explicit material specifications, tolerances, and surface finish requirements. Incomplete submissions trigger automated validation checks, prompting clients to resolve ambiguities before progression. This phase ensures dimensional intent is unambiguous for downstream engineering analysis.

AI-Assisted Quoting

Uploaded CAD data feeds into our proprietary AI quoting engine, which cross-references real-time variables including material market pricing, tooling complexity algorithms, and production capacity. The system generates a preliminary quote within 2 hours, detailing cost drivers like blank size optimization, secondary operation requirements, and material utilization rates. Crucially, this is not fully automated; Honyo’s manufacturing engineers validate all AI outputs against historical production data and physical constraints, ensuring quotes reflect achievable shop-floor realities. Clients receive a transparent breakdown with no hidden fees.

DFM Engineering Review

Every project undergoes mandatory Design for Manufacturability (DFM) analysis by our senior stamping engineers. This phase identifies and resolves critical issues such as:

Minimum bend radii violations relative to material thickness

Progressive die strip layout inefficiencies

Tolerance stack-up risks in multi-stage forming

Material grain direction conflicts with part geometry

We provide actionable feedback within 24 hours, including suggested modifications to reduce cost or improve yield. Clients approve revised designs or waive specific recommendations via digital signoff. Unresolved DFM flags halt progression to production—no exceptions.

Precision Production

Approved designs enter production on our CNC-controlled stamping lines (up to 200-ton capacity), featuring:

In-die sensors monitoring tonnage, part ejection, and strip feed accuracy

Automated vision systems performing 100% critical dimension checks at line speed

Statistical process control (SPC) with real-time Cp/Cpk tracking for high-risk features

All tooling uses hardened D2 or A2 tool steel with precision-ground components. Secondary operations (e.g., tapping, welding, plating) occur in-house under the same quality umbrella. Material certifications and first-article inspection reports (FAIRs) are generated per AS9102 standards.

Certified Delivery

Completed parts undergo final audit against client specifications, including:

Full-spectrum CMM validation for geometric tolerances

Material hardness and coating thickness verification

Packaging per ESD-sensitive or moisture-barrier requirements

We ship with comprehensive documentation: CoC (Certificate of Conformance), FAIR, SPC data, and non-destructive test results. Standard lead time is 10–15 business days from DFM approval, with expedited options tracked via client-accessible logistics dashboards.

Process Performance Metrics

Honyo’s closed-loop system delivers consistent results:

| Phase | Avg. Duration | Key Quality Metric |

|---|---|---|

| CAD Upload to Quote | < 2 hours | 98.7% quote accuracy rate |

| DFM Review | ≤ 24 hours | 42% average cost reduction via design optimization |

| Production | 10–15 days | 1.33+ Cpk on critical dimensions |

| Delivery | On schedule | 99.2% on-time shipment rate |

This workflow eliminates traditional handoffs between quoting, engineering, and production teams. By integrating AI-driven insights with deep stamping expertise, Honyo ensures manufacturability is engineered in from the first CAD upload—not discovered as a problem during tool tryout. Clients gain predictability in cost, quality, and delivery for even the most complex precision metal components.

Start Your Project

Looking for custom precision metal stamping solutions? Partner with Honyo Prototype for high-accuracy, low-to-high volume metal stamping services from our Shenzhen-based factory.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a tailored quote.

| Service Feature | Detail |

|---|---|

| Capability | Custom precision metal stamping |

| Location | Shenzhen, China |

| Lead Time | Competitive, project-dependent |

| Materials | Steel, stainless steel, aluminum, brass |

| Tolerances | Down to ±0.01 mm |

| Secondary Operations | Forming, welding, CNC, plating, assembly |

Reach out to Susan Leo at [email protected] for engineering support and fast response.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.