Contents

Manufacturing Insight: Custom Plastic Machining

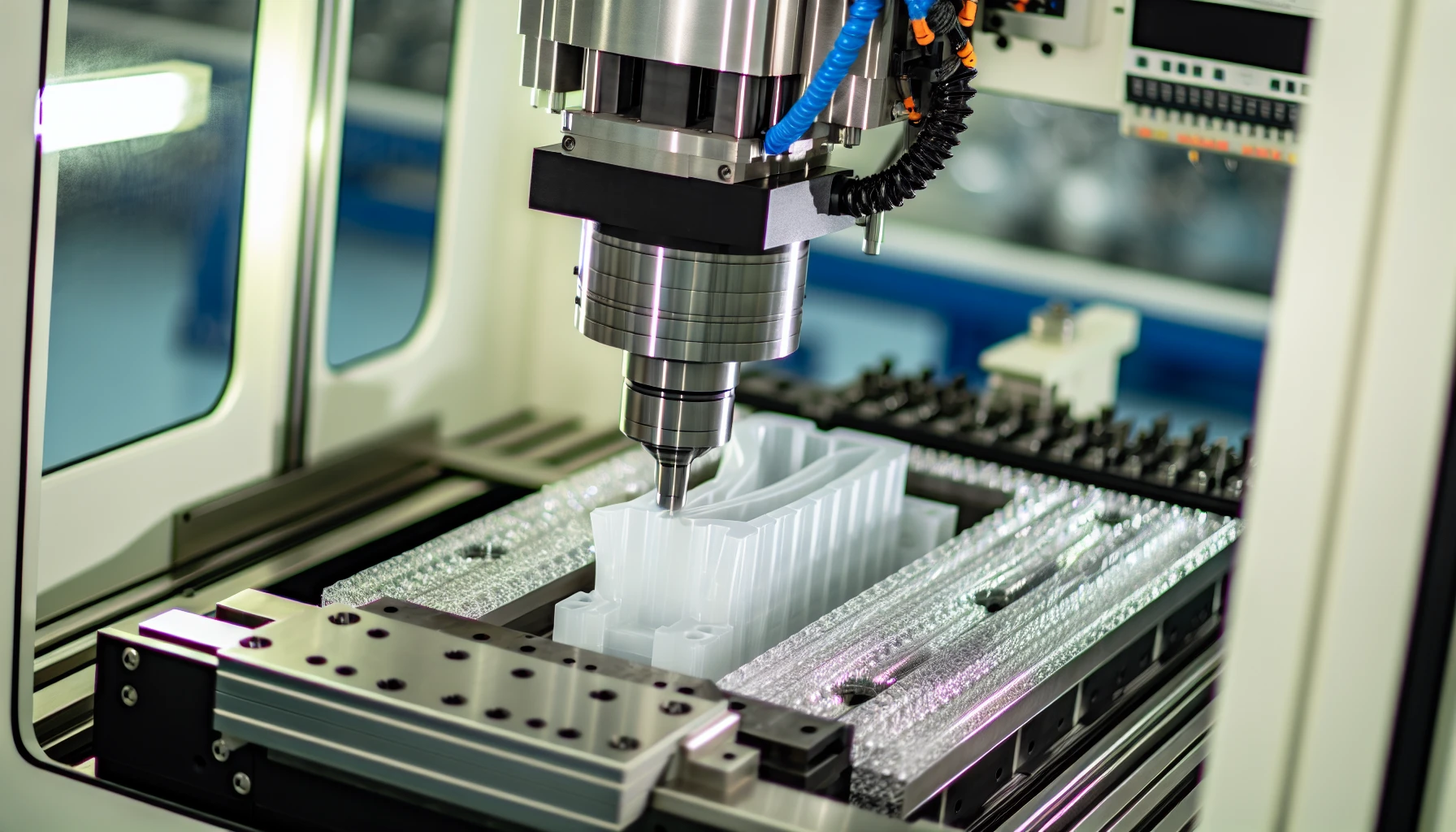

Precision Plastic Machining Solutions for Demanding Applications

At Honyo Prototype, we deliver mission-critical custom plastic machining services engineered for industries where dimensional accuracy, material integrity, and repeatability are non-negotiable. Our advanced CNC machining capabilities transform engineering-grade polymers—from acrylic and polycarbonate to high-performance PEEK and ULTEM—into complex, tight-tolerance components that meet rigorous aerospace, medical, and industrial specifications. Leveraging state-of-the-art 3-, 4-, and 5-axis milling and turning centers, we maintain tolerances down to ±0.0002 inches while optimizing surface finishes and structural properties for end-use functionality.

Our process integrates material science expertise with rigorous in-process quality control, ensuring every machined part adheres to ISO 9001 standards and your exact technical requirements. Whether prototyping or low-volume production, we eliminate traditional manufacturing bottlenecks through seamless digital workflows. Accelerate your development timeline immediately with our Online Instant Quote system, providing precise cost and lead-time estimates in under 60 seconds—no manual RFQ delays, no estimation gaps. Submit your CAD file today and experience how Honyo Prototype bridges precision engineering with operational efficiency.

Technical Capabilities

Custom plastic machining at Honyo Prototype leverages advanced 3-axis, 4-axis, and 5-axis CNC milling along with precision turning to achieve complex geometries and tight tolerances required in demanding industrial, medical, and aerospace applications. Our machining processes are optimized for both engineering-grade thermoplastics and metals, ensuring high repeatability and surface finish consistency. We maintain tight tolerances down to ±0.0002″ (±0.005 mm) depending on part geometry, material, and feature size.

The following table outlines the technical specifications for our custom plastic machining capabilities, including compatible materials such as ABS, Nylon, Aluminum, and Steel:

| Parameter | Specification |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning |

| Typical Tolerances | ±0.001″ (±0.025 mm) standard; down to ±0.0002″ (±0.005 mm) for critical features |

| Material Compatibility | ABS, Nylon (PA6, PA66, Glass-Filled), Aluminum (6061, 7075), Steel (1018, 4140, Stainless) |

| Maximum Work Envelope (Milling) | 30″ × 16″ × 16″ (762 mm × 406 mm × 406 mm) |

| Maximum Work Envelope (Turning) | Diameter: 12″ (305 mm); Length: 24″ (610 mm) |

| Surface Finish (Typical) | 32–125 μin (0.8–3.2 μm) Ra; polishable to <16 μin (<0.4 μm) Ra |

| Tooling & Fixturing | Carbide and diamond-coated tooling; custom soft jaws and vacuum fixtures |

| Quality Control | In-process and final inspection using CMM, optical comparators, and micrometers |

| Lead Time (Prototype) | 5–10 business days, depending on complexity and material availability |

Our facility supports hybrid fabrication, allowing seamless integration of metal and plastic components within the same assembly. Material selection is guided by application requirements such as wear resistance, chemical exposure, and thermal stability—particularly critical when machining hygroscopic materials like Nylon, which are pre-dried and processed under controlled conditions to ensure dimensional accuracy.

From CAD to Part: The Process

Honyo Prototype Custom Plastic Machining Process Overview

Honyo Prototype executes custom plastic machining through a rigorously defined five-stage workflow, integrating automation with engineering oversight to ensure precision, cost efficiency, and on-time delivery. This process is optimized for complex geometries in engineering-grade thermoplastics such as PEEK, PTFE, Ultem, and Acetal, while maintaining ISO 9001-compliant quality control.

CAD Upload and System Integration

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid, or native SOLIDWORKS) via our secure customer portal. Our system automatically validates file integrity, extracts critical geometric data including tolerances, wall thicknesses, and feature complexities, and populates metadata for downstream processing. This stage enforces strict data hygiene protocols to prevent interpretation errors, with immediate client alerts for unsupported formats or incomplete submissions.

AI-Powered Quoting Engine

Uploaded designs feed into Honyo’s proprietary AI quoting algorithm, which analyzes 200+ parametric variables including material selection, machine time estimation, fixture requirements, and secondary operations. The engine cross-references real-time material pricing from vetted suppliers, current machine utilization rates across our 45+ CNC mills and lathes, and historical scrap rate data for the specified polymer. Quotes are generated within 2 business hours, detailing cost breakdowns by operation and highlighting high-risk features requiring engineering review. Human validation by our quoting team ensures contextual accuracy, particularly for non-standard materials or micro-machining requirements.

Engineering-Led DFM Analysis

All projects undergo mandatory Design for Manufacturability (DFM) review by Honyo’s senior plastics machining engineers. This phase identifies latent risks such as inadequate draft angles for complex contours, thin-wall stability issues in glass-filled polymers, or thermal deformation risks during high-speed milling. Engineers collaborate directly with clients to propose actionable modifications—recommending optimized toolpaths, strategic stock allowances, or material substitutions—while preserving functional intent. Typical DFM resolutions reduce production iterations by 65% and accelerate time-to-first-article by 30%.

Precision Production Execution

Approved designs move to production in our climate-controlled machining facility. Each run follows a documented control plan specifying:

Material certification traceability (including lot-specific moisture content logs)

Machine-specific parameters (e.g., spindle speeds ≤ 8,000 RPM for PTFE to prevent melting)

In-process inspection checkpoints at critical stages

Key Production Quality Gates

| Inspection Stage | Verification Method | Acceptance Criteria |

|——————|———————|———————|

| Pre-Machining | CMM verification of raw stock | ASTM D638 dimensional compliance |

| Mid-Process | Optical comparator checks | ±0.025 mm feature alignment |

| First Article | Full CMM scan against CAD | GD&T compliance per ASME Y14.5 |

| Final Batch | Statistical process control (SPC) | Cpk ≥ 1.33 for critical dimensions |

Machining leverages HAAS and DMG MORI equipment with diamond-coated carbide tooling optimized for plastic chip evacuation, minimizing burrs and thermal stress. Cleanroom protocols prevent particulate contamination for medical and semiconductor applications.

Global Delivery and Documentation

Completed orders undergo final packaging in anti-static, humidity-controlled containers with serialized traceability labels. Honyo provides comprehensive documentation including:

Material test reports (MTRs) with lot traceability

Full inspection data packages (PDF and XML formats)

Customs-compliant shipping manifests for international shipments

Real-time logistics tracking via our client portal with DHL/FedEx integration

All shipments include a post-delivery feedback loop for continuous process refinement, with 98.7% on-time delivery performance across 2023. This end-to-end workflow ensures clients receive dimensionally accurate, functionally validated plastic components with minimized lead times and full supply chain transparency.

Start Your Project

Looking for precision custom plastic machining? Honyo Prototype delivers high-quality, CNC-machined plastic components tailored to your exact specifications. With our advanced manufacturing capabilities and strict quality control, we ensure fast turnaround and consistent accuracy for prototyping and low-volume production.

All manufacturing is performed at our Shenzhen factory, strategically located for efficient global logistics. Whether you need PEEK, Delrin, acrylic, or other engineering plastics, we support a wide range of materials and complex geometries.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Let’s bring your plastic component designs to life with precision and reliability.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.