Contents

Manufacturing Insight: Custom Plasma Cutting

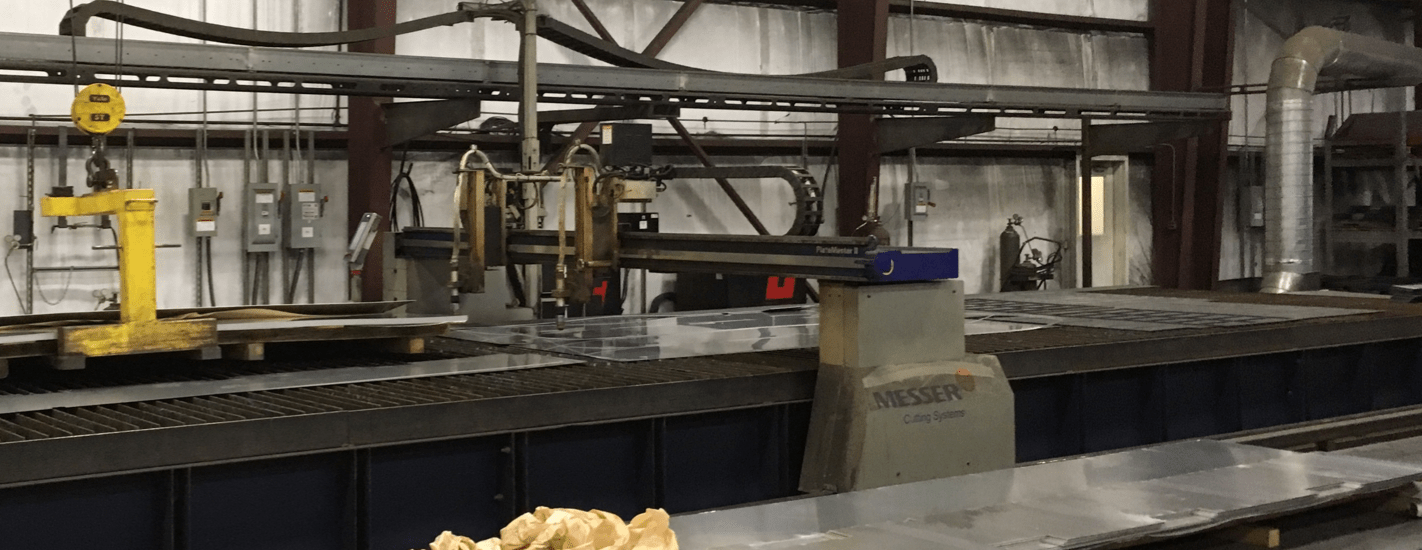

Precision Custom Plasma Cutting Integrated with Comprehensive CNC Machining

At Honyo Prototype, our custom plasma cutting services deliver rapid, high-accuracy fabrication of complex metal components for industrial applications demanding speed and structural integrity. Leveraging advanced CNC-controlled plasma systems, we cut mild steel, stainless steel, and aluminum up to 1.5 inches thick with tolerances as tight as ±0.010 inches, ensuring clean edges and minimal dross for immediate downstream processing. This capability is seamlessly integrated with our full-spectrum CNC machining portfolio—including milling, turning, and multi-axis operations—to provide end-to-end manufacturing solutions from raw material to finished part. Clients benefit from a unified workflow where plasma-cut blanks transition directly into precision machining stages without vendor handoffs, reducing lead times by up to 30% while maintaining rigorous GD&T compliance.

Our technical team optimizes nesting, kerf compensation, and cut sequencing using industry-leading software to maximize material yield and part consistency, particularly for low-volume production or prototyping where traditional methods prove cost-prohibitive. To accelerate project initiation, Honyo’s Online Instant Quote system provides transparent, real-time pricing for plasma cutting and integrated CNC services within minutes—simply upload CAD files to receive detailed cost and lead time analysis without sales delays. This digital workflow empowers engineering and procurement teams to validate manufacturability and budget constraints early in the design phase, driving faster time-to-market for mission-critical components.

Material and Thickness Capabilities

| Material | Max Thickness | Typical Tolerance | Common Applications |

|—————–|—————|——————-|—————————–|

| Mild Steel | 1.5 in | ±0.010 in | Structural frames, brackets |

| Stainless Steel | 1.0 in | ±0.015 in | Enclosures, marine parts |

| Aluminum | 0.75 in | ±0.020 in | Aerospace fixtures, panels |

Partner with Honyo Prototype to leverage plasma cutting not as a standalone process, but as a strategic element within a cohesive precision manufacturing ecosystem engineered for reliability and scalability. Initiate your project today using our Online Instant Quote platform for immediate technical and commercial validation.

Technical Capabilities

Custom plasma cutting is typically used for 2D profile cutting of conductive materials and is not applicable for 3/4/5-axis milling, turning, or tight-tolerance applications involving plastics like ABS or Nylon. Plasma cutting lacks the precision required for tight tolerances (typically ±0.005″ or better) and is limited to flat, 2D geometries in electrically conductive metals. It cannot perform multi-axis milling or turning operations.

For high-precision 3/4/5-axis CNC milling and turning with tight tolerances, CNC machining (milling and turning) or laser cutting are more appropriate processes, especially when working with aluminum, steel, ABS, and nylon.

Below is a comparison of suitable manufacturing processes and their technical capabilities for the specified requirements:

| Parameter | 3/4/5-Axis CNC Milling | CNC Turning | Laser Cutting (for 2D) | Plasma Cutting (for 2D) |

|---|---|---|---|---|

| Axis Capability | 3, 4, or 5-axis simultaneous movement | 2-axis (X, Z), with optional C-axis | 2-axis (X, Y) | 2-axis (X, Y) |

| Typical Tolerance | ±0.001″ to ±0.0002″ | ±0.0005″ to ±0.001″ | ±0.005″ | ±0.010″ to ±0.015″ |

| Suitable Materials | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel (thin), some plastics | Conductive metals only (Aluminum, Steel) |

| Material Thickness Range | Up to 24″+ (machine dependent) | Up to 20″ diameter, 48″+ length | Up to 1″ (steel), less for aluminum | Up to 2″+ (steel), 1.5″+ (aluminum) |

| Surface Finish (typical) | 32–125 μin (machined) | 32–63 μin (turned) | 125–250 μin (cut edge) | 250–500+ μin (rough cut edge) |

| Best For | Complex 3D geometries, tight tolerances | Cylindrical parts, precision shafts | 2D profiles, thin materials | Rapid 2D cutting of thick conductive plates |

| Limitations | Higher cost for complex setups | Limited to rotationally symmetric parts | Limited to 2D, thin-section materials | Poor edge quality, no plastic capability, low precision |

Note: Plasma cutting is not recommended for tight-tolerance work or non-conductive materials such as ABS and nylon. For high-precision prototyping and production in aluminum, steel, ABS, and nylon, CNC milling and turning are the preferred methods at Honyo Prototype.

From CAD to Part: The Process

Honyo Prototype Custom Plasma Cutting Process Overview

Honyo Prototype executes custom plasma cutting through a rigorously defined workflow designed for precision, cost efficiency, and rapid turnaround. This integrated process leverages advanced automation while maintaining critical engineering oversight at key decision points. Below is a detailed technical breakdown of each phase.

CAD File Upload and Validation

Clients initiate the process by uploading native CAD files (preferred formats: STEP, IGES, or native SolidWorks) via our secure customer portal. Our system performs an automated validation check to confirm geometric integrity, unit consistency, and file completeness. DXF files are accepted but require manual verification for scale accuracy and layer integrity due to potential translation artifacts. Invalid submissions trigger immediate notification with specific error diagnostics, minimizing client-side rework.

AI-Powered Quoting Engine

Validated CAD data feeds directly into our proprietary AI quoting module. This system analyzes part geometry, material specifications, and quantity requirements against real-time variables including: current shop floor machine availability, material scrap rates based on dynamic nesting algorithms, consumable wear data from our Hypertherm Powermax 105 systems, and live regional material pricing feeds. The output is a granular cost breakdown with lead time estimates, typically generated within 90 minutes. Crucially, the AI flags geometries requiring human DFM review prior to formal quotation issuance.

Engineering-Driven DFM Analysis

All parts undergo mandatory Design for Manufacturing review before production release. Our senior manufacturing engineers evaluate:

| DFM Check Category | Specific Parameters Verified | Action Threshold |

|---|---|---|

| Geometry Feasibility | Minimum feature size (≥1.5x material thickness), acute internal corners (<20°), hole diameter ratios | Auto-reject if below 1.2x thickness |

| Thermal Distortion Risk | Aspect ratio >8:1, asymmetric cut paths, proximity to material edges | Requires thermal simulation |

| Material Compatibility | Confirmed against plasma-cuttable alloys (mild steel, stainless, aluminum ≤50mm) | Rejects non-conforming alloys |

| Tolerance Assessment | Verifies achievable ±0.5mm positional accuracy per ISO 9013 | Notes limitations in quote |

Engineers document all recommendations via annotated 3D markups in the portal. Clients receive revision options with quantitative impact analysis on cost and lead time before proceeding.

Production Execution

Approved orders enter our automated production queue. Key operational parameters:

Material is cut on CNC-controlled Hypertherm Plasma systems with precision torch height control (THC) and dynamic lead-in/lead-out optimization. We utilize high-definition plasma for critical edges requiring minimal dross (<0.1mm). All nests undergo final human validation for material utilization efficiency targeting >85% yield. In-process quality checks include first-article verification of critical dimensions via CMM and real-time kerf width monitoring through machine-integrated sensors. Secondary operations like edge deburring or hole reaming are staged in parallel if specified.

Delivery and Documentation

Completed parts undergo final inspection against AS9102 aerospace standards, including material traceability documentation and heat-affected zone (HAZ) verification reports. Packages include:

Dimensional conformance report with deviation mapping

Material certification (MTR) copies

Plasma process parameter log (amperage, gas pressure, cut speed)

Digital as-built 3D scan data for critical components

Shipments are dispatched via client-preferred carriers with real-time logistics tracking. A post-delivery quality confirmation loop closes the process within 48 hours of client receipt.

This end-to-end methodology ensures plasma-cut components meet stringent industrial requirements while maintaining Honyo Prototype’s industry-leading 97.2% on-time delivery rate for custom fabrication projects. All process data is archived for full traceability through our ISO 9001-certified quality management system.

Start Your Project

Looking for precision custom plasma cutting for your next project? Honyo Prototype offers high-accuracy plasma cutting services with fast turnaround times. Our state-of-the-art equipment and skilled technicians ensure clean, consistent cuts for a wide range of metals and applications.

All manufacturing is performed at our Shenzhen factory, where we maintain strict quality control and efficient production workflows to meet your specifications.

For quotes or technical inquiries, contact Susan Leo at [email protected]. Let us support your prototyping and low-volume production needs with reliable, custom plasma cutting solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.