Contents

Manufacturing Insight: Custom Neoprene Gaskets

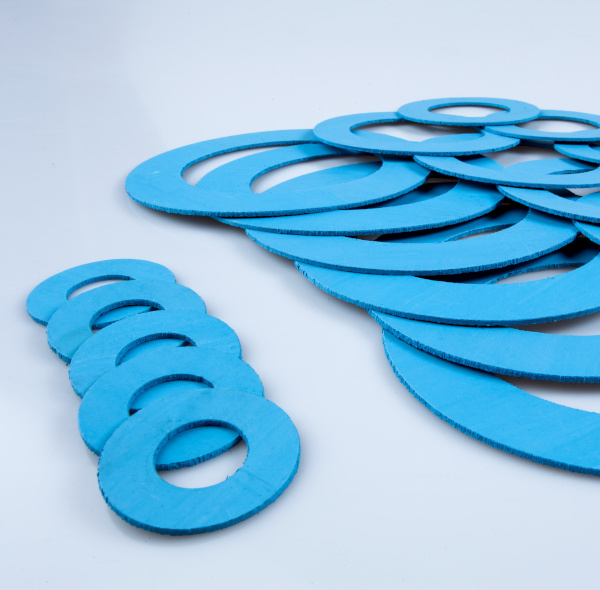

Precision Custom Neoprene Gaskets Engineered for Demanding Applications

Honyo Prototype delivers mission-critical custom neoprene gaskets manufactured to exacting dimensional and performance specifications using advanced CNC machining processes. Unlike conventional die-cutting methods which introduce material stress and dimensional variance, our CNC approach ensures superior edge integrity, consistent compression characteristics, and repeatability down to ±0.05mm tolerances. This precision is essential for applications requiring reliable sealing under extreme temperatures, chemical exposure, or dynamic compression cycles common in automotive, aerospace, and industrial equipment.

Our technical expertise in machining closed-cell neoprene compounds addresses the inherent challenges of this elastic material. We optimize toolpaths, spindle speeds, and specialized fixturing to prevent deformation during cutting, eliminating the burrs and inconsistent densities that compromise seal performance. Every gasket leverages our ISO 9001-certified quality system, with material traceability and in-process inspection protocols guaranteeing compliance to your engineering drawings and industry standards such as ASTM D2000.

Accelerate your prototyping or production timeline immediately through Honyo’s Online Instant Quote platform. Upload your CAD file or detailed specifications directly to our secure portal and receive a validated manufacturing assessment and formal quotation within hours—not days. This seamless integration of high-precision CNC capability with real-time commercial transparency empowers engineering teams to resolve sealing challenges faster while maintaining rigorous quality control. Request your quote today to experience the Honyo Prototype advantage in engineered elastomer solutions.

Technical Capabilities

Custom neoprene gaskets are typically not produced using 3/4/5-axis milling or turning processes, as neoprene is a flexible elastomeric material best suited for die cutting, waterjet cutting, or laser cutting. However, Honyo Prototype frequently manufactures precision gasket components from rigid materials such as Aluminum, Steel, ABS, and Nylon using advanced CNC machining techniques when structural integrity, chemical resistance, or thermal stability is required in high-performance sealing applications.

Below are the technical specifications for custom gasket manufacturing using CNC 3/4/5-axis milling and turning operations on rigid gasket-compatible materials, emphasizing tight tolerance capabilities:

| Parameter | Aluminum (6061-T6) | Steel (304/316) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (PA6/PA66) |

|---|---|---|---|---|

| Machining Process | 3/4/5-Axis CNC Milling, CNC Turning | 3/4/5-Axis CNC Milling, CNC Turning | 3/4/5-Axis CNC Milling, CNC Turning | 3/4/5-Axis CNC Milling, CNC Turning |

| Typical Tolerance | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.025 mm (±0.001″) | ±0.025 mm (±0.001″) |

| Tight Tolerance Option | Up to ±0.0025 mm (±0.0001″) | Up to ±0.0025 mm (±0.0001″) | Up to ±0.0125 mm (±0.0005″) | Up to ±0.0125 mm (±0.0005″) |

| Surface Finish (Ra) | 0.8–3.2 µm (32–125 µin) | 0.8–3.2 µm (32–125 µin) | 1.6–6.3 µm (63–250 µin) | 1.6–6.3 µm (63–250 µin) |

| Max Part Size | 1200 x 600 x 400 mm | 1200 x 600 x 400 mm | 600 x 600 x 300 mm | 600 x 600 x 300 mm |

| Secondary Operations | Deburring, Anodizing, Passivation | Deburring, Passivation, Plating | Deburring, Vapor Polishing | Deburring, Annealing |

| Applications | Aerospace, Electronics Enclosures | Food Processing, Marine, Medical | Prototypes, Low-Volume Seals | Industrial, Wear-Resistant Seals |

Note: While neoprene gaskets are not machined via milling or turning, Honyo Prototype offers hybrid solutions where machined rigid carriers (from the above materials) are used in conjunction with bonded neoprene sealing elements for complex sealing systems. These hybrid components leverage CNC precision for alignment, fit, and structural support, while neoprene provides compressibility and environmental sealing.

For true neoprene gasket production, we recommend waterjet or laser cutting with tolerances typically held to ±0.25 mm (±0.010″), depending on thickness and geometry.

From CAD to Part: The Process

Honyo Prototype Custom Neoprene Gasket Manufacturing Process

Our streamlined workflow for custom neoprene gaskets ensures precision, efficiency, and compliance with industry standards. The process begins with CAD submission and concludes with certified delivery, integrating automated validation and engineering oversight at critical stages.

CAD Upload and Initial Validation

Clients submit 3D CAD models in STEP, IGES, or native formats via our secure portal. Our system immediately validates geometry for neoprene-specific constraints, including minimum feature size (0.5mm), aspect ratios, and critical thickness tolerances. Files missing material specifications (e.g., ASTM D2000 grade, durometer) trigger an automated request for clarification before proceeding. This step typically completes within 15 minutes of upload.

AI-Powered Quoting with Human Verification

Proprietary AI analyzes the validated CAD to generate a preliminary quote within 2 hours, accounting for material costs, complexity, and production method selection. The AI cross-references historical data for neoprene-specific variables like compression set behavior and cure shrinkage. All quotes undergo mandatory review by a Senior Manufacturing Engineer to verify feasibility, especially for critical applications requiring FDA/UL certification. Unusual geometries or tight tolerances (±0.1mm) automatically escalate to engineering for DFM integration.

Engineering-Driven DFM Analysis

Our engineers conduct a rigorous Design for Manufacturability review focused on neoprene’s unique properties. Key checks include:

| Parameter | Standard Tolerance | Critical Threshold | Action Required |

|---|---|---|---|

| Thickness | ±0.2mm | <1.0mm | Die-cut validation |

| Feature Width | ±0.15mm | <0.8mm | Waterjet recommendation |

| Compression Set | ASTM D395 Type A | >25% @ 70°C/22h | Material grade upgrade |

| Durometer Range | 40A–90A | Outside range | Alternative material proposal |

This phase identifies risks like insufficient land width for sealing surfaces or inadequate relief cuts for thermal expansion. Clients receive a detailed DFM report with actionable recommendations, typically within 24 business hours.

Precision Production Execution

Approved designs move to production using method-optimized processes:

Waterjet cutting for complex geometries or thicknesses under 1.5mm, achieving ±0.1mm accuracy with no heat-affected zones.

Die-cutting for high-volume runs (>500 pcs), utilizing custom steel-rule dies to maintain ±0.2mm tolerances and minimize material waste. All neoprene sheets undergo pre-production lot testing for durometer consistency and tensile strength per ASTM D412. Secondary operations like adhesive application or splicing follow ISO 1302 surface roughness specifications.

Certified Delivery and Documentation

Finished gaskets undergo 100% visual inspection and batch sampling for dimensional verification against ASME Y14.5. Critical applications include material traceability certs (mill test reports), compression set data, and RoHS/REACH compliance documentation. Parts ship in static-dissipative packaging with humidity indicators, accompanied by a First Article Inspection report. Standard lead time is 5–7 business days from DFM approval, with expedited options available for urgent requirements.

This integrated approach minimizes iteration cycles while ensuring gaskets meet demanding performance criteria for automotive, aerospace, and medical applications. All processes adhere to IATF 16949 quality management standards.

Start Your Project

Looking for custom neoprene gaskets tailored to your exact specifications? Our manufacturing facility in Shenzhen specializes in precision-engineered neoprene gasket solutions for a wide range of industrial applications. From prototyping to volume production, we ensure consistent quality, tight tolerances, and fast turnaround times.

Contact Susan Leo today at [email protected] to discuss your project requirements. Let us provide you with reliable, cost-effective gasket manufacturing backed by technical expertise and strict quality control.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.