Introduction: Navigating the Global Market for custom model car parts

Navigating the global market for custom model car parts presents a unique challenge for B2B buyers aiming to enhance their offerings while ensuring quality and affordability. As the demand for detailed and specialized components grows, international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must be equipped with the right knowledge to source effectively. This guide delves into the multifaceted world of custom model car parts, exploring various types of components, their applications, and the importance of rigorous supplier vetting processes.

Buyers will find insights on how to evaluate suppliers based on quality, delivery times, and customer service—critical factors that can significantly impact their operations. Additionally, we provide a comprehensive overview of cost considerations, allowing businesses to align their sourcing strategies with budget constraints while maintaining quality standards. By addressing these key areas, this guide empowers B2B buyers to make informed purchasing decisions, ensuring they can navigate the complexities of the market confidently.

With a focus on actionable insights, this resource not only highlights best practices for sourcing custom model car parts but also outlines emerging trends that can influence future purchases. Whether you are looking to enhance your existing product line or explore new opportunities, this guide serves as a valuable tool in your strategic decision-making process.

Understanding custom model car parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Detailing Kits | Includes photo-etch, resin parts, and decals | Enhancing model aesthetics and realism | Pros: High customization; Cons: Can be expensive and complex to apply. |

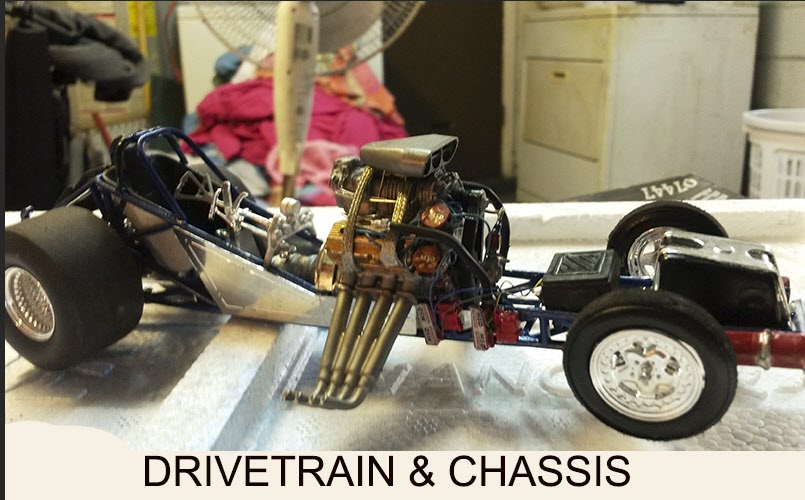

| Chassis and Suspension | Custom frames, dropped axles, and suspension parts | Building performance-focused models | Pros: Improved handling; Cons: Requires technical know-how for installation. |

| Wheels and Tires | Diverse styles, materials, and sizes | Upgrading model appearance and functionality | Pros: Significant aesthetic impact; Cons: Quality varies widely, impacting performance. |

| Engine Components | Detailed engine parts, wiring, and hoses | Customizing performance and visual appeal | Pros: Enhances model accuracy; Cons: Complexity may deter novice builders. |

| Interior Accessories | Detailed dashboards, seats, and controls | Creating immersive model environments | Pros: Adds realism; Cons: May require extensive modifications to fit. |

What Are Detailing Kits and Their B2B Relevance?

Detailing kits are essential for model car enthusiasts seeking to elevate the realism of their builds. These kits often include photo-etched parts, resin components, and high-quality decals. For B2B buyers, investing in detailing kits can significantly enhance the aesthetic appeal of model cars, making them more attractive to end consumers. However, the complexity and potential costs associated with these kits can be a consideration, particularly for businesses targeting entry-level hobbyists.

How Do Chassis and Suspension Parts Enhance Model Performance?

Chassis and suspension parts are crucial for those looking to build performance-oriented model cars. Custom frames, dropped axles, and specialized suspension components allow for better handling and a more authentic driving experience. B2B buyers should consider the technical expertise required for installation, as well as the compatibility with existing model kits. While these components can improve performance, they may also necessitate additional modifications, which could deter less experienced builders.

Why Are Wheels and Tires Important for Custom Models?

Wheels and tires are often the most visible components of a model car, making them vital for aesthetic upgrades. Available in various styles, materials, and sizes, they can drastically change a model’s appearance and functionality. For B2B buyers, selecting high-quality wheels and tires is essential, as they influence both the visual appeal and performance of the model. However, the market is saturated, and quality can vary, so careful sourcing is crucial to ensure customer satisfaction.

What Role Do Engine Components Play in Model Customization?

Engine components, including detailed parts, wiring, and hoses, are key for creating lifelike models. They allow builders to customize their vehicles for both performance and visual accuracy. B2B buyers should consider the potential complexity of these components, as they may require advanced skills for installation. While they can significantly enhance the model’s realism, the intricacy may pose a challenge for novice builders, impacting overall sales.

How Do Interior Accessories Contribute to Model Realism?

Interior accessories, such as dashboards, seats, and control panels, are pivotal for creating immersive model environments. These components allow for detailed customization, giving buyers the opportunity to enhance the overall realism of their models. For B2B buyers, offering a range of interior accessories can cater to diverse customer preferences. However, the need for extensive modifications to fit these parts can be a drawback for some builders, requiring careful consideration in product selection.

Key Industrial Applications of custom model car parts

| Industry/Sector | Specific Application of Custom Model Car Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Aftermarket | Custom detailing kits for model car enthusiasts | Enhances product appeal and customer satisfaction | Ensure compatibility with various model scales and high-quality materials |

| Education and Training | Use in educational programs for engineering and design students | Provides hands-on learning experiences | Look for suppliers that offer bulk pricing and educational discounts |

| Hobby Retail | Custom parts for retail model kits and hobbyist supplies | Expands product range and attracts diverse customer base | Assess supplier reliability and shipping options for international buyers |

| Film and Media | Scale models for set design and prop creation | Aids in creating realistic environments for productions | Focus on precision and detail to meet industry standards |

| Event and Trade Shows | Custom models for promotional displays and marketing campaigns | Increases brand visibility and engagement with target audience | Evaluate the turnaround time and customization options available |

How Are Custom Model Car Parts Applied in the Automotive Aftermarket?

In the automotive aftermarket, custom model car parts are essential for enthusiasts who seek to enhance the aesthetics and performance of their model cars. Detailing kits that include unique wheels, decals, and interior accessories allow hobbyists to create personalized models that stand out. For international buyers, particularly from regions such as Africa and South America, sourcing these parts requires a focus on quality and compatibility with various scales, ensuring that they meet the specific requirements of diverse customer bases.

What Role Do Custom Model Car Parts Play in Education and Training?

Custom model car parts are increasingly utilized in educational settings, particularly in engineering and design programs. These parts provide students with practical experience in assembly, design, and customization, fostering skills that are applicable in real-world scenarios. For B2B buyers in the education sector, sourcing these parts in bulk can be a cost-effective solution, especially when suppliers offer discounts for educational institutions. Additionally, buyers should consider the educational value of the parts in their curriculum.

How Do Hobby Retailers Benefit from Custom Model Car Parts?

Hobby retailers leverage custom model car parts to diversify their product offerings and cater to a broader audience of model enthusiasts. By providing unique and specialized parts, retailers can attract customers looking for specific enhancements for their models. For international buyers, it’s crucial to evaluate supplier reliability and shipping capabilities to ensure timely delivery, which can significantly impact customer satisfaction and sales performance.

In What Ways Are Custom Model Car Parts Used in Film and Media?

The film and media industry often employs custom model car parts to create realistic sets and props. Scale models, crafted with precision and detail, help production designers build immersive environments that enhance storytelling. Businesses in this sector must prioritize sourcing high-quality, detailed parts that can withstand the rigors of production. For international buyers, understanding the specific requirements of the film industry, including lead times and customization options, is essential for successful procurement.

How Are Custom Model Car Parts Utilized in Events and Trade Shows?

Custom model car parts serve a vital role in promotional displays and marketing campaigns at events and trade shows. Companies can create eye-catching models that showcase their brand, products, or services, thereby increasing visibility and engagement with potential customers. For B2B buyers sourcing these parts, evaluating the supplier’s ability to meet deadlines and offer customization options is crucial, as these factors can significantly influence the effectiveness of their marketing efforts.

3 Common User Pain Points for ‘custom model car parts’ & Their Solutions

Scenario 1: Sourcing Quality Custom Model Car Parts

The Problem: International B2B buyers often struggle to source high-quality custom model car parts that meet specific design requirements. This challenge is exacerbated by language barriers, differing industry standards, and a lack of reliable suppliers in their region. Buyers may receive subpar products that do not align with their expectations, leading to project delays and increased costs due to the need for replacements or modifications.

The Solution: To overcome this issue, B2B buyers should conduct thorough research to identify reputable suppliers who specialize in custom model car parts. Utilize online platforms and industry forums to gather reviews and recommendations. Establish clear communication channels with suppliers to discuss specifications in detail, ensuring that all parties have a mutual understanding of the required quality and design standards. Additionally, requesting samples before placing bulk orders can help verify the quality of the parts and reduce the risk of future complications.

Scenario 2: Navigating Supply Chain Challenges

The Problem: Supply chain disruptions can severely impact the availability of custom model car parts, particularly for buyers in regions with less developed logistics infrastructure. Delays in shipping, customs clearance issues, and fluctuating costs can hinder production schedules and lead to financial losses for businesses relying on timely deliveries.

The Solution: To mitigate supply chain challenges, B2B buyers should diversify their supplier base by engaging with multiple manufacturers and distributors across different geographical areas. This strategy not only reduces dependency on a single source but also allows buyers to compare costs and lead times effectively. Additionally, investing in supply chain management software can provide real-time tracking of orders and inventory levels, enabling proactive adjustments to production schedules. Establishing strong relationships with freight forwarders and understanding local customs regulations can also streamline the import process, minimizing potential delays.

Scenario 3: Ensuring Compatibility with Existing Models

The Problem: Another common pain point for B2B buyers is ensuring that custom model car parts are compatible with existing models or kits. Incompatibility can arise due to differences in scale, design, or manufacturing processes, leading to wasted resources and frustrated customers.

The Solution: To address compatibility issues, buyers should invest time in gathering comprehensive specifications and dimensions for both the existing models and the desired custom parts. Creating a detailed compatibility matrix can help visualize which parts fit with specific models. It is also beneficial to engage with manufacturers who offer customization services that allow for adjustments based on existing model specifications. Open dialogue with suppliers about any potential compatibility concerns can lead to valuable insights, ensuring that the final products meet the required standards. Furthermore, leveraging prototyping services can allow buyers to test parts before committing to larger orders, reducing the risk of incompatibility and fostering customer satisfaction.

Strategic Material Selection Guide for custom model car parts

When selecting materials for custom model car parts, understanding the properties and applications of various materials is crucial for ensuring optimal performance and durability. This guide analyzes four common materials used in the production of model car parts, focusing on their key properties, advantages and disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Plastic in Custom Model Car Parts?

Plastic, particularly polystyrene and ABS (Acrylonitrile Butadiene Styrene), is widely used in the manufacturing of model car parts due to its versatility and ease of molding. These materials exhibit good impact resistance and can be produced in various colors, which is advantageous for aesthetic detailing. However, plastics generally have lower temperature resistance compared to metals and can be susceptible to UV degradation over time.

Pros: Low cost, lightweight, and easy to work with. Ideal for intricate designs and fine details.

Cons: Lower durability compared to metals, potential for warping under high temperatures, and limited resistance to solvents.

For international buyers, it is essential to consider compliance with local regulations regarding plastic use, especially in regions with strict environmental laws.

How Does Metal Compare for Custom Model Car Parts?

Metal parts, often made from aluminum or brass, are favored for their strength and durability. These materials can withstand higher temperatures and pressures, making them suitable for components that require structural integrity, such as chassis or engine parts.

Pros: High durability, excellent temperature resistance, and a premium finish that enhances the appearance of model cars.

Cons: Higher manufacturing costs and complexity, requiring specialized equipment for machining and finishing.

International buyers should be aware of standards like ASTM for metals, ensuring that the materials meet the necessary specifications for safety and performance.

What Role Does Resin Play in Custom Model Car Part Production?

Resin, particularly in the form of epoxy or polyurethane, is increasingly popular for custom model car parts due to its ability to capture fine details and produce high-quality finishes. Resin parts are often used for specialized components like custom wheels or body kits.

Pros: Exceptional detail reproduction, good chemical resistance, and the ability to create lightweight but strong parts.

Cons: Generally higher costs and longer curing times, which can impact production schedules.

For buyers in regions like Africa and South America, understanding local supply chains for resin materials is crucial, as availability can vary significantly.

Why Consider Rubber in Custom Model Car Parts Manufacturing?

Rubber is often used for tires and flexible components in model cars due to its excellent grip and shock-absorbing properties. It can be molded into various shapes and is highly durable under stress.

Pros: Excellent flexibility, good wear resistance, and the ability to absorb shock, enhancing the performance of model cars.

Cons: Limited temperature range and potential degradation over time when exposed to certain chemicals.

Buyers should consider the specific requirements for rubber materials in their regions, including compliance with standards like JIS in Japan or DIN in Europe.

Summary Table of Material Selection for Custom Model Car Parts

| Material | Typical Use Case for custom model parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Body kits, small detail parts | Low cost and lightweight | Lower durability, UV degradation | Low |

| Metal | Chassis, engine components | High strength and durability | Higher cost and manufacturing complexity | High |

| Resin | Custom wheels, body kits | Exceptional detail reproduction | Higher costs and longer curing times | Medium |

| Rubber | Tires, flexible components | Excellent grip and shock absorption | Limited temperature range | Medium |

This strategic material selection guide provides essential insights for international B2B buyers in the custom model car parts market, enabling informed decisions that consider performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for custom model car parts

What Are the Main Stages of Manufacturing Custom Model Car Parts?

The manufacturing process for custom model car parts involves several critical stages, each contributing to the final product’s quality and precision. Understanding these stages can help B2B buyers assess potential suppliers more effectively.

Material Preparation: How Is Raw Material Selected and Processed?

The first step in manufacturing custom model car parts is material preparation. Common materials include plastic, resin, metal, and sometimes wood. The selection of materials depends on the desired characteristics of the final product, such as weight, durability, and finish.

Once selected, raw materials undergo processing, which may include cutting, grinding, or shaping to prepare them for forming. For instance, plastics may be pelletized and dried, while metals could be cast or machined. This preparation ensures that the materials meet the specifications required for subsequent stages.

Forming: What Techniques Are Used to Shape Model Car Parts?

The forming stage is where raw materials are shaped into the desired components. Various techniques are employed, including:

- Injection Molding: A widely used method for plastic parts, where molten plastic is injected into a mold to create precise shapes.

- Casting: This method involves pouring liquid material into a mold and allowing it to harden. It is commonly used for metal parts.

- 3D Printing: An increasingly popular technique that allows for rapid prototyping and complex geometries, ideal for custom designs.

- Machining: Subtractive processes like CNC machining are used for high precision and detail, particularly for metal parts.

Each technique has its advantages and is chosen based on the part’s complexity, volume requirements, and material properties.

Assembly: How Are Different Components Joined Together?

Once individual parts are formed, the assembly stage involves joining them to create the final product. This may include methods such as:

- Adhesives: Used for bonding plastics or metals, offering flexibility in assembly.

- Mechanical Fastening: Screws, bolts, and rivets are common methods for securing parts, especially in metal assemblies.

- Welding: A technique used primarily for metal parts, ensuring strong joints that can withstand stress.

Effective assembly processes are crucial, as they influence the overall functionality and durability of the model car parts.

Finishing: What Processes Enhance the Aesthetic and Functional Qualities?

The final stage, finishing, focuses on enhancing the aesthetic appeal and performance of the parts. This can involve:

- Painting and Coating: Applying paint or protective coatings to improve appearance and resistance to wear.

- Polishing: Achieving a smooth surface finish that enhances visual appeal.

- Quality Control Checks: Ensuring that finished products meet specified standards.

Finishing processes not only contribute to the look of the parts but can also affect their performance and longevity.

What Are the Key Quality Assurance Standards for Custom Model Car Parts?

Quality assurance is vital in the manufacturing of custom model car parts, ensuring that products meet specific standards and customer expectations. For international B2B buyers, familiarity with relevant standards and practices is essential.

Which International Standards Should Buyers Be Aware Of?

International standards, such as ISO 9001, provide a framework for quality management systems (QMS). Compliance with these standards indicates that a manufacturer adheres to best practices in quality assurance. Other relevant certifications may include:

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Certification: Relevant for manufacturers producing parts for the petroleum and natural gas industries, ensuring quality and safety.

Understanding these certifications helps buyers evaluate the credibility and reliability of suppliers.

How Are Quality Control Checkpoints Implemented in the Manufacturing Process?

Quality control (QC) is integrated into various stages of the manufacturing process to ensure product integrity. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections during production help identify defects early, reducing waste and ensuring consistency.

- Final Quality Control (FQC): Finished products undergo thorough testing to verify that they meet all quality standards before shipment.

By implementing these checkpoints, manufacturers can maintain high-quality standards throughout the production process.

What Common Testing Methods Are Used to Ensure Quality?

Several testing methods are employed to verify the quality of custom model car parts:

- Dimensional Inspection: Using tools like calipers and gauges to check that parts meet specified dimensions.

- Material Testing: Assessing the physical and chemical properties of materials to ensure they are suitable for their intended use.

- Functional Testing: Testing the assembled parts to ensure they perform as expected under simulated conditions.

These testing methods provide assurance that the products will meet the needs of end-users.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some strategies:

- Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality management systems.

- Quality Reports: Requesting detailed QC reports can help buyers understand the manufacturer’s quality history and practices.

- Third-party Inspections: Utilizing independent inspectors to verify compliance with quality standards can offer additional assurance.

By taking these steps, buyers can mitigate risks and ensure they are partnering with reputable manufacturers.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B transactions often introduce unique challenges related to quality control. Buyers should be aware of the following nuances:

- Regulatory Compliance: Different regions may have specific regulations that manufacturers must comply with. Understanding these can prevent issues during import/export.

- Cultural Differences: Variations in business practices and communication styles can affect quality expectations. Establishing clear guidelines and regular communication is essential.

- Logistical Challenges: Shipping and handling can impact product quality. Buyers should consider suppliers’ capabilities in managing logistics to ensure the integrity of parts during transit.

Navigating these nuances requires diligence and proactive engagement to establish successful partnerships in the global market for custom model car parts.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom model car parts’

Introduction

Sourcing custom model car parts for your business can be a complex process, particularly in international markets. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement landscape effectively. By following these steps, you can ensure that you acquire high-quality parts that meet your specific needs while minimizing risks associated with sourcing.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to have a clear understanding of your technical requirements. This includes the scale (e.g., 1/24 or 1/25), materials (plastic, resin, metal), and specific components needed (e.g., wheels, engines, detailing kits). Having detailed specifications not only helps in communicating effectively with suppliers but also aids in comparing different offerings.

- Considerations: Think about the end-use of the parts—will they be for display models or functional builds? This can influence the materials and craftsmanship required.

Step 2: Conduct Market Research

Understanding the market landscape is vital for making informed purchasing decisions. Research current trends in the model car parts industry, including popular designs, materials, and pricing strategies. This will help you identify potential suppliers and understand the competitive landscape.

- Action Points: Utilize online resources, attend industry trade shows, and connect with other model car enthusiasts or businesses to gather insights.

Step 3: Evaluate Potential Suppliers

Vetting suppliers is crucial to ensure reliability and quality. Look for suppliers with a proven track record, positive customer reviews, and relevant certifications. Request detailed company profiles, case studies, and references from other businesses in your industry.

- Key Questions: What is their production capacity? Do they have experience in international shipping? Are they responsive to inquiries?

Step 4: Request Samples and Prototypes

Before making a large order, always request samples or prototypes of the custom parts. This allows you to assess the quality, fit, and finish of the products. Evaluating samples can prevent costly mistakes and ensure the final products meet your expectations.

- Follow-Up: Use this opportunity to discuss any necessary modifications or customizations based on your feedback.

Step 5: Verify Supplier Certifications

Ensure that your chosen suppliers comply with relevant industry standards and certifications. This could include ISO certifications or specific compliance with safety and environmental regulations. Valid certifications demonstrate a commitment to quality and ethical practices.

- Documentation: Request copies of certifications and check their validity through the issuing organizations.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, it’s time to negotiate terms. This includes pricing, payment terms, lead times, and shipping arrangements. Clear communication during this phase can prevent misunderstandings later on.

- Tips: Aim for a win-win situation by being open about your budget while considering the supplier’s costs and constraints.

Step 7: Establish a Quality Control Process

Before the final shipment, establish a quality control process to verify that the received parts meet your specifications. This may involve random sampling or third-party inspections, especially when dealing with international suppliers.

- Importance: A robust quality control process mitigates the risk of receiving defective parts, which can impact your business operations and reputation.

By following this checklist, you can streamline your sourcing process for custom model car parts, ensuring that you make informed decisions that benefit your business in the long run.

Comprehensive Cost and Pricing Analysis for custom model car parts Sourcing

What Are the Key Cost Components in Sourcing Custom Model Car Parts?

When evaluating the cost structure for sourcing custom model car parts, several components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the desired profit margin.

-

Materials: The choice of materials significantly affects costs. For instance, high-quality resins and metals can raise expenses but improve durability and aesthetic appeal.

-

Labor: Skilled labor is essential for precision in creating custom parts. Labor costs vary based on the geographic location of the manufacturer and the complexity of the parts being produced.

-

Manufacturing Overhead: This encompasses the costs associated with running the production facility, including utilities, equipment maintenance, and administrative expenses. Understanding the overhead can help buyers assess the overall pricing strategy of suppliers.

-

Tooling: Initial tooling costs can be substantial, especially for custom molds or specialized machinery. These costs are often amortized over large production runs, making it crucial for buyers to consider their order volumes.

-

Quality Control: Implementing stringent quality control measures ensures product reliability, but it can add to the overall cost. Buyers should inquire about the QC processes to understand how they impact pricing.

-

Logistics: Shipping and handling costs vary widely based on the supplier’s location and the buyer’s destination. International logistics can introduce tariffs, customs fees, and extended lead times.

-

Margin: Suppliers will typically build in a margin that reflects their operational risk and market conditions. This can vary significantly based on the supplier’s reputation and reliability.

How Do Price Influencers Affect the Sourcing of Custom Model Car Parts?

Several factors influence pricing in the custom model car parts market, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Minimum order quantities (MOQs) can greatly affect pricing. Larger orders usually result in lower per-unit costs due to economies of scale.

-

Specifications and Customization: Highly specialized parts may incur additional costs. Buyers should provide clear specifications to avoid misunderstandings that can lead to unexpected expenses.

-

Materials and Quality Certifications: The use of premium materials and adherence to international quality standards can increase costs but may also offer a competitive advantage in terms of product longevity and customer satisfaction.

-

Supplier Factors: The reliability, reputation, and location of the supplier can influence pricing. Suppliers with a proven track record may charge a premium but can provide better service and product quality.

-

Incoterms: Understanding Incoterms is vital for international buyers. These terms dictate who is responsible for shipping, insurance, and tariffs, which can significantly affect the total landed cost.

What Are Effective Buyer Tips for Negotiating Custom Model Car Parts Pricing?

When engaging in negotiations for custom model car parts, international buyers should consider several strategies to optimize costs:

-

Leverage Volume Discounts: If possible, consolidate orders to meet or exceed MOQs, thus securing better pricing.

-

Seek Total Cost of Ownership Insights: Evaluate not only the purchase price but also the long-term costs associated with quality, durability, and maintenance.

-

Understand Pricing Nuances: Be aware that different regions may have unique pricing structures due to labor costs, material availability, and market demand. This is especially true for buyers from Africa, South America, the Middle East, and Europe, who may face additional challenges such as currency fluctuations and import duties.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms. Long-term partnerships often yield benefits in pricing and priority service.

What Should Buyers Keep in Mind Regarding Pricing Disclaimers?

It is essential for buyers to recognize that pricing in the custom model car parts industry can vary widely based on the factors discussed. The prices mentioned in supplier catalogs or websites are often indicative and can fluctuate due to changes in material costs, labor rates, and economic conditions. Buyers are encouraged to request detailed quotes that reflect their specific needs to ensure accurate budgeting and cost management.

Alternatives Analysis: Comparing custom model car parts With Other Solutions

Introduction to Alternative Solutions for Custom Model Car Parts

When considering custom model car parts, businesses often explore various solutions to enhance their model-building endeavors. Alternatives can provide diverse benefits ranging from cost-effectiveness to unique customization options. This analysis will compare custom model car parts against two viable alternatives: 3D Printing and Pre-Manufactured Model Kits. Each option offers distinct advantages and drawbacks that can influence the decision-making process for B2B buyers.

| Comparison Aspect | Custom Model Car Parts | 3D Printing | Pre-Manufactured Model Kits |

|---|---|---|---|

| Performance | High level of detail and accuracy for specific needs | Variable quality; dependent on printer and material | Consistent quality but limited customization |

| Cost | Higher initial investment for bespoke designs | Variable costs; can be economical for small runs | Generally lower upfront cost, but limited options |

| Ease of Implementation | Requires skilled labor and time for assembly | Requires design software and knowledge; can be complex | Simple assembly; ready-to-use components |

| Maintenance | Custom parts may require ongoing adjustments | Maintenance of the printer and software updates | Minimal maintenance; mostly straightforward |

| Best Use Case | Unique, specialized projects needing precision | Small batch production or unique prototypes | General model building for standard designs |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of 3D Printing for Model Car Parts?

3D printing offers a modern approach to creating custom parts, allowing for rapid prototyping and unique designs. The primary advantage is the ability to produce complex geometries that may not be feasible with traditional manufacturing methods. However, the quality can vary significantly based on the printer’s capabilities and the materials used, which may pose risks for high-stakes projects. Additionally, businesses must invest in the necessary design software and training, making the initial setup more complex.

How Do Pre-Manufactured Model Kits Compare in Terms of Cost and Usability?

Pre-manufactured model kits provide a straightforward solution for model builders, especially those looking for simplicity and ease of use. They typically come at a lower price point compared to custom parts and are designed for quick assembly. However, the trade-off is that these kits often lack the level of customization that some enthusiasts may desire, leading to a less personalized final product. This option is best suited for businesses looking for reliable, well-defined models without the need for intricate modifications.

Conclusion: Which Solution Should B2B Buyers Choose for Their Needs?

Selecting the right solution for model car parts ultimately depends on the specific requirements of the project and the resources available. Custom model car parts excel in providing tailored solutions for unique designs, though they come with higher costs and complexity. On the other hand, 3D printing offers flexibility and innovation but requires technical know-how and investment in equipment. Pre-manufactured kits serve as a practical choice for businesses prioritizing cost and simplicity over customization. By assessing project goals, budget constraints, and desired outcomes, B2B buyers can make informed decisions that align with their operational needs.

Essential Technical Properties and Trade Terminology for custom model car parts

What Are the Essential Technical Properties for Custom Model Car Parts?

Understanding the technical properties of custom model car parts is crucial for B2B buyers aiming to make informed decisions. Here are some key specifications that are critical in the industry:

1. Material Grade

Material grade indicates the quality and type of material used in manufacturing model car parts, such as plastic, resin, or metal. For instance, high-grade plastic can offer better durability and resistance to wear, while metal components may provide enhanced structural integrity. B2B buyers should prioritize materials that align with their project requirements to ensure long-lasting performance.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In model car parts, tighter tolerances typically yield better fits and functionality, which is vital for precision builds. Understanding tolerance levels helps buyers assess whether a part will meet their specific design needs, which is especially important for complex assemblies.

3. Scale Accuracy

Scale accuracy specifies how closely the part matches the intended scale of the model (e.g., 1/24 or 1/25). Accurate scaling ensures that all components fit together seamlessly, which is crucial for both aesthetics and functionality. Buyers should verify scale accuracy to avoid issues in assembly and overall visual appeal.

4. Finish Quality

Finish quality involves the surface treatment and detailing of the part, including painting, polishing, or etching. A high-quality finish can significantly enhance the visual appeal of a model car, making it more attractive to end consumers. Buyers should consider finish quality as part of their purchasing criteria, especially if the final product will be displayed.

5. Weight

Weight is an essential property that affects the balance and handling of model cars. Lighter components may improve speed and maneuverability, while heavier parts can add stability. B2B buyers should evaluate weight in relation to the intended use of the model to achieve the desired performance characteristics.

6. Compatibility

Compatibility refers to how well a part integrates with existing model kits or other components. This can include aspects like mounting points, connector types, or overall dimensions. Ensuring compatibility can save time and resources during assembly, making it a key consideration for B2B buyers.

What Are Common Trade Terms in the Custom Model Car Parts Industry?

Familiarity with industry jargon can greatly enhance communication and negotiation processes in B2B transactions. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the manufacturing of another company’s products. In the context of model car parts, OEM components are often preferred for their reliability and quality assurance. Buyers should consider OEM parts for consistency in performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for buyers to plan their inventory and budget effectively. Some suppliers may offer lower MOQs for customized parts, which can be advantageous for smaller operations or startups.

3. RFQ (Request for Quotation)

An RFQ is a formal process in which buyers request price quotes from suppliers for specific products. This is a critical step in the procurement process, allowing buyers to compare costs and terms from multiple vendors. A well-prepared RFQ can lead to better pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk allocation, and delivery responsibilities, which are crucial for global sourcing.

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the goods. Understanding lead times is essential for buyers to manage their project timelines and inventory effectively. Longer lead times may necessitate advanced planning and ordering.

6. Customization

Customization refers to the modification of standard parts to meet specific requirements or preferences. This can include changes in size, material, or design features. For B2B buyers, understanding customization options can open new avenues for product differentiation and customer satisfaction.

By comprehending these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing custom model car parts, ultimately leading to successful projects and satisfied end customers.

Navigating Market Dynamics and Sourcing Trends in the custom model car parts Sector

What Are the Current Market Dynamics and Key Trends in Custom Model Car Parts?

The custom model car parts sector is experiencing a notable evolution driven by several global trends. The rise of online marketplaces has transformed sourcing practices, enabling international B2B buyers from regions such as Africa, South America, the Middle East, and Europe to access a broader range of products. This shift towards digital platforms allows for enhanced visibility and comparison of suppliers, fostering competition and driving innovation.

Another critical trend is the increasing demand for personalization and customization among hobbyists and collectors. B2B buyers are seeking unique parts that cater to specific preferences, thus prompting manufacturers to diversify their offerings. Additionally, advancements in 3D printing technology are revolutionizing the production of custom parts, allowing for rapid prototyping and lower costs, which is particularly appealing to emerging markets.

Sustainability is also shaping market dynamics, as more buyers prioritize environmentally friendly practices. The demand for eco-conscious materials and ethical sourcing is becoming a key consideration in supplier selection. Buyers are increasingly interested in suppliers who adhere to sustainable practices and can provide transparency regarding their supply chain processes.

How Is Sustainability and Ethical Sourcing Impacting the Custom Model Car Parts Market?

Sustainability has emerged as a pivotal concern in the custom model car parts sector, influencing sourcing strategies and supplier relationships. The environmental impact of production processes, especially concerning plastic and resin materials, has prompted buyers to seek alternatives that reduce waste and carbon footprints.

Ethical sourcing is equally important, as B2B buyers are now more informed and conscientious about the origins of their materials. Companies that can demonstrate compliance with sustainability standards and certifications—such as ISO 14001 or materials that are recyclable—will likely have a competitive advantage.

Moreover, the use of ‘green’ materials, such as biodegradable plastics or recycled resins, is gaining traction. Suppliers who invest in sustainable practices not only appeal to environmentally conscious buyers but also mitigate risks associated with regulatory changes and shifting consumer preferences.

What Is the Historical Context of the Custom Model Car Parts Industry?

The custom model car parts industry has its roots in the post-World War II era, when the hobby of model building gained popularity. Initially, parts were primarily sourced from a limited number of manufacturers, often resulting in a lack of variety. However, as the hobby expanded, so did the market, leading to the emergence of specialized suppliers focusing on aftermarket parts.

The 1980s and 1990s saw significant advancements in manufacturing technologies, including the introduction of resin casting and photo-etching techniques. These innovations allowed for greater detail and customization, aligning with the hobbyists’ desire for more realistic models. Today, the industry is characterized by a diverse range of products and suppliers, supported by e-commerce platforms that facilitate global trade and consumer engagement.

In summary, understanding the current market dynamics, the importance of sustainability, and the historical context can empower international B2B buyers to make informed sourcing decisions in the custom model car parts sector.

Frequently Asked Questions (FAQs) for B2B Buyers of custom model car parts

-

How do I ensure the quality of custom model car parts from suppliers?

To ensure the quality of custom model car parts, start by vetting potential suppliers through their certifications and industry reputation. Request samples to assess the craftsmanship and materials used. Additionally, inquire about their quality assurance processes, including any third-party testing or adherence to international standards. Regular communication and setting clear quality expectations in your purchase agreements can also help maintain quality throughout the production process. -

What factors should I consider when sourcing custom model car parts internationally?

When sourcing custom model car parts internationally, consider factors such as supplier reliability, production capacity, and shipping logistics. Research the supplier’s experience in your specific market and their ability to meet your customization needs. Understand the local regulations and tariffs in both your country and the supplier’s country. Establishing clear communication channels and timelines is crucial to avoid delays and ensure a smooth transaction. -

What is the typical minimum order quantity (MOQ) for custom model car parts?

Minimum order quantities (MOQs) for custom model car parts can vary significantly depending on the supplier and the complexity of the parts. Generally, MOQs can range from 50 to several hundred units. Discuss your requirements upfront with potential suppliers to negotiate MOQs that fit your business needs. Some suppliers may offer lower MOQs for certain products or allow flexibility for first-time orders. -

What payment terms are standard when dealing with international suppliers?

Standard payment terms for international suppliers often include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers may require a deposit (typically 30-50%) to initiate production, with the balance due before shipment. It’s crucial to establish clear payment terms in your contract to protect both parties. Consider using secure payment methods that provide buyer protection to minimize risks. -

How can I customize model car parts to meet my specific requirements?

Customizing model car parts typically involves collaborating closely with your supplier to discuss your specifications, including dimensions, materials, and design features. Most suppliers offer options for bespoke designs, so provide detailed drawings or prototypes to communicate your vision. Utilize technology such as 3D modeling to visualize your requirements before production. Regular feedback during the prototype phase can ensure the final product meets your expectations. -

What logistics considerations should I keep in mind when importing model car parts?

When importing model car parts, consider logistics factors such as shipping methods, lead times, and customs clearance processes. Determine whether air freight or sea freight is more suitable for your order size and budget. Be aware of customs duties and taxes that may apply upon arrival. Establish a reliable shipping partner familiar with international regulations to streamline the process and avoid delays. -

What are the common risks associated with sourcing custom model car parts, and how can I mitigate them?

Common risks include quality issues, supplier reliability, and shipping delays. To mitigate these risks, conduct thorough due diligence on suppliers, including reviews and references. Establish clear contracts that outline quality expectations and timelines. Using escrow services for payments can also protect your investment until you receive satisfactory goods. Regular communication with your supplier can help address any issues promptly. -

How can I stay updated on the latest trends in custom model car parts?

To stay updated on trends in custom model car parts, subscribe to industry newsletters, attend trade shows, and participate in online forums. Engaging with communities on platforms like LinkedIn can provide insights into new technologies and designs. Following key manufacturers and influencers in the model car industry can also keep you informed about innovations and market shifts that could impact your sourcing strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Custom Model Car Parts Manufacturers & Suppliers List

1. MegaHobby – Model Car Detail Parts

Domain: megahobby.com

Registered: 1999 (26 years)

Introduction: Model Car Detail Parts include Car Decals, Car Exterior Details, Car Interior Details, Car Updates & Detailing Sets, Diorama Accessories & Figures, Engines, Wiring, Hoses, Polishing and Finishing, Resin Car Bodies, Wheels and Tires.

2. Ted’s Modeling Marketplace – 1/25 Scale Model Kits & Parts

Domain: tedsmodelingmarketplace.com

Registered: 2012 (13 years)

Introduction: 1/25 Scale Model Parts & Kits including Ford, Trucks, Detailing & Accessories. Categories include Engine Related, Truck Related, Kits, Diorama, and various scales (1/16, 1/43). Products include specific engine detailing, engine parts, exhaust components, fuel management, ignition components, turbo chargers, drive train & chassis, interior & cockpit parts, bodies & parts, wheels & tires, exterior p…

3. Scale Riders – Detail Up Parts

Domain: scaleriders.com

Registered: 2017 (8 years)

Introduction: Scale Model Detail Up Parts – Scale Riders offers a variety of detail up parts for scale models, including decals, engine detail, exterior detail, exhaust muffler fittings, interior detail, and wheels. The collection features products from various brands such as Aoshima, Tamiya, and more. Specific items include tire and wheel sets in different sizes (e.g., 14″, 15″, 17″, 18″, 19″, 20″) with prices…

4. Detail Master – Scale Model Car Accessories

Domain: detailmaster.com

Registered: 1996 (29 years)

Introduction: Detail Master specializes in 1:24 / 1:25 scale model car accessories, offering a variety of products including etch parts, wires & hoses, fittings, billet parts, trucks, car mats & mud flaps, and decals. The company has been in business for over 34 years and guarantees 100% satisfaction or your money back. They provide worldwide shipping, with secure payment options including American Express, App…

5. VCG Resins – Model Car and Truck Parts

Domain: vcgresins.com

Registered: 2011 (14 years)

Introduction: VCG Resins offers a variety of model car and truck parts and accessories, including: Engine Parts, Transmissions/Transmission Parts, Chassis and Suspension, Drag Racing Parts, Truck/Work Truck Parts, Off Road Parts, Emergency Vehicle Parts, Tools/Diorama Accessories, Electrical components, Wheels/Tires, Engine Kits, Underhood and Interior parts, Body Parts Kits, and Pro Tech Detailing Parts. Their…

6. Pro Tech Model Products – Holley Carburetor 1/25 Scale

Domain: protechmodelparts.com

Registered: 2006 (19 years)

Introduction: Pro Tech Model Products specializes in aftermarket hobby products for model cars and model railroads. Key products include: 1. PTMC 74 (1/25 scale) – Holley Street Carburetor with Choke – $3.75 2. PTMC 75 (1/25 scale) – Holley Street/Strip Carburetor – $3.75 3. PTMC 76 (1/25 scale) – Monster Tachometer – $5.75 4. PTMC 77 (1/25 scale) – MSD Pro Mag 44 Magneto – $6.75 5. PTMC 78 (1/25 scale) – Plug …

7. Iceman Collections – Custom Parts

Domain: icemancollections.com

Registered: 2017 (8 years)

Introduction: Customizing Parts from Iceman Collections. Free shipping for all US orders over $100. In-stock items are ready to ship. Sign up for the newsletter and Iceman Rewards to earn points towards discounts.

8. Auto World Store – AMT 1963 Chevy Corvette 1:25 Scale Model Kit

Domain: autoworldstore.com

Registered: 2009 (16 years)

Introduction: Auto World Store offers a wide variety of scale model kits including: 1:18 scale diecast replicas, 1:25 scale model cars and trucks, AMT scale model kits, MPC and Polar Lights model kit lines. Featured products include:

– AMT 1963 Chevy Corvette 1:25 Scale Model Kit – $30.99

– AMT 1966 Chevy Impala Modified Stocker 1:25 Scale Model Kit – $36.49 (Sale Price: $20.99, Save $15.50)

– AMT 1971 Plymouth…

9. eBay – Model Car Kit Parts

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: model car kit parts products for sale | eBay, Related Searches: Car Model Parts, Model Cars Parts, Model Car Resin Parts, 1 25 Scale Model Car Parts, Model Parts, Plastic Car Model Kits, Plastic Car Kit Model, Model Cars Kits, 1 24 Model Car Parts, Model Car Supplies, Plastic Model Car Kits, Vintage Model Car Kits, Examples of products: 1971 Chevelle Model Kit, 4×4 Model Kits, Alien Resin Model Ki…

Strategic Sourcing Conclusion and Outlook for custom model car parts

In the evolving landscape of custom model car parts, strategic sourcing emerges as a pivotal component for B2B buyers seeking quality, variety, and competitive pricing. By leveraging a diverse range of suppliers, businesses can access specialized components that enhance product offerings and cater to unique market demands. The insights gathered from industry leaders highlight the importance of sourcing high-quality detailing parts, resin components, and custom accessories that can elevate model car projects and satisfy discerning customers.

As international buyers from regions such as Africa, South America, the Middle East, and Europe navigate this market, they should prioritize establishing relationships with reliable suppliers who demonstrate a commitment to quality and innovation. With an increasing emphasis on customization and personal expression within the model car community, the potential for growth is substantial.

Looking ahead, the strategic sourcing of custom model car parts not only provides immediate advantages but also positions businesses to thrive in a competitive marketplace. Now is the time to explore diverse sourcing options, enhance your product lines, and ultimately, drive your business forward in this dynamic sector. Embrace the opportunities that lie ahead and invest in partnerships that will support your growth trajectory.