Contents

Manufacturing Insight: Custom Milled Aluminum

Precision Aluminum Components Engineered for Your Project Timeline

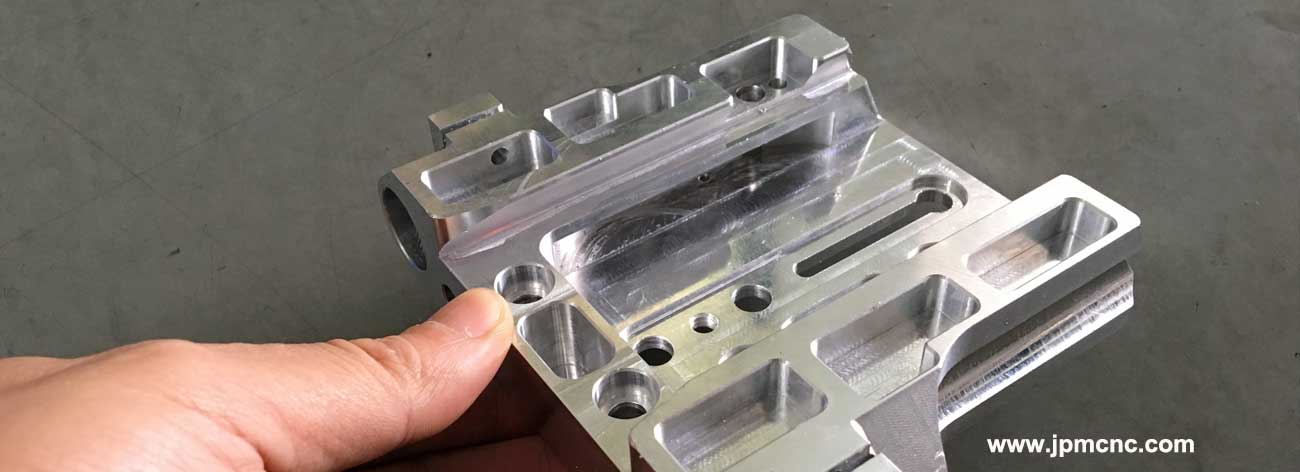

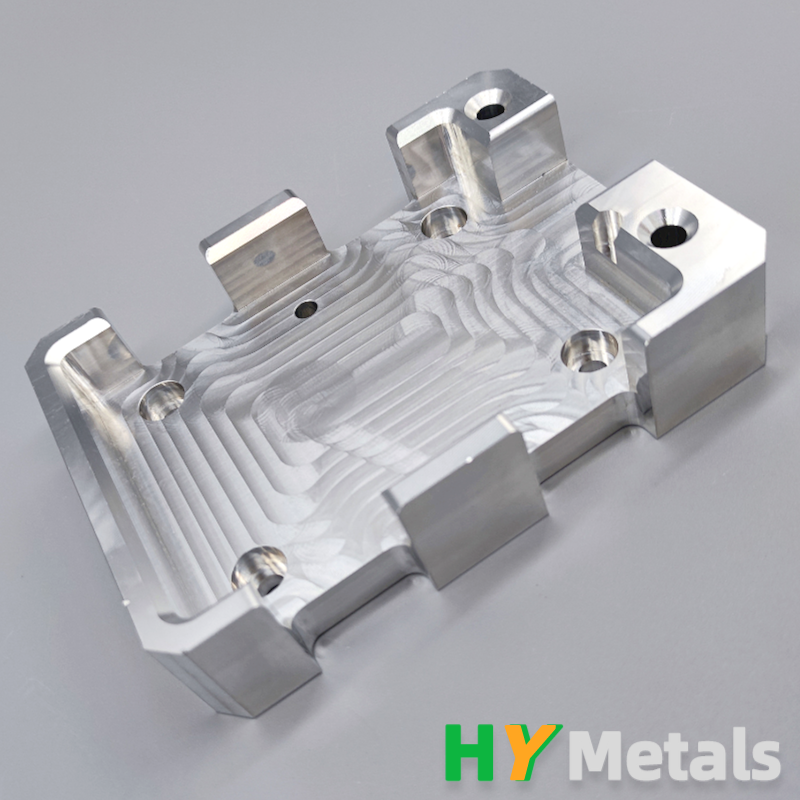

Honyo Prototype delivers industry-leading custom milled aluminum components through advanced CNC machining processes designed for prototyping and low-volume production. Our multi-axis milling centers achieve tight tolerances down to ±0.0002 inches across complex geometries, leveraging aerospace-grade 6061-T6 and 7075-T6 aluminum alloys for optimal strength-to-weight performance. Every part undergoes rigorous in-process metrology using calibrated CMMs and optical comparators, ensuring dimensional accuracy and surface finish consistency critical for functional testing and validation.

We eliminate quoting bottlenecks with our proprietary Online Instant Quote platform. Upload your STEP or IGES file to receive a detailed technical review and competitive pricing within 2 hours—not days—accelerating your design-to-prototype cycle. This integration of high-precision machining capability with real-time commercial feedback provides engineering teams the agility to iterate rapidly while maintaining strict compliance with AS9100 and ISO 9001 standards. Trust Honyo to transform your aluminum component requirements into validated physical assets on your schedule.

Senior Manufacturing Engineer, Honyo Prototype

Technical Capabilities

Custom milled aluminum components are manufactured using advanced CNC machining processes, including 3-axis, 4-axis, and 5-axis milling, as well as precision turning. These methods enable complex geometries, superior surface finishes, and tight tolerances required in aerospace, medical, automotive, and industrial applications. While aluminum is the most commonly used material due to its machinability, strength-to-weight ratio, and corrosion resistance, other materials such as steel, ABS, and nylon are also frequently machined based on application requirements.

The table below outlines the technical specifications and capabilities for custom milled parts across different materials and processes:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Typical Materials |

|---|---|---|---|---|---|

| Max Work Envelope | 24″ x 24″ x 20″ | 24″ x 24″ x 20″ | 20″ x 20″ x 18″ | Ø24″ x 30″ length | Aluminum (6061, 7075, 2024) |

| Axis of Motion | X, Y, Z | X, Y, Z, A (rotary) | X, Y, Z, A, B (dual rotary) | X, Z (rotating workpiece) | Steel (1018, 4140, 17-4 PH) |

| Positioning Accuracy | ±0.0002″ | ±0.0002″ | ±0.0001″ | ±0.0002″ | ABS (thermoplastic) |

| Repeatability | ±0.0001″ | ±0.0001″ | ±0.0001″ | ±0.0001″ | Nylon (PA6, PA66) |

| Standard Tolerance | ±0.005″ | ±0.005″ | ±0.003″ | ±0.002″ | |

| Tight Tolerance Capability | ±0.001″ (typical) | ±0.001″ | ±0.0005″ | ±0.0005″ (diametrical) | |

| Surface Finish (typical) | 32–64 μin Ra | 32–64 μin Ra | 16–32 μin Ra | 16–64 μin Ra | |

| Max Spindle Speed | 15,000 RPM | 15,000 RPM | 20,000 RPM | 6,000 RPM (varies by size) | |

| Tool Changer Capacity | 24–30 tools | 24–30 tools | 30–40 tools | 8–12 tools | |

| Lead Time (prototype) | 5–7 days | 7–10 days | 10–14 days | 5–7 days | |

| Common Applications | Brackets, housings, plates | Index-rotated parts | Aerospace contours, molds | Shafts, bushings, fittings |

Note: Tight tolerance machining requires thermal stability, high-precision tooling, and in-process inspection (e.g., CMM or probe systems). Material selection impacts machinability, tool life, and achievable tolerances—aluminum allows faster cycle times, while steel and engineering plastics like nylon require adjusted feeds, speeds, and tool geometry.

From CAD to Part: The Process

Honyo Prototype Custom Milled Aluminum Process Overview

Our custom milled aluminum service follows a streamlined, engineer-to-engineer workflow designed for speed, accuracy, and manufacturability. The process begins when a client uploads a native CAD file (STEP, IGES, or Parasolid) to our secure customer portal. Our system performs an immediate AI-driven preliminary analysis, checking for basic geometric validity, unit consistency, and potential red flags like undercuts or thin walls below 0.5mm. This step ensures the file is production-ready before human review.

AI-Powered Quoting with Embedded DFM Insights

Within two hours, clients receive a detailed quote generated by our proprietary AI engine, trained on 15,000+ historical aluminum milling projects. Unlike generic quoting tools, this system integrates real-time machine availability, material costs (primarily 6061-T6 and 7075-T6), and labor rates. Crucially, the quote includes preliminary Design for Manufacturability (DFM) feedback—highlighting features that could increase cost or lead time, such as non-standard tolerances (<±0.05mm), complex fixturing needs, or inefficient toolpath opportunities. This allows clients to make informed adjustments before commitment.

Engineer-Led DFM Collaboration

After quote acceptance, our manufacturing engineers conduct a rigorous manual DFM review. We analyze wall thickness consistency, hole depth-to-diameter ratios, surface finish requirements, and feature accessibility for 3-axis vs. 5-axis milling. Clients receive a marked-up DFM report within 24 business hours, with specific recommendations—e.g., suggesting chamfers instead of sharp corners to prevent tool breakage or optimizing pocket depths to reduce cycle time. This collaborative phase often cuts production time by 15–30% through proactive design refinement.

Precision Production Execution

Approved designs move to our Haas and DMG MORI CNC milling centers. All aluminum parts undergo:

Material certification verification (mill test reports provided)

In-process CMM checks at critical stages

Final inspection per AS9102 aerospace standards (including FAI reports)

Our production dashboard provides real-time updates on machine status, with typical lead times of 3–10 business days for prototypes and bridge production runs up to 500 units.

Quality-Assured Delivery

Every shipment includes:

Dimensional inspection report (PDF and .xlsx)

Material certification

Non-conformance documentation (if applicable)

Packaging tailored to client specifications (e.g., anti-corrosion VCI bags for marine applications)

Parts are shipped via DHL/FedEx with tracking, and we maintain a 99.2% on-time delivery rate for milled aluminum components. This closed-loop process—from CAD upload to certified delivery—ensures minimal rework and maximum value for engineering teams needing rapid, reliable metal prototypes.

Start Your Project

Looking for high-precision custom milled aluminum components? Honyo Prototype delivers tight-tolerance CNC milling services from our state-of-the-art factory in Shenzhen. Ideal for prototypes and low-volume production runs, our aluminum milling solutions offer fast turnaround, superior surface finishes, and strict quality control.

Contact Susan Leo today to request a quote or submit your design for review. Email [email protected] and get expert support tailored to your project requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.