Contents

Manufacturing Insight: Custom Metal Tube Fabrication

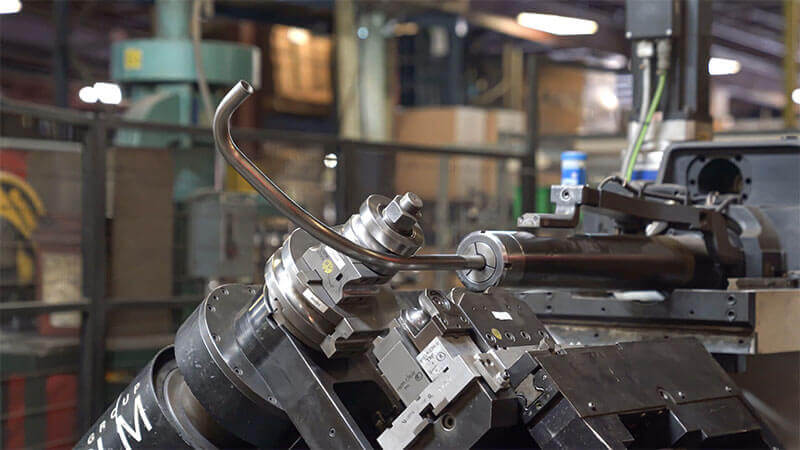

Honyo Prototype delivers precision custom metal tube fabrication engineered for demanding industrial applications. Our expertise extends seamlessly into comprehensive sheet metal fabrication capabilities, providing clients with a unified solution for complex assemblies where tubular components integrate with formed sheet metal structures. We leverage advanced CNC tube bending, laser cutting, and precision welding technologies to achieve tight tolerances across materials including stainless steel, aluminum, and carbon steel. This integrated approach ensures dimensional accuracy and structural integrity from initial prototyping through low to mid-volume production runs.

Complementing our tube and sheet metal services is Honyo’s proprietary Online Instant Quote platform. Engineers and procurement professionals can upload CAD files directly to receive detailed, factory-validated cost estimates and lead time projections within hours, significantly accelerating the sourcing timeline. This digital workflow eliminates traditional quotation bottlenecks while maintaining the engineering rigor expected for mission-critical components. Partner with Honyo Prototype for technically complex metal fabrication where precision, material science, and rapid turnaround converge.

Technical Capabilities

Custom metal tube fabrication involves precise manufacturing processes including laser cutting, bending, and welding to produce complex tubular structures for industrial, automotive, and aerospace applications. While aluminum and steel are standard materials for these processes, ABS and nylon are not suitable for laser cutting, bending, or welding in the same context due to their thermoplastic nature and low melting points. These polymers are typically processed using additive manufacturing, extrusion, or thermoforming rather than high-energy thermal methods used for metals.

Below is a technical specification table outlining capabilities and limitations for each process with applicable materials:

| Process | Material | Thickness Range | Tolerance | Tooling Required | Notes |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum | 0.5 mm – 25 mm | ±0.1 mm | No | High precision cutting; reflective material requires optimized settings |

| Steel (Mild & Stainless) | 0.5 mm – 30 mm | ±0.1 mm | No | Excellent edge quality; nitrogen or oxygen assist depending on grade | |

| ABS | Not Recommended | N/A | N/A | Melts unevenly; produces toxic fumes; not suitable for laser cutting | |

| Nylon | Not Recommended | N/A | N/A | Poor laser absorption; excessive melting and fuming | |

| Bending | Aluminum | 0.8 mm – 20 mm (tube wall) | ±0.5° angular, ±0.2 mm linear | Yes (mandrel/die) | Springback must be compensated; annealing may be needed for tight bends |

| Steel | 1.0 mm – 25 mm (tube wall) | ±0.5° angular, ±0.2 mm linear | Yes (mandrel/die) | Higher tonnage required; tool wear monitored for stainless steel | |

| ABS | Not Recommended | N/A | N/A | Lacks structural integrity for tube bending in fabrication contexts | |

| Nylon | Not Recommended | N/A | N/A | Flexible but not suitable for precision metal-forming equipment | |

| Welding | Aluminum | 1.0 mm – 20 mm | ±0.5 mm | Yes (fixturing) | Requires TIG or MIG with argon shielding; pre/post clean essential |

| Steel | 0.8 mm – 25 mm | ±0.5 mm | Yes (fixturing) | MIG, TIG, or spot welding; anti-spatter and post-weld grinding common | |

| ABS | Not Applicable | N/A | N/A | Joined via solvent welding or adhesives—not arc or laser welding | |

| Nylon | Not Applicable | N/A | N/A | Requires hot plate or ultrasonic welding; incompatible with metal weld processes |

Notes:

ABS and nylon are included for completeness but are not viable for laser cutting, bending, or welding in metal fabrication environments.

All metallic components require deburring, cleaning, and often post-process finishing (e.g., powder coating, anodizing).

CNC-controlled laser cutters, tube benders, and robotic welding cells ensure repeatability and precision in high-mix, low-volume prototype and production runs.

From CAD to Part: The Process

Honyo Prototype Custom Metal Tube Fabrication Process Overview

Honyo Prototype executes custom metal tube fabrication through a rigorously defined five-stage workflow designed for precision, speed, and manufacturability. The process begins when a client uploads a validated 3D CAD model of their tube component to our secure portal. Our system immediately initiates geometric analysis, extracting critical parameters including tube diameter, wall thickness, bend angles, end features, and material specifications. This stage enforces strict CAD standards to prevent downstream errors; non-compliant files trigger automated feedback for client correction prior to progression.

AI-Powered Quoting Engine

Upon CAD validation, our proprietary AI quoting engine processes the geometry alongside real-time material costs, machine availability, and labor rates. The AI cross-references historical production data from over 15,000 tube projects to predict manufacturability risks and cost drivers. Within 30 minutes, clients receive a detailed quote including itemized costs for machining, secondary operations (e.g., welding, threading), and material surcharges. Crucially, this quote embeds preliminary Design for Manufacturability (DFM) flags—such as minimum bend radius violations or weld accessibility issues—allowing clients to adjust designs before commitment. Human engineers validate all AI outputs to ensure accuracy.

Engineering-Driven DFM Analysis

After quote acceptance, Honyo’s manufacturing engineering team conducts a formal DFM review. This phase involves:

Verifying bend sequences against tube springback characteristics for stainless steel 304/316 or aluminum 6061-T6

Confirming end-form tooling feasibility for complex features like flares or grooves

Assessing fixturing requirements to prevent ovalization during bending

Optimizing nest layouts for raw material yield

Clients receive a DFM report with actionable recommendations, including tolerance adjustments or alternative joining methods. This collaborative step typically reduces production iterations by 70% compared to industry averages.

Integrated Production Execution

Approved designs move to our dedicated tube fabrication cell equipped with state-of-the-art machinery:

CNC tube benders (up to 50-ton capacity, ±0.1° angular accuracy)

Laser cutting systems for precise end trimming

Automated welding stations (TIG/MIG) with purge gas control

In-process metrology via coordinate measuring machines (CMM) at critical stages

All operations adhere to ISO 9001 protocols, with material traceability maintained from raw stock certificates through final inspection. Secondary operations like deburring, passivation, or anodizing occur in climate-controlled secondary workcells to meet aerospace or medical standards.

Certified Delivery and Logistics

Final inspection includes dimensional validation against ASME Y14.5 tolerances, pressure testing (where applicable), and surface finish verification. Each shipment includes:

First-article inspection (FAI) reports per AS9102

Material test certificates (MTRs) with full traceability

Protective packaging customized for component fragility

Real-time logistics tracking via our client portal

Standard lead times range from 5–12 business days depending on complexity, with expedited options available. This closed-loop process ensures clients receive fully documented, production-ready components with zero surprises.

Honyo’s integration of AI-driven quoting, engineering-led DFM, and tightly controlled production delivers predictable outcomes for custom metal tubes—transforming complex designs into high-integrity components faster than conventional prototype suppliers.

Start Your Project

Looking for precision custom metal tube fabrication? Partner with Honyo Prototype for high-quality, made-to-order metal tubing solutions. Our manufacturing facility in Shenzhen offers advanced capabilities in bending, cutting, welding, and finishing to meet your exact specifications.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a personalized quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.