Contents

Manufacturing Insight: Custom Metal Processing Machines

Precision Sheet Metal Fabrication Engineered for Your Success

At Honyo Prototype, we transform complex design challenges into high-precision sheet metal components through advanced custom metal processing capabilities. Our end-to-end Sheet Metal Fabrication services leverage state-of-the-art laser cutting, CNC punching, precision bending, and automated welding systems to deliver parts meeting stringent tolerances from 0.005″ to ISO 2768-mK standards. Whether prototyping low-volume aerospace brackets or scaling to high-mix automotive production runs, our engineering team optimizes material utilization, reduces lead times by 30% versus industry averages, and ensures repeatability across aluminum, stainless steel, and specialty alloys up to 6mm thickness.

Critical to accelerating your time-to-market is our proprietary Online Instant Quote platform. Upload STEP, DWG, or DXF files to receive a validated technical quotation with manufacturability feedback in under 90 seconds—no manual back-and-forth required. This integration of engineering rigor with digital procurement efficiency eliminates quoting bottlenecks while providing transparent cost breakdowns for material, forming, and secondary operations.

Partner with Honyo Prototype to convert your sheet metal concepts into certified, production-ready components with the speed and precision your business demands. Submit your design today and experience seamless fabrication from quote to delivery.

Technical Capabilities

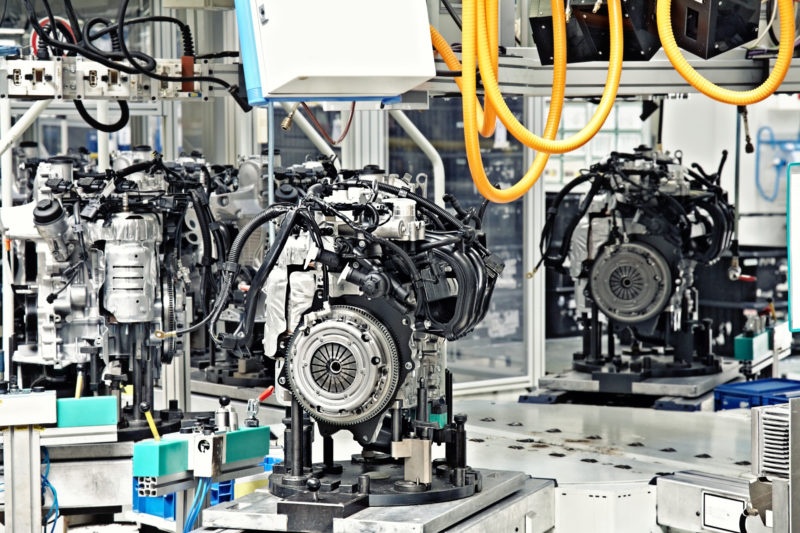

Custom metal processing machines at Honyo Prototype are engineered for precision, repeatability, and integration across high-mix, low-volume production environments. Our systems specialize in laser cutting, bending, and welding operations, supporting a range of materials including Aluminum, Steel, ABS, and Nylon. While ABS and Nylon are non-metallic and typically limited to secondary or hybrid processing (e.g., fixturing or laser marking), our platforms are designed with material-specific parameters to ensure optimal performance.

Below is a summary of technical specifications for each process category:

| Process | Material Compatibility | Thickness Range | Tolerance (Typical) | Power/Force Specifications | Key Features |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum, Steel, ABS, Nylon | 0.5 – 25 mm | ±0.1 mm | Fiber laser: 1–6 kW | High-speed CNC control, nitrogen/oxygen assist gas, automated material handling, FMS integration |

| Bending | Aluminum, Steel | 0.8 – 12 mm | ±0.2° angular | Press force: 30–300 tons | CNC programmable backgauges, tool auto-change, crowning compensation, safety interlocks |

| Welding | Aluminum, Steel | 1.0 – 20 mm | ±0.3 mm | MIG/TIG: 150–500 A; Fiber laser: 2–4 kW | Robotic arm integration (6-axis), pulse control, gas shielding, seam tracking sensors |

Note: ABS and Nylon are compatible only with non-melting processes such as laser marking or cutting using CO₂ lasers (not fiber); these materials are not suitable for bending or welding in structural applications. Processing parameters for polymers are adjusted to prevent combustion or warping. All machines support digital twin simulation and are compliant with ISO 12100 and CE safety standards.

From CAD to Part: The Process

Honyo Prototype Custom Metal Processing Machine Workflow

Honyo Prototype executes a rigorously controlled engineering-to-manufacturing sequence for custom metal processing machines, ensuring precision, cost efficiency, and adherence to industrial standards. This integrated workflow begins with client-provided design data and culminates in certified delivery, leveraging automation for speed while maintaining human engineering oversight at critical decision points.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS/Autodesk formats) via our secure customer portal. Our system automatically performs geometric validation checks, verifying unit consistency, watertight topology, and feature compatibility with subtractive/additive metal processes. Invalid geometries trigger immediate client notification with specific error diagnostics, preventing downstream delays. All data undergoes encryption per ISO 27001 standards, with version control enforced to eliminate revision conflicts.

AI-Assisted Quoting Engine

Validated CAD models enter our proprietary AI quoting system, which deconstructs geometry into manufacturable features while cross-referencing real-time inputs: material availability (e.g., 6061-T6 aluminum, 316L stainless, Inconel 718), machine capacity (5-axis milling up to 2,000mm travel), secondary operations (anodizing, passivation), and global logistics costs. The AI calculates machine time using physics-based toolpath simulations and applies dynamic labor/rate matrices. Crucially, this is not a black-box estimate—our quoting engineers review AI outputs for geometric complexity outliers and validate against historical production data. Typical quote turnaround is under 4 business hours.

| Parameter | Impact on Quote Calculation | Example Values in System |

|---|---|---|

| Material Complexity | Raw material cost + machining difficulty | 6061-T6: Base rate; Ti-6Al-4V: +320% |

| Geometric Tolerance | Secondary process requirements | ±0.025mm: Standard; ±0.005mm: +45% |

| Feature Density | Toolpath optimization efficiency | <50 features/part: Optimal; >200: +22% |

| Surface Finish | Post-processing time | 32 Ra: Milling only; 8 Ra: +2 grinding ops |

Engineering-Driven DFM Analysis

Quotes include actionable Design for Manufacturability (DFM) feedback generated through collaborative engineering review. Our cross-functional team (machining specialists, tooling engineers, quality assurance) assesses: tool access for internal cavities, minimum wall thickness relative to material ductility, datum scheme optimizability, and thermal distortion risks in large assemblies. Critical findings are prioritized—e.g., “12mm deep blind hole exceeds standard tool length; recommend taper or EDM alternative.” Clients receive annotated 3D PDFs with color-coded issue maps and redesign options. DFM resolution typically requires 1–2 iterative cycles, with formal engineering sign-off before work authorization.

Precision Production Execution

Approved designs move to production in our ISO 9001-certified facility. Each machine component undergoes:

Material certification verification (mill test reports matched to heat numbers)

First-article inspection using CMM and optical comparators against GD&T callouts

In-process checks at critical stages (e.g., after roughing, before hardening)

Real-time machine monitoring for tool wear and vibration anomalies via MTConnect

Complex assemblies follow a documented kitting sequence with torque-controlled fastening and functional testing protocols. All processes comply with AS9100 aerospace standards where applicable, with full traceability from raw bar stock to finished component.

Certified Delivery and Documentation

Final delivery includes the physical machine components alongside comprehensive digital dossiers:

FAI reports (AS9102 format) with dimensional conformance data

Material traceability certificates (including PMI test results)

Process validation records for non-destructive testing (e.g., penetrant inspection)

Packing list with serialized part tagging for inventory integration

Shipments use climate-controlled logistics partners with GPS tracking, and all deliveries include a digital twin access portal showing as-built deviations against original CAD. Critical path visibility is maintained through the client portal, with automated alerts for milestone completions. This closed-loop process ensures machine components meet functional specifications while providing auditable evidence for regulated industries.

Start Your Project

Looking for custom metal processing machines tailored to your production needs? Honyo Prototype delivers precision-engineered solutions from our Shenzhen manufacturing facility. With advanced capabilities in CNC machining, sheet metal fabrication, and assembly, we support low to high-volume runs with consistent quality and fast turnaround.

Contact Susan Leo today to discuss your project specifications and discover how our custom machinery solutions can enhance your manufacturing efficiency.

Email: [email protected]

Honyo Prototype – Your trusted partner in precision metal processing.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.