Introduction: Navigating the Global Market for custom metal forming

In today’s competitive landscape, navigating the global market for custom metal forming poses significant challenges for B2B buyers. Sourcing high-quality custom metal components that meet specific project requirements while balancing cost and delivery timelines can be daunting. This comprehensive guide delves into the nuances of custom metal forming, exploring various types of fabrication processes, from sheet metal to specialized forming techniques. We will also cover essential applications across multiple industries, ensuring that readers grasp the wide-ranging utility of these components.

Moreover, we will provide actionable insights into supplier vetting processes, helping businesses identify reliable partners that can deliver superior quality consistently. Understanding pricing structures, including factors that influence costs, will empower buyers to make informed decisions that align with their budgetary constraints. By examining the unique needs of international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Vietnam, this guide equips you with the tools and knowledge necessary to navigate the complexities of sourcing custom metal parts effectively.

With a focus on practical solutions and expert advice, this guide serves as an invaluable resource for companies looking to enhance their supply chain strategies and achieve operational excellence in custom metal forming.

Understanding custom metal forming Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sheet Metal Fabrication | Utilizes thin metal sheets; high precision and durability | Chassis, enclosures, brackets | Pros: Versatile, cost-effective for both prototypes and production. Cons: Limited thickness range compared to other methods. |

| Metal Stamping | Involves pressing metal into desired shapes using dies | High-volume production parts | Pros: Efficient for mass production, consistent quality. Cons: High initial tooling costs. |

| CNC Machining | Uses computer-controlled machines for precise cutting | Custom parts with complex designs | Pros: High precision, flexibility in design. Cons: Longer lead times for setup. |

| Hydroforming | Uses high-pressure fluid to shape metal into complex forms | Automotive and aerospace components | Pros: Excellent for complex shapes, reduces material waste. Cons: More expensive than traditional methods. |

| Forging | Deforms metal using compressive forces, often at high temperatures | Heavy-duty components and tools | Pros: High strength and durability, good for critical applications. Cons: Limited to simpler shapes. |

What Are the Key Characteristics of Sheet Metal Fabrication?

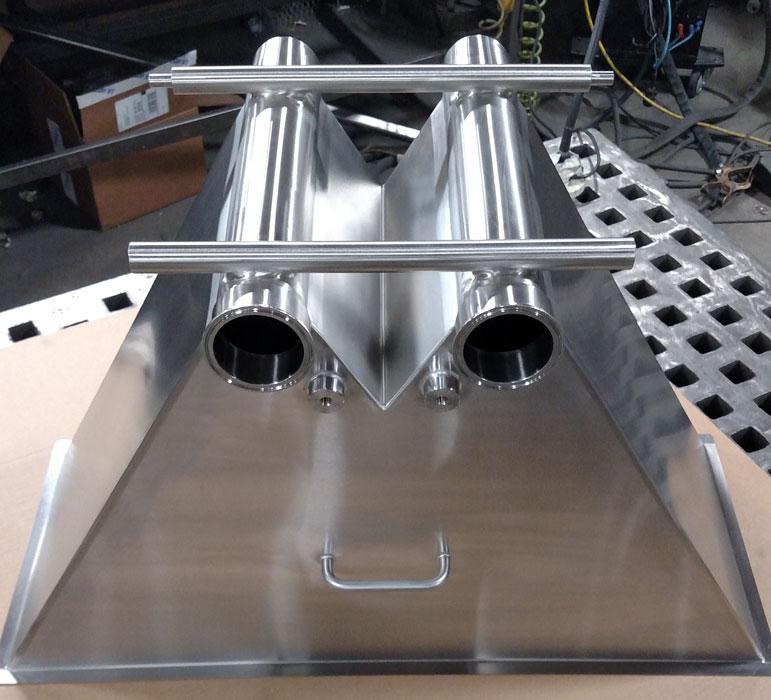

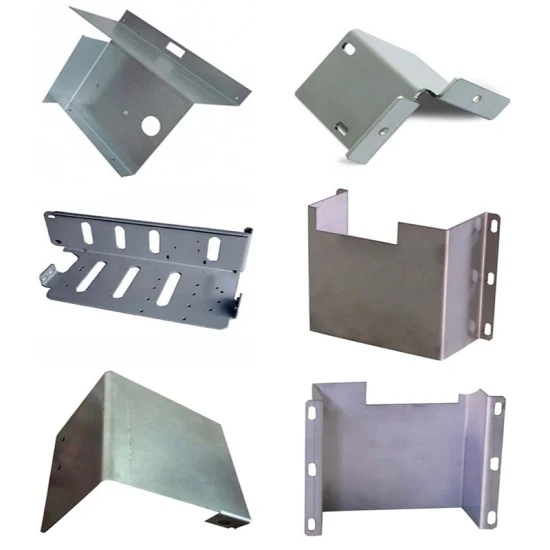

Sheet metal fabrication is a widely-used process that involves cutting, bending, and assembling thin sheets of metal. This method is particularly suitable for creating components that require high precision and durability, such as enclosures, brackets, and chassis. B2B buyers should consider factors like material type, thickness, and the specific manufacturing processes required. The ability to produce both prototypes and large production runs quickly makes this method highly appealing, though buyers should note the limitations in thickness compared to other forming methods.

How Does Metal Stamping Benefit High-Volume Production?

Metal stamping is a manufacturing process that uses dies and presses to shape metal into specific forms. This technique is ideal for high-volume production, making it a preferred choice for industries requiring consistent parts, such as automotive and electronics. B2B buyers should weigh the high initial costs of tooling against the long-term cost savings achieved through mass production. The uniformity and efficiency of this method can significantly enhance production timelines and reduce per-unit costs.

What Advantages Does CNC Machining Offer for Custom Parts?

CNC machining is a versatile process that employs computer-controlled machines to cut and shape materials with high precision. This method is particularly suitable for creating custom parts that have intricate designs or require tight tolerances. B2B buyers should consider the lead times associated with setup and programming, as these can be longer than other methods. However, the flexibility in design and the ability to work with a wide range of materials make CNC machining a valuable option for businesses needing specialized components.

Why Choose Hydroforming for Complex Shapes?

Hydroforming is a specialized metal forming process that uses high-pressure fluid to shape metal into complex geometries. This technique is particularly advantageous in the automotive and aerospace sectors, where intricate designs are often required. B2B buyers should evaluate the cost implications, as hydroforming can be more expensive than traditional methods. However, the reduction in material waste and the ability to produce lightweight yet strong components make it an attractive option for high-performance applications.

What Are the Key Considerations for Forging in Heavy-Duty Applications?

Forging is a process that involves shaping metal through compressive forces, typically at elevated temperatures. This method is renowned for producing high-strength components suitable for heavy-duty applications, such as tools and machinery parts. B2B buyers must consider the complexity of shapes achievable through forging, as it is better suited for simpler geometries. While forging can offer superior durability and performance, the initial costs and longer lead times may be a drawback for some applications.

Key Industrial Applications of custom metal forming

| Industry/Sector | Specific Application of custom metal forming | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of chassis and body components | Enhanced durability and lightweight designs for improved efficiency | Ensure suppliers have ISO certifications and can meet tight tolerances. |

| Aerospace | Manufacturing of structural components and enclosures | Compliance with strict safety standards and lightweight materials | Verify ITAR registration and experience with aerospace materials. |

| Electronics | Creation of enclosures and mounting brackets | Protection of sensitive components while maintaining design flexibility | Look for rapid prototyping capabilities and material variety. |

| Construction | Fabrication of structural beams and supports | Increased strength and reliability in building infrastructure | Assess local regulations and material sourcing options. |

| Medical Devices | Production of specialized surgical instruments | High precision and biocompatibility for patient safety | Confirm adherence to medical device regulations and quality control processes. |

How Is Custom Metal Forming Used in the Automotive Industry?

In the automotive sector, custom metal forming is essential for creating chassis and body components that require high precision and durability. This process allows manufacturers to produce lightweight parts that enhance fuel efficiency without compromising structural integrity. For international buyers, particularly in regions like Africa and South America, sourcing from certified suppliers who can provide quality assurance and meet stringent automotive standards is crucial. Additionally, understanding local regulations on material sourcing can streamline the procurement process.

What Role Does Custom Metal Forming Play in Aerospace Applications?

Aerospace applications leverage custom metal forming to manufacture critical structural components and enclosures that must adhere to strict safety standards. The lightweight nature of formed metals is vital for enhancing fuel efficiency and performance in aircraft. Buyers in the Middle East and Europe should prioritize suppliers with ITAR registration and proven experience in aerospace materials to ensure compliance with international regulations. Additionally, the ability to meet tight tolerances is a key consideration for aerospace applications.

How Is Custom Metal Forming Used in Electronics Manufacturing?

In the electronics industry, custom metal forming is utilized to create protective enclosures and mounting brackets for sensitive components. This process not only safeguards the electronics from environmental factors but also offers flexibility in design, allowing for integration with various systems. For businesses in regions like Vietnam and the Middle East, sourcing partners should be evaluated based on their rapid prototyping capabilities and material variety to accommodate diverse electronic applications.

Why Is Custom Metal Forming Important in Construction?

Custom metal forming plays a significant role in the construction industry by fabricating structural beams and supports that enhance the strength and reliability of building infrastructure. The ability to produce customized shapes and sizes allows for tailored solutions that meet specific architectural requirements. Buyers in Africa and South America should consider local sourcing options to reduce lead times and costs while ensuring compliance with regional construction regulations.

How Does Custom Metal Forming Benefit the Medical Device Sector?

In the medical device industry, custom metal forming is critical for producing specialized surgical instruments that require high precision and biocompatibility. This ensures patient safety and compliance with stringent health regulations. International buyers, particularly from Europe and the Middle East, should focus on suppliers with robust quality control processes and certifications that align with medical device standards to mitigate risks associated with product safety and efficacy.

3 Common User Pain Points for ‘custom metal forming’ & Their Solutions

Scenario 1: Delayed Deliveries Impacting Production Schedules

The Problem: One of the significant pain points for B2B buyers in custom metal forming is the challenge of delayed deliveries. Companies often rely on just-in-time manufacturing to minimize inventory costs, making timely delivery of custom metal parts critical. When suppliers fail to meet promised delivery dates, it can lead to halted production lines, missed deadlines, and ultimately, dissatisfied customers. This scenario is particularly pressing for businesses operating in regions with complex logistics, like parts of Africa and South America, where transportation issues can exacerbate delays.

The Solution: To mitigate the risk of delayed deliveries, buyers should prioritize suppliers that offer transparent production timelines and real-time tracking capabilities. Engaging with vendors who have robust logistics networks and can provide expedited services is crucial. Buyers should also consider establishing clear communication channels and setting up regular check-ins during the production process. Requesting detailed production schedules and tracking updates can allow for proactive adjustments in case of potential delays. Moreover, incorporating buffer stock for essential parts can provide a safety net during unforeseen disruptions.

Scenario 2: Quality Assurance Challenges in Custom Metal Parts

The Problem: Ensuring the quality of custom metal parts is another common challenge faced by B2B buyers. Variability in manufacturing processes, material quality, and adherence to specifications can lead to defects, which can compromise product integrity. This is especially critical in industries like automotive and aerospace, where subpar components can have serious safety implications. Buyers often struggle to identify suppliers who consistently deliver high-quality products, leading to costly reworks and project delays.

The Solution: To address quality assurance challenges, B2B buyers should seek suppliers with recognized certifications, such as ISO 9001 or AS9100, which demonstrate a commitment to quality management systems. It’s beneficial to request samples or prototypes before placing large orders, allowing buyers to evaluate the quality firsthand. Implementing a clear quality control checklist that outlines specifications, tolerances, and testing requirements can help ensure that received parts meet the necessary standards. Furthermore, establishing a strong relationship with suppliers can facilitate open communication about quality expectations and enable prompt resolutions for any issues that arise.

Scenario 3: Inadequate Design Support Leading to Cost Overruns

The Problem: Many B2B buyers encounter difficulties during the design phase of custom metal parts, often resulting in cost overruns and project delays. A lack of expertise in metal forming processes can lead to designs that are difficult or costly to manufacture. This is particularly common among companies that may not have in-house engineering capabilities or are working with new materials and processes. Such challenges can result in wasted materials, increased labor costs, and ultimately, a product that does not meet market needs.

The Solution: To overcome design-related challenges, buyers should engage with suppliers that offer comprehensive design support services. This includes utilizing design for manufacturability (DFM) principles, where suppliers provide feedback on how to optimize designs for production efficiency. Collaborating early in the design phase can help identify potential issues before they escalate. Buyers can also benefit from leveraging advanced software tools and simulations provided by suppliers to visualize the manufacturing process and identify cost-saving opportunities. Investing in training or consulting on metal forming best practices can empower buyers to create more efficient designs, ultimately leading to reduced costs and improved time-to-market.

Strategic Material Selection Guide for custom metal forming

What Are the Key Properties of Common Materials Used in Custom Metal Forming?

When selecting materials for custom metal forming, it is crucial to understand the properties and characteristics that influence product performance. This section analyzes four common materials: Aluminum, Stainless Steel, Carbon Steel, and Copper, providing insights into their advantages, disadvantages, and implications for international B2B buyers.

How Does Aluminum Perform in Custom Metal Forming Applications?

Aluminum is renowned for its lightweight nature, excellent corrosion resistance, and good thermal conductivity. It typically has a temperature rating up to 600°F (315°C) and can withstand moderate pressure. The primary advantage of aluminum is its ease of fabrication, making it suitable for complex geometries and intricate designs.

Pros: Aluminum’s lightweight nature reduces shipping costs and makes it ideal for applications requiring weight savings, such as automotive and aerospace components. It also offers good resistance to oxidation and corrosion, making it suitable for outdoor applications.

Cons: However, aluminum can be more expensive than steel and may not be as strong under high-stress conditions. It is also less suitable for high-temperature applications compared to other metals.

For international buyers, it’s essential to consider compliance with standards such as ASTM B221 for aluminum extrusions and EN 573 for aluminum alloys, ensuring that the material meets regional specifications.

What Are the Benefits and Limitations of Stainless Steel in Metal Forming?

Stainless steel is highly regarded for its strength, durability, and excellent corrosion resistance. It can handle high temperatures (up to 1500°F or 815°C) and pressures, making it suitable for a wide range of applications, including food processing and chemical handling.

Pros: The primary advantage of stainless steel is its ability to withstand harsh environments, including exposure to chemicals and moisture. It also has a long lifespan and requires minimal maintenance.

Cons: The main drawback is its cost, which is generally higher than that of carbon steel. Additionally, stainless steel can be more challenging to machine and form, requiring specialized tools and processes.

International buyers should be aware of standards like ASTM A240 for stainless steel sheets and plates and ISO 9001 for quality management, ensuring that the material meets global quality benchmarks.

How Does Carbon Steel Compare in Custom Metal Forming?

Carbon steel is a versatile material that offers excellent strength and durability at a relatively low cost. It typically has a temperature rating of around 800°F (427°C) and can withstand significant pressure, making it suitable for structural applications.

Pros: The key advantage of carbon steel is its affordability and ease of availability. It is widely used in construction, automotive, and manufacturing industries due to its strength and formability.

Cons: However, carbon steel is prone to corrosion and rusting without proper treatment, which may limit its use in outdoor or humid environments. It also has lower ductility compared to aluminum and stainless steel, which can complicate forming processes.

For B2B buyers in regions like Africa and South America, understanding compliance with standards such as ASTM A36 for structural steel and DIN 1011 for carbon steel is critical for ensuring product quality and safety.

What Role Does Copper Play in Custom Metal Forming Applications?

Copper is known for its excellent electrical and thermal conductivity, making it a preferred choice for electrical applications and heat exchangers. It typically has a temperature rating of up to 2000°F (1093°C) and can handle moderate pressures.

Pros: The primary advantage of copper is its superior conductivity, which is essential for electrical components. It also has good corrosion resistance, particularly in marine environments.

Cons: The main limitation is its cost, which can be higher than other metals, and its softness, which may not be suitable for high-stress applications.

International buyers should consider compliance with standards such as ASTM B152 for copper sheets and plates and JIS H3250 for copper alloys, ensuring that the materials meet local regulations.

Summary Table of Material Selection for Custom Metal Forming

| Material | Typical Use Case for custom metal forming | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Higher cost, lower strength under stress | Medium |

| Stainless Steel | Food processing, chemical handling | Excellent durability and corrosion resistance | Higher cost, challenging to machine | High |

| Carbon Steel | Construction, automotive manufacturing | Affordable and strong | Prone to corrosion, lower ductility | Low |

| Copper | Electrical applications, heat exchangers | Superior electrical and thermal conductivity | Higher cost, softness limits applications | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions in custom metal forming projects. Understanding the properties, advantages, and limitations of these materials ensures optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for custom metal forming

What Are the Key Stages in the Manufacturing Process of Custom Metal Forming?

Custom metal forming is a critical component of the manufacturing sector, particularly for B2B buyers who require precision-engineered parts. The manufacturing process typically involves several key stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Metal Forming?

The first stage of custom metal forming begins with material selection and preparation. Common materials include aluminum, steel, copper, and various alloys. The process often starts with sourcing high-quality metal sheets, which are then cut to size. Techniques such as laser cutting, waterjet cutting, and CNC routing are employed to ensure precision. Depending on the complexity of the design, the material may undergo additional treatments like annealing to enhance ductility, making it easier to form without cracking.

What Techniques Are Used in the Forming Process?

Once the materials are prepared, they are subjected to various forming techniques. Common methods include bending, stamping, and deep drawing.

- Bending involves using hydraulic or mechanical presses to achieve the desired angle or shape.

- Stamping is used for producing parts with high volumes and features intricate shapes, while simultaneously cutting and forming the material.

- Deep Drawing is a process where a flat sheet is formed into a hollow shape, useful for creating components like enclosures and housings.

Each technique is chosen based on the specific requirements of the part being produced, including its complexity, volume, and material properties.

How Is the Assembly Process Managed in Custom Metal Forming?

After the individual components are formed, they are assembled into the final product. This stage may involve welding, riveting, or using PEM inserts for mechanical fastening. The choice of assembly method depends on the design specifications and the intended application of the product. For example, welding is often preferred for its strength and durability, particularly in applications that require structural integrity.

What Quality Control Standards Are Relevant for Custom Metal Forming?

Quality assurance is paramount in custom metal forming, especially for international B2B buyers who demand compliance with various industry standards. Key international standards include ISO 9001:2015 for quality management systems, ISO 13485 for medical devices, and AS9100 for aerospace. Compliance with these standards ensures that manufacturers maintain consistent quality and reliability in their processes.

What Are the Critical QC Checkpoints in Metal Forming?

Quality control in custom metal forming typically involves several checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, allowing for timely adjustments.

- Final Quality Control (FQC): This final inspection phase verifies that the finished product meets all specifications and quality standards before shipping.

Which Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to verify the integrity and performance of custom metal parts. Common techniques include:

- Visual Inspection: A straightforward method to identify surface defects or anomalies.

- Dimensional Inspection: Using calipers and gauges to ensure parts meet specified dimensions.

- Non-destructive Testing (NDT): Techniques such as ultrasonic testing and radiography are employed to detect internal flaws without damaging the components.

- Tensile Testing: This evaluates the material’s strength and ductility, ensuring it can withstand operational stresses.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several strategies:

- Supplier Audits: Conducting on-site inspections allows buyers to assess a supplier’s manufacturing capabilities and quality management systems firsthand.

- Requesting Quality Reports: Suppliers should provide documentation that outlines their quality assurance practices and results from recent inspections or tests.

- Third-Party Inspections: Engaging independent inspection agencies can provide unbiased assessments of a supplier’s quality control processes.

What Are the Quality Control and Certification Nuances for International Buyers?

International B2B buyers often face unique challenges regarding quality control and certifications. Different regions may have varying standards and regulations, which can complicate the procurement process. For example, buyers from the Middle East might prioritize CE marking for compliance with European standards, while those in South America may require local certifications for importation.

To navigate these complexities, buyers should:

- Understand Regional Standards: Familiarize themselves with the specific quality standards applicable to their industry and region.

- Communicate Clearly with Suppliers: Establish clear expectations regarding certifications and compliance from the outset of the relationship.

- Consider Local Regulations: Be aware of tariffs, import duties, and local compliance requirements that may impact the cost and feasibility of sourcing parts internationally.

Conclusion

Custom metal forming involves a detailed manufacturing process that requires stringent quality control measures to meet the demands of B2B buyers. By understanding the key stages of manufacturing, relevant quality assurance standards, and effective verification methods, buyers can make informed decisions when selecting suppliers. This knowledge not only enhances the procurement process but also ensures that the final products meet the necessary standards for quality and performance in various applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom metal forming’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring custom metal forming services. By following these steps, you will ensure a streamlined procurement process that meets your project’s technical requirements while aligning with your business’s strategic goals.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is essential for successful custom metal forming. Specify dimensions, tolerances, materials, and finish types that your project demands. This will facilitate accurate quotes and reduce misunderstandings with potential suppliers.

- Considerations: Include details such as thickness, weight, and any specific industry standards that must be adhered to, especially if you’re in regulated markets.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with expertise in custom metal forming. Look for companies with a proven track record in your industry, as well as those who can handle your order volume.

- Tip: Utilize online directories, industry forums, and trade shows to gather a list of potential suppliers. Pay attention to reviews and testimonials from other B2B buyers.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that your shortlisted suppliers hold relevant certifications. This may include ISO certifications, ITAR registration, or compliance with specific industry standards.

- Importance: Certifications indicate a supplier’s commitment to quality and reliability, which is crucial for ensuring that your project meets all necessary specifications and regulations.

Step 4: Request and Compare Quotes

Once you have a list of qualified suppliers, request quotes based on your technical specifications. Ensure that you provide the same details to each supplier to facilitate a fair comparison.

- What to Look For: Pay attention to pricing, lead times, and any additional costs such as shipping or tariffs, especially when dealing with international suppliers.

Step 5: Assess Production Capabilities

Inquire about the supplier’s production capabilities to ensure they can meet your order requirements. This includes their machinery, technology, and workforce expertise.

- Key Factors: Look for information on their capacity for handling different materials, the ability to produce complex shapes, and whether they offer additional services like assembly or finishing.

Step 6: Verify Quality Control Processes

Quality assurance is vital in custom metal forming. Ask potential suppliers about their quality control measures and processes in place to ensure that all parts meet your specifications.

- Questions to Ask: Inquire about their inspection methods, frequency of quality checks, and any guarantees they provide regarding the quality of their products.

Step 7: Establish Clear Communication Channels

Effective communication is crucial throughout the procurement process. Ensure that you have established clear channels of communication with your chosen supplier.

- Best Practices: Set up regular check-ins and updates, and use project management tools to track progress. This will help to address any potential issues promptly and maintain transparency.

By following this checklist, you will be well-equipped to navigate the complexities of sourcing custom metal forming services, ensuring that your procurement process is efficient and effective.

Comprehensive Cost and Pricing Analysis for custom metal forming Sourcing

What Are the Key Cost Components in Custom Metal Forming?

In custom metal forming, several key cost components contribute to the overall pricing structure. The primary components include:

-

Materials: The choice of material significantly impacts pricing. Common materials like aluminum, stainless steel, and carbon steel vary in cost based on market fluctuations, availability, and specific grades required for the project. Specialty materials, such as titanium or high-strength alloys, can lead to higher costs.

-

Labor: Labor costs encompass the wages for skilled workers involved in the fabrication process. The complexity of the design and the required level of craftsmanship influence labor costs. Automated processes can reduce labor costs but may require higher initial investments in machinery.

-

Manufacturing Overhead: This includes costs associated with running the facility, such as utilities, equipment maintenance, and administrative expenses. These costs are typically distributed across all manufactured parts, affecting the price per unit.

-

Tooling: Tooling costs refer to the expenses incurred for creating molds, dies, or specific tools needed for custom parts. High initial tooling costs can be amortized over large production runs, making it critical for buyers to consider volume when assessing tooling expenses.

-

Quality Control (QC): Implementing quality control measures ensures that the parts meet specified tolerances and standards. This can involve additional testing and inspection processes, contributing to overall costs.

-

Logistics: Shipping and handling costs vary based on the destination, size, and weight of the shipment. International shipping may also involve tariffs and customs duties, which can significantly affect the total price.

-

Margin: Suppliers typically add a profit margin to cover their costs and achieve profitability. This margin can vary based on the supplier’s market position, competition, and the perceived value of their services.

What Influences Pricing in Custom Metal Forming Projects?

Several factors influence the pricing of custom metal forming:

-

Volume and Minimum Order Quantity (MOQ): Higher volumes often lead to lower per-unit costs due to economies of scale. Conversely, low-volume orders may incur higher pricing due to fixed costs being spread over fewer units.

-

Specifications and Customization: The complexity and specificity of the design can drive up costs. More intricate designs requiring advanced manufacturing techniques will generally be more expensive.

-

Material Selection: As mentioned, the type of material chosen plays a significant role in pricing. Buyers should consider both the upfront costs and the long-term performance characteristics of the materials.

-

Quality and Certifications: Parts that require specific certifications (e.g., ISO, AS9100) or higher quality standards may incur additional costs due to the stringent processes involved.

-

Supplier Factors: The reputation, location, and capabilities of the supplier can also affect pricing. Suppliers with advanced technology or specialized expertise may command higher prices.

-

Incoterms: Understanding Incoterms is crucial for international transactions as they dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

How Can Buyers Negotiate Better Prices in Custom Metal Forming?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant savings:

-

Leverage Volume Discounts: Consolidating orders to achieve higher volumes can unlock better pricing. Discussing long-term contracts can also provide stability and cost predictability.

-

Evaluate Total Cost of Ownership (TCO): Buyers should consider not just the initial price but also maintenance, operational efficiency, and lifespan of the parts when assessing value.

-

Request Detailed Quotes: Ensure that quotes include a breakdown of all costs. This transparency allows for better comparison between suppliers and highlights areas for negotiation.

-

Be Aware of Pricing Nuances: Understand the local market dynamics, including material costs and labor rates, to better negotiate with suppliers. This knowledge can empower buyers to advocate for fair pricing.

-

Consider Alternate Suppliers: Diversifying the supplier base can create competitive pressure, encouraging suppliers to provide better pricing or terms.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier policies, and specific project requirements. Always consult with suppliers for accurate quotes tailored to your unique needs.

Alternatives Analysis: Comparing custom metal forming With Other Solutions

In the competitive landscape of manufacturing, particularly for B2B buyers, understanding the various methods available for producing metal parts is crucial. Custom metal forming is a popular choice, but alternative solutions also merit consideration. This section provides a comparative analysis of custom metal forming against two viable alternatives: metal stamping and CNC machining. Each method has its unique strengths and weaknesses, making it important for buyers to evaluate them based on their specific needs.

| Comparison Aspect | Custom Metal Forming | Metal Stamping | CNC Machining |

|---|---|---|---|

| Performance | High precision; suitable for complex shapes | High-speed production; less precision | Extremely precise; versatile for various materials |

| Cost | Moderate; initial setup costs can be high | Cost-effective for high volumes | Higher costs for setup; cost-effective for low volumes |

| Ease of Implementation | Requires specialized equipment and design | Streamlined for mass production | Requires skilled labor; setup can be complex |

| Maintenance | Moderate; depends on tooling wear | Low; machines are robust | High; regular calibration needed |

| Best Use Case | Low to medium volumes; custom designs | High-volume production; simple designs | Prototypes and one-offs; complex geometries |

What are the Advantages and Disadvantages of Metal Stamping Compared to Custom Metal Forming?

Metal stamping is a manufacturing process that uses dies and stamping presses to shape and cut metal sheets. Its primary advantage lies in its ability to produce large quantities of parts quickly and cost-effectively. This method is particularly effective for simple geometries and can significantly lower per-unit costs when producing high volumes. However, it is less suited for intricate designs or low-volume runs, as the initial tooling costs can be prohibitive.

How Does CNC Machining Offer a Different Approach to Custom Metal Forming?

CNC machining utilizes computer-controlled tools to remove material from a workpiece, allowing for high precision and versatility in creating complex parts. This method excels in producing one-off components or small batches where precision is paramount. CNC machining is adaptable to various materials, including metals, plastics, and composites, making it an excellent choice for diverse applications. However, it typically involves higher setup costs and longer lead times than custom metal forming, especially for larger production runs.

How Can B2B Buyers Determine the Best Solution for Their Needs?

When evaluating the right solution for metal part production, B2B buyers should consider their specific requirements, including the complexity of the part, volume needed, budget constraints, and lead times. Custom metal forming is ideal for unique, low to medium volume projects that require a high level of detail. In contrast, metal stamping is more suited for high-volume production of simpler parts, while CNC machining offers unparalleled precision for complex designs but may come at a higher cost. By assessing these factors, buyers can make an informed decision that aligns with their operational goals and financial capabilities.

Essential Technical Properties and Trade Terminology for custom metal forming

What Are the Key Technical Properties in Custom Metal Forming?

When engaging in custom metal forming, understanding specific technical properties is crucial for making informed purchasing decisions. Here are several key specifications to consider:

Material Grade

Material grade refers to the quality and type of metal used, such as stainless steel, aluminum, or carbon steel. Each grade possesses distinct characteristics such as strength, corrosion resistance, and machinability. Selecting the appropriate material grade is essential for ensuring that the final product meets the required performance and longevity standards for its intended application.

Tolerance

Tolerance indicates the permissible limit of variation in a physical dimension. It is typically expressed in thousandths of an inch (e.g., ±0.005”). In B2B settings, precise tolerances are vital for ensuring that parts fit together correctly, particularly in assemblies. Inaccurate tolerances can lead to assembly failures, increased costs, and extended lead times.

Thickness

The thickness of the metal sheet directly impacts the part’s strength, weight, and application suitability. Most manufacturers offer a range of thicknesses (e.g., 0.024” to 0.250”). Understanding the required thickness for a specific application helps buyers select the right materials that will not only meet structural needs but also optimize production costs.

Surface Finish

Surface finish refers to the texture and quality of a part’s exterior, which can be critical for aesthetic and functional reasons. Common finishes include anodizing, powder coating, and plating. In a B2B context, the choice of surface finish can affect corrosion resistance, wear properties, and overall appearance, influencing customer satisfaction and product lifecycle.

Yield Strength

Yield strength is the amount of stress a material can withstand before deforming permanently. This property is crucial for applications where parts will endure significant loads. Buyers need to ensure that the yield strength of the selected material aligns with the operational demands of the finished product, preventing premature failure.

What Are Common Trade Terms Used in Custom Metal Forming?

Familiarity with industry jargon can significantly enhance communication and negotiations in custom metal forming. Here are some common terms:

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of custom metal forming, understanding OEM relationships can help buyers identify reliable suppliers who can meet specific design and quality requirements.

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to produce or sell. This term is critical for B2B buyers as it impacts inventory management and cost-effectiveness. Understanding the MOQ can help buyers negotiate better terms and plan production runs more efficiently.

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to obtain price quotes for specific products or services. For B2B buyers, issuing an RFQ can lead to competitive pricing and better understanding of supplier capabilities, ultimately facilitating more informed purchasing decisions.

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is essential for B2B buyers to navigate shipping costs, risks, and responsibilities effectively.

Lead Time

Lead time refers to the total time taken from placing an order to the delivery of the finished product. Understanding lead times is crucial for B2B buyers to manage project timelines and inventory levels, ensuring that production schedules align with market demands.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and product quality in custom metal forming projects.

Navigating Market Dynamics and Sourcing Trends in the custom metal forming Sector

What Are the Current Market Dynamics and Key Trends in Custom Metal Forming?

The custom metal forming sector is witnessing a transformative phase driven by several global factors. Increased demand for precision-engineered components in industries such as automotive, aerospace, and construction is a significant driver of market growth. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, seek to streamline their supply chains, they are increasingly turning to advanced manufacturing technologies. Automation and Industry 4.0 are redefining production processes, enabling faster turnaround times and reduced costs. The rise of digital platforms for instant quoting and ordering, such as those offered by SendCutSend and Xometry, empowers businesses to make informed purchasing decisions and enhances operational efficiency.

Emerging trends include the integration of artificial intelligence (AI) and machine learning (ML) in design and manufacturing processes. These technologies facilitate predictive maintenance, optimize production schedules, and improve quality control, thereby reducing waste and enhancing product reliability. Moreover, the shift towards just-in-time (JIT) manufacturing is prompting companies to adopt more flexible sourcing strategies. As a result, B2B buyers are increasingly looking for suppliers that can accommodate low-volume orders with quick turnaround times, allowing them to adapt to changing market demands without incurring excess inventory costs.

How Does Sustainability and Ethical Sourcing Impact B2B Buyers in Custom Metal Forming?

As environmental concerns gain prominence globally, sustainability and ethical sourcing have become critical considerations for B2B buyers in the custom metal forming sector. The environmental impact of metal fabrication, including energy consumption and waste generation, necessitates a focus on sustainable practices. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint, utilizing eco-friendly materials, and implementing waste-reduction initiatives.

The importance of ethical supply chains cannot be overstated. Buyers are seeking partners who uphold fair labor practices and ensure the responsible sourcing of raw materials. Certifications such as ISO 14001 (Environmental Management) and certifications for recycled materials can serve as indicators of a supplier’s commitment to sustainability. Furthermore, the growing demand for “green” materials, such as recycled aluminum and sustainably sourced steel, is reshaping procurement strategies. By aligning with suppliers that adhere to sustainable practices, B2B buyers not only enhance their brand reputation but also contribute to a more sustainable future.

How Has the Custom Metal Forming Sector Evolved Over Time?

The evolution of the custom metal forming sector has been marked by significant technological advancements and changing market demands. Initially characterized by traditional methods such as forging and stamping, the industry has transitioned towards more sophisticated techniques, including laser cutting, CNC machining, and additive manufacturing. This shift has enabled manufacturers to produce complex geometries with higher precision and efficiency.

The introduction of digital technologies has further revolutionized the landscape, allowing for real-time collaboration between designers and manufacturers. The rise of online platforms for custom metal fabrication has democratized access to high-quality manufacturing services, enabling smaller businesses to compete alongside larger enterprises. As the industry continues to adapt to the challenges posed by globalization and environmental sustainability, the focus on innovation and collaboration remains paramount for B2B buyers looking to thrive in this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of custom metal forming

-

How do I solve quality assurance issues when sourcing custom metal forming?

To address quality assurance (QA) concerns, start by verifying that potential suppliers have relevant certifications such as ISO 9001 or ISO 13485. Request samples or prototypes to evaluate their craftsmanship and material quality. It’s also beneficial to establish clear specifications and tolerances in your contract. Consider conducting factory audits or third-party inspections to ensure adherence to your standards. By maintaining open communication and establishing a robust QA process, you can minimize risks associated with product quality. -

What is the best way to vet suppliers for custom metal forming?

Vetting suppliers involves several key steps: first, research their reputation through online reviews and industry recommendations. Request references from past clients to gauge their reliability and quality. Evaluate their manufacturing capabilities, including machinery and technology used, to ensure they meet your requirements. Additionally, assess their compliance with international standards and regulations, particularly if you’re sourcing from different regions. Finally, consider visiting their facilities to gain firsthand insight into their operations and culture. -

What are typical minimum order quantities (MOQs) for custom metal forming?

Minimum order quantities (MOQs) for custom metal forming can vary significantly based on the supplier and the complexity of the parts. Many suppliers may have MOQs ranging from 50 to 1,000 units, especially for standard components. However, some manufacturers offer flexible options for prototypes or low-volume orders. It’s essential to discuss your specific needs with potential suppliers to find a mutually agreeable MOQ that aligns with your production requirements. -

How can I ensure timely delivery for international shipments of custom metal parts?

To ensure timely delivery, choose suppliers with proven logistics capabilities and experience in international shipping. Confirm their shipping methods and estimated delivery times, factoring in potential customs delays. Utilize tracking systems to monitor your shipment’s progress. Additionally, consider working with freight forwarders who specialize in international trade to navigate logistics complexities. Establishing clear communication with your supplier regarding timelines and delivery expectations is crucial for successful project execution. -

What payment terms should I expect when sourcing custom metal forming?

Payment terms can vary widely among suppliers, but common practices include upfront deposits ranging from 30% to 50% of the total order value, with the balance due upon delivery or before shipping. Some suppliers may offer credit terms for established relationships. It’s essential to clarify payment methods accepted, such as wire transfers, letters of credit, or PayPal, and ensure that all terms are documented in your contract to avoid misunderstandings. -

What materials are commonly used in custom metal forming, and how do they impact pricing?

Common materials for custom metal forming include aluminum, stainless steel, carbon steel, and brass. The choice of material significantly influences pricing due to factors such as availability, machining complexity, and mechanical properties. For example, aluminum is generally more expensive than carbon steel but offers excellent corrosion resistance and lightweight characteristics. Discuss material options with your supplier, and consider the long-term benefits versus initial costs to make informed decisions. -

How do I handle customization requests for specific designs in metal forming?

When requesting customization, provide detailed specifications, including CAD files or sketches, and outline any specific requirements such as dimensions, tolerances, and finishes. Collaborate closely with your supplier during the design phase to address any potential manufacturing challenges. Many suppliers offer design assistance and can suggest optimizations to improve manufacturability. Establish a feedback loop to refine designs and ensure that the final product meets your expectations. -

What are the common applications for custom metal forming in various industries?

Custom metal forming is utilized across multiple industries, including automotive, aerospace, electronics, and construction. Common applications include chassis, brackets, enclosures, and custom tooling. Each industry may have specific requirements regarding material properties, tolerances, and certifications. Understanding the end-use of your components can guide material selection and design considerations, ensuring that the parts perform optimally in their intended applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Custom Metal Forming Manufacturers & Suppliers List

1. SendCutSend – Custom Sheet Metal Fabrication

Domain: sendcutsend.com

Registered: 2015 (10 years)

Introduction: SendCutSend offers custom sheet metal fabrication services including laser cutting, CNC routing, waterjet cutting, anodizing, bending & forming, countersinking, dimple forming, hardware insertion, plating, powder coating, tapping, tumbling, and deburring. They provide instant pricing for custom sheet metal parts, with a turnaround time of as little as 2-4 days for standard orders. Customers can up…

2. Cramers Inc – Custom Sheet Metal Fabrication

Domain: cramersinc.com

Registered: 2004 (21 years)

Introduction: Custom Sheet Metal Fabrication and Forming services including:

– Custom Fabrication: Tailored metal fabrication services to any specifications.

– Roll Forming: Production of cylinders, tanks, and specially shaped custom metal parts.

– Laser Cutting: State-of-the-art laser cutting of various metals such as stainless steel, aluminum, brass, and copper.

– Brake Forming: Accurate forming and bending m…

3. Tendon Manufacturing – Precision Metal Fabrication

Domain: tendon.com

Registered: 1996 (29 years)

Introduction: Tendon Manufacturing specializes in precision metal fabrication and manufacturing in the USA, based in Cleveland, Ohio since 1988. Key services include: 1. Metal Fabrication: Custom solutions tailored to specifications. 2. Laser Cutting: State-of-the-art technology for intricate and precise parts. 3. CNC Machining: Advanced capabilities for accurate and complex components. 4. Welding: TIG and MIG …

4. Southern Metal Fab – Custom Metal Forming Solutions

Domain: southernmetalfab.com

Registered: 2001 (24 years)

Introduction: Custom Metal Forming capabilities include: 1. Metal Forming Equipment: Mechanical and CNC Hydraulic Press Brakes (4 machines, capacities to 12′ x 400 tons), Plate Rolling (3 machines, capacities to 1/2″ x 10′ ), Angle Rolling (2 machines, capacities to 15″ x 5″ x 5/8″), Beam Punches (50-ton hydraulic), CNC Punching (30-ton Strippit Punch Press), Ironworkers (3 multi-function machines, capacities t…

5. PIMCO – Custom Sheet Metal Fabrication

Domain: pimco-piper.com

Registered: 2023 (2 years)

Introduction: Custom Sheet Metal Fabrication & Forming services at PIMCO include precision-crafted metal components tailored to exact specifications. Key features include: 85+ years of experience, turn-key in-house solutions, precision sheet metal fabrication with tight tolerances, comprehensive forming capabilities (cutting, bending, welding, shaping), small to large-scale production for prototyping and full-s…

6. Ponoko – Custom Sheet Metal Fabrication

Domain: ponoko.com

Registered: 2006 (19 years)

Introduction: Custom online sheet metal fabrication service for startups & enterprises. Key features include:

– Prototyping & production capabilities

– Fiber laser cutting, bending & tapping

– Use of 250+ metals

– Custom parts delivered in hours, not weeks (money-back guarantee)

– No minimum order quantity

– $0 setup fee

– Free shipping

– Dimensional accuracy of ±0.003in / 0.08mm

– Made in USA

– Same-…

7. Custom Metal Forming – Metal Shaping Solutions

Domain: custommetalforming.info

Registered: 2017 (8 years)

Introduction: Custom Metal Forming specializes in various metal shaping processes including brake forming, compression bending, roll forming, and stretch wrap forming. The company operates a complete sheet metal and welding facility and is ISO 9001:2008 and AS9100 certified, ensuring high-quality services. They emphasize outstanding customer service and competitive pricing.

8. Toledo Metal Spinning – Custom Metal Fabrication Services

Domain: toledometalspinning.com

Registered: 1997 (28 years)

Introduction: Custom Metal Fabrication services including Deep Drawing, Metal Spinning, Rolled & Welded Cylinder Fabrication, Precision Machining, Laser Cutting, and Welding. Deep Drawing capabilities with presses up to 400 metric tons and bed size of 48″ x 48″. Metal Spinning processes include CNC and manual methods, producing parts that mirror the tool used. Rolled and Welded Cylinder Fabrication using materi…

Strategic Sourcing Conclusion and Outlook for custom metal forming

In conclusion, effective strategic sourcing in custom metal forming is paramount for international B2B buyers looking to enhance their supply chain efficiency and product quality. Key takeaways include the importance of leveraging advanced manufacturing technologies such as laser cutting and waterjet services, which can significantly reduce lead times and costs. Additionally, understanding the diverse range of materials and finishes available can help businesses tailor solutions to their specific needs while maintaining competitive pricing.

As buyers from regions like Africa, South America, the Middle East, and Europe navigate the complexities of sourcing, prioritizing suppliers with robust capabilities, certifications, and proven track records will be essential. The flexibility of sourcing options—from low-volume prototypes to large-scale production—offers businesses the adaptability needed to respond to market demands swiftly.

Looking ahead, the evolving landscape of custom metal forming presents exciting opportunities for growth and innovation. We encourage you to explore partnerships with leading manufacturers to harness these advancements, ensuring your business remains at the forefront of the industry. Embrace strategic sourcing today to secure a competitive edge for tomorrow.