Contents

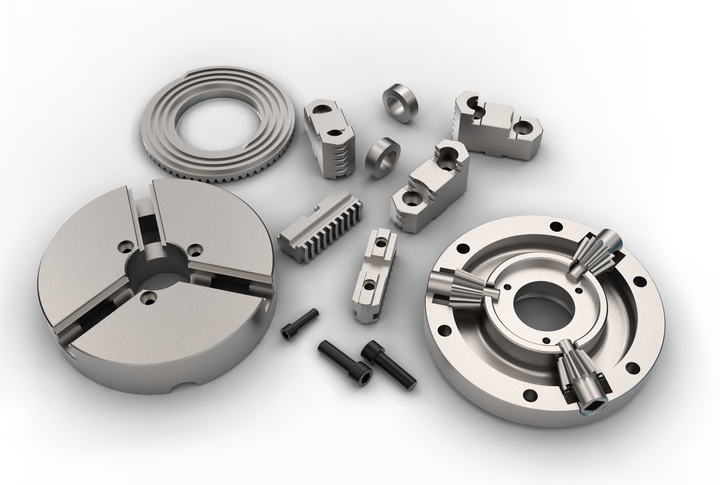

Manufacturing Insight: Custom Metal Cnc

Precision Sheet Metal Fabrication for Demanding Applications

At Honyo Prototype, we engineer custom metal solutions where dimensional accuracy, material integrity, and rapid turnaround are non-negotiable. Our Sheet Metal Fabrication services transform complex designs into high-integrity components using advanced CNC punching, laser cutting, bending, and welding processes. We specialize in low-to-mid volume production runs for aerospace, medical, and industrial automation sectors, working with materials including 5052-H32 aluminum, 304/316 stainless steel, and cold-rolled steel to meet stringent AS9100 and ISO 13485 standards.

Integrating CNC Precision with Sheet Metal Expertise

While CNC machining handles solid block components, our sheet metal workflow leverages CNC-controlled systems to ensure sub-0.005″ tolerance consistency across nested parts, complex bends, and multi-stage assemblies. This integrated approach eliminates process handoffs, reducing geometric deviations and accelerating path-to-assembly for enclosures, brackets, and structural frames. Every stage—from flat pattern development through post-fabrication finishing—undergoes in-process metrology using Zeiss CMMs and optical comparators.

Accelerate Your Timeline with Verified Quoting

Eliminate procurement delays with Honyo’s Online Instant Quote platform. Upload native STEP or DXF files to receive a comprehensive, engineer-validated cost analysis within 2 hours—not days. Our algorithm assesses manufacturability in real-time, flagging potential DFM issues like bend interference or minimum flange requirements before quoting. This transparent process delivers accurate pricing for laser cutting, forming, hardware insertion, and finishing, with lead times starting at 5 business days for prototyping.

Why Engineering Teams Choose Honyo

We bridge the gap between design intent and production reality through co-engineering support. Our quoting system provides actionable feedback on material selection, secondary operation sequencing, and cost drivers—enabling informed decisions before metal is cut. For time-sensitive projects requiring certified documentation or first-article inspection reports, our dedicated NPI team ensures compliance without compromising speed. Request your instant quote today to experience precision fabrication engineered for your specifications.

Technical Capabilities

Custom metal CNC fabrication at Honyo Prototype integrates precision laser cutting, CNC bending, and automated welding to deliver high-tolerance components for industrial and commercial applications. The process supports a range of materials including aluminum, steel, and select engineering plastics such as ABS and nylon, although non-metallic materials are processed using compatible methods outside of traditional metal-focused CNC systems.

Below is a detailed technical specification table outlining capabilities for each process:

| Process | Material Compatibility | Thickness Range | Tolerance | Surface Finish | Equipment Type | Notes |

|---|---|---|---|---|---|---|

| Laser Cutting | Aluminum, Steel, ABS, Nylon | 0.5 mm – 25 mm | ±0.1 mm | Smooth, deburred edge | Fiber Laser (up to 4 kW) | ABS and nylon processed with CO₂ laser; not for structural metal applications |

| CNC Bending | Aluminum, Steel | 0.8 mm – 12 mm | ±0.2° angular | As-rolled or coated | CNC Press Brake (up to 100 tons) | Tooling optimized for sharp bends and minimal springback |

| MIG/TIG Welding | Aluminum, Steel | 1.0 mm – 20 mm | ±0.5 mm fit-up | Machinable, grindable | Automated MIG, TIG stations | Full penetration welds; certified welders per ISO 3834 |

| General | Aluminum (6061, 5052, 7075), Steel (Mild, Stainless 304/316), ABS (industrial grade), Nylon (PA6, PA66) | — | — | — | Multi-stage fabrication cells | Plastics handled in segregated work zones to prevent contamination |

All metal components undergo post-process inspection using CMM and optical comparators. Secondary operations such as tapping, countersinking, and surface treatments (anodizing, powder coating, passivation) are available upon request. Design for manufacturability (DFM) reviews are standard to optimize lead time and cost.

From CAD to Part: The Process

Honyo Prototype Custom Metal CNC Process Overview

Our end-to-end custom metal CNC manufacturing process is engineered for precision, efficiency, and transparency, specifically designed to meet the demanding requirements of industrial and medical clients. Below is a detailed breakdown of each phase.

CAD Upload Portal

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native formats like SolidWorks) through our secure online portal. The system validates file integrity and geometry completeness, ensuring manufacturability from the outset. Supported materials include aluminum alloys (6061-T6, 7075), stainless steels (303, 304, 316), titanium (Grade 5), and brass. File validation checks for unit consistency, watertight geometry, and tolerance specifications to prevent downstream delays.

AI-Powered Quoting Engine

Upon upload, our proprietary AI engine analyzes the CAD model to generate an instant preliminary quote within 2 hours. The algorithm factors in material density, machine time estimates based on feature complexity, toolpath simulation data, and current shop floor capacity. Critical parameters such as part volume, surface finish requirements (e.g., Ra 0.8 µm vs. Ra 3.2 µm), and secondary operations (tapping, deburring) are auto-detected. A Honyo applications engineer reviews the AI output to validate feasibility and adjust for nuanced requirements like thin-wall features or tight positional tolerances (<±0.05mm).

Engineering DFM Review

Every project undergoes a formal Design for Manufacturability review by our senior CNC engineering team. We provide actionable feedback within 24 business hours, highlighting opportunities to optimize cost and lead time without compromising function. Typical recommendations include adjusting fillet radii to match standard tooling, modifying deep cavity geometries to reduce tool deflection, or suggesting alternative stock sizes to minimize raw material waste. Clients receive a marked-up PDF report with annotated suggestions and estimated cost/time impacts per modification. This phase requires client approval before proceeding to production.

Precision Production Execution

Approved designs move to our climate-controlled manufacturing floor equipped with Haas, DMG MORI, and Makino 3- to 5-axis CNC mills and lathes. Key production protocols include:

Material certification verification with traceable heat numbers

In-process CMM inspections at critical stages (e.g., after roughing, before finishing)

Real-time tool wear monitoring via spindle load sensors

First-article inspection reports compliant with AS9102 or ISO 13084 standards

All metal parts undergo final cleaning in ultrasonic degreasers and pass/fail validation against the original CAD model using Faro or Zeiss CMM systems.

Quality-Controlled Delivery

Completed orders are packaged in anti-corrosion VCI paper with custom foam cradling for fragile geometries. Each shipment includes:

Dimensional inspection report with GD&T analysis

Material test certificate (MTR)

Traceability documentation (lot numbers, machine IDs, operator logs)

Compliance documentation for ITAR, ISO 13485, or NADCAP as required

Standard lead time is 7–12 business days for quantities under 50 pieces, with expedited 72-hour options for critical-path components. Real-time shipment tracking is available via our client portal from dispatch through delivery.

This integrated workflow reduces time-to-part by 30% compared to industry averages while maintaining first-pass yield rates above 98.5% for complex metal components. We prioritize proactive communication at each transition point to ensure alignment with your project timeline and quality expectations.

Start Your Project

Looking for precision custom metal CNC services? Partner with Honyo Prototype for high-quality, on-demand manufacturing solutions. Our state-of-the-art facility in Shenzhen delivers tight-tolerance parts with fast turnaround times.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Factory location: Shenzhen, China

Let us provide you with reliable, scalable CNC machining tailored to your specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.