Contents

Manufacturing Insight: Custom Made Aluminum Parts

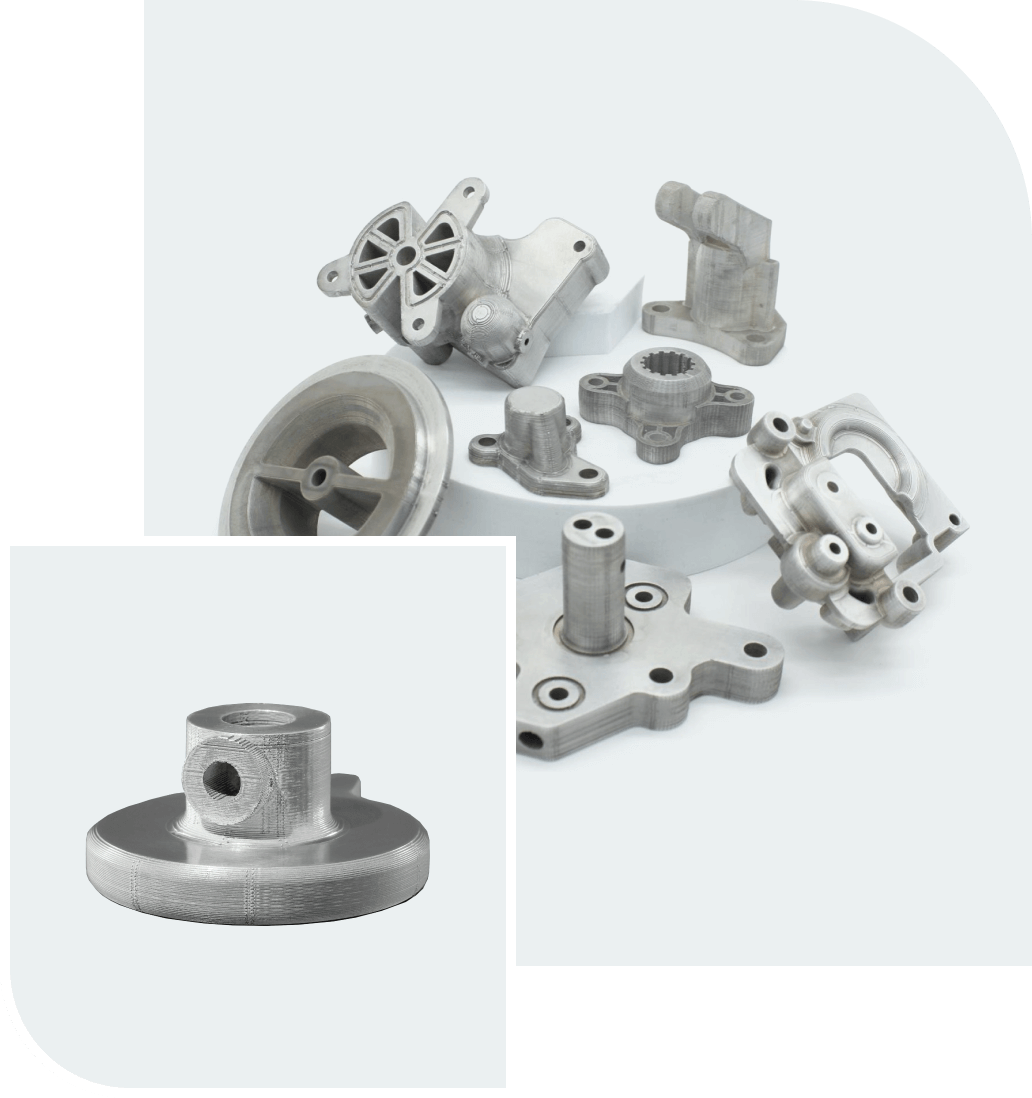

Precision Aluminum Components Engineered for Your Application

As a Senior Manufacturing Engineer at Honyo Prototype, I understand the critical role aluminum plays in high-performance industries like aerospace, medical devices, and automotive systems. Our CNC machining services transform raw aluminum stock into mission-critical components with uncompromising precision, leveraging advanced 5-axis milling, turning, and multi-tasking capabilities. We specialize in complex geometries, tight tolerances down to ±0.0002 inches, and stringent surface finish requirements—ensuring your parts meet exact functional and regulatory demands.

Honyo’s expertise spans key aluminum alloys, each selected for optimal strength-to-weight ratio, corrosion resistance, and machinability. Below is a snapshot of our most frequently processed materials and their typical applications:

| Aluminum Alloy | Common Applications | Typical Tolerances Achieved |

|---|---|---|

| 6061-T6 | Structural brackets, enclosures | ±0.0005 in (12.7 µm) |

| 7075-T6 | Aerospace fittings, defense components | ±0.0002 in (5 µm) |

| 2024-T3 | Aircraft structures, high-stress parts | ±0.0003 in (7.6 µm) |

| 5052-H32 | Marine hardware, fuel systems | ±0.001 in (25.4 µm) |

Our end-to-end process integrates CAD/CAM validation, in-process CMM verification, and first-article inspection to eliminate rework and accelerate time-to-assembly. Unlike generic machine shops, Honyo engineers collaborate during the design phase to optimize manufacturability—reducing material waste and costly iterations. This proactive approach ensures your aluminum components perform reliably under real-world thermal, vibrational, and load conditions.

Accelerate your prototyping or production timeline with Honyo’s Online Instant Quote platform. Upload your STEP or IGES file, specify material, quantity, and critical tolerances, and receive a detailed quote within hours—not days. This streamlined digital workflow eliminates procurement delays, giving engineering teams immediate cost visibility for budget planning and rapid design validation. For urgent projects, our dedicated manufacturing cells support expedited lead times without sacrificing quality.

Ready to transform your aluminum component vision into reality? Visit Honyo Prototype’s Online Instant Quote portal today to start your project with precision engineering expertise at your fingertips.

Technical Capabilities

Custom made aluminum parts produced via 3, 4, and 5-axis CNC milling and turning are engineered for high precision, complex geometries, and tight tolerance requirements across aerospace, medical, automotive, and industrial applications. These processes allow for superior surface finish, repeatability, and dimensional accuracy. While aluminum is the primary material due to its favorable strength-to-weight ratio and machinability, other materials such as steel, ABS, and nylon are also commonly processed to meet specific functional or environmental demands.

| Feature | Specification Details |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including multi-axis turning centers) |

| Tolerance Capability | ±0.005 mm (±0.0002″) typical; tight tolerances down to ±0.0025 mm (±0.0001″) achievable with process control |

| Surface Finish | As-machined: 1.6–3.2 μm (63–125 μin); post-processed finishes available (e.g., anodizing, bead blasting) |

| Materials Supported | Aluminum (6061-T6, 7075-T6, 2024-T3, etc.), Steel (1018, 4140, 17-4 PH), ABS (thermoplastic), Nylon (PA6, PA66) |

| Aluminum Characteristics | Lightweight, excellent machinability, good corrosion resistance; ideal for high-speed milling and tight tolerance components |

| Steel Characteristics | High strength and durability; used for wear-resistant or high-load applications; slower machining rates than aluminum |

| ABS Characteristics | Low cost, impact-resistant thermoplastic; easy to machine; suitable for prototypes and non-structural parts |

| Nylon Characteristics | High toughness, low friction, chemical resistance; requires controlled machining to prevent deformation |

| Max Part Size (Milling) | Up to 1200 x 600 x 500 mm (47 x 24 x 20 in), depending on machine envelope |

| Max Part Size (Turning) | Up to Ø300 mm diameter x 500 mm length, based on lathe capacity |

| Positioning Accuracy | ±0.005 mm (±0.0002″) on linear axes; angular accuracy ±0.005° on rotary axes |

| Repeatability | ±0.003 mm (±0.0001″) across multiple production runs |

| Secondary Operations | Deburring, tapping, heat treating, anodizing (Type II & III), passivation, precision cleaning |

Parts are manufactured under strict quality control using calibrated CMMs, optical comparators, and surface profilometers to ensure compliance with engineering drawings and GD&T specifications. Design for manufacturability (DFM) feedback is provided to optimize cost, lead time, and performance.

From CAD to Part: The Process

Upload CAD

Clients initiate the process by uploading their 3D CAD model (STEP, IGES, or native formats) via Honyo’s secure online portal. Our system performs an initial validation check for file integrity, unit consistency, and geometric completeness. This step ensures the design meets baseline requirements for downstream processing, eliminating common submission errors before formal quoting begins.

AI Quote Generation

Honyo’s proprietary AI engine analyzes the validated CAD geometry, material specifications (e.g., 6061-T6, 7075-T6), and requested quantities to generate a real-time preliminary quote. The AI cross-references historical production data, current machine utilization rates, and material market pricing to calculate accurate cost and lead time estimates. Critical parameters such as part volume, feature complexity, and surface finish requirements are automatically assessed, providing clients with transparent pricing within minutes of upload.

DFM Analysis and Collaboration

Following quote acceptance, our engineering team conducts a rigorous Design for Manufacturability (DFM) review. This phase identifies potential manufacturability risks including thin walls, deep cavities, excessive tolerancing, or non-optimal tool access. We provide a detailed DFM report with actionable recommendations—such as adjusting draft angles or simplifying undercuts—to enhance producibility without compromising functional intent. Client engineers collaborate with our team via secure review sessions to finalize the design, ensuring alignment on cost, quality, and timeline objectives.

Production Execution

Approved designs move to our CNC machining cells equipped with state-of-the-art 3-, 4-, and 5-axis milling centers. Aluminum parts undergo precision machining using optimized toolpaths and high-performance cutting tools tailored to the specific alloy. In-process inspections verify critical dimensions at defined checkpoints, while secondary operations—including deburring, anodizing (Type II or III), bead blasting, or precision tapping—are executed per specifications. All processes adhere to ISO 9001:2015 standards with full material traceability from certified suppliers.

Delivery and Documentation

Completed parts undergo final QA inspection using calibrated CMMs and optical comparators against the original CAD model. Each shipment includes a comprehensive inspection report, material certification, and process validation records. Parts are packaged using anti-corrosion methods suitable for aluminum, with global logistics partners ensuring on-time delivery. Real-time shipment tracking and post-delivery support complete the workflow, maintaining a closed-loop feedback system for continuous improvement.

Typical Aluminum Part Specifications

| Parameter | Standard Capability | Tight Tolerance Option |

|——————–|—————————|————————|

| Dimensional Tolerance | ±0.1 mm | ±0.025 mm |

| Surface Roughness | Ra 3.2 μm | Ra 0.8 μm (machined) |

| Max Part Size | 1000 x 600 x 500 mm | Custom fixture options |

| Lead Time (Prototype) | 5-7 business days | Expedited 72-hour path |

Start Your Project

Looking for custom made aluminum parts tailored to your exact specifications? Honyo Prototype delivers precision CNC-machined aluminum components with fast turnaround times. Our manufacturing facility in Shenzhen ensures high-quality production at competitive prices.

Contact Susan Leo today to discuss your project requirements. Email us at [email protected] for a quick quote and technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.