Contents

Manufacturing Insight: Custom Machining Cost

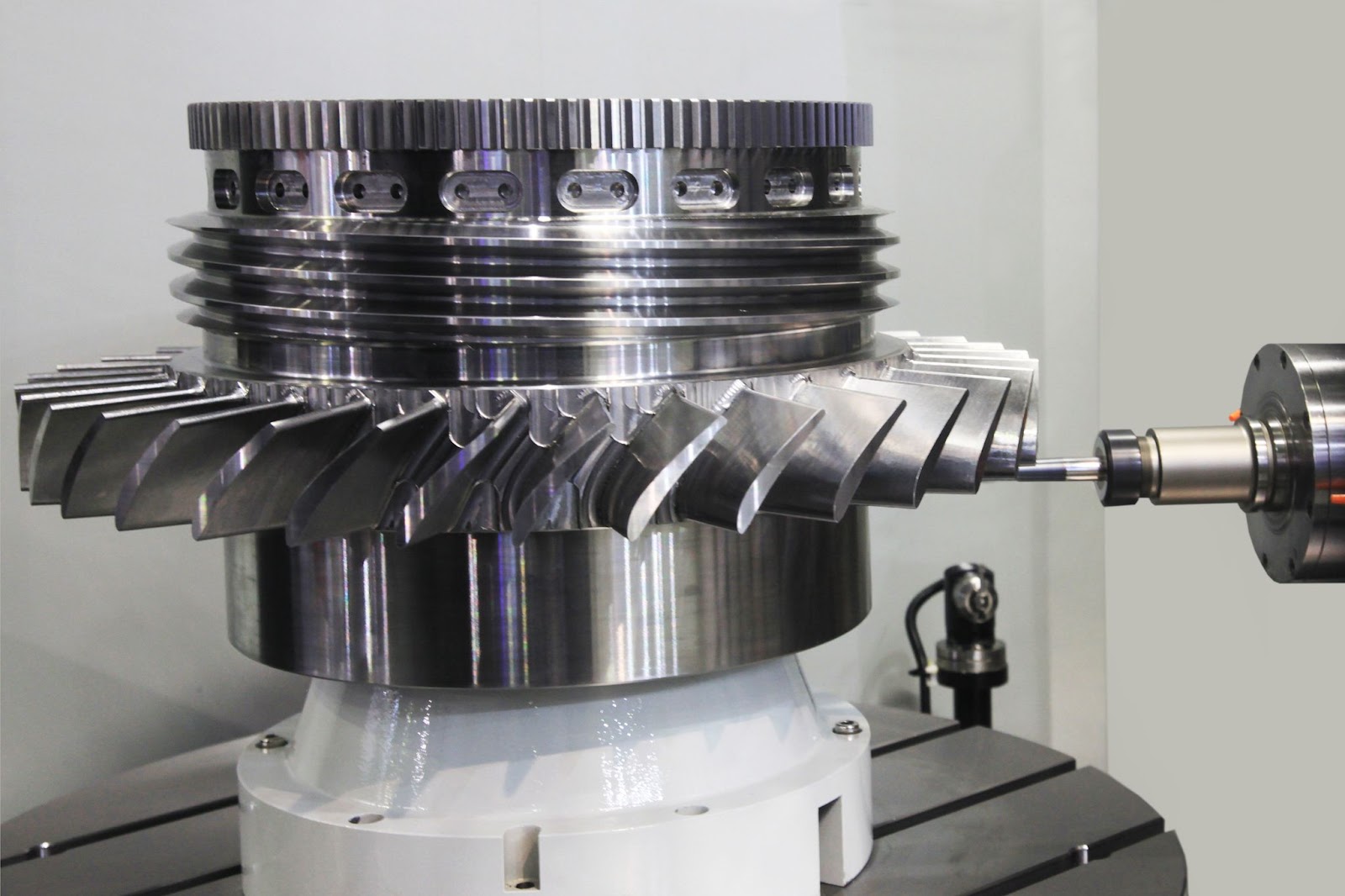

Understanding custom machining costs is a critical strategic factor in bringing precision-engineered components from concept to reality. For engineering teams and procurement professionals, navigating the variables that influence pricing—material selection, geometric complexity, tolerances, volume, and secondary operations—is essential for accurate budgeting and project viability. At Honyo Prototype, we recognize that cost transparency and predictability are non-negotiables in today’s competitive manufacturing landscape. Our advanced CNC Machining services, encompassing 3-, 4-, and 5-axis milling alongside precision turning, are engineered specifically for complex prototypes and low-to-medium volume production runs. We leverage state-of-the-art equipment, rigorous quality control protocols, and deep expertise in challenging materials like titanium, inconel, and high-performance polymers to deliver parts that meet exacting specifications without hidden cost surprises.

Honyo Prototype eliminates the traditional barriers of lengthy quotation cycles and estimation uncertainty. Our core differentiator is the industry-leading Online Instant Quote System, providing accurate, detailed cost breakdowns in seconds, not days. This platform, built on real-time machine utilization data and refined material cost algorithms, allows you to instantly evaluate the cost impact of design modifications, material choices, and volume adjustments during the critical early stages of development. There is no submission waiting period and no requirement for manual intervention for standard geometries; the system processes your STEP or IGES file immediately, delivering a comprehensive quote reflecting true manufacturing effort.

This immediate cost visibility empowers your engineering and sourcing teams to make informed design-for-manufacturability decisions faster, accelerating time-to-prototype while maintaining strict budgetary control. By integrating precise cost intelligence directly into your design workflow through our Online Instant Quote System, Honyo Prototype transforms custom machining from a potential cost risk into a predictable, strategic advantage for your next project.

Technical Capabilities

Custom machining cost is influenced by several technical and operational factors, particularly when working with 3-axis, 4-axis, and 5-axis milling, as well as precision turning operations. Key cost drivers include machine type, setup time, complexity, tolerance requirements, material type, and secondary operations. Below is a breakdown of technical specifications affecting cost across these parameters.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance (±0.001″ or ±0.025 mm) Impact |

|---|---|---|---|---|---|

| Typical Applications | Prismatic parts, flat surfaces | Indexing features, multiple sides | Complex contours, aerospace parts | Cylindrical components, shafts | Critical for medical, aerospace, and tooling |

| Setup Time | Low (standard fixtures) | Moderate (rotary indexing) | High (complex fixturing & alignment) | Low to moderate | Increases setup time due to precision alignment |

| Machining Time | Low to medium | Medium | High (simultaneous multi-axis) | Low (high RPM capability) | Increases time due to reduced feed/speed |

| Tooling Complexity | Standard end mills, drills | Additional rotary axis tooling | High-end tooling, collision avoidance | Turning inserts, parting tools | May require specialized, wear-resistant tooling |

| Material Compatibility | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Harder materials (e.g., steel) amplify cost |

| Aluminum (e.g., 6061-T6) | Low cost, fast machining, low tool wear | Slightly higher cost due to indexing | Higher cost due to machine rate and programming | Very cost-effective, high throughput | Tolerance adds ~15–25% to base cost |

| Steel (e.g., 4140, 1018) | Moderate cost, slower speeds, higher tool wear | 20–30% cost increase over aluminum | 35–50% cost increase over aluminum | Moderate to high cost, slower cuts | Tolerance adds ~25–40% due to thermal and tool deflection control |

| ABS (Thermoplastic) | Low material cost, fast cutting, risk of melting | Moderate fixturing care needed | Rarely required; overkill for plastics | Common for prototypes, low heat | Challenging due to thermal expansion; adds ~20% |

| Nylon (e.g., 6/6) | Requires sharp tools, low heat | Moderate fixturing needed | Rarely justified | Common, needs clearance and feed control | Swelling and creep require environmental control; +25–35% |

| Tolerance Impact | Standard: ±0.005″ | Standard: ±0.005″ | Standard: ±0.005″ | Standard: ±0.005″ | Each halving of tolerance adds ~20–35% in time and inspection |

| Inspection Requirements | Visual, calipers | CMM for angular features | Full CMM or laser scanning | Micrometers, optical comparators | Mandatory CMM reporting, multiple checkpoints |

| Programming Complexity | Low (2.5D CAM) | Moderate (3+1 axis CAM) | High (simultaneous 5-axis CAM) | Simple G-code or canned cycles | Requires simulation, toolpath optimization |

Notes on Cost Drivers

Tight tolerances significantly increase cost across all processes due to slower machining parameters, increased inspection, and higher scrap risk. Material selection directly impacts tool life and cycle time—aluminum is fastest and most economical, while steel increases both time and tooling cost. Plastics like ABS and nylon require careful thermal management but are generally lower cost unless tight tolerances are specified. 5-axis milling is typically reserved for complex geometries where setup reduction justifies the higher hourly rate. Turning remains the most efficient method for axially symmetric parts, especially in aluminum and steel.

From CAD to Part: The Process

Honyo Prototype Custom Machining Cost Process Overview

Honyo Prototype employs a structured, technology-driven workflow to deliver transparent and accurate custom machining cost estimates while ensuring manufacturability and quality. This process minimizes client risk and accelerates time-to-market through integrated digital and engineering validation steps.

CAD File Submission and Validation

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid, SolidWorks) via our secure portal. Our system performs immediate file validation, checking geometric integrity, unit consistency, and metadata completeness. Incomplete submissions trigger automated requests for missing details such as material specifications, critical tolerances, or surface finish requirements. This step ensures all technical prerequisites for accurate quoting are met before cost analysis begins.

AI-Powered Preliminary Quotation

Validated CAD files enter our proprietary AI quotation engine, which analyzes over 200 geometric and process parameters. The algorithm cross-references real-time data on material costs, machine availability, tooling requirements, and historical production metrics to generate a preliminary cost estimate within 2 business hours. This stage provides clients with a rapid, data-backed cost range and lead time projection, highlighting potential cost drivers such as complex features or low-volume surcharges. Human engineers oversee all AI outputs to prevent algorithmic misinterpretation of ambiguous design elements.

Engineering-Led DFM Analysis

Following quotation, our manufacturing engineering team conducts a formal Design for Manufacturability (DFM) review. This collaborative phase identifies opportunities to optimize the design for cost, lead time, and yield without compromising functionality. Key focus areas include:

| DFM Focus Area | Typical Impact on Cost |

|---|---|

| Feature complexity | 15-30% reduction via simplification |

| Tolerance stack-ups | 10-25% savings through strategic relaxation |

| Material utilization | 20-40% waste reduction via nesting optimization |

| Secondary operations | Elimination or consolidation opportunities |

Clients receive a detailed DFM report with annotated CAD markups and specific revision recommendations. Revised designs may re-enter the AI quotation loop for updated cost validation.

Production Execution

Approved designs move to production in our climate-controlled facility. We deploy tiered resource allocation:

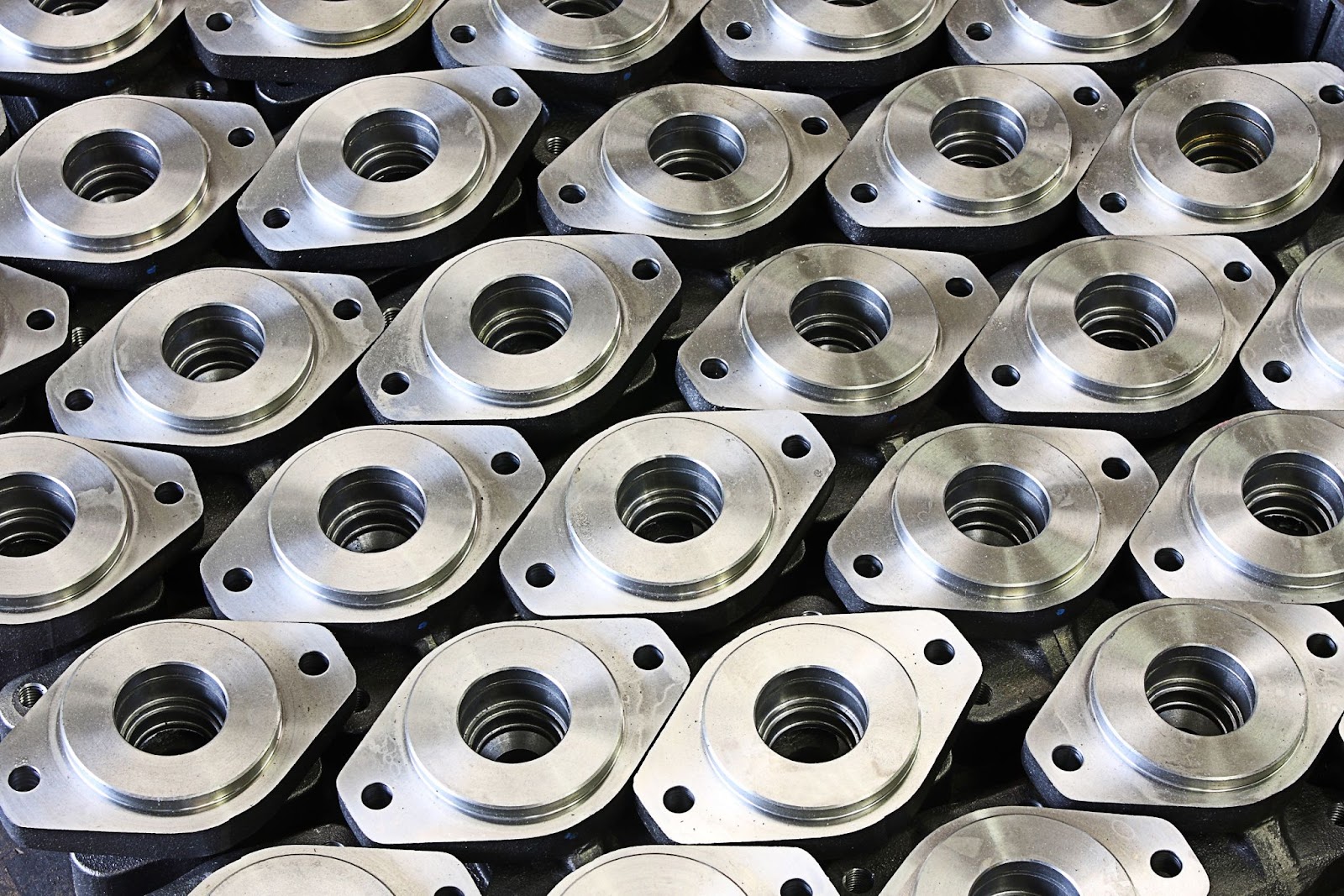

High-mix/low-volume jobs utilize flexible CNC cells with modular fixturing

Repeat production leverages dedicated cells with custom tooling

Critical aerospace/medical components follow AS9100/ISO 13485 workflows

Real-time machine monitoring tracks progress against the quoted timeline, with automated alerts for any deviations. All first-article inspections use calibrated CMM equipment against the original CAD model.

Logistics and Delivery Assurance

Completed parts undergo final QA verification before entering our integrated logistics system. Clients receive:

Digital packing lists with traceable lot numbers

Real-time shipment tracking via major carriers (DHL, FedEx, UPS)

Automated delivery confirmation with customs documentation for international shipments

Our delivery commitment includes a 99.2% on-time rate for standard projects, with expedited options available for urgent requirements. All cost-influencing factors identified during the AI quotation and DFM stages are reconciled in the final invoice, ensuring no unexpected charges.

Cost Transparency Foundation

The entire process is engineered to eliminate traditional quoting ambiguities. By anchoring costs in validated CAD data and exposing manufacturability factors early, clients gain visibility into the actual drivers of their project economics. This approach typically reduces cost surprises by 70-85% compared to conventional quotation methods in the prototype machining industry.

Start Your Project

Get an accurate quote for your custom machining project today. Contact Susan Leo at [email protected] to discuss your requirements and receive a competitive cost estimate. Our manufacturing facility is located in Shenzhen, ensuring fast turnaround and high-quality precision machining for your prototypes and production parts.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.