Contents

Manufacturing Insight: Custom Machined Plastic Parts

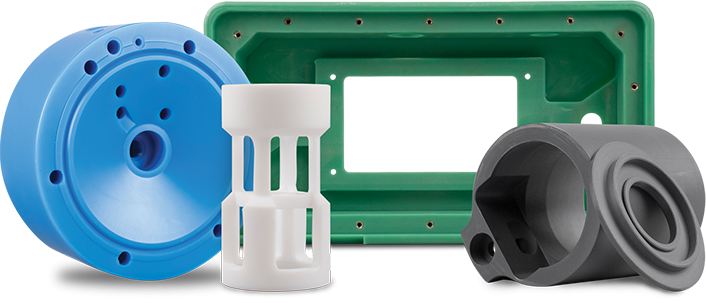

Precision Plastic CNC Machining for Demanding Applications

Honyo Prototype delivers mission-critical custom machined plastic parts through advanced CNC machining processes engineered for uncompromising accuracy and material integrity. Our facility specializes in transforming high-performance engineering thermoplastics—including PEEK, Ultem, Delrin, PTFE, and polycarbonate—into complex components meeting stringent aerospace, medical, and industrial requirements. Utilizing state-of-the-art 3-, 4-, and 5-axis CNC milling and turning centers, we consistently achieve tolerances down to ±0.0002″ while maintaining strict ISO 9001:2015 protocols for traceability and quality control.

Material and Process Expertise Driving Reliability

We address the unique challenges of plastic machining through optimized toolpath strategies, temperature-controlled environments, and proprietary fixturing that prevents deformation in low-modulus materials. Our engineering team collaborates closely with clients to select optimal resins and machining parameters, ensuring critical properties like chemical resistance, wear performance, and dimensional stability are preserved. Secondary operations—including precision threading, custom surface finishes, and cleanroom assembly—are integrated seamlessly to deliver fully validated components ready for deployment.

Accelerate Procurement with Real-Time Quoting

Eliminate traditional quoting delays with Honyo’s Online Instant Quote system. Upload your STEP or IGES file to receive a detailed manufacturability analysis and competitive pricing within minutes—not days. This digital workflow provides transparent cost drivers, lead time projections, and material recommendations, enabling rapid iteration during the design phase. For urgent prototyping or low-volume production runs, our streamlined process reduces time-to-part by up to 70% compared to conventional supplier engagement models.

Partner with Honyo Prototype to transform complex plastic part specifications into production-ready solutions with engineering rigor and supply chain agility. Initiate your project today through our instant quoting platform to experience precision manufacturing without procurement friction.

Technical Capabilities

Custom machined plastic parts are precision components manufactured using advanced CNC machining techniques such as 3-axis, 4-axis, and 5-axis milling, as well as CNC turning. These processes enable complex geometries, high repeatability, and tight tolerances down to ±0.0002″ (±0.005 mm), depending on material and design. While metals like aluminum and steel are commonly machined, engineering-grade plastics such as ABS and nylon are frequently used for applications requiring chemical resistance, electrical insulation, low weight, and wear resistance.

The choice of material influences machinability, dimensional stability, and final part performance. Aluminum and steel are selected for structural strength and thermal conductivity, while ABS offers ease of machining and impact resistance, and nylon provides excellent mechanical properties and low friction.

Below is a summary of technical specifications for custom machined plastic parts with comparative material properties relevant to CNC machining:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Typical Tolerance (Machined) |

|---|---|---|---|---|---|

| Motion Axes | X, Y, Z | X, Y, Z + Rotary (A) | X, Y, Z + Two Rotary (A/B or C) | X, Z (+ C-axis for milling) | ±0.0005″ (±0.013 mm) to ±0.0002″ (±0.005 mm) |

| Surface Finish (Typical) | 32–64 μin (Ra) | 32–64 μin (Ra) | 16–32 μin (Ra) | 16–63 μin (Ra) | Varies by material and toolpath |

| Max Part Size (Typical) | 24″ x 36″ x 20″ | 20″ x 20″ x 16″ | 18″ x 16″ x 12″ | Ø24″ x 48″ length | Dependent on machine envelope |

| Lead Time (Standard) | 5–10 days | 7–12 days | 10–15 days | 5–10 days | Excludes setup and programming |

| Material | Machinability | Typical Applications | Max Operating Temp (°C) | Tolerance Capability (Plastics) | Notes |

|---|---|---|---|---|---|

| ABS | Excellent | Prototypes, housings, jigs | 80–95°C | ±0.001″ (±0.025 mm) | Low shrinkage, good impact strength, easy to machine |

| Nylon (PA6/PA66) | Good | Gears, bearings, insulators | 120–150°C | ±0.001″ to ±0.002″ (±0.025–0.05 mm) | Hygroscopic – requires drying; excellent wear resistance |

| Aluminum (6061, 7075) | Excellent | Enclosures, structural parts | 120–200°C (melting ~660°C) | ±0.0005″ (±0.013 mm) | High thermal conductivity, lightweight, excellent for tight tolerance |

| Steel (1018, 4140) | Moderate to Good | High-strength components, tooling | 200–400°C (melting ~1370°C) | ±0.0005″ (±0.013 mm) | Higher tool wear; used when strength and rigidity are critical |

Notes:

5-axis milling allows for single-setup machining of complex organic shapes and undercuts, reducing cumulative tolerance stack-up.

Tight tolerance machining requires thermal and vibration control, high-precision tooling, and experienced process validation.

Plastics require specialized cutting strategies (reduced RPM, sharp tools, proper chip removal) to prevent melting or deformation.

Post-machining processes such as stress relieving (for metals) or annealing (for plastics) may be used to maintain dimensional stability.

Honyo Prototype supports full documentation, first article inspection (FAI), and CMM reporting for critical features to ensure compliance with technical specifications.

From CAD to Part: The Process

CAD File Submission

Clients initiate the process by uploading native or neutral CAD formats including STEP AP203/214, IGES, Parasolid, and native SOLIDWORKS files through our secure customer portal. We require complete 3D models with critical dimensions and tolerances explicitly defined per ASME Y14.5 standards. Incomplete submissions trigger an automated notification requesting supplementary documentation to prevent downstream delays.

AI-Powered Quoting Engine

Uploaded geometries undergo real-time analysis via our proprietary AI quoting system trained on 12,000+ historical plastic machining projects. The algorithm evaluates material utilization, machine time estimates, fixture requirements, and secondary operations while referencing live material pricing feeds from certified suppliers. Quotes include granular cost breakdowns for material grade options and are generated within 90 minutes for standard geometries. Complex assemblies may require manual validation by quoting engineers.

Engineering-Led DFM Analysis

All quotes undergo mandatory Design for Manufacturability review by our plastics-specialized engineering team. This phase includes:

Wall thickness validation against material-specific flow characteristics

Tolerance stack-up analysis using Monte Carlo simulation

Identification of non-machinable features requiring design modification

Material suitability assessment based on environmental exposure requirements

Clients receive an interactive DFM report with annotated CAD markups and actionable recommendations. Average resolution time for DFM feedback is 4 business hours.

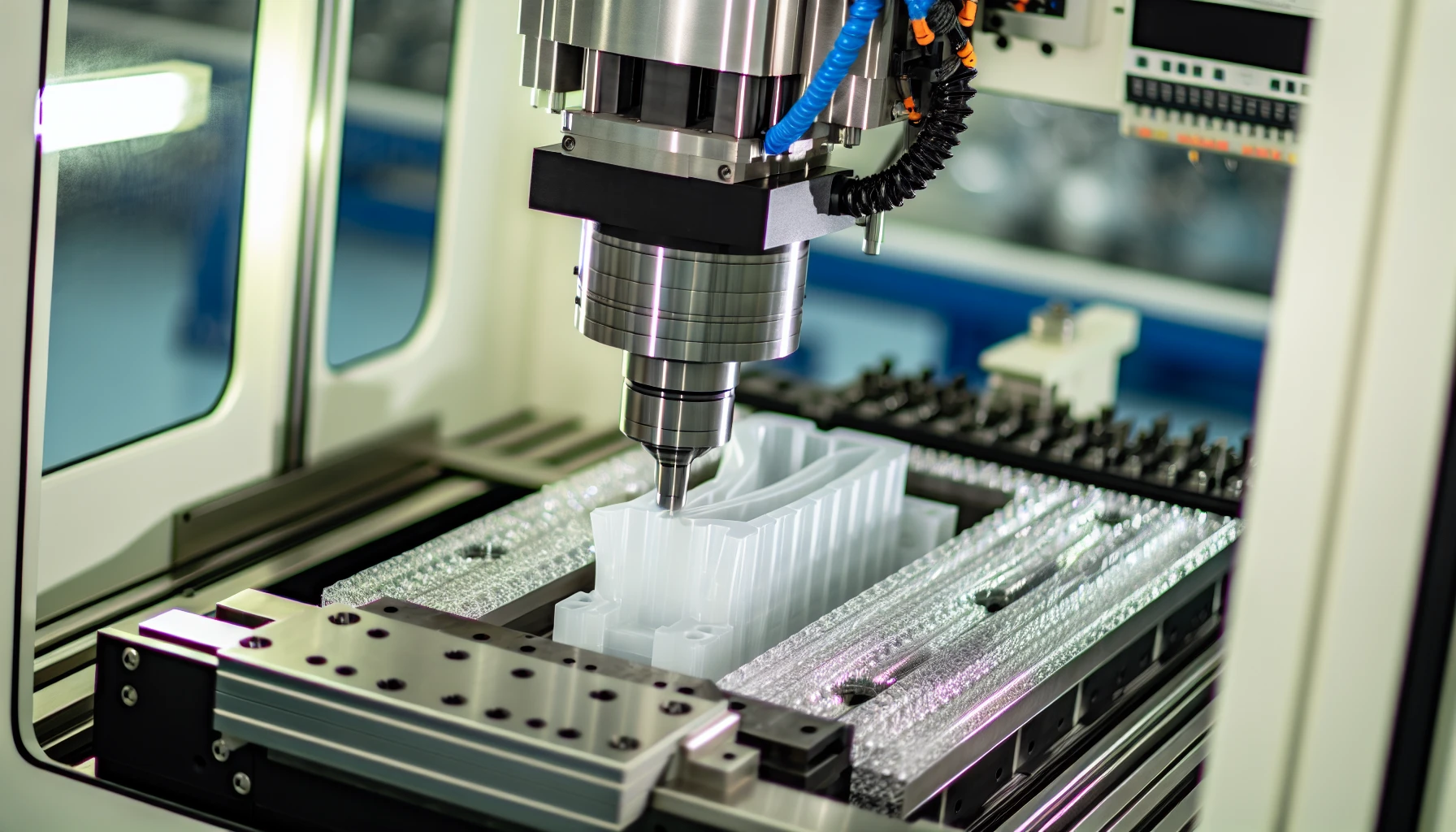

Precision Machining Production

Approved designs move to our climate-controlled machining facility operating under ISO 9001:2015 certification. Key production parameters:

| Material Category | Common Grades | Max Tolerance (±) | Typical Lead Time |

|---|---|---|---|

| Engineering Thermoplastics | PEEK, PEI, PPSU | 0.025 mm | 5-7 days |

| Standard Plastics | Acetal, Nylon, PVC | 0.05 mm | 3-5 days |

| Optical Clarity Grades | PMMA, PC | 0.01 mm | 7-10 days |

Machining occurs on Haas and DMG MORI 5-axis centers with in-process CMM verification. All critical dimensions undergo first-article inspection per AS9102 standards before full production release.

Quality-Controlled Delivery

Final inspection includes material certification traceability, full FAIR documentation, and environmental stress testing per client specifications. Parts ship in ESD-safe packaging with serialized lot tracking. Standard delivery includes:

Dimensional report with actual vs nominal measurements

Material test certificates (UL, FDA, or RoHS as specified)

Digital quality dossier accessible via client portal

Expedited air freight options maintain full chain-of-custody documentation with real-time logistics tracking. Average on-time delivery performance is 98.7% across our global client base.

This integrated workflow reduces time-to-part by 40% compared to industry averages while eliminating costly design iterations through upfront engineering collaboration. All process stages maintain full auditability for regulated industries including medical and aerospace.

Start Your Project

Need custom machined plastic parts built to your exact specifications? Our precision manufacturing facility in Shenzhen delivers high-quality, on-time production for prototyping and low-to-mid volume runs.

Contact Susan Leo today to discuss your project requirements. We specialize in CNC machining, material selection guidance, and fast turnaround for engineering-grade plastics.

Email Susan Leo at [email protected] to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.