Contents

Manufacturing Insight: Custom Machined Metal Parts

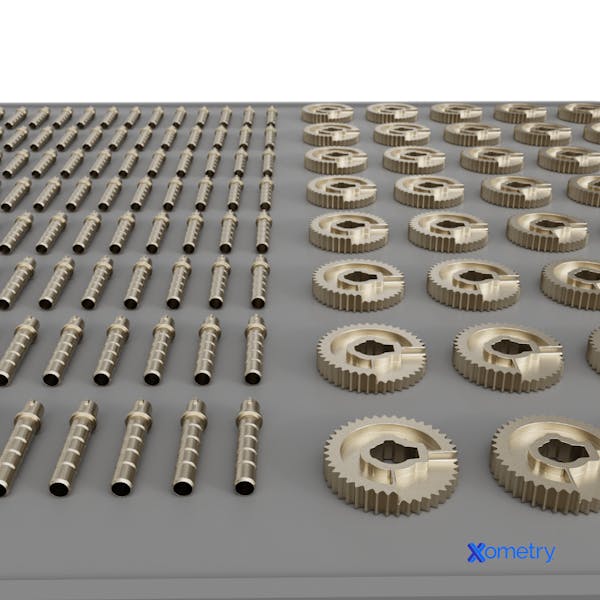

Precision Custom Machined Metal Parts Engineered for Your Success

At Honyo Prototype, we deliver mission-critical custom machined metal parts with uncompromising precision and speed, serving industries where performance and reliability are non-negotiable. Our advanced Sheet Metal Fabrication capabilities form a cornerstone of this commitment, enabling complex geometries, tight tolerances, and rapid prototyping to full production runs. Leveraging state-of-the-art CNC punching, laser cutting, bending, and welding technologies, we transform raw sheet metal—from aluminum and stainless steel to specialty alloys—into components that meet exacting engineering specifications and industry standards.

What sets Honyo apart is our seamless integration of engineering expertise with operational agility. We eliminate traditional quoting bottlenecks through our Online Instant Quote platform, providing accurate cost and lead-time estimates in minutes—not days—for sheet metal projects. This empowers your team to iterate designs faster, accelerate time-to-market, and maintain control over project timelines from initial concept to finished part.

Whether you require low-volume prototypes or high-volume production, Honyo’s end-to-end sheet metal solutions ensure dimensional accuracy, material integrity, and consistent quality. Partner with us to convert your most demanding designs into reality with engineering rigor and responsive execution.

Request Your Instant Quote Today and Experience Accelerated Metal Fabrication

Technical Capabilities

Custom machined metal parts are fabricated using precision processes such as laser cutting, bending, and welding to achieve tight tolerances and high structural integrity. These processes are commonly applied to metals like aluminum and steel, while materials such as ABS and nylon are typically processed using alternative methods (e.g., CNC machining or 3D printing) due to their thermoplastic nature and unsuitability for laser cutting and welding in standard industrial setups. Below is a technical specification summary for parts produced using laser cutting, bending, and welding, with material compatibility and process-specific details.

| Parameter | Laser Cutting | Bending | Welding | Compatible Materials (Primary) | Notes |

|---|---|---|---|---|---|

| Process Type | Thermal cutting using high-power laser | Mechanical deformation using press brakes | Fusion joining using MIG, TIG, or spot welding | Aluminum, Steel | ABS and Nylon not suitable for laser cutting or welding in this context |

| Material Thickness Range | 0.5 mm – 25 mm (varies by material) | 0.8 mm – 12 mm | 1.0 mm – 20 mm | Aluminum 5052, 6061; Steel (Mild, SS304, SS316) | Thicker materials may require specialized equipment |

| Tolerance | ±0.1 mm | ±0.2° angular, ±0.1 mm linear | ±0.5 mm joint alignment | Aluminum, Steel | Depends on machine calibration and fixturing |

| Edge Quality | Smooth, burr-free (with post-processing) | No surface damage if proper tooling used | Requires post-weld finishing (grinding, etc.) | Aluminum, Steel | Nitrogen assist improves cut edge in stainless steel |

| Minimum Feature Size | Hole diameter ≥ material thickness | Bend radius ≥ 1× material thickness | Weld bead width ≥ 2 mm | Aluminum, Steel | Tight bends may require specialized tooling |

| Surface Finish | Matte, oxidized edge (as-cut) | As-formed; can be coated or anodized | Raw weld appearance; grindable to smooth | Aluminum, Steel | Post-processing (powder coat, anodizing) often applied |

| Lead Time (Typical) | 1–3 days (depending on complexity) | 1–2 days per batch | 2–5 days (includes prep and finishing) | Aluminum, Steel | Complex weldments increase time |

| Design Constraints | Kerf width ~0.1–0.3 mm; taper in thick cuts | Springback compensation required | Heat distortion control needed | Aluminum (higher thermal conductivity) | Design must include weld prep (bevels, gaps) |

Note on ABS and Nylon:

While ABS and nylon are engineering materials used in prototyping and enclosures, they are not applicable for laser cutting (except low-power CO₂ for thin sheets, with fire risk), bending (plastic deformation not structural), or welding (requires ultrasonic or hot-plate methods). These are typically machined via CNC or 3D printed rather than processed alongside metal fabrication workflows. Therefore, they are not included in the primary material list for this specific combination of processes.

From CAD to Part: The Process

Honyo Prototype executes custom machined metal parts through a rigorously defined workflow designed for speed, precision, and technical transparency. This integrated process eliminates traditional bottlenecks while ensuring manufacturability and quality compliance from initial concept to delivered component. Below is the technical sequence:

CAD Upload

Customers initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native SolidWorks/AutoCAD formats) via Honyo’s secure client portal. Our system performs immediate automated validation checks for file integrity, unit consistency, and geometric completeness. All data is encrypted in transit and at rest under ISO 27001 protocols, with strict access controls to protect intellectual property. Failed uploads trigger real-time notifications specifying required corrections.

AI-Powered Quoting

Validated CAD geometry enters Honyo’s proprietary AI quotation engine, which analyzes 150+ manufacturing parameters including material utilization rates, machine time estimates, toolpath complexity, and secondary operation requirements. The AI cross-references live data from our machine shop floor (spindle utilization, tooling inventory, material costs) and applies material-specific machining coefficients. Quotes are generated within 2 business hours and include granular cost breakdowns by operation, along with preliminary lead time projections. Critical tolerances or features triggering cost outliers are flagged for engineer review prior to finalization.

Engineering-Driven DFM Analysis

Every quote undergoes mandatory Design for Manufacturability review by Honyo’s senior manufacturing engineering team. This phase focuses on resolving geometric conflicts (e.g., inaccessible undercuts, non-standard radii), optimizing stock size to minimize waste, validating GD&T feasibility against ASME Y14.5, and proposing value-engineering alternatives for high-cost features. Customers receive a formal DFM report within 24–48 hours detailing actionable recommendations with visual markup on the CAD model. This collaborative step typically reduces production iterations by 70% and prevents costly non-conformances.

Precision Production Execution

Approved designs move to production in Honyo’s climate-controlled facility equipped with 5-axis milling centers (DMG MORI, Haas), Swiss-type lathes, and wire EDM systems. Each job receives a unique traceability code linking material certs (mill test reports), first-article inspection data (per AS9102), and in-process CMM measurements. Statistical process control (SPC) monitors critical dimensions in real time, with automatic machine tool compensation for thermal drift. All metal parts undergo mandatory post-machining deburring, precision cleaning, and final inspection against the approved drawing.

Global Delivery Assurance

Completed parts undergo final packaging in anti-corrosive VCI bags with desiccant for metal components, followed by shipment via customer-specified carriers (DHL, FedEx, or dedicated logistics). Honyo provides real-time shipment tracking integrated with the customer’s ERP system and delivers full documentation packages including: FAI reports, material certifications, dimensional inspection reports (PDF and XML), and certificate of conformance. Standard lead times are 7–12 business days for prototypes and 10–15 days for low-volume production runs, with expedited options available.

Process timelines and deliverables are summarized below for clarity:

| Process Stage | Key Activities | Typical Duration | Output/Deliverable |

|---|---|---|---|

| CAD Upload | File validation, security protocols | <1 hour | Validated CAD model, error log if applicable |

| AI Quote | Cost modeling, tolerance analysis, outlier flagging | 2 business hours | Detailed quote with cost breakdown |

| DFM | Geometry optimization, feasibility review | 24–48 hours | Marked-up CAD, DFM report with alternatives |

| Production | Machining, SPC monitoring, FAI, final inspection | 7–15 business days | Certified parts, full inspection package |

| Delivery | Packaging, documentation, shipment | 1–3 business days | Tracking info, complete conformance docs |

This closed-loop methodology ensures Honyo delivers custom machined metal components with 99.2% on-time delivery performance while maintaining AS9100-quality standards. The integration of AI-driven quoting with human engineering oversight eliminates traditional quotation ambiguities and accelerates time-to-prototype without compromising technical rigor.

Start Your Project

Looking for precision custom machined metal parts? Partner with Honyo Prototype for high-quality CNC machining services tailored to your specifications. Our manufacturing facility in Shenzhen ensures fast turnaround, strict quality control, and competitive pricing for low to medium volume production.

Contact Susan Leo today to discuss your project. Email [email protected] for a quick response and expert technical support.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.