Introduction: Navigating the Global Market for custom lucite

The global market for custom lucite products presents a unique challenge for B2B buyers looking to create impactful branding and recognition solutions. Sourcing high-quality custom lucite awards and displays requires not only an understanding of the material’s versatility but also a keen eye for supplier reliability and cost-effectiveness. This guide offers a comprehensive exploration of the custom lucite landscape, detailing various types of products, their applications across different industries, and essential criteria for vetting suppliers.

From elegant awards and promotional items to functional displays and embedments, the applications of custom lucite are vast and varied. Buyers will benefit from insights into cost structures, allowing for informed budgeting and financial planning. Furthermore, this guide addresses the nuances of sourcing from diverse regions, particularly for international B2B buyers from Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia.

By equipping decision-makers with actionable knowledge and strategies, this resource empowers businesses to make informed purchasing decisions that enhance their branding efforts and recognize achievements effectively. Whether you are looking to celebrate milestones or promote your brand, understanding the global market for custom lucite is essential to achieving your objectives.

Understanding custom lucite Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lucite Embedments | Encases objects in clear Lucite, customizable shapes and sizes | Awards, commemorative items, branding | Pros: High durability, aesthetic appeal; Cons: Can be more expensive than standard trophies. |

| Acrylic Awards | Available in various colors and shapes, often engraved | Corporate events, employee recognition | Pros: Versatile design options; Cons: May scratch easily if not properly maintained. |

| Custom Acrylic Plaques | Flat, engraved plaques with personalized designs | Office décor, recognition displays | Pros: Professional appearance; Cons: Limited dimensionality compared to 3D options. |

| 3D Lucite Shapes | Three-dimensional designs, often themed or symbolic | Gifts, awards, promotional items | Pros: Eye-catching and unique; Cons: Higher production time and cost. |

| Lucite Displays | Clear acrylic structures for showcasing products or awards | Trade shows, retail displays | Pros: Enhances product visibility; Cons: Can be bulky depending on design. |

What are the Key Characteristics of Lucite Embedments for B2B Buyers?

Lucite embedments are distinctive for their ability to encase objects within a clear acrylic block, offering a sleek and professional presentation. They are commonly used for awards, commemorative items, and branding initiatives. B2B buyers should consider the customization options available, including shape and size, as these factors can significantly impact the final presentation. Additionally, the durability of Lucite makes it an excellent choice for long-lasting recognition pieces.

How Do Acrylic Awards Differ in Terms of Design and Application?

Acrylic awards stand out due to their versatility in colors and shapes, often enhanced by engraving. These awards are primarily used in corporate events and employee recognition programs. When purchasing, buyers should evaluate the engraving quality and the potential for color incorporation, as these elements contribute to the award’s overall impact. While acrylic awards offer a cost-effective solution, buyers must be aware of their susceptibility to scratches if not maintained properly.

What Makes Custom Acrylic Plaques a Popular Choice for B2B Recognition?

Custom acrylic plaques are flat and often feature personalized engravings, making them ideal for office décor and recognition displays. Their professional appearance appeals to businesses looking to honor achievements or milestones. Buyers should consider the design flexibility, as these plaques can be tailored to fit various themes and branding needs. However, the limited dimensionality compared to 3D options may be a drawback for those seeking a more dynamic presentation.

Why Choose 3D Lucite Shapes for Unique Corporate Gifts or Awards?

3D Lucite shapes are designed to capture attention with their unique, three-dimensional forms, often reflecting themes or symbols relevant to the recipient. These pieces are perfect for gifts, awards, or promotional items, providing a memorable way to celebrate achievements. B2B buyers should factor in production time and costs, as these items can be more expensive and take longer to create than standard flat awards, but the end result is often worth the investment.

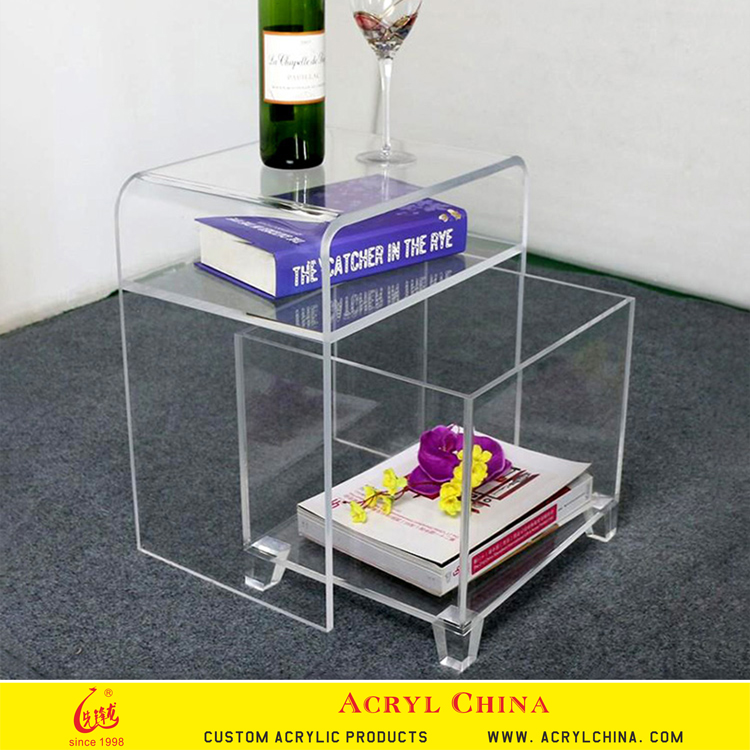

How Can Lucite Displays Enhance Product Visibility at Trade Shows?

Lucite displays are clear acrylic structures designed to showcase products or awards, making them particularly effective for trade shows and retail environments. These displays enhance product visibility and can be customized to suit specific branding needs. Buyers must consider the design’s bulkiness and how it fits into their overall display strategy. While they provide an attractive solution for product presentation, the weight and size may impact logistics during events.

Key Industrial Applications of custom lucite

| Industry/Sector | Specific Application of custom lucite | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Awards & Recognition | Custom trophies and awards for corporate events | Enhances brand visibility and employee motivation | Quality of materials, customization options, and lead times |

| Retail & Display | Lucite displays for merchandise and promotional items | Increases product visibility and enhances customer experience | Durability, design flexibility, and shipping logistics |

| Education & Training | Engraved plaques and awards for academic achievements | Recognizes student achievements and boosts morale | Customization options, price points, and delivery timelines |

| Hospitality & Events | Table centerpieces and event signage made from lucite | Creates an elegant atmosphere and enhances branding | Design adaptability, bulk ordering capabilities, and cost-effectiveness |

| Medical & Pharmaceutical | Lucite encasements for awards and recognition in healthcare | Highlights achievements and fosters a culture of excellence | Compliance with industry standards, durability, and customization |

How is Custom Lucite Used in Awards & Recognition?

In the awards and recognition sector, custom lucite is predominantly used to create trophies and plaques that celebrate achievements in corporate and academic environments. These awards not only recognize individual or team accomplishments but also serve to enhance brand visibility. International buyers, especially from regions like Africa and the Middle East, should consider the quality of materials and the range of customization options available to ensure that the awards reflect the prestige of the event. Lead times are crucial, as many organizations require awards for specific events or ceremonies.

What Role Does Custom Lucite Play in Retail & Display?

Custom lucite is widely utilized in retail settings for creating eye-catching displays that showcase merchandise and promotional items. These displays enhance product visibility, drawing in customers and improving sales. For B2B buyers in South America and Europe, key considerations include the durability of the lucite, its ability to withstand various environmental conditions, and design flexibility to align with branding. Effective sourcing should also account for shipping logistics, ensuring timely delivery for promotional events.

How is Custom Lucite Beneficial in Education & Training?

In the education sector, custom lucite is often employed for creating engraved plaques and awards that recognize student achievements, such as graduations or academic excellence. This application not only fosters a sense of pride among students but also boosts morale within educational institutions. Buyers from Europe, particularly Germany, should focus on customization options that allow for unique designs and personalization. Price points and delivery timelines are also significant factors, especially for institutions with tight budgets.

Why is Custom Lucite Important for Hospitality & Events?

In the hospitality and events industry, custom lucite serves as a sophisticated choice for table centerpieces and event signage. These elements create an elegant atmosphere that can enhance guest experience and promote brand identity. For international buyers, particularly in the Middle East, sourcing considerations should include design adaptability to fit various themes and occasions, along with the ability to handle bulk orders without compromising quality. Cost-effectiveness is also a critical aspect, as event budgets can be tight.

How is Custom Lucite Used in the Medical & Pharmaceutical Sector?

In the medical and pharmaceutical sectors, custom lucite is used for creating awards and recognition items that highlight achievements in healthcare. This application promotes a culture of excellence and encourages staff motivation. Buyers should ensure compliance with industry standards, particularly in terms of safety and durability. Additionally, customization is vital for these awards to convey the significance of the achievements being recognized, making it a crucial factor for B2B buyers in these sectors.

3 Common User Pain Points for ‘custom lucite’ & Their Solutions

Scenario 1: Difficulty in Achieving Desired Customization for Lucite Products

The Problem: Many B2B buyers find themselves frustrated by the limitations of standard customization options offered by suppliers. They may have specific branding requirements, such as unique colors, logos, or even intricate designs that need to be embedded within the Lucite products. In regions like Africa and South America, where creative branding is essential for standing out in competitive markets, this lack of flexibility can lead to missed opportunities for impactful marketing and recognition. Buyers often feel their vision is compromised, resulting in products that do not resonate with their brand identity.

The Solution: To overcome this challenge, buyers should seek suppliers that specialize in bespoke Lucite solutions. Prior to engagement, they should prepare a detailed brief outlining their specific requirements, including dimensions, colors, and design elements. It’s advisable to request samples of previous custom work to gauge the supplier’s capability. Additionally, engaging in an open dialogue during the design phase allows for collaborative input, ensuring that the final product aligns with the buyer’s branding strategy. Investing time in selecting the right partner can lead to innovative solutions that elevate brand presence.

Scenario 2: Concerns Over Product Durability and Quality

The Problem: Buyers often face apprehension regarding the durability and quality of custom Lucite products. In markets where logistics can be challenging, such as in the Middle East or remote areas of Europe, there is a heightened concern that products may arrive damaged or deteriorate over time. This fear can lead to hesitance in placing bulk orders, which affects inventory management and budgeting.

The Solution: To mitigate these concerns, buyers should prioritize suppliers that provide clear specifications about the materials used and their durability ratings. Requesting third-party certifications or test results can further validate the quality claims of the product. Additionally, establishing a robust quality assurance protocol, including pre-shipment inspections, can ensure that the products meet the required standards before they leave the supplier’s facility. Buyers should also consider suppliers who offer warranties or guarantees on their products, providing an additional layer of security in their purchasing decisions.

Scenario 3: Navigating Complex Import Regulations and Costs

The Problem: International buyers, particularly from regions such as Europe and Africa, often encounter challenges with import regulations and associated costs when sourcing custom Lucite items. These complexities can include tariffs, customs documentation, and varying compliance standards, which can lead to unforeseen delays and increased expenses. This unpredictability can hinder timely promotions or events, causing frustration among procurement teams.

The Solution: To effectively navigate these complexities, buyers should conduct thorough research on the import regulations specific to their country and the source country of the Lucite products. Collaborating with a logistics partner who specializes in international shipping can streamline the process, ensuring that all necessary documentation is prepared and submitted correctly. Buyers should also factor in potential import duties and taxes when budgeting for their custom Lucite purchases. By planning ahead and utilizing expert logistics support, buyers can minimize risks and ensure that their products arrive on time and within budget, allowing for smoother operational flow.

Strategic Material Selection Guide for custom lucite

What Are the Key Properties of Common Materials Used in Custom Lucite?

When selecting materials for custom lucite applications, it’s essential to consider various options that can enhance product performance. The most common materials include acrylic, polycarbonate, glass, and PETG. Each material has unique properties that can significantly influence the final product’s durability, aesthetic appeal, and cost-effectiveness.

How Does Acrylic Perform in Custom Lucite Applications?

Acrylic, often referred to by brand names like Lucite, is a popular choice due to its excellent clarity and weather resistance. It offers a temperature rating of up to 80°C (176°F) and is resistant to UV light, making it suitable for both indoor and outdoor applications.

Pros: Acrylic is lightweight and easy to fabricate, allowing for intricate designs and shapes. It is also more affordable than other materials, making it a cost-effective option for bulk orders.

Cons: While acrylic is durable, it can scratch easily and is less impact-resistant compared to polycarbonate. It may also become brittle over time if exposed to harsh environmental conditions.

Impact on Application: Acrylic is compatible with various printing and engraving techniques, allowing for vibrant colors and detailed designs. This makes it ideal for awards, signage, and decorative items.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM D4802 for acrylic materials. Additionally, they should consider the shipping costs and potential tariffs when importing acrylic products.

What Are the Benefits of Polycarbonate in Custom Lucite?

Polycarbonate is another robust option known for its high impact resistance and temperature tolerance, with ratings up to 120°C (248°F). This material is particularly advantageous in applications requiring durability.

Pros: Polycarbonate is nearly unbreakable, making it suitable for high-traffic areas or environments where safety is a concern. It also offers excellent optical clarity and can be molded into complex shapes.

Cons: The primary drawback is its higher cost compared to acrylic. Polycarbonate can also yellow over time when exposed to UV light, although UV-resistant options are available.

Impact on Application: Due to its strength, polycarbonate is ideal for protective barriers, safety shields, and high-end display cases.

Considerations for International Buyers: Buyers should be aware of the specific certifications required in their region, such as DIN EN 13501 for fire safety in Europe. Additionally, sourcing polycarbonate from reputable suppliers ensures compliance with local regulations.

Why Choose Glass for Custom Lucite Products?

Glass is a traditional material that offers exceptional clarity and scratch resistance. It can withstand high temperatures and is chemically inert, making it suitable for various applications.

Pros: Glass provides a premium look and feel, enhancing the aesthetic appeal of awards and displays. It is also highly resistant to scratching and can be easily cleaned.

Cons: The primary disadvantage is its weight and fragility, making shipping and handling more challenging. Glass is also more expensive than acrylic and polycarbonate.

Impact on Application: Glass is ideal for high-end awards and decorative items where aesthetics take precedence over durability.

Considerations for International Buyers: When importing glass products, buyers must consider the potential for breakage during shipping and ensure compliance with international shipping regulations.

What Role Does PETG Play in Custom Lucite Applications?

PETG (Polyethylene Terephthalate Glycol) is a thermoplastic known for its ease of fabrication and impact resistance, making it a viable alternative to acrylic and polycarbonate.

Pros: PETG is easy to thermoform and can be printed on directly, allowing for vibrant graphics. It is also less prone to shattering than glass, making it safer for various applications.

Cons: While PETG is durable, it is less scratch-resistant than acrylic and can warp under high temperatures.

Impact on Application: PETG is suitable for point-of-purchase displays, signage, and other applications where visual appeal is essential without compromising safety.

Considerations for International Buyers: Buyers should check for compliance with ASTM standards for PETG materials and consider the environmental impact, as PETG is recyclable.

Summary Table of Material Selection for Custom Lucite

| Material | Typical Use Case for custom lucite | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic | Awards, signage, decorative items | Lightweight and cost-effective | Scratches easily, less impact-resistant | Low |

| Polycarbonate | Protective barriers, display cases | High impact resistance | Higher cost, can yellow over time | High |

| Glass | High-end awards, decorative displays | Premium look, scratch-resistant | Heavy and fragile | High |

| PETG | Signage, point-of-purchase displays | Easy to fabricate and print on | Less scratch-resistant, warps under heat | Medium |

This strategic material selection guide provides a comprehensive overview for B2B buyers looking to make informed decisions regarding custom lucite applications. By understanding the properties, advantages, and limitations of each material, buyers can better align their choices with their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for custom lucite

What Are the Key Stages in the Manufacturing Process of Custom Lucite?

The manufacturing of custom lucite involves several critical stages that ensure the final product meets the desired quality and specifications. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with selecting high-quality acrylic resin, which serves as the primary material for lucite products. This resin is often supplied in large sheets and requires careful inspection for any defects. Suppliers should ensure that the material meets specific standards, such as transparency and durability, to guarantee the final product’s quality.

Forming: The next stage involves shaping the acrylic into the desired form. Techniques such as casting, extrusion, or laser cutting are commonly used. Casting is particularly popular for creating embedments, where objects are encased in lucite. This method allows for intricate designs and ensures that the objects are preserved in a clear, durable medium. The forming process must be executed under controlled temperature conditions to prevent warping or defects.

Assembly: Following forming, components may need to be assembled. This could involve attaching bases, adding engravings, or combining multiple pieces. Attention to detail is crucial in this stage, as any misalignment can compromise the aesthetic and functional quality of the final product.

Finishing: The final stage involves polishing and inspecting the lucite products. Polishing enhances the clarity and shine of the acrylic, while inspections ensure that all specifications are met. Any imperfections are addressed through additional polishing or reworking. A rigorous finishing process is essential for maintaining the high standards expected by B2B buyers.

How Is Quality Assurance Implemented in Custom Lucite Manufacturing?

Quality assurance (QA) is a fundamental aspect of lucite manufacturing, ensuring that products meet international standards and customer expectations. Several key methodologies and standards are employed to maintain quality throughout the production process.

International Standards: Compliance with international standards such as ISO 9001 is critical. This standard outlines the criteria for a quality management system and helps organizations ensure they meet customer and regulatory requirements consistently. For manufacturers targeting international markets, adherence to CE marking or API standards may also be necessary, depending on the application of the lucite products.

Quality Control Checkpoints: Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to identify any deviations from quality standards. This could involve monitoring temperature, pressure, and material properties.

- Final Quality Control (FQC): After finishing, a comprehensive inspection is carried out to assess the overall quality of the finished product. This includes visual inspections and functional testing.

Testing Methods: Common testing methods for lucite products include clarity tests, impact resistance tests, and dimensional checks. Clarity tests ensure that the acrylic maintains its transparency, while impact resistance tests assess the durability of the material. Dimensional checks verify that the products meet specified measurements.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

Supplier Audits: Conducting audits is one of the most effective ways to assess a supplier’s quality management practices. Audits can be performed on-site or remotely, focusing on production processes, material sourcing, and adherence to quality standards. Buyers should seek suppliers who welcome audits and are transparent about their processes.

Quality Reports: Requesting quality reports from suppliers can provide insights into their QC practices. These reports should detail inspection results, testing outcomes, and any corrective actions taken for quality issues. Regular reporting indicates a commitment to quality and accountability.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control. These services typically involve random sampling of products and testing against industry standards, offering an additional layer of assurance for buyers.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances related to quality control when sourcing custom lucite products. Understanding regional standards, certifications, and logistics can significantly impact the procurement process.

Regional Standards: Different regions may have varying standards for lucite products. For instance, European buyers must be aware of CE marking requirements, while buyers in the Middle East might need to consider local certification standards. Understanding these requirements can prevent compliance issues and ensure smooth market entry.

Certification and Documentation: Suppliers should provide documentation proving compliance with relevant quality standards. Certificates of conformity, testing reports, and material safety data sheets (MSDS) are essential documents that buyers should request. These documents not only confirm the quality of the products but also serve as a legal safeguard in case of disputes.

Logistics and Handling: The transportation of lucite products requires careful handling to prevent damage during transit. Buyers should inquire about the supplier’s packaging standards and logistics processes to ensure that products arrive in perfect condition. Understanding the supplier’s capabilities in this area can mitigate risks associated with international shipping.

By paying close attention to the manufacturing processes and quality assurance practices of suppliers, B2B buyers can make informed decisions, ensuring they acquire high-quality custom lucite products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom lucite’

To successfully procure custom lucite products, it is essential to follow a systematic approach that ensures quality, reliability, and cost-effectiveness. This guide provides a clear checklist for B2B buyers aiming to make informed sourcing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before beginning the sourcing process. This includes defining the dimensions, thickness, color options, and any custom engravings or embedments required. Precise specifications help avoid miscommunication with suppliers and ensure that the final product meets your expectations.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers specializing in custom lucite products. Utilize industry directories, trade shows, and online platforms to identify manufacturers with a strong reputation. Pay special attention to their experience in your specific market region, as local suppliers may better understand your needs and logistical challenges.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with international quality standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management. Additionally, check if they meet any regional regulations relevant to your industry, especially if you are sourcing from different countries.

Step 4: Request Samples and Prototypes

Once you have narrowed down your supplier options, request samples or prototypes of their custom lucite products. This step allows you to assess the quality of materials, craftsmanship, and how well they can meet your design specifications. Evaluate the samples against your defined criteria to ensure they align with your expectations.

Step 5: Assess Production Capacity and Lead Times

Understanding a supplier’s production capacity and lead times is essential for effective planning. Ask potential suppliers about their current workload and average turnaround times for custom orders. This insight helps you gauge whether they can meet your project deadlines and manage larger orders if required.

Step 6: Negotiate Terms and Pricing

Once you have selected a preferred supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Ensure that all aspects of the agreement are documented to avoid misunderstandings later. Consider discussing bulk order discounts or flexible payment options to enhance your overall procurement strategy.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the production and delivery of your custom lucite products. This may involve setting up regular communication with the supplier and conducting inspections upon receiving the goods. A robust quality assurance strategy ensures that you receive products that meet your specifications and standards consistently.

By following these steps, B2B buyers can effectively navigate the sourcing process for custom lucite products, ensuring they select suppliers that meet their specific needs while maintaining quality and reliability.

Comprehensive Cost and Pricing Analysis for custom lucite Sourcing

What Are the Key Cost Components in Custom Lucite Sourcing?

When sourcing custom lucite products, understanding the cost structure is crucial for effective budgeting and pricing negotiations. The primary components that contribute to the overall cost include:

-

Materials: The quality of lucite resin significantly impacts costs. Premium-grade lucite may command higher prices but offers enhanced clarity and durability. Additionally, if custom colors or effects are desired, this will further increase material costs.

-

Labor: Skilled labor is essential for cutting, shaping, and finishing lucite products. Labor costs vary depending on the complexity of the design and the level of craftsmanship required. More intricate designs necessitate more skilled labor, resulting in higher costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, maintenance, utilities, and administrative costs. Efficient manufacturing processes can help minimize overhead costs, but these efficiencies may not be available with every supplier.

-

Tooling: Custom molds and tools are necessary for producing unique designs. The initial investment in tooling can be significant, especially for complex shapes, but this cost is typically amortized over larger production runs.

-

Quality Control (QC): Ensuring the quality of lucite products involves inspection processes that add to overall costs. Suppliers that adhere to stringent quality standards might charge more but offer better reliability and fewer defects.

-

Logistics: The cost of transporting lucite products can vary based on destination, shipping methods, and packaging requirements. International shipping can be particularly costly, and understanding Incoterms is essential for managing these expenses.

-

Margin: Suppliers will add a profit margin to their costs, which varies by company and market conditions. This margin reflects their business strategy and the competitive landscape.

What Factors Influence Pricing for Custom Lucite Products?

Several key factors can significantly influence the pricing of custom lucite products:

-

Volume and Minimum Order Quantity (MOQ): Pricing structures often include discounts for bulk orders. Understanding the MOQ can help buyers negotiate better pricing if they can commit to larger quantities.

-

Specifications and Customization: Highly customized products or unique specifications generally incur additional costs. Simple, standardized products tend to have lower prices due to streamlined production processes.

-

Material Quality and Certifications: Certifications for environmental compliance or safety standards can affect pricing. Premium materials with certifications will typically lead to higher costs but provide assurance of quality.

-

Supplier Factors: The supplier’s reputation, production capabilities, and geographical location can impact pricing. Suppliers with advanced technology or a strong track record may charge premium prices but offer superior products.

-

Incoterms: Understanding shipping terms can help buyers manage costs effectively. FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms can significantly alter the total cost of ownership and budgeting.

How Can Buyers Negotiate Better Prices for Custom Lucite?

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, several negotiation strategies can enhance cost efficiency:

-

Volume Commitments: Offering to place larger orders can incentivize suppliers to provide better pricing. Always inquire about volume discounts or flexible MOQs.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also shipping, handling, and potential quality issues. A slightly higher upfront price may lead to lower overall costs if the product lasts longer and requires less maintenance.

-

Supplier Relationships: Building strong relationships with suppliers can yield better pricing and terms. Long-term partnerships often lead to better service and negotiation leverage.

-

Market Research: Understanding market prices and trends can empower buyers to negotiate effectively. Being informed about competitors’ pricing and alternative suppliers allows for more strategic discussions.

What Should Buyers Keep in Mind Regarding Pricing Nuances in International Markets?

International buyers should be aware of various pricing nuances when sourcing custom lucite:

-

Currency Fluctuations: Exchange rate variations can significantly impact costs. It’s advisable to establish pricing agreements that account for potential currency fluctuations.

-

Import Duties and Taxes: Different countries have varying import regulations, which can add unexpected costs. Ensure to factor these into your total cost calculations.

-

Cultural Considerations: Understanding cultural nuances in negotiation styles can be beneficial. Building rapport and trust may lead to more favorable terms.

-

Local Competition: In some regions, local suppliers may offer competitive pricing due to lower shipping costs. Exploring local options might yield cost savings while supporting local businesses.

By understanding these components and strategies, B2B buyers can navigate the complexities of custom lucite sourcing more effectively, ensuring they achieve the best value for their investment.

Alternatives Analysis: Comparing custom lucite With Other Solutions

Exploring Viable Alternatives to Custom Lucite

When considering custom lucite for awards, displays, or encapsulations, it’s essential to evaluate alternative materials and technologies that can fulfill similar needs. This analysis will compare custom lucite against two viable alternatives: glass awards and resin-based products. Each option presents unique benefits and challenges, which can significantly impact a buyer’s decision based on their specific use case.

| Comparison Aspect | Custom Lucite | Glass Awards | Resin-Based Products |

|---|---|---|---|

| Performance | High clarity, durable, lightweight | Excellent clarity, heavy, prone to breakage | Versatile, can mimic various designs |

| Cost | Moderate to high depending on customization | Generally higher due to material and shipping | Typically lower cost for bulk orders |

| Ease of Implementation | Custom designs readily available, fast turnaround | May require longer lead times for custom designs | Simple production process, quick to produce |

| Maintenance | Easy to clean, resistant to scratches | Requires careful handling, can chip or break | Generally low maintenance, durable |

| Best Use Case | Corporate awards, promotional displays | Prestigious awards, high-end gifts | Budget awards, promotional items |

What Are the Advantages and Disadvantages of Glass Awards?

Glass awards are often associated with prestige and elegance, making them a popular choice for high-profile ceremonies. Their performance in terms of clarity is exceptional, and they offer a classic aesthetic that many companies prefer. However, the cost of glass awards tends to be higher due to the material’s fragility and shipping requirements. They also require more careful handling to avoid breakage, which can be a significant drawback for organizations that prioritize durability. While glass awards are ideal for prestigious events, they may not be the best fit for everyday corporate recognition.

How Do Resin-Based Products Compare in Terms of Usability?

Resin-based products provide a flexible alternative to custom lucite and glass awards. They can be produced quickly and are typically more cost-effective, especially for bulk orders. Their ability to mimic various designs and colors allows for creative freedom, making them suitable for promotional items or budget awards. However, while resin can achieve impressive results, it may not offer the same level of clarity or perceived value as lucite or glass. Organizations seeking functional yet affordable recognition items might find resin to be an attractive option.

Conclusion: How to Choose the Right Solution for Your Needs?

When selecting the right solution for awards or display needs, B2B buyers should consider factors such as the intended use, budget constraints, and desired aesthetic. Custom lucite stands out for its durability and clarity, making it an excellent choice for corporate awards and long-lasting displays. Glass awards convey prestige but come with higher costs and fragility. Conversely, resin-based products offer a budget-friendly option with quick turnaround times but may lack the high-end appeal of lucite or glass. By assessing these aspects, buyers can make informed decisions that align with their organizational goals and brand identity.

Essential Technical Properties and Trade Terminology for custom lucite

What Are the Key Technical Properties of Custom Lucite?

When sourcing custom lucite products, understanding the essential technical properties can significantly impact decision-making. Here are some critical specifications to consider:

-

Material Grade

The material grade of lucite refers to the quality and characteristics of the acrylic resin used. Higher-grade lucite offers superior clarity, UV resistance, and impact strength. For B2B buyers, selecting a higher grade can ensure longevity and maintain aesthetic appeal, particularly in applications like awards, displays, or promotional items. -

Thickness

Thickness is a vital specification that affects durability and appearance. Common thicknesses range from 1/8 inch to 1 inch, depending on the product’s intended use. For example, thicker lucite is often preferred for awards and displays, as it provides a more substantial feel and reduces the risk of breakage during handling or shipping. -

Tolerance

Tolerance refers to the permissible variation in dimensions during the manufacturing process. For custom lucite products, maintaining tight tolerances (e.g., ±0.01 inches) ensures that components fit together seamlessly, which is crucial for items that require precise assembly or fit within specific display cases. This property is particularly important for B2B buyers in industries where precision is paramount. -

Finish

The finish of lucite can vary from polished to matte, affecting both aesthetics and functionality. A polished finish enhances clarity and light transmission, making it ideal for display cases and awards. Conversely, a matte finish can reduce glare and fingerprint visibility, which is beneficial in environments like offices or exhibition spaces. -

UV Stability

UV stability indicates the material’s resistance to degradation when exposed to ultraviolet light. This property is essential for outdoor applications or environments with significant sunlight exposure. B2B buyers should prioritize UV-stable lucite to ensure that products remain vibrant and undamaged over time. -

Impact Resistance

Lucite is known for its superior impact resistance compared to glass, making it less likely to shatter upon impact. This property is critical for applications in high-traffic areas or where safety is a concern. Choosing lucite with high impact resistance can reduce liability and ensure the safety of employees and customers.

What Are Common Trade Terms Related to Custom Lucite?

Familiarizing yourself with industry jargon can streamline communication and enhance negotiation effectiveness. Here are some essential trade terms relevant to custom lucite procurement:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. For custom lucite, working with an OEM can ensure high-quality manufacturing standards and tailored solutions to meet specific design requirements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding the MOQ helps businesses plan their budgets and inventory effectively. For custom lucite items, MOQs can vary widely, so it’s crucial to negotiate terms that align with your purchasing needs. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price bids from suppliers for specific products or services. When dealing with custom lucite, submitting an RFQ can help buyers compare costs and terms from multiple manufacturers, ensuring they get the best value. -

Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help B2B buyers navigate global logistics more efficiently, particularly when sourcing lucite from international suppliers. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the finished product. Understanding lead times for custom lucite can help businesses plan marketing campaigns or product launches more effectively, ensuring that they have the necessary items on hand when needed. -

Customization Options

This term encompasses various modifications available for lucite products, such as color, shape, size, and engraving. Knowing the available customization options is essential for B2B buyers looking to create unique products that reflect their brand identity or meet specific client needs.

By grasping these essential properties and terms, B2B buyers can make informed decisions when sourcing custom lucite products, ultimately leading to successful procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the custom lucite Sector

What are the Global Drivers and Key Trends in the Custom Lucite Sector?

The custom lucite sector is experiencing robust growth, fueled by several global drivers. The increasing demand for personalized awards and promotional products in corporate settings is a significant factor. Businesses across Africa, South America, the Middle East, and Europe are increasingly seeking unique, high-quality awards that reflect their brand identity. Additionally, the rise of e-commerce has made it easier for B2B buyers to source custom lucite products online, broadening the market reach for manufacturers.

Emerging trends also include the integration of technology in sourcing processes. Advanced customization options, such as 3D printing and laser engraving, are becoming standard, allowing for intricate designs that meet specific client requirements. Furthermore, data analytics is playing a crucial role in inventory management and demand forecasting, enabling suppliers to respond swiftly to market changes. B2B buyers are encouraged to leverage these technological advancements to streamline procurement processes and enhance product offerings.

Another dynamic aspect is the shift toward localized sourcing. Companies are increasingly looking to partner with suppliers within their regions to mitigate risks associated with global supply chains, such as delays and increased shipping costs. This trend is particularly relevant for international buyers in regions like Europe and the Middle East, where proximity can enhance collaboration and reduce lead times.

How is Sustainability Impacting Sourcing in the Custom Lucite Sector?

Sustainability has emerged as a critical concern in the custom lucite industry, influencing sourcing decisions among B2B buyers. The environmental impact of production processes, including energy consumption and plastic waste, is prompting companies to seek suppliers who prioritize eco-friendly practices. This shift is particularly pronounced in Europe, where regulatory frameworks around sustainability are stringent.

Ethical sourcing has become a priority, with businesses demanding transparency in their supply chains. Buyers are increasingly interested in suppliers that can demonstrate adherence to sustainable practices, such as using recycled materials or energy-efficient production methods. Certifications like ISO 14001 (Environmental Management) and the Global Recycled Standard are becoming essential for suppliers aiming to attract environmentally conscious clients.

Moreover, the trend towards ‘green’ lucite products is gaining momentum. Manufacturers are innovating to create lucite alternatives that are biodegradable or made from renewable resources. B2B buyers should consider suppliers who invest in sustainable materials and can provide documentation to validate their claims, as this not only enhances brand reputation but also aligns with the growing consumer preference for environmentally responsible products.

What is the Historical Context of the Custom Lucite Sector?

The custom lucite sector has evolved significantly since its inception in the mid-20th century. Initially popularized for its clarity and versatility, lucite quickly became a favored material for various applications, from signage to decorative objects. The introduction of innovative manufacturing techniques, such as casting and molding, allowed for greater customization, paving the way for personalized products.

As businesses began to recognize the potential of lucite for awards and corporate gifts, the market expanded. The 1980s and 1990s saw a surge in demand for custom lucite awards, as companies sought unique ways to recognize employee achievements. Today, the sector continues to thrive, driven by technological advancements and changing consumer preferences for personalized, high-quality products. B2B buyers can leverage this rich history to inform their sourcing strategies, ensuring they partner with suppliers who understand the nuances of the market and can deliver exceptional products.

Frequently Asked Questions (FAQs) for B2B Buyers of custom lucite

-

How do I ensure the quality of custom lucite products from suppliers?

To ensure quality, start by requesting samples from potential suppliers. Evaluate the clarity, finish, and durability of the lucite material. Additionally, inquire about their manufacturing processes, quality assurance protocols, and certifications (such as ISO). Establish clear specifications for your order, including dimensions, color, and engraving details. Lastly, consider conducting a factory visit or utilizing third-party inspection services to verify production standards before placing a large order. -

What is the best way to customize lucite awards for corporate events?

The best way to customize lucite awards is to work closely with the supplier to define your design requirements. This includes selecting the shape, size, color, and any engravings or logos you want to include. Request mock-ups or digital proofs to visualize the final product before production. Consider the theme of your event and the message you want to convey to ensure the awards align with your corporate identity and values. -

What should I consider when vetting lucite suppliers internationally?

When vetting international lucite suppliers, consider their experience and reputation in the industry. Look for customer reviews and case studies to assess their reliability. Verify their compliance with international trade regulations and quality standards. Request references from other B2B clients and check their responsiveness to inquiries. Additionally, evaluate their production capacity and delivery timelines to ensure they can meet your needs without delays. -

What are the typical minimum order quantities (MOQs) for custom lucite products?

Minimum order quantities for custom lucite products can vary widely among suppliers. Generally, MOQs can range from as low as 10 units to several hundred, depending on the complexity of the design and the supplier’s production capabilities. Always clarify the MOQ before finalizing your order to ensure it aligns with your budget and project requirements. If your needs are smaller, inquire about the possibility of a one-time order or a sample run. -

What payment terms are common in international lucite sourcing?

Common payment terms in international sourcing for lucite products often include a deposit upfront (usually 30% to 50%) with the balance due before shipment. Some suppliers may offer flexible payment options, such as letters of credit or payment through platforms like PayPal or escrow services for added security. It’s crucial to discuss and negotiate payment terms upfront to avoid any misunderstandings and ensure a smooth transaction. -

How can I manage logistics and shipping for custom lucite orders?

To manage logistics for custom lucite orders, work closely with your supplier to understand their shipping capabilities and options. Decide whether you prefer air or sea freight, considering factors like cost and delivery speed. Ensure the supplier packages the products securely to prevent damage during transit. Collaborate with a freight forwarder to handle customs clearance and documentation, especially for international shipments, to streamline the process and minimize delays. -

What are the best practices for designing custom lucite awards?

Best practices for designing custom lucite awards include keeping your design simple and impactful. Use high-contrast colors for engravings to enhance visibility and appeal. Consider incorporating your brand elements, such as logos or taglines, to reinforce brand identity. Collaborate with a designer or the supplier to create a balanced design that aligns with the theme of the event while ensuring that the awards are functional and aesthetically pleasing. -

What are the common challenges in sourcing custom lucite internationally, and how can I overcome them?

Common challenges include language barriers, cultural differences, and varying quality standards. To overcome these, establish clear communication channels and consider using professional translation services if necessary. Build relationships with suppliers to foster trust and understanding. Additionally, familiarize yourself with the supplier’s local regulations and market conditions. Conduct thorough due diligence and maintain regular updates throughout the production and shipping process to address any issues proactively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Custom Lucite Manufacturers & Suppliers List

1. USA Acrylic Awards – Custom Acrylic Embedments

Domain: usacrylicawards.com

Registered: 2020 (5 years)

Introduction: Acrylic Embedded Awards made of Lucite®; Custom-crafted acrylic embedded displays that encase and preserve objects or printed materials in clear, durable Lucite® for a sleek, professional presentation. Products include: 6″ Lucite® Badge Embedment (from $47.80), 3D Apple Shaped Lucite® Embedments (from $52.60), Iceberg & Mountain Shaped Lucite® Embedments (from $43.40), Book Shaped Lucite® Embedmen…

2. Plasticare Inc – Custom Clear Acrylic

Domain: plasticareinc.com

Registered: 1998 (27 years)

Introduction: Custom Clear Acrylic is a rigid plastic that is easy to machine, polish, and glue. It is commonly used for displays, signage, windows, aquariums, and sneeze guards. Available thicknesses include 1/16″, 1/8″, 3/16″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1.25″, 1.5″, and 2″. The product is cut to size using a 10′ CNC panel saw with a cutting tolerance of +/- .060″. Edge finish options include Fingersafe, Sand…

3. Etsy – Customized Lucite Night Lights

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Customized Lucite Night Lights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Signs.com – Custom Acrylic Signs

Domain: signs.com

Registered: 1997 (28 years)

Introduction: Acrylic Signs – Custom Acrylic Signs for Outdoor and Indoor Use | Signs.com. Features include: Next Day Production, Price Match Guarantee, 100% Satisfaction Guarantee, Free Shipping over $99. Available types include Frosted Acrylic, A-Frame Signs, Standard and Premium options, and Dry Erase A-Frame. Suitable for various uses such as Real Estate signs.

5. Tap Plastics – Custom Acrylic Sheets

Domain: tapplastics.com

Registered: 1999 (26 years)

Introduction: Acrylic (Plexiglass) sheets available in custom cut-to-size options. Various thicknesses and colors offered. Ideal for a range of applications including signage, displays, and protective barriers. Lightweight, shatter-resistant, and UV resistant. Easy to fabricate and maintain.

6. Altrum – Custom Lucite Awards

Domain: altrum.com

Registered: 2003 (22 years)

Introduction: Custom Lucite awards are made from acrylic (also known as plexiglass), known for its clarity, smooth texture, and malleability. They can be molded into various 2D or 3D shapes and allow for objects to be embedded, creating a floating effect. The awards can be customized in color (opaque, transparent, neon) and require careful sanding and polishing. They can be combined with other materials like me…

7. Crown Awards – Acrylic Awards

Domain: crownawards.com

Registered: 2000 (25 years)

Introduction: Crown Awards offers a wide range of acrylic awards including corporate acrylics, sport acrylics, and recognition acrylics. They provide personalized engraving options and a 24-hour turnaround for in-stock acrylics on web orders placed by 5:00 PM EST. Types of acrylics available include: Design Your Own Acrylics, Corporate Acrylics, Sport Acrylics, Star Acrylics, Colored Acrylics, Championship Acry…

Strategic Sourcing Conclusion and Outlook for custom lucite

What Are the Key Takeaways for B2B Buyers in Custom Lucite?

In conclusion, the strategic sourcing of custom lucite products offers international B2B buyers a unique opportunity to enhance brand recognition and corporate identity. By leveraging the versatility and aesthetic appeal of lucite awards and displays, businesses can create memorable experiences for employees and clients alike. Key takeaways include the importance of selecting quality suppliers who understand your specific needs, the potential for personalized branding through custom designs, and the value of sourcing locally to minimize lead times and shipping costs.

How Can Strategic Sourcing Drive Success in Custom Lucite Procurement?

The strategic sourcing process not only fosters better supplier relationships but also enables businesses to negotiate favorable terms and ensure consistent quality. As the demand for innovative awards and display solutions continues to rise across Africa, South America, the Middle East, and Europe, now is the time for B2B buyers to explore the possibilities that custom lucite offers.

What Should B2B Buyers Do Next in Their Custom Lucite Journey?

Embrace the future of branding and recognition by investing in high-quality custom lucite products that resonate with your audience. Engage with suppliers that prioritize craftsmanship and customer service, and consider how these products can elevate your corporate image. As you navigate this vibrant market, remember that your choice in sourcing can significantly impact your brand’s presence and success. Start your journey today and unlock the full potential of custom lucite for your organization.