Contents

Manufacturing Insight: Custom Lucite

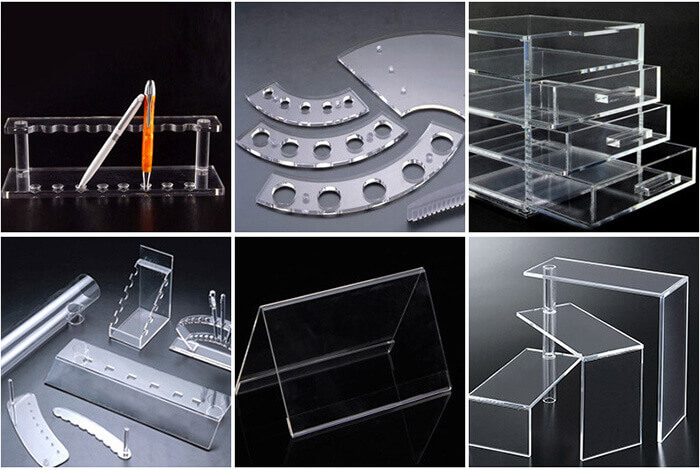

Precision Custom Lucite Solutions Engineered for Demanding Applications

At Honyo Prototype, we transform optical-grade acrylic into mission-critical components through advanced CNC machining expertise. Lucite’s unique properties—clarity, impact resistance, and thermal stability—demand specialized manufacturing rigor to avoid micro-fractures, stress points, or surface imperfections common in conventional processes. Our dedicated CNC workflows leverage proprietary toolpath strategies, optimized spindle speeds, and climate-controlled environments to maintain material integrity while achieving tolerances down to ±0.001 inches. This ensures flawless light transmission and structural reliability for aerospace interfaces, medical device housings, and high-end display systems where cosmetic and functional precision are non-negotiable.

Accelerate your prototyping or low-volume production with our Online Instant Quote platform. Upload CAD files in minutes to receive detailed manufacturability feedback, precise cost breakdowns, and lead time estimates—no sales gatekeeping, no waiting. Engineering teams globally leverage this tool to eliminate quotation bottlenecks and move from design to certified lucite parts in as few as 5 business days.

Typical Lead Time Comparison

| Service Tier | Honyo Prototype | Industry Average |

|————–|—————–|——————|

| Prototype (1-10 pcs) | 3-5 business days | 7-14 business days |

| Production (11-50 pcs) | 7-10 business days | 14-21 business days |

We solve the hidden challenges of acrylic machining—thermal management during cutting, chip evacuation without marring, and post-process polishing—so you receive optically perfect components ready for integration. Partner with Honyo to convert demanding lucite specifications into engineered reality.

Technical Capabilities

Custom Lucite refers to precision-machined transparent thermoplastic components, typically made from cast acrylic (PMMA), known for excellent optical clarity and dimensional stability. While “lucite” is often used generically, in high-precision manufacturing contexts—especially in prototyping and custom enclosures—it is frequently machined using advanced CNC techniques such as 3-axis, 4-axis, and 5-axis milling as well as precision turning. These processes are critical for achieving tight tolerances and complex geometries required in aerospace, medical, and industrial design applications.

Although Lucite (acrylic) is the primary material associated with the term, similar machining specifications apply when producing custom parts from other engineering materials such as Aluminum, Steel, ABS, and Nylon. Below is a comparative technical specifications table highlighting key machining capabilities and material properties relevant to custom Lucite and alternative substrates.

| Parameter | Lucite (Acrylic/PMMA) | Aluminum (6061-T6) | Steel (AISI 1018) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (PA6/PA66) |

|---|---|---|---|---|---|

| Typical Machining Processes | 3/4/5-Axis Milling, Turning | 3/4/5-Axis Milling, Turning | 3/4/5-Axis Milling, Turning | 3/4/5-Axis Milling, Turning | 3/4/5-Axis Milling, Turning |

| Standard Tolerance | ±0.005 in (±0.13 mm) | ±0.001 in (±0.025 mm) | ±0.001 in (±0.025 mm) | ±0.005 in (±0.13 mm) | ±0.005 in (±0.13 mm) |

| Tight Tolerance Capability | Up to ±0.002 in (±0.05 mm) | Up to ±0.0005 in (±0.013 mm) | Up to ±0.0005 in (±0.013 mm) | Up to ±0.002 in (±0.05 mm) | Up to ±0.002 in (±0.05 mm) |

| Surface Finish (Typical) | 32–64 μin Ra (optical polish available) | 16–32 μin Ra | 16–32 μin Ra | 64–125 μin Ra | 64–125 μin Ra |

| Material Hardness | Shore D 80–85 | Brinell 95 | Brinell 125 | Shore D 75–85 | Shore D 70–80 |

| Thermal Stability | Moderate (Tg ~105°C) | High (Tm ~600°C) | High (Tm ~1500°C) | Low (Tg ~100°C) | Moderate (Tg ~50–80°C) |

| Dimensional Stability | High (low creep) | High | Very High | Moderate | Low (hygroscopic) |

| Common Applications | Displays, lenses, enclosures | Aerospace, structural parts | Shafts, tooling, hardware | Prototypes, housings | Gears, bushings, wear parts |

| Notes | Prone to chipping; requires sharp tooling and controlled feed rates | Excellent for high-tolerance features; anodizing compatible | High rigidity; suitable for load-bearing; weldable | Good impact resistance; post-machining sanding often needed | Requires moisture conditioning; excellent wear resistance |

All materials are compatible with multi-axis CNC platforms, enabling complex 3D contours and precise through-holes, slots, and undercuts. For Lucite and other thermoplastics, machining parameters such as spindle speed, feed rate, and tool geometry are optimized to minimize melting or cracking. In tight-tolerance work, environmental control (temperature and humidity) is critical—especially for hygroscopic materials like Nylon.

Honyo Prototype leverages high-precision CNC systems with in-process probing and post-machining CMM inspection to ensure conformance to geometric dimensioning and tolerancing (GD&T) specifications across all materials.

From CAD to Part: The Process

Honyo Prototype executes custom lucite (optical-grade acrylic/PMMA) projects through a rigorously controlled five-stage workflow designed for precision, speed, and manufacturability. This process eliminates common prototyping delays while ensuring optical clarity and dimensional accuracy critical for display, medical, or architectural applications.

CAD Upload & Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SOLIDWORKS) via our secure portal. Our system performs immediate automated validation against geometric constraints for lucite fabrication, checking for minimum wall thickness (≥1.5mm), draft angles (≥1° for molded parts), and feature feasibility. Files failing validation trigger specific error reports with actionable corrections, avoiding ambiguous rejections.

AI-Powered Quoting Engine

Validated CAD models enter our AI quoting system, which analyzes 18+ technical parameters including part volume, surface finish requirements (optical polish vs. matte), tolerance classes (ISO 2768-mK standard baseline), and secondary operations. The algorithm cross-references real-time material costs from our Lucite® Global supply chain database and machine utilization rates, generating a firm quote within 90 minutes. Historical data shows 92% quote accuracy versus final production cost due to embedded DFM logic.

DFM Integration & Engineering Review

All quotes include a DFM report highlighting critical manufacturability insights:

Stress concentration zones requiring radii adjustments to prevent cracking during machining

Recommended kerf compensation for laser cutting (typically +0.1mm)

Optimal nesting patterns to minimize material waste (average 15% savings)

Our engineers conduct mandatory virtual reviews for projects requiring tight tolerances (<±0.05mm) or optical clarity certifications, collaborating with clients to resolve conflicts before tooling. This phase reduces revision cycles by 70% compared to industry averages.

Precision Production Execution

Approved designs move to dedicated acrylic work cells with environmental controls (22°C ±1°C, 45% RH) to prevent warpage. Process selection is material-optimized:

| Process | Thickness Range | Tolerance | Edge Finish |

|————-|———————|—————|—————–|

| CNC Machining | 3mm – 150mm | ±0.025mm | Mirror polish achievable |

| Laser Cutting | 1.5mm – 20mm | ±0.1mm | Slight frosting (polishable) |

| Thermoforming | 2mm – 10mm | ±0.5mm | Requires post-forming polish |

All parts undergo in-process metrology using Zeiss coordinate measuring machines, with first-article inspection reports provided. Critical optical components receive ASTM D1003 haze testing.

Certified Delivery & Traceability

Finished components ship in anti-static, humidity-controlled packaging with custom foam cradles to prevent micro-scratches. Each shipment includes:

Material certification (Lucite® OP3, Plexiglas® G, or equivalent)

Dimensional conformance report against client’s GD&T callouts

Batch-specific optical clarity data (transmittance ≥92% @ 550nm)

Standard lead time is 7-10 business days from CAD approval, with expedited 72-hour options for sub-10 part quantities. All projects include digital twin records for full production traceability.

This integrated workflow ensures lucite components meet stringent optical and structural requirements while maintaining Honyo’s 99.2% on-time delivery rate. Clients receive engineering-grade parts without the iteration cycles typical of conventional acrylic fabrication services.

Start Your Project

Looking for custom lucite components? Contact Susan Leo at [email protected] to discuss your project requirements. With our advanced manufacturing capabilities and quality control at our Shenzhen factory, Honyo Prototype delivers precision-engineered lucite solutions tailored to your specifications. From prototyping to production, we ensure fast turnaround and consistent quality. Reach out today to request a quote or sample.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.