Contents

Manufacturing Insight: Custom Enclosure Solutions

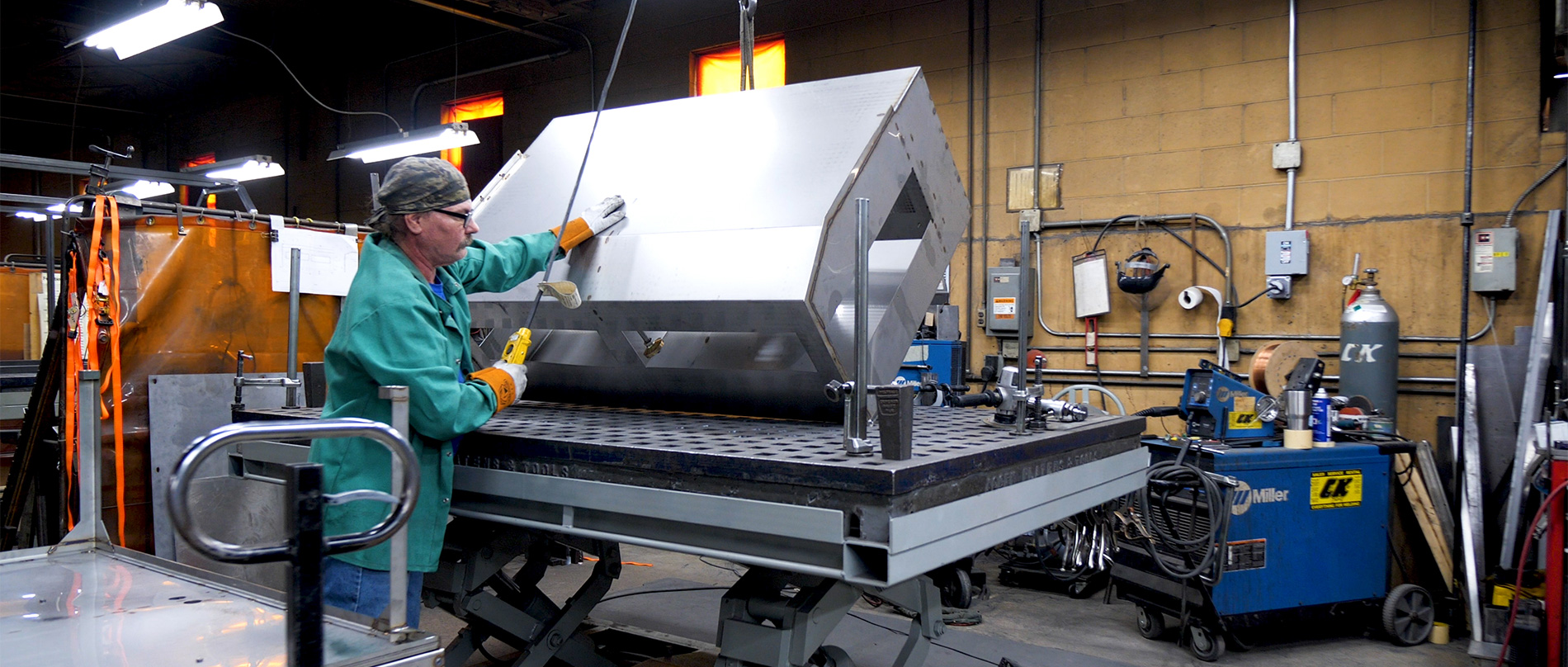

Precision Custom Enclosure Solutions Engineered for Mission-Critical Applications

Honyo Prototype delivers industry-leading custom enclosure solutions where dimensional accuracy, material integrity, and rapid turnaround are non-negotiable. Our advanced CNC machining capabilities form the cornerstone of this service, enabling the production of complex metal and engineering-grade polymer enclosures to exacting tolerances. Utilizing state-of-the-art 3-, 4-, and 5-axis milling and turning centers, we consistently achieve ±0.005mm precision while managing critical tolerance stack-ups inherent in multi-component assemblies. This ensures seamless integration of PCBs, connectors, and thermal management systems within demanding operational environments.

Material versatility is central to our approach. Whether your application requires the EMI shielding of aluminum 6061-T6, the corrosion resistance of stainless steel 316L, or the lightweight durability of polycarbonate, our machining processes are optimized for structural integrity and surface finish consistency. We prioritize manufacturability from the earliest design stages, providing actionable DFM feedback to eliminate cost drivers and accelerate time-to-prototype.

Accelerate your development cycle with Honyo’s Online Instant Quote platform. Engineers and procurement teams can upload STEP or IGES files, specify materials and quantities, and receive a detailed, binding quotation within hours—not days. This transparency streamlines sourcing for low-volume production and functional prototypes, allowing you to maintain momentum without compromising on quality or precision.

| Key Capability | Technical Specification | Application Benefit |

|---|---|---|

| Dimensional Accuracy | ±0.005mm typical | Ensures perfect component fit and EMI gasket sealing |

| Material Range | Metals, Composites, Polymers | Supports thermal, structural, and regulatory requirements |

| Lead Time (Prototype) | As low as 5 business days | Reduces time-to-test for critical design validation |

| Max Work Envelope | 1000 x 600 x 500 mm | Accommodates large-scale industrial enclosures |

Technical Capabilities

Custom enclosure solutions at Honyo Prototype are engineered to meet high-precision requirements across diverse industrial applications. These enclosures are manufactured using advanced 3, 4, and 5-axis CNC milling and precision turning processes, ensuring complex geometries and tight tolerances down to ±0.0005” (0.0127 mm). Multi-axis machining enables undercuts, angled surfaces, and intricate internal features without the need for secondary operations, improving accuracy and reducing lead times. Our turning capabilities support both external and internal diameter precision for cylindrical components, often integrated into enclosure housings, mounting flanges, or sealing interfaces.

We support a range of engineering-grade materials including aluminum (6061-T6, 7075-T6), stainless and carbon steel (303, 304, 4140), and high-performance thermoplastics such as ABS and nylon (PA6, PA66). Aluminum offers an optimal strength-to-weight ratio and excellent thermal and electrical conductivity, ideal for lightweight electronic enclosures. Steel provides superior durability and EMI shielding for rugged environments. ABS delivers good impact resistance and machinability for non-structural housings, while nylon offers low friction, chemical resistance, and electrical insulation for moving or high-wear components.

All enclosures are inspected using coordinate measuring machines (CMM) and optical comparators to validate dimensional compliance. Surface finishes, anodizing (Type II & III), passivation, and custom coatings are available per project requirements.

| Feature | Specification Details |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (Swiss and Mill-Turn) |

| Typical Tolerances | ±0.0005” (0.0127 mm); tighter tolerances achievable with special process control |

| Standard Materials | Aluminum (6061-T6, 7075-T6), Steel (303, 304, 4140), ABS, Nylon (PA6, PA66) |

| Material Properties | Aluminum: Lightweight, conductive; Steel: High strength, EMI shielding; ABS: Impact-resistant; Nylon: Low friction, chemical-resistant |

| Surface Finishes | As-machined, bead blast, anodize (Type II clear/dyed, Type III hardcoat), passivation, powder coating |

| Inspection & Quality | First-article inspection (FAI), CMM, optical comparators, GD&T-compliant reporting |

| Lead Time (Typical) | 7–15 business days, based on complexity and finishing requirements |

| Common Applications | Industrial control enclosures, medical device housings, aerospace components, test fixtures, robotics |

From CAD to Part: The Process

Honyo Prototype delivers custom enclosure solutions through a streamlined, technology-enhanced workflow designed for speed, accuracy, and manufacturability. The process begins when a client uploads their 3D CAD model to our secure online portal. We accept industry-standard formats including STEP, IGES, Parasolid, and native files from SolidWorks, Creo, and Fusion 360. Our system immediately performs an initial validation check for geometry integrity, unit consistency, and file completeness to prevent downstream delays.

The validated CAD model then enters our proprietary AI-driven quoting engine. This system analyzes over 200 geometric and material parameters—including wall thickness distribution, feature complexity, draft angles, and surface finish requirements—to generate a preliminary cost estimate and lead time within minutes. Crucially, this is not a fully automated quote; our manufacturing engineers review the AI output to contextualize factors like material availability, secondary operation requirements, and historical production data, ensuring the quote reflects real-world feasibility.

Following client acceptance of the quote, the project advances to Design for Manufacturability (DFM) analysis. Our engineering team conducts a rigorous technical review focused on enclosure-specific challenges such as EMI shielding integration, thermal management pathways, gasket compression zones, and assembly sequence optimization. We provide actionable feedback through annotated 3D markups and a prioritized revision list, collaborating directly with the client’s design team to resolve critical issues while preserving functional intent. This phase typically resolves 95% of potential production risks before tooling begins.

Approved designs move to production using our integrated digital manufacturing ecosystem. Enclosures are fabricated via precision CNC machining for metals (aluminum, steel, brass) or advanced injection molding for engineering plastics (ABS, PC, PPO), with in-house capabilities for finishing processes including anodizing, powder coating, and silk screening. Every component undergoes real-time process monitoring with IoT-enabled machinery, and first-article inspections verify critical dimensions against the original CAD per ASME Y14.5 standards.

Final delivery includes comprehensive documentation: a traceability report linking serial numbers to production batches, material certifications, and dimensional inspection data. We manage global logistics with DDP (Delivered Duty Paid) options and provide real-time shipment tracking. Typical lead times from CAD approval to delivery are maintained through our capacity forecasting system:

| Material Type | Prototype Lead Time | Low-Volume Production Lead Time |

|---|---|---|

| Aluminum (CNC) | 5-7 business days | 10-12 business days |

| Engineering Plastics (Molded) | 10-12 business days | 18-22 business days |

| Sheet Metal | 7-9 business days | 14-16 business days |

Throughout this workflow, Honyo maintains ISO 9001-certified quality management practices with embedded checkpoints at each transition phase. Our closed-loop feedback system captures production insights to continuously refine both the AI quoting algorithm and DFM guidelines, ensuring each iteration delivers greater value to the client. This end-to-end control guarantees enclosures meet stringent requirements for structural integrity, environmental sealing, and aesthetic quality while minimizing time-to-market.

Start Your Project

Looking for custom enclosure solutions tailored to your exact specifications? Partner with Honyo Prototype for precision-manufactured enclosures built to meet the highest industry standards. Our dedicated team ensures rapid prototyping, scalable production, and consistent quality—all from our state-of-the-art factory in Shenzhen.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Let’s bring your enclosure concept from design to reality—efficiently and reliably.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.