Contents

Manufacturing Insight: Custom Cylinder Head

Precision Custom Cylinder Heads Engineered for Peak Performance

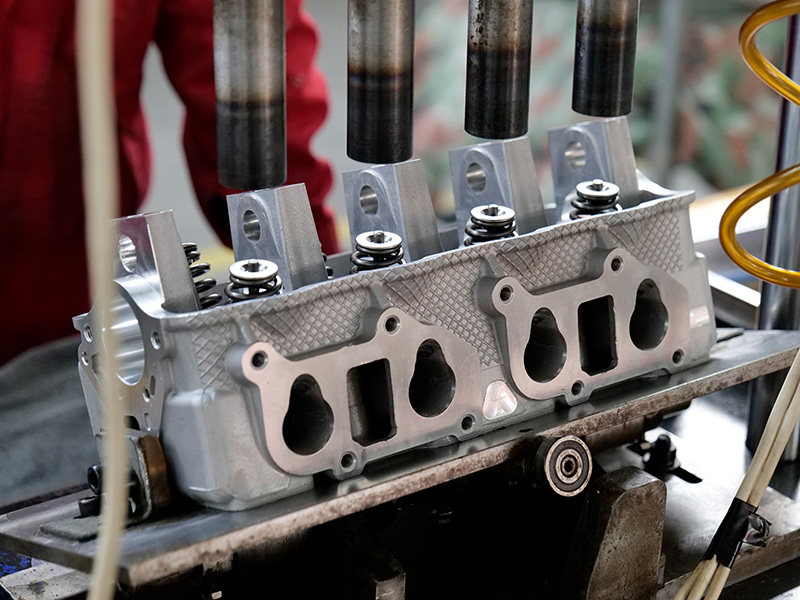

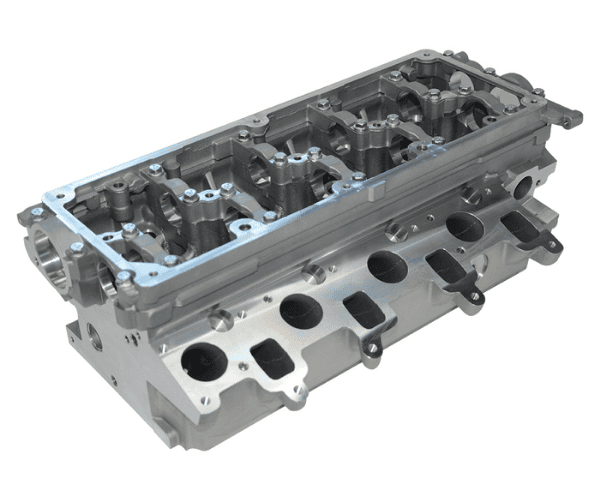

At Honyo Prototype, we specialize in delivering mission-critical custom cylinder heads through advanced CNC machining capabilities tailored for high-performance automotive, motorsport, and industrial engine applications. Our engineering team leverages state-of-the-art 5-axis CNC centers and stringent quality protocols to transform complex CAD models into precision-machined components with tolerances held to ±0.0002 inches. This ensures optimal combustion efficiency, thermal management, and structural integrity for demanding operational environments—whether supporting OEM R&D initiatives or low-volume aftermarket production.

Material selection is foundational to performance, and we routinely machine cylinder heads from aerospace-grade aluminum alloys (e.g., 356-T6, 2618), cast iron, and specialty nickel-based superalloys. Each component undergoes rigorous in-process metrology, including CMM validation of critical features such as valve seat concentricity, port geometry, and coolant passage integrity. Our process eliminates the delays inherent in traditional supply chains by integrating design consultation, rapid prototyping, and scalable production within a single workflow.

Accelerate your development timeline with Honyo’s Online Instant Quote platform. Upload your STEP or IGES files to receive a detailed manufacturability analysis and competitive pricing within hours—not days—enabling faster iteration cycles and reduced time-to-test for your next-generation engine program.

| Key Capability | Specification | Application Impact |

|---|---|---|

| Geometric Complexity | 5-axis simultaneous machining | Optimized port flow, custom chamber designs |

| Material Versatility | Aluminum, cast iron, Inconel, titanium alloys | Thermal stability under extreme loads |

| Dimensional Accuracy | ±0.0002″ (5µm) on critical sealing surfaces | Reduced head gasket failures |

| Lead Time | Prototype: 7–10 business days | Rapid validation for dyno testing |

Partner with Honyo Prototype to convert engineering intent into high-fidelity cylinder heads that meet the uncompromising standards of modern powertrain innovation. Initiate your project with confidence using our Online Instant Quote system—where precision engineering meets operational agility.

Technical Capabilities

Custom cylinder heads require high-precision manufacturing to ensure optimal engine performance, sealing integrity, and thermal management. These components are typically produced using advanced 3-axis, 4-axis, and 5-axis CNC milling and turning operations to achieve complex geometries, intricate coolant and intake/exhaust porting, and precise valve seat machining. Tight tolerances—often within ±0.005 mm to ±0.025 mm—are maintained throughout critical features such as valve guides, spark plug bores, and port contours.

The choice of material depends on the application: aluminum is common for lightweight performance engines, steel is used for high-stress or high-temperature testing fixtures, and engineering plastics like ABS and nylon may be used for rapid prototyping or non-metallic test models.

Below is a summary of technical specifications relevant to custom cylinder head manufacturing:

| Feature | Specification Details |

|---|---|

| Machining Processes | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning for bolt holes, register diameters, and sealing surfaces |

| Typical Tolerances | ±0.005 mm to ±0.025 mm on critical features; tighter tolerances achievable with inspection validation |

| Surface Finish | 0.8–3.2 µm Ra on sealing and mating surfaces; port surfaces may be left as-machined or polished |

| Materials | Aluminum (6061, 7075), Steel (4140, 4340), ABS (for prototypes), Nylon (for non-structural test models) |

| Aluminum Applications | Production and performance cylinder heads; excellent thermal conductivity and machinability |

| Steel Applications | Test fixtures, high-pressure validation components, or specialty high-durability builds |

| ABS Applications | Rapid prototyping, fit checks, port flow mock-ups; not for functional engine use |

| Nylon Applications | Non-metallic prototypes, thermal insulation testing; limited mechanical strength |

| Critical Machined Features | Intake/exhaust ports, valve seat sealing surfaces, spark plug bores, coolant jackets, cam bores |

| Secondary Operations | Deburring, precision cleaning, CMM inspection, leak testing (for metal units) |

| Equipment Used | High-speed CNC machining centers with probing, automated tool changers, and thermal compensation |

Manufacturing custom cylinder heads demands tight integration between CAD/CAM modeling, toolpath optimization, and in-process inspection to ensure dimensional accuracy across multi-axis operations. Honyo Prototype supports full-scale metallic and non-metallic fabrication with documented quality control for aerospace, motorsport, and industrial engine development programs.

From CAD to Part: The Process

Honyo Prototype Custom Cylinder Head Manufacturing Process

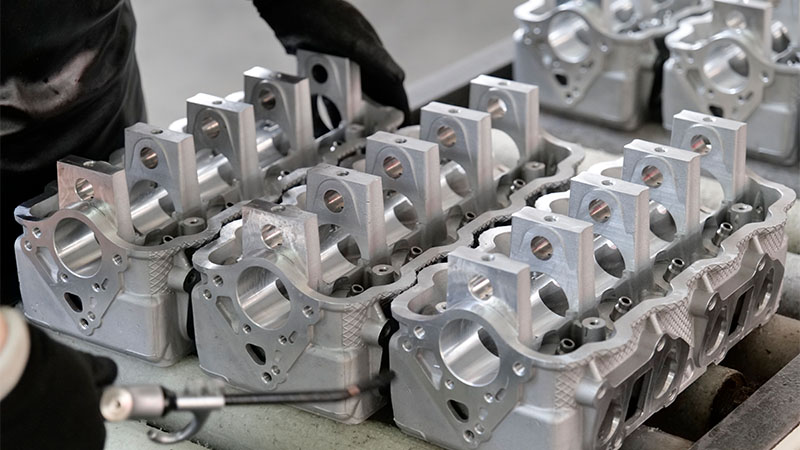

Honyo Prototype utilizes a structured, technology-driven workflow for custom cylinder head production, ensuring precision, manufacturability, and rapid turnaround. This process begins with client-provided CAD data and culminates in validated delivery, integrating AI efficiency with deep engineering expertise specific to high-integrity cast components.

The process initiates when the client uploads a complete 3D CAD model of the cylinder head design to Honyo’s secure portal. Accepted formats include STEP AP203/214, Parasolid, or native formats from主流 CAD systems (Siemens NX, CATIA, Creo). Critical metadata must accompany the upload: specified material grade (e.g., A356-T6 aluminum, Ni-resist iron), required certifications (e.g., ASTM B108, AMS 4110), pressure test parameters, and critical tolerance zones. Incomplete submissions trigger an automated notification for resubmission, preventing downstream delays.

Upon validated CAD receipt, Honyo’s proprietary AI quoting engine processes the geometry against real-time data streams. The engine analyzes volume, feature complexity (valve seat angles, coolant passage density, port curvature), material cost fluctuations, and current machine center utilization. It cross-references this with historical production data from over 12,000 cylinder heads manufactured. The output is a detailed quote within 4 business hours, specifying cost drivers, estimated lead time, and mandatory design constraints. Unlike generic quoting tools, Honyo’s AI flags inherent manufacturability risks at this stage, such as wall thickness below castability limits or undercuts requiring complex core pulls.

The Design for Manufacturability (DFM) phase follows quote acceptance and is the technical cornerstone of Honyo’s value. A dedicated manufacturing engineer performs a rigorous analysis using specialized casting simulation software (MAGMAsoft) and CNC pathing validation tools. This examines thermal gradients for hot tearing susceptibility, core assembly feasibility, machining accessibility for critical datums (valve guides, cam bores), and gaging strategy for final inspection. Common findings include recommendations for localized wall thickness adjustments, optimized gate/riser locations for directional solidification, or chamfer additions for deburring. The engineer provides a formal DFM report with annotated CAD markups and collaborates with the client to resolve conflicts—this iterative step typically reduces production scrap rates by 35-50% compared to non-DFM-reviewed designs.

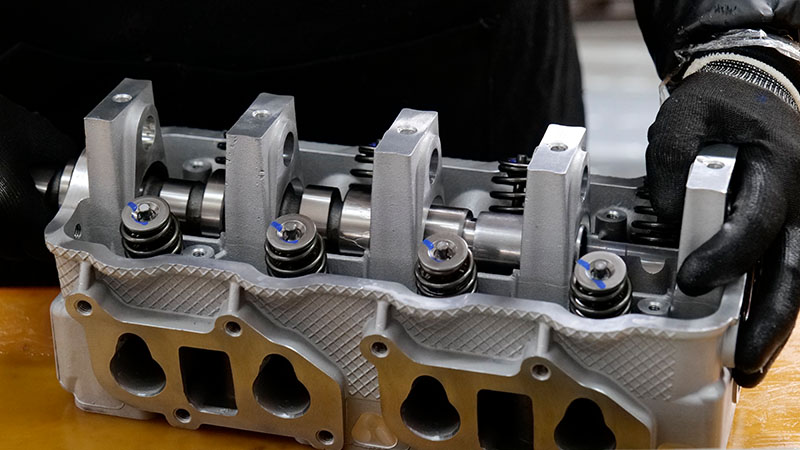

Production commences only after DFM sign-off. For aluminum heads, Honyo employs vacuum-assisted low-pressure casting (LPC) in proprietary sand molds, followed by heat treatment (T6) and precision machining on 5-axis DMG MORI centers. Critical operations include CNC milling of deck surfaces to ±0.025mm flatness, robotic drilling of coolant passages, and laser welding for hard-facing valve seats. Each head undergoes sequential in-process verification: CMM checks of primary datums after rough machining, pressure testing (typically 1.5x operating pressure per SAE J2816), and final validation of port flow coefficients. Cast iron heads utilize centrifugal casting with induction-melted Ni-resist alloys, followed by stress-relieving and specialized hard-milling.

Delivery encompasses physical shipment and comprehensive documentation. All cylinder heads ship with a full traceability package: material certs (including spectral analysis), heat treat logs, dimensional reports (highlighting critical-to-function features), pressure test records, and NDT results (X-ray per ASTM E505 Level 2 for porosity). Lead times are rigorously tracked against the AI-quoted schedule, with expedited options available for qualifying projects. Standard timelines for common configurations are shown below:

| Component Type | Material | Typical Lead Time (Weeks) | Key Variables Affecting Timeline |

|---|---|---|---|

| Aluminum V8 Head | A356-T6 | 6-8 | Complexity of integrated cam tunnel, port polishing requirements |

| Performance Inline-4 | 354-T6 | 5-7 | Thin-wall sections (<3mm), multi-angle valve seats |

| Diesel Iron Head | Ni-Resist D5 | 10-12 | Core assembly complexity, mandatory MPI after machining |

This integrated process ensures Honyo delivers cylinder heads meeting stringent automotive durability standards while minimizing client time-to-test. The closed-loop system—from AI-driven quoting through validated delivery—provides transparency and mitigates the geometric and metallurgical risks inherent in cylinder head prototyping. Clients receive not just a component, but a manufacturability-validated asset ready for dyno validation.

Start Your Project

Looking for a custom cylinder head solution tailored to your specifications? Partner with Honyo Prototype for precision-engineered components built to perform. Our manufacturing facility in Shenzhen ensures high-quality production with fast turnaround times.

Contact Susan Leo today at [email protected] to discuss your project requirements and get a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.