Contents

Manufacturing Insight: Custom Cut Metal Shapes

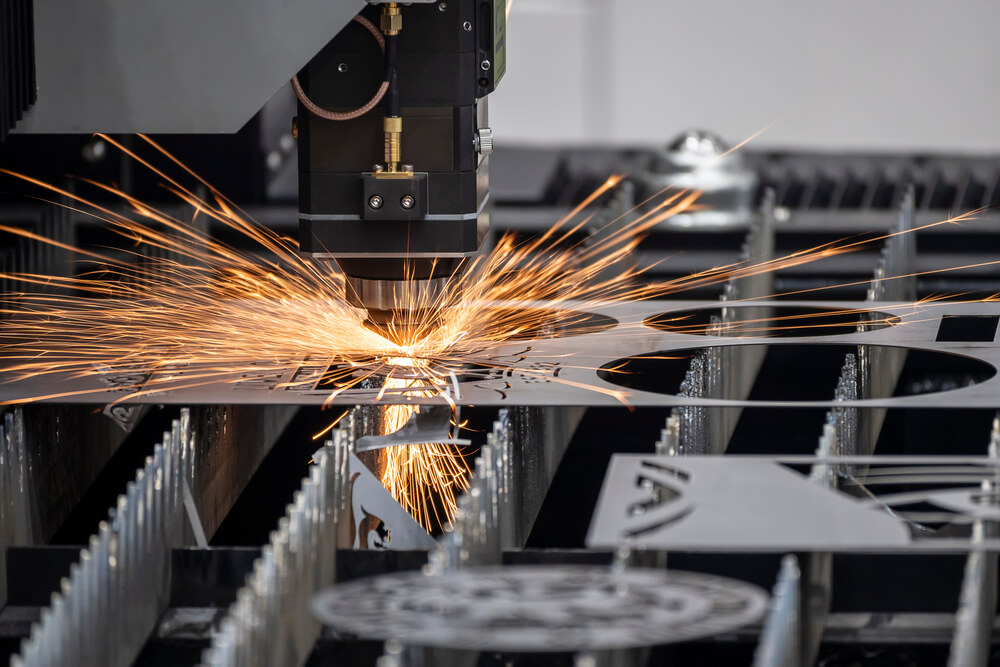

Precision Custom Cut Metal Shapes for Demanding Applications

Honyo Prototype delivers engineered excellence in sheet metal fabrication, specializing in custom cut metal shapes that meet exact dimensional and functional requirements. Our advanced capabilities span laser cutting, precision CNC punching, and waterjet machining, enabling tight tolerances down to ±0.005 inches across diverse materials including aluminum, stainless steel, brass, and specialty alloys. We support complex geometries, intricate contours, and high-mix/low-volume production runs typical in aerospace, medical device, and industrial equipment prototyping. Every component undergoes rigorous in-process inspection to ensure compliance with AS9100 and ISO 9001 standards, eliminating costly rework for your sub-contractors.

Accelerate your design-to-manufacturing workflow with Honyo’s Online Instant Quote platform. Upload your DXF, DWG, or STEP files to receive a detailed cost analysis and lead time estimate within minutes—no manual RFQ delays. Our system automatically evaluates material utilization, machine time, and secondary operations while providing real-time DFM feedback to optimize your design for manufacturability. This seamless integration between engineering intent and production execution reduces procurement cycles by up to 70%, allowing your team to iterate faster and meet aggressive development timelines. Partner with Honyo to transform CAD files into precision metal components with uncompromised quality and transparent, data-driven pricing.

Technical Capabilities

Custom cut metal shapes are precision-manufactured components produced using advanced fabrication techniques including laser cutting, bending, and welding. These processes enable tight tolerances, complex geometries, and high repeatability for both prototyping and production runs. While laser cutting and bending are primarily applicable to sheet metals, welding is used to assemble metal components. Non-metallic materials such as ABS and nylon can be laser cut but are generally not bent or welded using the same industrial methods as metals.

Below is a detailed technical specification table outlining the capabilities and material compatibility for each process:

| Process | Material Compatibility | Thickness Range | Tolerance (Typical) | Surface Finish | Additional Notes |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum, Steel, ABS, Nylon | 0.5 mm – 25 mm | ±0.1 mm | Smooth, oxide-free (metals); sealed edges (plastics) | High precision; minimal burr; nitrogen or oxygen assist depending on material |

| Bending | Aluminum, Steel | 0.8 mm – 6 mm (sheet) | ±0.2° angular / ±0.1 mm linear | As-is from forming; may show tool marks | Requires bend allowances; minimum flange length and bend radius apply |

| Welding | Aluminum, Steel | 1 mm – 20 mm | ±0.5 mm (joint fit-up) | As-welded, ground, or polished | MIG, TIG, or spot welding used; post-weld machining or finishing available |

Notes:

Aluminum: Grade 5052, 6061 commonly used for forming and welding; excellent corrosion resistance and lightweight properties.

Steel: Mild steel (e.g., A36) and stainless steel (e.g., 304, 316) suitable for structural and industrial applications.

ABS & Nylon: Limited to laser cutting only; not suitable for bending or welding in standard metal fabrication workflows. Ideal for insulators, jigs, or non-structural components.

All laser cut parts can include tab-and-slot features for assembly without fasteners.

Bending is performed using CNC press brakes with adjustable tooling for various radii and angles.

Welding procedures follow AWS D1.1 or equivalent standards, with optional certification and inspection reports.

These specifications support rapid prototyping and low-to-mid volume production with full traceability and quality control.

From CAD to Part: The Process

Honyo Prototype employs a rigorously structured workflow for custom cut metal shapes designed to maximize efficiency, minimize errors, and ensure on-time delivery for industrial clients. Our integrated process eliminates traditional handoffs between quoting, engineering, and production teams through digital continuity.

CAD Upload and System Validation

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, DWG, DXF) via our secure customer portal. The system performs immediate automated validation checks for file integrity, unit consistency, and geometric completeness. Invalid submissions trigger an instant notification with specific error details, preventing downstream delays. Validated files enter the quoting pipeline with full geometry retention for precise analysis.

AI-Powered Quoting with Embedded DFM

Our proprietary AI engine processes the CAD geometry alongside real-time shop floor data including material availability, machine utilization, and labor rates. Crucially, this phase integrates preliminary Design for Manufacturability analysis, identifying potential issues like non-standard tolerances, kerf compensation needs, or material waste hotspots before quote generation. The resulting quote provides exact pricing, lead time, and a preliminary DFM report highlighting actionable recommendations—all within 2 business hours for standard geometries. This eliminates the common industry disconnect between quoted assumptions and manufacturability.

Engineer-Validated DFM and Client Collaboration

Critical complex geometries or materials trigger escalation to our senior manufacturing engineering team. Engineers perform deep-dive DFM analysis using specialized nesting and simulation software, verifying laser/waterjet path optimization, heat-affected zone risks, and secondary operation requirements. Clients receive a formal DFM report with annotated visuals and modification suggestions. We mandate client sign-off on all DFM adjustments prior to production commencement, ensuring alignment on quality expectations and preventing costly revisions later.

Precision Production Execution

Approved designs move directly to production scheduling with zero manual re-entry. Our CNC cutting cells (fiber laser, CO2 laser, and abrasive waterjet) receive machine-ready files containing optimized toolpaths and material-specific parameters. All cuts undergo in-process verification:

First-article inspection per AS9102 for aerospace/medical clients

In-line metrology measuring critical dimensions after cutting

Real-time material tracking via barcoded work orders

Secondary operations like bending, tapping, or surface treatment follow seamlessly within our facility under the same quality system.

Quality-Controlled Delivery

Final inspection includes full first-article reports (FAIR) with CMM data where specified, material certification traceability, and dimensional verification against the original CAD. Parts ship in custom protective packaging with serialized documentation. Standard lead times vary by technology and complexity as shown below:

| Process | Typical Lead Time | Max Thickness (Mild Steel) | Tolerance Capability |

|---|---|---|---|

| Fiber Laser | 3-5 business days | 25mm | ±0.1mm |

| CO2 Laser | 4-6 business days | 30mm | ±0.15mm |

| Abrasive Waterjet | 5-7 business days | 150mm | ±0.25mm |

All shipments include digital quality records accessible via client portal. We maintain 98.7% on-time delivery performance for custom cut orders through our integrated workflow, with expedited options available for urgent requirements. This closed-loop system ensures clients receive precisely specified parts with full traceability from digital design to physical delivery.

Start Your Project

Looking for precision custom cut metal shapes tailored to your exact specifications? Honyo Prototype delivers high-quality, CNC-accurate metal fabrication from our state-of-the-art factory in Shenzhen. Whether you need prototypes or low-volume production, we support a wide range of materials and finishes to meet your engineering and design requirements.

Contact Susan Leo today at [email protected] to discuss your project and receive a fast, competitive quote. Let us be your trusted partner for reliable, on-time metal part manufacturing.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.