Introduction: Navigating the Global Market for custom copper

In an increasingly interconnected global market, sourcing custom copper solutions can pose significant challenges for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The diversity of applications—from construction materials to intricate designs for home decor—necessitates a thorough understanding of the various types of custom copper products available. This guide aims to illuminate the complexities of sourcing custom copper by providing insights into product specifications, supplier vetting processes, cost considerations, and market trends.

With a focus on empowering international buyers, this comprehensive resource details the essential factors that influence purchasing decisions. Buyers will learn how to identify reputable suppliers, evaluate product quality, and navigate pricing structures effectively. Additionally, the guide explores the unique cultural and market dynamics in key regions, such as Vietnam and Saudi Arabia, ensuring that buyers can tailor their sourcing strategies to local needs and preferences.

By equipping B2B buyers with actionable insights and expert knowledge, this guide serves as an invaluable tool for making informed decisions in the custom copper market. Whether you are seeking standard products or bespoke designs, understanding the landscape of custom copper will enable you to optimize your procurement process and enhance your competitive edge in the marketplace.

Understanding custom copper Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Copper Sheets | Available in various thicknesses and sizes; can be cut to order | Construction, architecture, signage | Pros: Versatile, easy to work with; Cons: Price can vary significantly based on specifications. |

| Copper Extrusions | Custom shapes and profiles; excellent for structural integrity | Electrical components, automotive parts | Pros: High strength-to-weight ratio; Cons: Longer lead times for specialized profiles. |

| Handcrafted Copper Fixtures | Unique designs; often artisanal; made for aesthetics and function | Interior design, hospitality, custom homes | Pros: Distinctive and high-quality; Cons: Generally more expensive due to craftsmanship. |

| Copper Tubing | Flexible, available in various diameters; suitable for plumbing | HVAC, plumbing, refrigeration | Pros: Corrosion-resistant, durable; Cons: Requires specific fittings and tools for installation. |

| Custom Copper Stills | Tailored designs for distillation; often handcrafted | Beverage production, artisanal distilleries | Pros: High-quality materials; Cons: Custom builds can be costly and time-consuming. |

What Are the Characteristics of Custom Copper Sheets?

Custom copper sheets are highly versatile and can be produced in a range of thicknesses and sizes to meet specific project requirements. These sheets can be cut to order, allowing for tailored applications in construction, architecture, and signage. When purchasing, consider the intended use, as the thickness and finish can significantly impact performance and aesthetics. Additionally, pricing can vary based on the specifications, so it’s essential to obtain quotes from multiple suppliers.

How Do Copper Extrusions Stand Out in Custom Applications?

Copper extrusions are designed to create specific shapes and profiles, providing excellent structural integrity for various applications. Commonly used in electrical components and automotive parts, these extrusions are valued for their high strength-to-weight ratio. Buyers should be aware that while extrusions can be customized, the lead times for specialized profiles may be longer than standard products. It’s crucial to assess the urgency of your project and plan accordingly.

Why Choose Handcrafted Copper Fixtures for Your Business?

Handcrafted copper fixtures offer a unique blend of aesthetics and functionality, making them ideal for interior design projects, hospitality venues, and custom homes. These fixtures are often produced by skilled artisans, resulting in distinctive designs that stand out. While the quality and artistry justify the higher price point, buyers should evaluate their budget and the potential return on investment that unique fixtures can provide in attracting customers or enhancing property value.

What Are the Benefits of Using Copper Tubing?

Copper tubing is a popular choice for plumbing, HVAC, and refrigeration applications due to its flexibility and availability in various diameters. It is known for its corrosion resistance and durability, making it a reliable option for long-term use. However, buyers should consider the specific fittings and tools required for installation, as these can add to the overall project costs. Additionally, ensure compliance with local building codes when selecting copper tubing for plumbing applications.

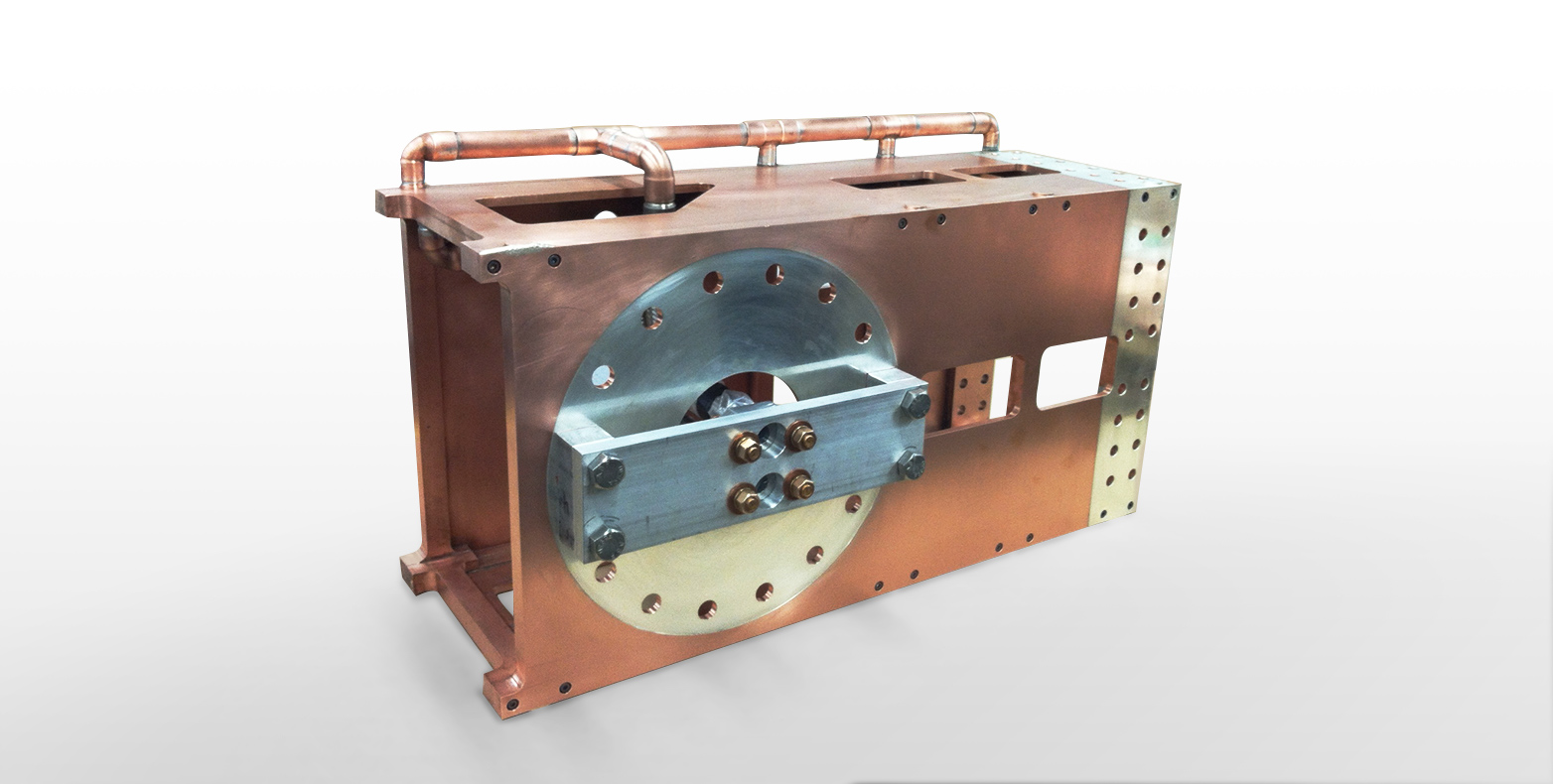

How Are Custom Copper Stills Tailored for Distillation?

Custom copper stills are specifically designed for distillation processes, particularly in beverage production and artisanal distilleries. These stills can be tailored to meet the unique requirements of each distillery, ensuring optimal performance and quality. While the high-quality materials used in custom stills contribute to their effectiveness, buyers should be prepared for potentially higher costs and longer lead times associated with custom builds. It’s essential to work closely with manufacturers to ensure that the final product meets all necessary specifications and production goals.

Key Industrial Applications of custom copper

| Industry/Sector | Specific Application of custom copper | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Custom copper roofing and gutters | Enhanced durability and aesthetic appeal | Assess local climate conditions and architectural compatibility. |

| Manufacturing | Copper heat exchangers and components | Improved efficiency in thermal management | Ensure compliance with international quality standards. |

| Distillation | Custom copper stills for beverage production | Superior quality of distilled products | Verify craftsmanship and material purity for food safety. |

| Art and Design | Handcrafted copper fixtures and installations | Unique, high-value decorative elements | Seek artisans with proven expertise in custom copperwork. |

| Electrical Engineering | Custom copper wiring and connectors | Enhanced conductivity and reliability | Confirm specifications for electrical standards and safety. |

How Is Custom Copper Used in Construction Projects?

In the construction industry, custom copper is primarily utilized for roofing and gutter systems. The material’s resistance to corrosion and its natural aesthetic qualities make it an excellent choice for both functional and decorative applications. Copper roofs can last over 50 years, providing long-term value to builders and homeowners alike. International buyers, particularly from regions with extreme weather like the Middle East, should consider sourcing copper that meets local building codes and standards for durability.

What Are the Benefits of Custom Copper in Manufacturing?

Manufacturers often employ custom copper components, such as heat exchangers, due to their superior thermal conductivity. This enhances efficiency in processes like cooling and heating, ultimately reducing energy costs. For B2B buyers in regions like South America, where energy efficiency is critical, sourcing high-quality copper that meets international standards can lead to significant operational savings. It is essential to evaluate suppliers based on their ability to deliver consistent quality and timely shipments.

Why Is Custom Copper Important for Distillation Industries?

In the distillation sector, particularly for spirits production, custom copper stills are favored for their ability to enhance the flavor and quality of the distilled product. The material’s properties allow for better heat distribution and the removal of undesirable compounds during the distillation process. Buyers, especially from Europe and Africa, should prioritize suppliers who can guarantee the purity of the copper used in their stills, as this directly impacts the safety and quality of the final product.

How Can Custom Copper Add Value to Art and Design?

In the art and design sector, custom copper is used to create unique fixtures and installations that elevate the aesthetic value of spaces. From handcrafted lighting to bespoke furniture pieces, custom copper works are seen as high-value art. B2B buyers looking for distinctive design elements should seek artisans who specialize in custom copper creations, ensuring that the craftsmanship aligns with their brand’s vision and quality standards.

What Are the Key Considerations for Custom Copper in Electrical Engineering?

In electrical engineering, custom copper wiring and connectors are essential for applications requiring high conductivity and reliability. The material’s excellent electrical properties make it a preferred choice for various electronic components. International buyers must ensure that the copper sourced complies with local electrical standards and safety regulations, as this can affect the performance and safety of electrical systems. Sourcing from reputable manufacturers with certifications is crucial for maintaining high-quality electrical infrastructure.

3 Common User Pain Points for ‘custom copper’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Custom Copper Materials

The Problem: Many B2B buyers, particularly in industries like construction, plumbing, and art, struggle with sourcing high-quality custom copper materials. They often encounter issues such as inconsistent quality, delays in delivery, and a lack of transparency regarding the sourcing practices of suppliers. This can lead to project delays, increased costs, and frustration, as buyers may end up with materials that do not meet their specifications or quality standards.

The Solution: To mitigate these issues, B2B buyers should prioritize establishing strong relationships with reputable suppliers who are transparent about their sourcing and manufacturing processes. Begin by conducting thorough research to identify suppliers with a proven track record in delivering high-quality copper products. Look for certifications or testimonials that affirm their quality standards. Additionally, consider visiting suppliers’ facilities, if feasible, to evaluate their production methods firsthand. Creating a detailed specification document outlining your specific requirements—such as the grade of copper, dimensions, and finish—will ensure that both parties are aligned on expectations. Finally, implement a robust communication strategy to keep all stakeholders informed throughout the sourcing process, minimizing the risk of misunderstandings or delays.

Scenario 2: Challenges in Customization and Design Specifications

The Problem: Custom copper products often require precise design specifications, and many buyers face challenges in articulating their needs effectively. This can lead to miscommunication with manufacturers, resulting in products that do not meet the buyer’s expectations. For instance, architects and designers might struggle to convey intricate design details, leading to costly revisions and delays in project timelines.

The Solution: To address this pain point, B2B buyers should invest time in developing comprehensive design briefs that clearly outline their vision. This includes sketches, detailed descriptions, and any relevant dimensions. Utilizing 3D modeling software can also be beneficial in creating visual representations of the desired product, allowing for better communication with manufacturers. Furthermore, engaging in collaborative workshops with suppliers can enhance understanding and creativity, ensuring that both parties can explore innovative solutions. Regular check-ins during the design process will facilitate timely feedback and adjustments, ultimately leading to a final product that aligns with the buyer’s expectations.

Scenario 3: Understanding Regulatory Compliance and Industry Standards

The Problem: Another significant challenge for B2B buyers dealing with custom copper is navigating the complex landscape of regulatory compliance and industry standards. Different regions may have varying regulations regarding materials used in construction, plumbing, or artistic applications. Buyers may find themselves at risk of legal issues or project delays if they inadvertently use materials that do not comply with local codes or industry standards.

The Solution: To effectively manage compliance concerns, B2B buyers should familiarize themselves with the relevant regulations in their respective markets. This involves consulting with local regulatory bodies or industry associations to gain insights into the specific standards that apply to custom copper products. Additionally, buyers should work closely with suppliers who are knowledgeable about compliance and can provide documentation or certifications that verify adherence to industry standards. Incorporating compliance checks into the project timeline will ensure that all materials are vetted before use. Lastly, consider establishing a compliance checklist that includes all necessary regulations, certifications, and testing requirements, streamlining the process of ensuring that your custom copper products meet all necessary legal and industry standards.

Strategic Material Selection Guide for custom copper

What Are the Key Properties of Common Materials Used in Custom Copper?

When selecting materials for custom copper applications, it is essential to consider their properties, suitability, and compliance with industry standards. Here are four common materials used in custom copper fabrication, analyzed from a B2B perspective.

1. Copper Alloy C11000 (Electrolytic Tough Pitch Copper)

Key Properties: C11000 is known for its excellent electrical conductivity (up to 100% IACS), making it ideal for electrical applications. It has a melting point of approximately 1,984°F (1,085°C) and exhibits good corrosion resistance, particularly in non-oxidizing environments.

Pros & Cons: The primary advantage of C11000 is its high conductivity, which is crucial for electrical components. However, it can be more expensive than other copper alloys, and its softness may limit its use in high-stress applications. Manufacturing complexity is moderate, as it can be easily formed and welded.

Impact on Application: C11000 is suitable for applications involving electrical wiring, connectors, and components. Its compatibility with various media makes it a versatile choice.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with ASTM B370 standards. Familiarity with local sourcing and supply chain logistics is crucial to mitigate costs.

2. Copper Alloy C26000 (Brass)

Key Properties: C26000, commonly known as yellow brass, contains approximately 70% copper and 30% zinc. It provides good corrosion resistance and has a melting point around 1,740°F (950°C). Its moderate strength and ductility make it suitable for various applications.

Pros & Cons: C26000 is relatively cost-effective compared to pure copper and offers good machinability. However, it may not perform well in highly acidic environments. The manufacturing process can be complex due to its alloying elements, which may require specialized techniques.

Impact on Application: This alloy is often used in plumbing fittings, decorative items, and electrical components. Its compatibility with various media, including water and air, enhances its usability.

Considerations for International Buyers: Compliance with JIS H 3250 standards is important for buyers in Asia. Understanding local regulations regarding brass use in plumbing is also essential.

3. Copper-Nickel Alloy (CuNi)

Key Properties: Copper-nickel alloys, typically composed of 90% copper and 10% nickel, are known for their outstanding corrosion resistance, especially in marine environments. They have a melting point of approximately 2,200°F (1,204°C) and maintain good strength at elevated temperatures.

Pros & Cons: The primary advantage of CuNi alloys is their excellent resistance to biofouling and corrosion, making them ideal for marine applications. However, they are more expensive than standard copper alloys, and their manufacturing process can be complex due to the need for specialized welding techniques.

Impact on Application: These alloys are often used in shipbuilding, offshore structures, and heat exchangers due to their ability to withstand harsh environments.

Considerations for International Buyers: Buyers from Europe and South America should ensure compliance with DIN 17665 standards. Knowledge of marine regulations and environmental standards is also critical.

4. Copper Alloy C44300 (Admiralty Brass)

Key Properties: C44300, known as Admiralty brass, contains copper, zinc, and small amounts of tin and arsenic. It offers excellent resistance to corrosion in seawater and has a melting point of around 1,740°F (950°C).

Pros & Cons: This alloy is particularly advantageous for marine applications due to its resistance to dezincification and corrosion. However, it is less conductive than pure copper and can be more expensive. The manufacturing process may require additional steps to ensure quality.

Impact on Application: C44300 is commonly used in heat exchangers, ship fittings, and valves, making it suitable for various marine applications.

Considerations for International Buyers: Compliance with ASTM B111 standards is essential for buyers in the Middle East and Africa. Understanding local market preferences for marine-grade materials can also enhance procurement strategies.

Summary Table of Material Selection for Custom Copper

| Material | Typical Use Case for custom copper | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| C11000 | Electrical wiring and components | High electrical conductivity | Higher cost, limited stress use | High |

| C26000 | Plumbing fittings and decorative items | Cost-effective, good machinability | Poor performance in acidic environments | Medium |

| Copper-Nickel | Marine applications and heat exchangers | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| C44300 | Marine fittings and valves | Resistance to dezincification | Less conductive, higher cost | Medium |

This guide aims to equip B2B buyers with the necessary insights to make informed decisions regarding material selection for custom copper applications, ensuring compliance and suitability for their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for custom copper

What Are the Main Stages in the Manufacturing Process of Custom Copper?

The manufacturing of custom copper products involves several critical stages, each contributing to the final quality and functionality of the product.

-

Material Preparation: The process begins with sourcing high-grade copper, often in the form of sheets, bars, or coils. Suppliers should ensure that the copper meets specific standards for purity and conductivity, which are crucial for applications in industries like electronics and plumbing. Before fabrication, the copper is inspected for defects, and any necessary cutting or shaping is performed to prepare it for the next stage.

-

Forming Techniques: Once the material is ready, various forming techniques are employed. These can include methods like stamping, bending, and rolling, depending on the product specifications. Advanced techniques such as CNC machining may be utilized for precision components. Each method requires skilled labor and the right machinery to achieve the desired dimensions and tolerances.

-

Assembly: After forming, components may need to be assembled. This could involve soldering, welding, or riveting, depending on the design and intended use of the product. Attention to detail during assembly is crucial, as any misalignment can affect the product’s performance and longevity.

-

Finishing Processes: The final stage involves various finishing processes that enhance both the aesthetic and functional properties of the copper product. These can include polishing, coating, or patination, which not only improve appearance but also protect the metal from corrosion and wear. Quality control checks during this stage ensure that the final product meets the specified requirements.

What Quality Assurance Measures Are Essential for Custom Copper Manufacturing?

Quality assurance (QA) is vital in ensuring that custom copper products meet international standards and customer expectations.

-

International Standards Compliance: Many B2B buyers should look for suppliers that comply with international quality management standards, such as ISO 9001. This certification indicates that the supplier has established a quality management system that focuses on continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe or API (American Petroleum Institute) standards for oil and gas applications may also be relevant.

-

Quality Control Checkpoints: Effective QC involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to catch any defects early.

– Final Quality Control (FQC): A thorough examination of the finished product before it is shipped, ensuring it meets all specifications and standards. -

Common Testing Methods: Various testing methods are employed to verify product quality. These include non-destructive testing (NDT) techniques such as ultrasonic testing, which checks for internal flaws without damaging the product, and visual inspections to assess surface quality. Mechanical testing, such as tensile strength tests, may also be conducted to ensure the product can withstand its intended use.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial.

-

Conducting Audits: Buyers should consider conducting audits of potential suppliers. This can be done either in-person or remotely, assessing the manufacturing facilities, quality control processes, and adherence to industry standards. A comprehensive audit will provide insights into the supplier’s capabilities and commitment to quality.

-

Requesting Quality Reports: Suppliers should be able to provide detailed quality assurance reports, which outline their testing methods, results, and compliance with relevant standards. Reviewing these documents can help buyers assess whether the supplier meets their quality expectations.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and quality control systems. These services can conduct inspections at various stages of production and provide certification that can be crucial for international trade.

What Are the Unique Quality Control Considerations for International B2B Buyers?

When sourcing custom copper products from international suppliers, there are specific nuances to consider regarding quality control.

-

Cultural and Regulatory Differences: Buyers must be aware of the cultural and regulatory differences that may influence quality standards. For example, a supplier’s interpretation of quality may vary based on local regulations and industry practices. Understanding these differences is essential for setting clear expectations.

-

Logistics and Supply Chain Factors: International shipping can introduce risks such as damage or delays. Buyers should work with suppliers who have robust logistics and supply chain management systems in place to ensure products are delivered in optimal condition.

-

Post-Sale Support and Service: Quality assurance does not end with the delivery of the product. Buyers should consider suppliers who offer comprehensive post-sale support, including warranty services and technical assistance. This support can be crucial for addressing any issues that may arise after the purchase.

Conclusion

In summary, understanding the manufacturing processes and quality assurance practices for custom copper products is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, along with robust quality control measures and supplier verification methods, buyers can ensure they partner with reliable suppliers who deliver high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom copper’

Introduction

Sourcing custom copper products requires a strategic approach to ensure quality, cost-effectiveness, and supplier reliability. This guide serves as a practical checklist for B2B buyers navigating the procurement process, particularly those operating in diverse international markets. By following these steps, you can streamline your sourcing efforts and secure the best custom copper solutions for your business needs.

Step 1: Define Your Technical Specifications

Clearly outline your project requirements, including dimensions, material grade, and specific finishes. This step is critical as it sets the foundation for your procurement process and helps in communicating effectively with potential suppliers. Be specific about:

– Product Type: Sheets, bars, tubing, or custom shapes.

– Quality Standards: Industry-specific certifications or standards that must be met.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in custom copper products. Utilize online directories, industry associations, and trade shows to find reputable manufacturers. Pay attention to:

– Supplier Experience: Look for companies with a proven track record in delivering custom copper solutions.

– Client Testimonials: Seek feedback from previous clients to gauge reliability and quality.

Step 3: Evaluate Supplier Capabilities

Before making a commitment, assess the capabilities of potential suppliers. This includes their production capacity, technology, and craftsmanship. Focus on:

– Manufacturing Techniques: Ensure they employ advanced methods suitable for your custom requirements.

– Quality Assurance Processes: Inquire about their quality control measures to ensure product consistency.

Step 4: Request Samples and Prototypes

To validate the supplier’s ability to meet your specifications, request samples or prototypes of custom copper products. This step allows you to evaluate the quality and craftsmanship firsthand. Consider:

– Material Quality: Check for any defects or inconsistencies in the copper.

– Design Accuracy: Ensure the sample matches your specifications in dimensions and finish.

Step 5: Verify Certifications and Compliance

Confirm that your chosen supplier adheres to relevant industry standards and regulations. This is essential for ensuring product safety and quality. Look for:

– Certifications: ISO certifications, environmental compliance, and industry-specific standards.

– Documentation: Request documentation proving compliance with international regulations, particularly if exporting/importing.

Step 6: Negotiate Terms and Pricing

Engage in discussions regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to better pricing and favorable terms for both parties. Pay attention to:

– Minimum Order Quantities: Understand the supplier’s policies on minimum orders.

– Lead Times: Ensure that delivery timelines align with your project schedules.

Step 7: Establish a Communication Plan

Once you select a supplier, establish a clear communication plan. Open lines of communication are vital for addressing any concerns and ensuring smooth project execution. Focus on:

– Regular Updates: Set up a schedule for progress updates and feedback.

– Point of Contact: Designate a specific contact person for streamlined communication.

By following this checklist, B2B buyers can confidently navigate the complexities of sourcing custom copper, ensuring they select the right suppliers and secure high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for custom copper Sourcing

What Are the Key Cost Components in Custom Copper Sourcing?

When engaging in custom copper sourcing, understanding the various cost components is crucial for effective budgeting and financial planning. The primary cost elements include:

-

Materials: The price of copper fluctuates based on market conditions, quality, and availability. Premium-grade copper will naturally command a higher price, affecting the overall project cost.

-

Labor: Skilled labor is essential for custom copper fabrication. Labor costs can vary significantly based on geographic location, expertise, and the complexity of the design.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, equipment depreciation, and rent. Effective management of overhead can lead to cost savings.

-

Tooling: Custom designs often require specialized tooling and machinery. The initial investment in tools can be substantial but is amortized over the production run.

-

Quality Control (QC): Ensuring that the custom copper products meet specified quality standards involves additional costs. Robust QC processes safeguard against defects, which could lead to costly reworks or replacements.

-

Logistics: Transportation and shipping costs are significant, especially for international transactions. Factors like distance, shipping method, and urgency can influence logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. Understanding this margin can aid buyers in identifying competitive pricing.

How Do Price Influencers Affect Custom Copper Quotes?

Several factors can influence the pricing of custom copper products:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often benefit from economies of scale, leading to lower per-unit costs. Conversely, smaller orders may incur higher prices due to fixed costs.

-

Specifications and Customization: Highly customized products with intricate designs or specific dimensions can lead to increased costs. Buyers should be clear about their requirements to receive accurate quotes.

-

Materials Used: The choice of copper alloy and additional materials can significantly affect pricing. Buyers should weigh the benefits of higher-quality materials against their budget constraints.

-

Quality Certifications: Products that meet specific industry standards or certifications often come at a premium. This is particularly relevant for sectors requiring compliance with strict regulations.

-

Supplier Factors: The reputation, reliability, and location of the supplier can impact pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding the agreed-upon Incoterms in the contract is essential. They dictate who bears the shipping costs, insurance, and risk at different stages of the delivery process, affecting the total landed cost.

What Are Essential Tips for B2B Buyers in Custom Copper Procurement?

Navigating the complexities of custom copper sourcing requires strategic planning. Here are some actionable tips for international buyers:

-

Negotiation: Engage suppliers in discussions about pricing and terms. Leverage multiple quotes to establish a competitive landscape, and be prepared to negotiate on both price and payment terms.

-

Cost Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance, operational, and disposal costs. A lower initial price may lead to higher long-term costs.

-

Pricing Nuances for International Transactions: Be aware of currency fluctuations, tariffs, and taxes that can affect the final price. Buyers should also consider the impact of geopolitical factors on supply chains.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, preferential treatment, and improved service. Long-term partnerships can also facilitate smoother negotiations.

-

Clear Specifications: Provide detailed and precise specifications to avoid misunderstandings that can lead to costly changes or delays. Utilize visual aids or prototypes when possible.

Disclaimer on Indicative Prices

Prices for custom copper products are subject to change based on market conditions, material availability, and specific project requirements. Buyers should request formal quotes from suppliers to obtain accurate pricing tailored to their needs.

Alternatives Analysis: Comparing custom copper With Other Solutions

Understanding the Alternatives to Custom Copper Solutions

In the realm of industrial applications and bespoke designs, custom copper is often favored for its unique properties and aesthetic appeal. However, there are various alternative materials and solutions that can also meet the needs of B2B buyers. Understanding these alternatives is crucial for making an informed decision that aligns with specific project requirements and budget constraints.

Comparison Table

| Comparison Aspect | Custom Copper | Stainless Steel | Plastic Composites |

|---|---|---|---|

| Performance | Excellent thermal and electrical conductivity; corrosion-resistant. | Good strength; lower conductivity compared to copper. | Lightweight; varying strength depending on type. |

| Cost | Higher upfront cost; price varies by design and complexity. | Generally lower initial cost; varies by grade. | Often the most economical option; varies by type. |

| Ease of Implementation | Requires skilled artisans for custom designs; longer lead times. | Readily available; easier to fabricate. | Generally easy to mold and shape; rapid production. |

| Maintenance | Low maintenance; may require periodic polishing. | Low maintenance; resistant to corrosion. | Low maintenance but can degrade under UV exposure. |

| Best Use Case | High-end, bespoke applications requiring aesthetics and durability. | Industrial applications where strength is critical. | Cost-sensitive projects needing lightweight solutions. |

Exploring Stainless Steel as an Alternative to Custom Copper

Stainless steel is a popular alternative, particularly in industries where strength and durability are paramount. It offers good resistance to corrosion and requires minimal maintenance, making it a practical choice for many applications. However, stainless steel lacks the thermal and electrical conductivity of copper, which can be a significant drawback in specific applications like electrical components or heat exchangers. Additionally, while it can be more cost-effective upfront, the overall lifecycle cost can increase if specialized fabrication is needed.

Evaluating Plastic Composites for Specific Applications

Plastic composites are increasingly used in various industries due to their lightweight nature and cost-effectiveness. They can be molded into complex shapes easily, making them ideal for mass production and projects with tight budgets. However, they generally do not offer the same level of strength or thermal properties as custom copper. Additionally, certain types of plastic composites may degrade under UV exposure or extreme temperatures, limiting their applicability in outdoor or high-temperature environments.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between custom copper and its alternatives, B2B buyers should assess their specific project requirements, including performance needs, budget constraints, and desired aesthetic qualities. Custom copper excels in applications where conductivity, aesthetics, and durability are critical, while stainless steel may suit projects prioritizing strength and lower initial costs. Plastic composites present a viable option for projects focused on budget and weight but may fall short in performance aspects. By carefully weighing these factors, buyers can make informed decisions that align with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for custom copper

What Are the Key Technical Properties of Custom Copper That B2B Buyers Should Know?

When purchasing custom copper products, understanding the technical properties is essential for ensuring quality and suitability for specific applications. Here are some critical specifications to consider:

-

Material Grade

– Copper is categorized into various grades, each with distinct properties. Common grades include C11000 (electrical grade) and C26000 (brass). The choice of grade affects conductivity, corrosion resistance, and mechanical strength. For B2B buyers, selecting the appropriate grade is vital for applications like electrical wiring or plumbing, where performance standards are paramount. -

Tolerance

– Tolerance refers to the permissible limit of variation in dimensions. In custom copper manufacturing, tight tolerances ensure that components fit correctly during assembly, reducing the risk of malfunctions. For buyers, understanding tolerances is crucial in high-precision industries, such as aerospace and medical equipment, where even minor deviations can lead to significant operational issues. -

Thickness and Gauge

– The thickness of copper sheets and extrusions is typically measured in gauges, with lower numbers indicating thicker material. The choice of thickness impacts durability, weight, and cost. B2B buyers should consider the application’s structural requirements when selecting thickness, as this affects both performance and manufacturing costs. -

Conductivity

– Copper is known for its excellent electrical and thermal conductivity. The International Annealed Copper Standard (IACS) measures this property, with pure copper rated at 100% IACS. High conductivity is essential for electrical applications, making it a key specification for buyers in industries like electronics and renewable energy. -

Corrosion Resistance

– Copper’s resistance to corrosion varies with environmental factors and alloy compositions. Understanding the corrosion properties of specific copper grades helps buyers select materials that will endure harsh conditions, thereby reducing maintenance costs and extending product life. This is particularly important for applications in marine or industrial settings. -

Finish

– The surface finish of custom copper products can significantly affect aesthetics and functionality. Options include polished, brushed, or patina finishes. Buyers should consider the desired appearance and the application requirements when specifying finishes, as they can impact both the visual appeal and the performance of the copper components.

What Are Common Trade Terms Used in the Custom Copper Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, partnering with an OEM can streamline the supply chain, ensuring that components meet specific quality and performance standards. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for buyers to assess cost efficiency and inventory management, especially when dealing with custom copper orders that may have higher production costs. -

RFQ (Request for Quotation)

– An RFQ is a document used to solicit price quotes from suppliers for specific goods or services. It outlines the buyer’s requirements and is essential for comparing costs and terms from different suppliers in the custom copper market. -

Incoterms (International Commercial Terms)

– Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps B2B buyers navigate shipping, insurance, and risk management, ensuring clarity in contracts and reducing potential disputes. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to receiving the product. In the custom copper industry, lead times can vary significantly based on the complexity of the order and the supplier’s capabilities. Buyers must consider lead times when planning projects to avoid delays. -

Customization

– Customization involves tailoring products to meet specific requirements or designs. In the context of custom copper, this can include variations in size, shape, and finish. For B2B buyers, the ability to customize products ensures that they can meet unique project needs while maintaining brand identity.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing custom copper products, ensuring they meet both functional and aesthetic requirements.

Navigating Market Dynamics and Sourcing Trends in the custom copper Sector

What Are the Current Market Dynamics and Key Trends in the Custom Copper Sector?

The custom copper market is witnessing a transformative phase driven by increasing global demand across various industries, including construction, electronics, and renewable energy. The growing emphasis on aesthetic appeal in architectural designs has propelled the demand for custom copper products such as fixtures, roofing, and decorative elements. Notably, regions like Africa and South America are experiencing a surge in infrastructure projects, creating a robust market for custom copper suppliers. Additionally, the Middle East, particularly Saudi Arabia, is investing heavily in luxury real estate, where custom copper features are highly sought after.

Emerging B2B technology trends are reshaping sourcing strategies in the custom copper sector. Digital platforms are increasingly facilitating direct connections between manufacturers and international buyers, streamlining the procurement process. Online customization tools allow buyers to visualize their specifications, enhancing engagement and satisfaction. Furthermore, advancements in supply chain technology, such as blockchain, are improving transparency and traceability, which are critical for international buyers concerned about the origin and quality of materials.

How Are Sustainability and Ethical Sourcing Practices Shaping the Custom Copper Market?

Sustainability has become a pivotal concern in the custom copper industry, influencing sourcing decisions and supplier selection. The environmental impact of copper mining and production is significant, leading to increased scrutiny from consumers and businesses alike. As a result, ethical sourcing practices are gaining traction. Buyers are prioritizing suppliers who demonstrate a commitment to sustainable mining practices, such as using recycled copper and minimizing waste.

Incorporating ‘green’ certifications into the supply chain is becoming essential for B2B buyers. Certifications such as LEED (Leadership in Energy and Environmental Design) and the Responsible Minerals Initiative signal a supplier’s dedication to sustainable practices. These certifications not only enhance a company’s reputation but also meet the growing demand from consumers for products that align with their environmental values. As international buyers navigate the custom copper market, selecting suppliers with verified sustainability credentials is crucial for aligning with global environmental standards.

What Is the Historical Context of Custom Copper Craftsmanship?

The evolution of custom copper craftsmanship can be traced back thousands of years, with copper being one of the first metals utilized by humans. Historically, copper was prized for its malleability and conductivity, making it a preferred material for various applications. In ancient civilizations, artisans crafted copper items for both functional and decorative purposes, laying the groundwork for modern custom copper work.

In recent decades, the resurgence of interest in handcrafted goods has revitalized the custom copper sector. Today, skilled artisans blend traditional techniques with modern design, producing unique pieces that cater to diverse market needs. This blend of history and innovation continues to shape the custom copper landscape, making it a vibrant sector for international B2B buyers seeking distinctive and high-quality products.

In summary, the custom copper market is evolving rapidly, influenced by global demand, technological advancements, and a strong focus on sustainability. B2B buyers are encouraged to leverage these trends to make informed purchasing decisions that align with both market dynamics and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of custom copper

-

1. How can I ensure the quality of custom copper products before purchasing?

To ensure the quality of custom copper products, request samples or prototypes from potential suppliers. Assess their manufacturing processes and quality control measures, such as ISO certifications. Additionally, consider third-party inspections and audits to verify compliance with international standards. Establish a clear communication channel to discuss specifications and expectations, which will help mitigate risks associated with quality discrepancies. -

2. What are the key factors to consider when selecting a custom copper supplier?

When selecting a supplier, evaluate their experience in the industry and their reputation for reliability. Review their product offerings to ensure they can meet your specific needs, including customization options. Check customer testimonials and case studies to gauge their service quality. Additionally, assess their capacity to handle your order volume and delivery timelines, as well as their compliance with international trade regulations. -

3. What customization options are typically available for custom copper products?

Customization options for copper products can include size, thickness, design, and finish. Many suppliers offer bespoke solutions tailored to specific applications, such as architectural elements or specialized industrial parts. When discussing customization, provide detailed specifications and drawings to ensure clarity. Some suppliers may also offer design assistance to optimize your product for functionality and aesthetics. -

4. What are the minimum order quantities (MOQs) for custom copper products?

Minimum order quantities for custom copper products vary by supplier and can depend on the complexity of the design and production process. Generally, MOQs can range from a few pieces for simpler products to larger quantities for complex or specialized items. Discuss your requirements upfront with suppliers to understand their MOQs and negotiate terms that accommodate your purchasing needs. -

5. What payment terms should I expect when sourcing custom copper internationally?

Payment terms for international orders can vary widely, but common practices include upfront deposits (typically 30-50%) and the balance upon completion or delivery. Some suppliers may offer flexible terms based on order size or relationship history. Be sure to clarify payment methods (e.g., wire transfer, credit terms) and potential currency fluctuations that could affect pricing. Establishing clear payment terms upfront helps prevent misunderstandings later in the transaction. -

6. How can I navigate international shipping and logistics for custom copper orders?

To navigate international shipping, work with suppliers experienced in exporting goods. Discuss shipping options, including freight forwarders and incoterms (like FOB or CIF), to clarify responsibilities for shipping costs and customs duties. Ensure that the supplier can provide necessary documentation, such as commercial invoices and certificates of origin, to facilitate smooth customs clearance. Consider insurance options to protect against loss or damage during transit. -

7. What are the common challenges faced in international trade of custom copper products?

Common challenges in the international trade of custom copper include fluctuating metal prices, compliance with local regulations, and potential delays in shipping due to customs inspections. Additionally, cultural differences may affect communication and negotiation styles. To mitigate these challenges, conduct thorough market research, maintain open communication with suppliers, and work with legal or trade experts familiar with the relevant regulations in your target markets. -

8. How can I effectively communicate my design requirements to a custom copper manufacturer?

Effectively communicating design requirements involves providing detailed specifications, including dimensions, materials, finishes, and any specific functionalities. Use visual aids such as drawings, sketches, or CAD files to illustrate your concepts clearly. Engage in collaborative discussions with the manufacturer to ensure they fully understand your vision. Regular check-ins during the design and production phases can help address any questions or adjustments needed, ensuring the final product aligns with your expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Custom Copper Manufacturers & Suppliers List

1. Copper Custom – Springfield 2020 Waypoint 6.5 CM

Domain: coppercustom.com

Registered: 2013 (12 years)

Introduction: [{‘name’: ‘Springfield 2020 Waypoint 6.5 CM w/ Carbon Fiber Barrel – Ridgeline’, ‘price’: ‘$1,999.00’, ‘original_price’: ‘$2,400.00’, ‘availability’: ‘Out of Stock’}, {‘name’: ‘Walther PDP Full Size Optic Ready LE 9mm’, ‘price’: ‘$549.00’, ‘original_price’: ‘$649.00’, ‘availability’: ‘Out of Stock’}, {‘name’: ‘MP44 Rifle 8mm Kurz’, ‘price’: ‘$6,200.00’, ‘availability’: ‘Out of Stock’}, {‘name’: ‘M…

2. Custom Copper Works – Handcrafted Copper Products

Domain: customcopperworks.biz

Registered: 2012 (13 years)

Introduction: Custom Copper Works specializes in handcrafted copper products, including:

1. **Copper Soaking Tubs**:

– Free-standing Copper Slipper Bath Tubs

– Double Wall Copper Soaking Bath Tubs

– Japanese Style Jacuzzi Soaking Tubs

2. **Copper Top Tables**:

– Copper Top Tables with Wood Bases

– Copper Top Tables with Forged Iron Bases

**Customization Options**:

– 100% custom designs tail…

3. Premier Copper Products – Custom 36 Hammered Copper Plate

Domain: premiercopperproducts.com

Registered: 2006 (19 years)

Introduction: Custom 36″ Hammered Copper Plate – SKU: PLATE36_1 – Ideal for creating custom copper signs or personal plaques – Handcrafted by skilled artisans – Customization options available for size and finish – Focus on quality, craftsmanship, and exceptional service – Made from 99.7% pure reclaimed copper with natural antibacterial properties – Family-owned business dedicated to sustainability and excellen…

Strategic Sourcing Conclusion and Outlook for custom copper

In the competitive landscape of custom copper sourcing, international B2B buyers must prioritize strategic sourcing to maximize value and ensure quality. The ability to procure tailored copper solutions—from architectural elements to specialized industrial applications—offers businesses a unique advantage. Engaging with reputable suppliers who emphasize craftsmanship and material integrity is essential for achieving bespoke results that meet specific project requirements.

As we look to the future, the demand for custom copper products is expected to grow, driven by advancements in technology and evolving market needs. Buyers from Africa, South America, the Middle East, and Europe should leverage this opportunity by forming strategic partnerships with suppliers who can deliver not only high-quality products but also innovative solutions tailored to their market contexts.

Investing in strategic sourcing will not only enhance product offerings but also bolster brand reputation and customer satisfaction. Now is the time to explore the potential of custom copper in your supply chain—connect with trusted manufacturers and elevate your business by integrating bespoke copper solutions that stand out in the marketplace.