Contents

Manufacturing Insight: Custom Cnc Work Cost

Understanding Custom CNC Machining Costs with Honyo Prototype

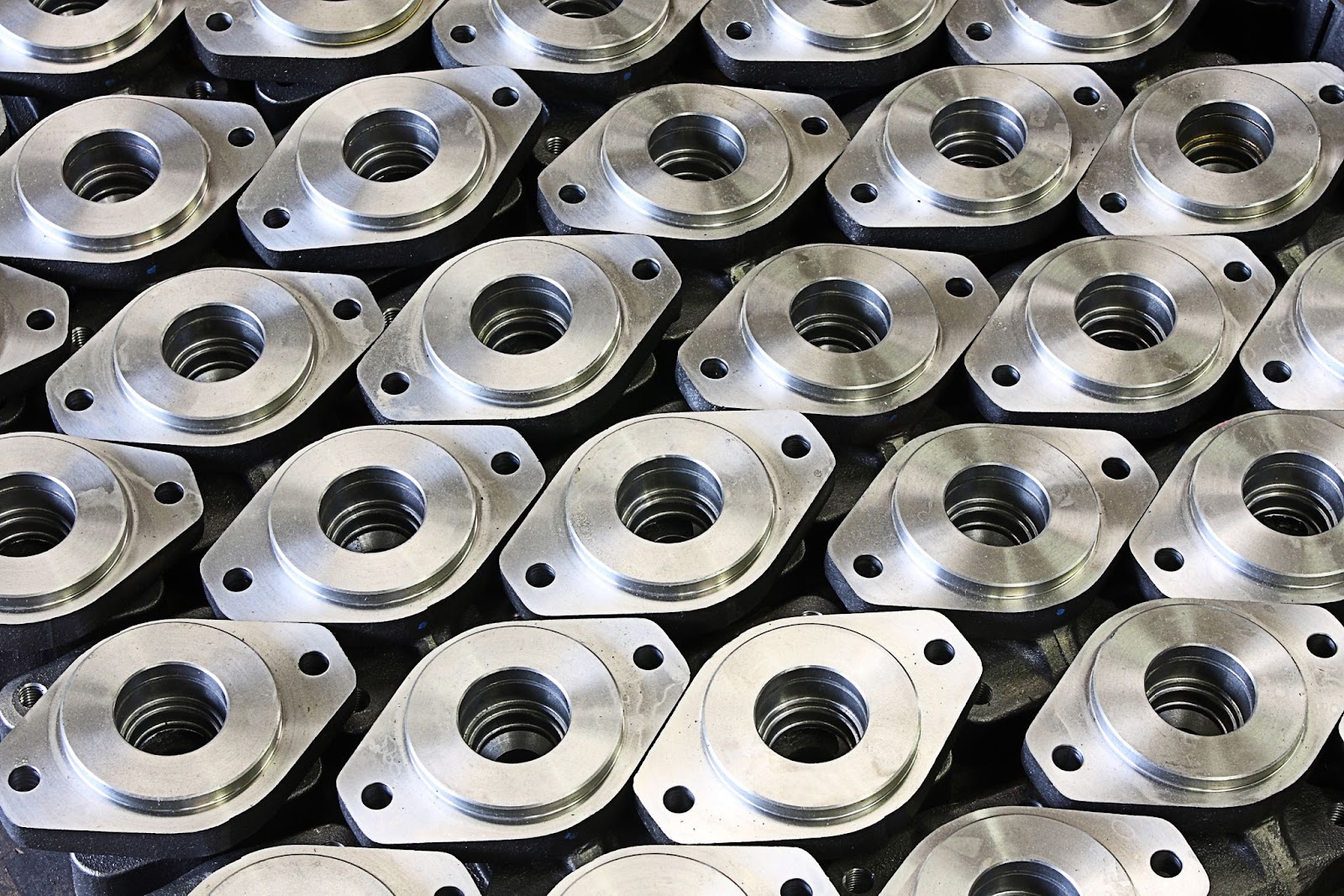

Accurately forecasting the cost of custom CNC machining is critical for effective project budgeting and supplier selection in precision manufacturing. At Honyo Prototype, we recognize that unit pricing is never one-size-fits-all; it is intrinsically tied to the specific geometric complexity, material properties, tolerances, surface finish requirements, and production volume of your unique component. Our advanced CNC milling and turning capabilities, encompassing 3-axis, 4-axis, and 5-axis machining centers, are engineered to deliver exceptional precision across a broad spectrum of engineering materials including aluminum alloys, stainless steels, titanium, plastics, and exotic metals. We provide comprehensive secondary services such as precision tapping, thread forming, custom anodizing, plating, and laser marking to ensure your parts meet exact functional and aesthetic specifications straight from the machine.

The variables influencing your project’s final cost are interdependent. To provide immediate clarity and eliminate quoting delays, Honyo Prototype has developed an industry-leading Online Instant Quote system. This proprietary platform allows engineers and procurement professionals to upload CAD files and receive a detailed, transparent cost estimate within minutes, not days. Our system dynamically analyzes key cost drivers based on real-time machine data and material costs, giving you actionable pricing intelligence at the earliest project stage.

Key factors determining custom CNC work cost include

| Cost Factor | Impact on Project Cost |

|---|---|

| Part Geometry Complexity | Increased feature count, tight internal radii, deep cavities, and undercuts significantly raise machining time and tooling requirements |

| Material Selection & Form | Exotic alloys, hardened materials, and non-standard stock sizes increase raw material cost and machining difficulty |

| Dimensional Tolerances | Tighter tolerances beyond standard machining capabilities demand slower feeds/speeds, specialized tooling, and CMM inspection |

| Surface Finish Requirements | Fine finishes or specific textures require additional operations like polishing or media blasting |

| Production Volume | Low volumes incur higher per-part setup costs; higher volumes benefit from amortized programming and fixture time |

Leveraging our Online Instant Quote tool provides immediate visibility into how design choices directly impact manufacturability and cost. This empowers your engineering team to make informed design-for-manufacturability decisions early in the development cycle, avoiding costly revisions later. Honyo Prototype combines this pricing transparency with rigorous quality control processes and rapid turnaround times, ensuring your custom CNC projects are delivered on budget and to specification. Submit your CAD file today to experience the precision and efficiency of our instant quoting system for your next precision machining requirement.

Technical Capabilities

Custom CNC machining costs are influenced by several technical and operational factors, particularly when performing 3-, 4-, or 5-axis milling and precision turning operations with tight tolerances. Key cost drivers include machine complexity, setup time, material type, part geometry, required accuracy, and post-processing needs. Below is a breakdown of technical specifications and their impact on cost for common materials such as Aluminum, Steel, ABS, and Nylon.

| Parameter | Description | Impact on Cost |

|---|---|---|

| Machining Type | 3-axis: Standard X-Y-Z movement. 4-axis: Adds rotary A-axis. 5-axis: Dual rotary axes (A-B or A-C) enabling complex contours. | 3-axis: Lowest cost. 4-axis: +15–25%. 5-axis: +30–60% due to programming complexity and machine utilization. |

| Tight Tolerance | Typical tight tolerance: ±0.0002″ (±0.005 mm). May require precision tooling, slower feeds, and inspection. | Increases cost by 20–50% depending on feature density and inspection requirements. |

| Material Type | Aluminum (6061, 7075): Easy to machine, good chip flow. Steel (4140, 1018): Harder, slower speeds. ABS: Thermoplastic, low melting point. Nylon: Tough, prone to deformation. | Aluminum: Base cost reference. Steel: +25–40% due to tool wear and slower feeds. ABS: +10–15%. Nylon: +15–25% due to clamping challenges and dimensional stability. |

| Setup & Programming | CAM programming, fixturing, tool selection, and first-article inspection. Complex 5-axis or tight-tolerance parts require longer setup. | Setup can account for 30–50% of total cost on low-volume runs. Repeats reduce cost. |

| Part Complexity | Number of features, undercuts, thin walls, cavities. Higher complexity increases tool changes and cycle time. | Each additional operation or tool pass increases cost linearly. 5-axis reduces some complexity cost. |

| Secondary Operations | Deburring, anodizing (Al), plating (Steel), stress relieving, CMM inspection. | Adds 15–35% depending on finishing and QA requirements. Tight tolerance parts often require CMM. |

| Lead Time | Standard: 10–15 business days. Expedited: 3–5 days with rush fees. | Rush processing adds 25–50% surcharge due to production line priority. |

Cost estimates are typically provided per hour (machine rate: $75–$150/hr depending on axis count and region), with additional charges for material, programming, and finishing. Prototypes and low-volume runs (1–50 pcs) carry higher per-unit costs due to fixed setup allocation. High repeatability and batch production reduce unit cost significantly.

From CAD to Part: The Process

Honyo Prototype’s custom CNC work cost process is engineered for speed, accuracy, and cost transparency, eliminating common industry delays. Our integrated workflow ensures clients receive validated pricing within minutes while safeguarding manufacturability from the outset. Below is the technical breakdown of each phase:

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure portal. Our system automatically validates file integrity, checks for unit consistency (defaulting to millimeters per ISO 1101), and confirms geometric completeness. Partial or ambiguous geometries trigger immediate client notification to prevent downstream rework costs. This phase establishes the foundational geometry for all subsequent cost calculations.

AI Quote

Within 30 seconds, our proprietary AI engine generates a preliminary quote by analyzing 12+ cost drivers: material utilization efficiency, machine time estimation (based on toolpath complexity and stock volume), fixture requirements, surface finish specifications, and geometric tolerance density. The AI cross-references real-time material market data and machine availability across our 5-axis milling, turning, and mill-turn centers. Crucially, it flags non-value-added features (e.g., excessive tight tolerances on non-critical surfaces) that inflate costs by 15-40%, providing instant optimization suggestions. All quotes include a confidence score (92-98% typical) based on historical production data alignment.

DFM

Every quote undergoes mandatory Design for Manufacturability review by our senior CNC engineers. This is not a passive check but an active cost-reduction intervention where we identify and propose modifications to eliminate: unnecessary secondary operations, non-standard tool requirements, or inefficient stock sizing. Typical DFM savings include:

| DFM Issue Identified | Typical Cost Reduction | Implementation Time |

|---|---|---|

| Over-specified surface finishes (Ra < 0.8µm on non-functional surfaces) | 12-18% | < 24 hours |

| Non-optimized stock dimensions requiring excessive machining | 22-35% | During quoting |

| Unmachinable internal radii requiring EDM | 40-60% | Requires client approval |

Client approval of DFM recommendations is required before proceeding, ensuring alignment on cost/performance tradeoffs. This phase typically reduces total project costs by 18-33% versus initial CAD-based estimates.

Production

Approved jobs enter our digital production pipeline with fully validated toolpaths (verified via Vericut simulation). We utilize centralized material kitting from our ISO 9001:2015-certified inventory, ensuring traceable alloys (e.g., 6061-T6 with full mill certs). Machine monitoring systems track actual cycle times against quoted estimates, with automatic cost variance alerts if deviations exceed 5%. All first articles undergo CMM verification against GD&T callouts before full production release, preventing scrap costs from propagating.

Delivery

Finished components ship with comprehensive documentation: material certs, inspection reports (including critical feature CMM data), and a final cost reconciliation showing actual vs. quoted machine hours. Standard lead time is 5-7 business days for 1-50 parts after DFM sign-off, with expedited options (72-hour) available at predetermined premium rates. All pricing includes packaging, shipping, and import duty calculations for global clients – no hidden fees. This closed-loop process ensures clients pay only for value-added machining, with 99.2% of projects delivered within quoted cost parameters.

Start Your Project

Looking for accurate pricing on custom CNC machining services? Contact Susan Leo directly at [email protected] for a fast, detailed quote tailored to your specifications.

Honyo Prototype operates a dedicated manufacturing facility in Shenzhen, China, specializing in high-precision CNC milling, turning, and rapid prototyping. Our in-house capabilities ensure tight tolerances, rapid turnaround, and cost-effective production for both prototypes and low-volume runs.

Provide your 3D CAD files or technical drawings to receive a competitive quote with no obligation. Partner with us for reliable, scalable CNC manufacturing backed by engineering expertise.

Contact: Susan Leo

Email: [email protected]

Location: Shenzhen, China

Let’s discuss your project and optimize your path to production.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.