Contents

Manufacturing Insight: Custom Cnc Plastic Parts

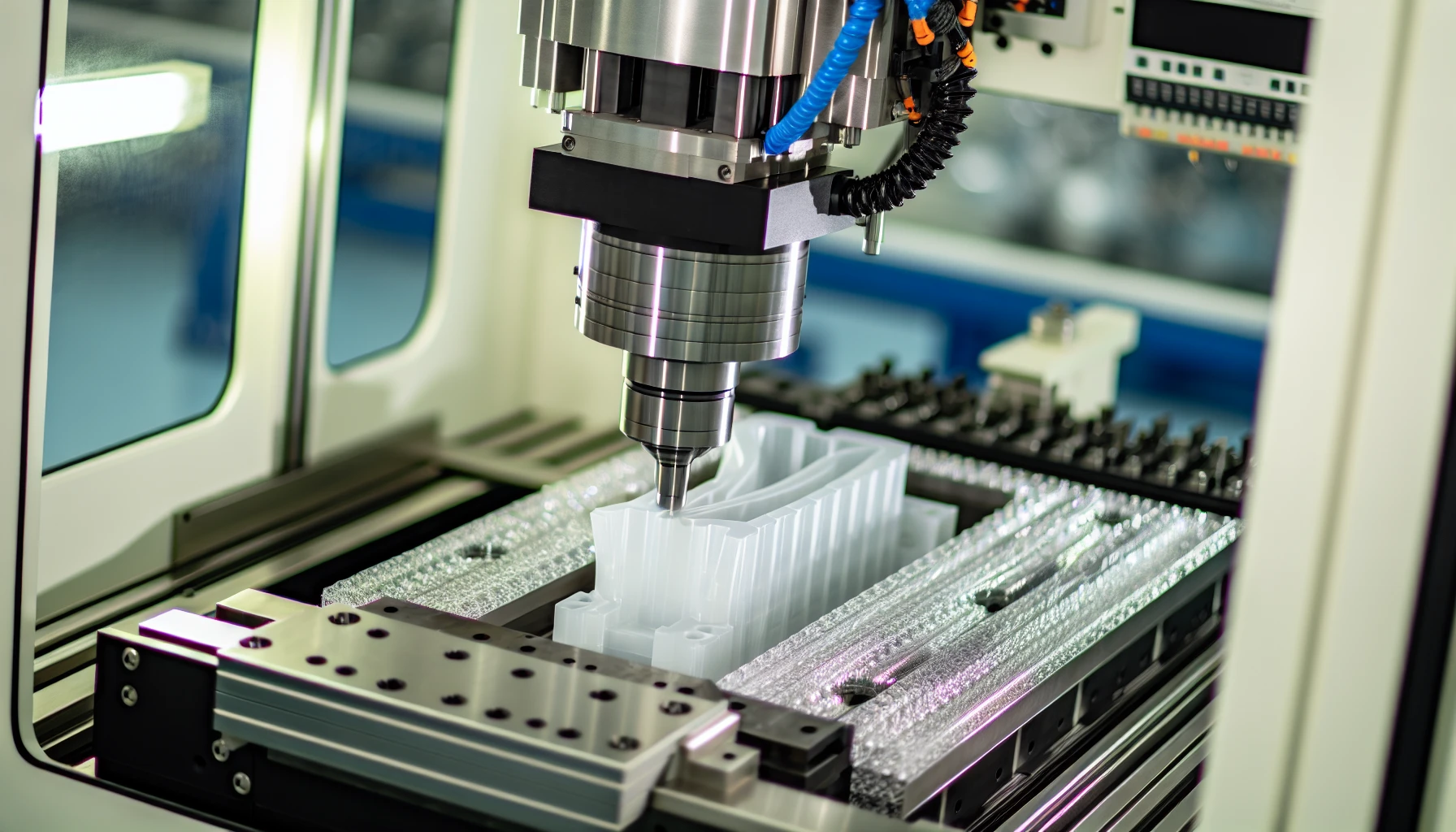

Precision Plastic Components Engineered for Performance and Speed

Honyo Prototype delivers industry-leading CNC machining services for custom plastic parts, serving engineering teams and procurement professionals who demand exacting tolerances and material integrity. Our advanced 3-, 4-, and 5-axis milling and turning centers consistently achieve ±0.005 mm accuracy across complex geometries, ensuring your functional prototypes, jigs, fixtures, and end-use components meet rigorous performance specifications. We specialize in machining high-performance engineering plastics including PEEK, Ultem, PPSU, Acetal, Polycarbonate, and Nylon, with strict adherence to ISO 9001:2015 quality standards throughout production.

Accelerate Your Development Cycle with Real-Time Cost Transparency

Eliminate quoting delays that stall critical project timelines. Honyo’s proprietary Online Instant Quote platform provides validated pricing in under 60 seconds for CNC plastic parts—simply upload your STEP or IGES file to receive immediate cost analysis, lead time estimates, and manufacturability feedback. This seamless integration with your design workflow enables rapid iteration, informed material selection, and precise budget forecasting without manual back-and-forth communication. Our system automatically evaluates geometric complexity, material utilization, and machine time to deliver accurate, actionable quotes 24/7.

End-to-End Expertise from Concept to Certified Production

Beyond precision machining, Honyo provides comprehensive support including DFM analysis, material certification documentation, secondary operations coordination, and first-article inspection reports. Our engineering team collaborates directly with clients to resolve challenges in thin-wall features, tight-tolerance assemblies, or chemical-resistant applications—turning demanding specifications into reliable, production-ready plastic components. When your project requires uncompromising quality and accelerated time-to-market, Honyo Prototype combines technical mastery with digital efficiency to become your strategic manufacturing partner.

Key Plastic Materials Processed

| Material Type | Common Applications | Key Properties |

|———————|————————————–|————————————|

| High-Performance | Aerospace seals, medical implants | Chemical resistance, high temp |

| Engineering Thermoplastics | Enclosures, gears, bearings | Wear resistance, strength |

| Standard Plastics | Prototypes, jigs, low-stress parts | Cost-effective, ease of machining |

Technical Capabilities

Custom CNC plastic parts are manufactured using advanced 3-axis, 4-axis, and 5-axis milling processes, as well as CNC turning, to achieve high precision and complex geometries. These components are often required in industries such as aerospace, medical, automotive, and industrial equipment, where tight tolerances and material performance are critical.

The following table outlines the technical specifications for custom CNC machined parts, covering both plastic and metal materials commonly used at Honyo Prototype:

| Specification Category | Details |

|---|---|

| Machining Capabilities | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including mill-turn and live tooling) |

| Tolerance Range | ±0.005 mm (±0.0002″) for critical dimensions; typical tolerances ±0.025 mm (±0.001″) |

| Surface Finish (as machined) | Ra 0.8–3.2 µm (32–125 µin); post-processing options available (e.g., polishing, bead blasting) |

| Materials – Plastics | ABS (Acrylonitrile Butadiene Styrene), Nylon (PA6, PA66), Acetal (POM), PEEK, Polycarbonate (PC), PMMA (Acrylic), UHMW-PE |

| Materials – Metals | Aluminum (6061-T6, 7075-T6, 2024-T3), Steel (1018, 4140, 4340), Stainless Steel (303, 304, 316), Titanium (Grade 2, 5) |

| Maximum Work Envelope | Milling: 1000 x 600 x 500 mm (39.4 x 23.6 x 19.7 in); Turning: Ø300 mm x 500 mm (11.8 x 19.7 in) |

| Positioning Accuracy | ±0.005 mm (±0.0002″) on all linear axes |

| Repeatability | ±0.003 mm (±0.0001″) |

| Coolant/Lubrication | Flood coolant for metals; air cooling or minimum quantity lubrication (MQL) for plastics to prevent warping |

| Secondary Operations | Deburring, anodizing (Aluminum), passivation (Stainless Steel), heat treatment, laser marking, precision grinding |

Honyo Prototype maintains strict process controls to ensure dimensional accuracy and surface integrity, especially when machining sensitive plastics such as ABS and Nylon, which require optimized feed rates, spindle speeds, and clamping strategies to minimize thermal deformation. Multi-axis milling enables complex contours and undercuts without re-fixturing, while CNC turning ensures high concentricity and precision for rotational parts.

From CAD to Part: The Process

Honyo Prototype Custom CNC Plastic Parts Process Overview

Our end-to-end workflow for custom CNC plastic parts ensures precision, speed, and manufacturability while minimizing client risk. The process is engineered specifically for polymer machining challenges including thermal management, chip evacuation, and material-specific toolpath strategies.

CAD File Upload and Initial Assessment

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid) via our secure portal. Our system validates geometric integrity and identifies critical features such as thin walls, undercuts, or tight tolerances inherent to plastics. Material specifications are cross-referenced against our database of 50+ engineered polymers including PEEK, Ultem, PTFE, and acrylics to preempt compatibility issues.

AI-Powered Instant Quoting with Engineering Validation

Proprietary AI algorithms analyze the CAD geometry, material selection, and requested quantities to generate a preliminary quote within minutes. The AI factors in plastic-specific variables:

Thermal expansion coefficients affecting dimensional stability

Required spindle RPM reductions for non-conductive materials

Specialized tooling needs for abrasion-resistant polymers

This AI output undergoes immediate review by our CNC engineering team who validate feasibility and adjust parameters for complex features like micro-threads or optical surfaces. Clients receive a transparent quote detailing machine hours, material waste factors, and secondary operation costs.

Engineering-Led DFM Analysis and Optimization

All quotes trigger mandatory Design for Manufacturability review by senior plastic machining specialists. We provide actionable feedback addressing polymer-specific concerns:

Wall thickness adjustments to prevent sink marks in semi-crystalline materials

Draft angle recommendations for delrin or nylon parts

Strategic part orientation suggestions to minimize internal stresses

Alternative material proposals when requested plastics exhibit poor machinability (e.g., substituting cast acrylic for extruded)

Clients receive a marked-up DFM report with 3D visual annotations within 24 hours, including cost-impact analysis for suggested modifications.

Precision CNC Production with Material Protocols

Approved designs move to our climate-controlled machining floor where:

Plastics are acclimated for 72+ hours in 22°C/45% RH chambers

Machines employ high-pressure air coolant systems instead of liquid to prevent static buildup

Toolpaths use ramp-down strategies to avoid melting in thermoplastics

In-process CMM checks verify critical dimensions at 25%, 50%, and 75% completion stages

Each lot includes material certification and process documentation traceable to ISO 9001 standards, with special handling for FDA/USP Class VI compliant polymers.

Quality-Controlled Delivery and Logistics

Final inspection includes:

Full FAI report against ASME Y14.5 GD&T requirements

Surface roughness validation per ISO 25178 for optical applications

First-article samples shipped with production batches for high-volume orders

Parts ship in anti-static, humidity-controlled packaging via DHL/FedEx with real-time tracking. Standard lead time is 5-7 business days from DFM approval, with expedited 72-hour options for qualifying geometries. All deliveries include digital quality dossiers accessible through our client portal for audit compliance.

Start Your Project

Need precision custom CNC plastic parts? Contact Susan Leo at [email protected] for fast, reliable prototyping and production services.

Our advanced CNC machining facility in Shenzhen delivers high-quality plastic components with tight tolerances, excellent surface finishes, and quick turnaround times.

Whether you require small-batch prototypes or large-scale manufacturing, we support a wide range of engineering-grade plastics including ABS, PC, POM, PEEK, and more.

Partner with Honyo Prototype for consistent quality, technical expertise, and end-to-end manufacturing support.

Reach out today to request a quote or discuss your project requirements.

Susan Leo

Email: [email protected]

Factory Location: Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.