Guide Contents

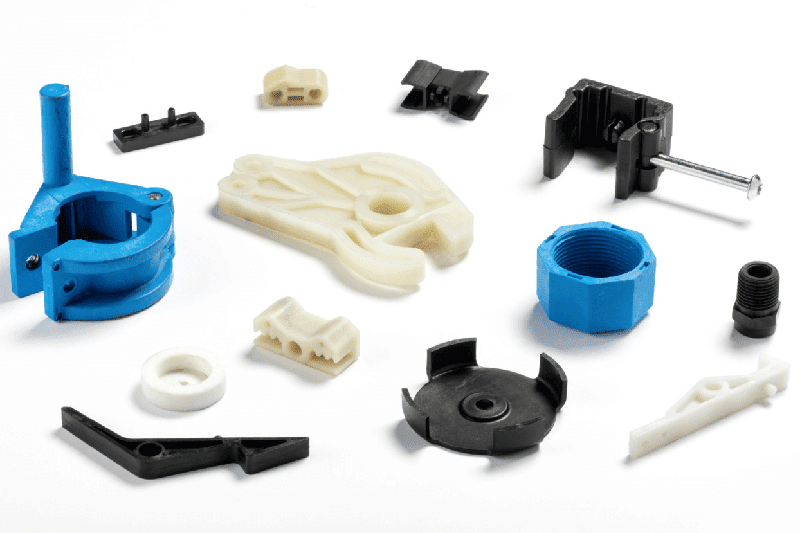

Project Insight: Custom Cnc Plastic Parts

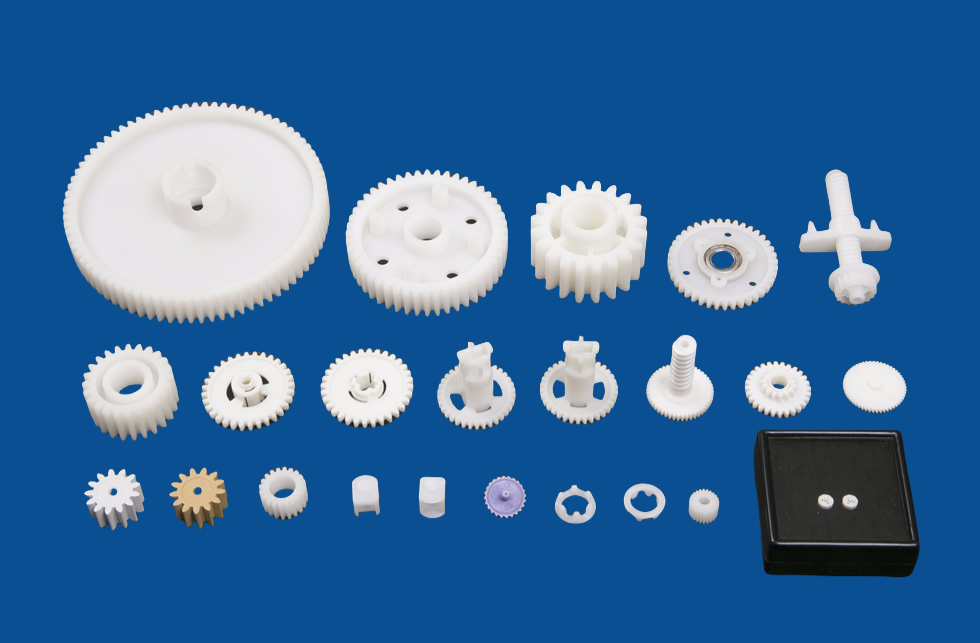

Manufacturing Insight: Custom CNC Plastic Parts

At Honyo Prototype, we know that in today’s competitive product development landscape, the ability to iterate quickly without sacrificing precision is the difference between market leadership and missed opportunities. As a Shenzhen-based precision manufacturing partner, we combine cutting-edge CNC capabilities with digital innovation to transform your designs into functional prototypes and end-use parts—faster and more accurately than ever before.

Precision Engineering: The Foundation of Reliable Prototypes

Tight tolerances of ±0.01mm ensure critical dimensions meet functional requirements, even for complex geometries

Advanced 3/4/5-axis machining capabilities handle intricate features without compromising accuracy

Validated for medical devices, aerospace components, and high-performance industrial applications where failure isn’t an option

Accelerating Innovation with Unmatched Speed

Prototype delivery in 24–72 hours for urgent product validation and testing

Agile production scaling from single units to 500+ parts without retooling delays

Real-time production tracking and proactive communication to keep your project on schedule

Your Digital Manufacturing Partner: AI-Powered Efficiency

Online Instant Quote: Upload your CAD file and receive an accurate price and lead time estimate in seconds—no email chains, no waiting

AI-Powered Platform: Automated design for manufacturability (DFM) analysis with actionable suggestions to optimize cost, quality, and cycle time

Fast Turnaround: Streamlined workflows and in-house expertise ensure parts ship within days, not weeks, keeping your product roadmap on track

At Honyo Prototype, we don’t just manufacture parts—we accelerate innovation. Let’s build the future, together.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

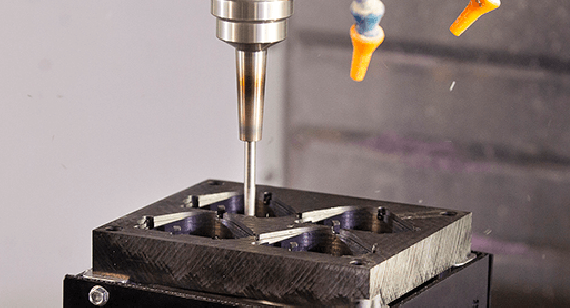

Precision CNC Machining Technology

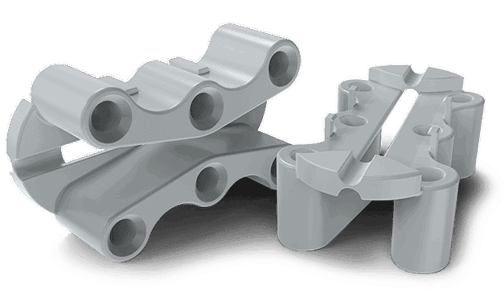

Multi-axis mastery: 3/4/5-axis machining for complex geometries, intricate features, and undercuts—without compromising on surface finish or dimensional accuracy.

Micron-level precision: Tight tolerances of ±0.01mm ensure parts meet stringent functional requirements for end-use applications in medical, aerospace, and industrial sectors.

Material versatility: Engineered for high-performance plastics including ABS, POM (Acetal), PC, Nylon, PTFE, and more—optimized for strength, thermal stability, and chemical resistance.

Scalable Production Capacity

Seamless scaling: From 1 prototype to 10,000+ production parts—no minimum order quantities, ideal for startups iterating rapidly or scaling to volume.

Flexible batch optimization: Tailored workflows for R&D iterations, low-volume runs, or high-volume production—all with consistent quality and zero setup compromises.

ISO-Certified Quality Assurance

Global standards compliance: ISO 9001-certified quality management system with rigorous process controls at every stage.

Multi-stage inspection: Automated CMM, optical comparators, and in-process checks to validate tolerances, surface quality, and dimensional integrity.

Full traceability: Complete documentation for regulatory compliance and quality assurance—every part, every batch.

Smart Digital Manufacturing Ecosystem

Instant AI-Powered Quotes: Upload your CAD file for a real-time, transparent cost breakdown—no manual quotes, no delays. Get pricing in seconds, not days.

Design Optimization Engine: AI analyzes geometry to suggest manufacturability tweaks, material choices, and cost-saving modifications—without sacrificing precision.

Accelerated Lead Times: Prototypes delivered in as little as 3 days; production runs completed in 1–2 weeks with expedited options for urgent projects.

At Honyo Prototype, we fuse cutting-edge CNC technology with intelligent automation to turn your designs into precision-engineered plastic parts—faster, smarter, and with unwavering reliability.

Materials & Surface Finishes

Material Options & Finishes

Precision-engineered plastics for functional prototypes and end-use parts—optimized for performance, cost, and speed.

Precision Plastic Material Selection

Choose materials that match your application’s mechanical, thermal, and chemical demands. Honyo’s material library is curated for CNC machining excellence:

PEEK (Polyetheretherketone)

Extreme performance for medical, aerospace, and high-temp applications.

Biocompatible, chemical-resistant, and withstands 250°C continuous use.

Ideal for surgical instruments, aerospace components, and sterilizable parts.

ABS (Acrylonitrile Butadiene Styrene)

Balanced strength, impact resistance, and cost-efficiency.

Perfect for consumer electronics housings, automotive trim, and rugged prototypes.

Easily painted or textured for premium aesthetics.

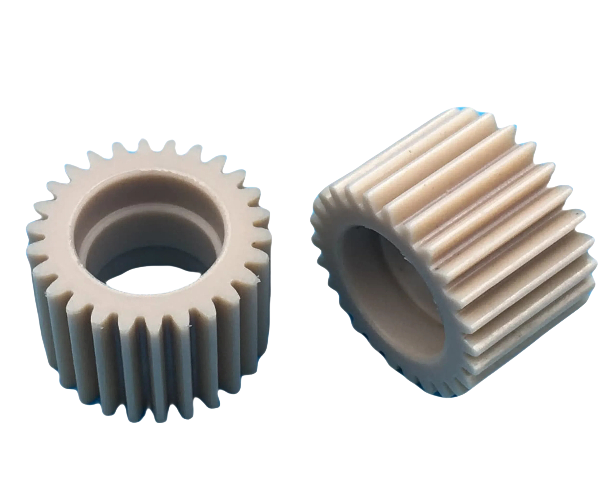

Nylon (PA6/PA66)

Wear-resistant and flexible for moving parts.

Self-lubricating properties reduce friction in gears, bearings, and sliders.

Resists abrasion and moisture—ideal for industrial machinery components.

Polycarbonate (PC)

High-impact strength with optical clarity.

Transparent or tinted options for lenses, protective shields, and lighting components.

Withstands extreme temperatures (-40°C to 135°C).

Acetal (POM)

Precision engineering for low-friction, high-stiffness parts.

Excellent dimensional stability for gears, bushings, and precision mechanical assemblies.

Resists fatigue and creep under continuous load.

PMMA (Acrylic)

Superior optical clarity and UV resistance.

Used for display cases, signage, and optical components where transparency is critical.

Easily polished to a glass-like finish.

💡 Pro Tip: Our AI-driven material selector cross-references your design specs (e.g., load, temperature, chemical exposure) to recommend the exact plastic—no guesswork.

Surface Finishing Expertise for Plastics

Enhance functionality and aesthetics with finishes tailored to plastic properties:

Precision Polishing

Achieve optical-grade clarity for lenses, displays, or consumer-facing components.

Custom Painting & Powder Coating

Durable, UV-resistant coatings for vibrant colors or corrosion protection—ideal for outdoor or high-visibility parts.

Textured Surfaces

Add grip, reduce fingerprints, or create premium tactile finishes (e.g., matte, leather grain, or custom patterns).

Electroplating (for select plastics)

Metallic appearance without weight—perfect for automotive trim or decorative elements.

UV-Resistant Coatings

Extend outdoor lifespan by preventing yellowing and degradation from sunlight.

⚠️ Note: Anodizing is exclusive to metals—plastics require specialized surface treatments. We only recommend finishes proven for plastic compatibility.

AI-Powered Material Optimization & Instant Quoting

Cut costs, not corners with Honyo’s innovation-driven workflow:

Real-Time AI Cost Analysis: Upload your CAD file instantly—our platform analyzes geometry, tolerances, and material options to deliver a precise quote in seconds.

Design for Manufacturability (DFM) Feedback: Get automated suggestions to simplify geometry, reduce machining time, and lower costs—without compromising function.

Fast Turnaround Guarantee:

Prototypes in 3 days | Production runs in 7–10 days

No minimum order quantities—scale from 1 to 10,000+ parts seamlessly.

Founder-Backed Precision: Led by Susan Leo, our team combines 20+ years of aerospace-grade expertise with cutting-edge automation to deliver repeatable precision at startup-friendly speeds.

✨ Ready to optimize? Get your instant quote in 60 seconds—no engineering degree required.

From Quote to Part: Our Process

How It Works: From CAD to Part

Seamless, transparent, and optimized for speed—your vision to precision part in record time.

Step 1: Upload Your CAD File

Drag-and-drop interface for STEP, STL, IGES, or SolidWorks files—no technical expertise required.

Secure cloud storage with enterprise-grade encryption and zero file-size limits.

Instant validation checks to flag common upload issues before submission.

Step 2: Get Instant AI-Powered Quote

Real-time pricing in seconds via Honyo’s proprietary AI engine—no waiting for manual quotes.

Transparent cost breakdown: material, machining time, setup fees, and quantity optimizations.

AI-driven suggestions to reduce expenses (e.g., simplifying geometries, selecting cost-effective materials).

Step 3: Proactive DFM Analysis

Our engineering team reviews your design for manufacturability—before production begins.

Actionable feedback to eliminate potential issues (e.g., wall thickness, undercuts, tolerances).

Collaborative refinement process to maximize performance while minimizing cost and lead time.

Step 4: Precision Production & Rapid Delivery

±0.01mm tolerances achieved across 3/4/5-axis CNC machines—ideal for functional prototypes and end-use parts.

Fully automated quality control at every stage, with ISO-certified inspection reports.

Fast turnaround: Prototypes delivered in as little as 3 days, with global shipping and real-time tracking.

Honyo Prototype’s Shenzhen smart factory combines AI efficiency with human expertise—so you spend less time waiting and more time innovating.

Start Your Project with Honyo

Start Your Project with Honyo Prototype

At Honyo Prototype, we empower hardware startups and product engineers with precision CNC plastic parts that accelerate time-to-market. Susan Leo and our engineering team leverage AI-driven manufacturing insights to deliver unmatched accuracy—combining ±0.01mm tolerances with rapid turnaround—so you can iterate faster and launch with confidence.

Why Honyo Delivers More Value

AI-Powered Instant Quotes: Upload your CAD file and receive a real-time, cost-optimized quote in under 60 seconds—no manual estimates, no delays.

Uncompromising Precision: Achieve ±0.01mm tolerances across 3/4/5-axis machining for functional prototypes and end-use components that meet medical, aerospace, and industrial standards.

Industry-Leading Turnaround: Get parts in as little as 3 days with expedited options for urgent prototyping—skip mold costs and lead times of injection molding for low-volume runs.

Transparent Cost Engineering: No hidden fees. Our platform calculates exact pricing based on material, geometry complexity, and volume—so you optimize budgets without sacrificing quality.

Ready to Launch Your Project?

Get an Instant Quote: Upload your design and see pricing in seconds—no commitment required.

Connect Directly with Susan Leo: Email [email protected] or call +86 139 2843 8620 for personalized technical guidance.

Visit Our Facilities: Tour our Shenzhen/Dongguan operations to witness our ISO-certified CNC workflows—by appointment only.

Innovation isn’t a feature—it’s our manufacturing DNA. Let’s build the future, faster.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.