Contents

Manufacturing Insight: Custom Cnc Parts Cost

Understanding Custom CNC Parts Cost Drivers

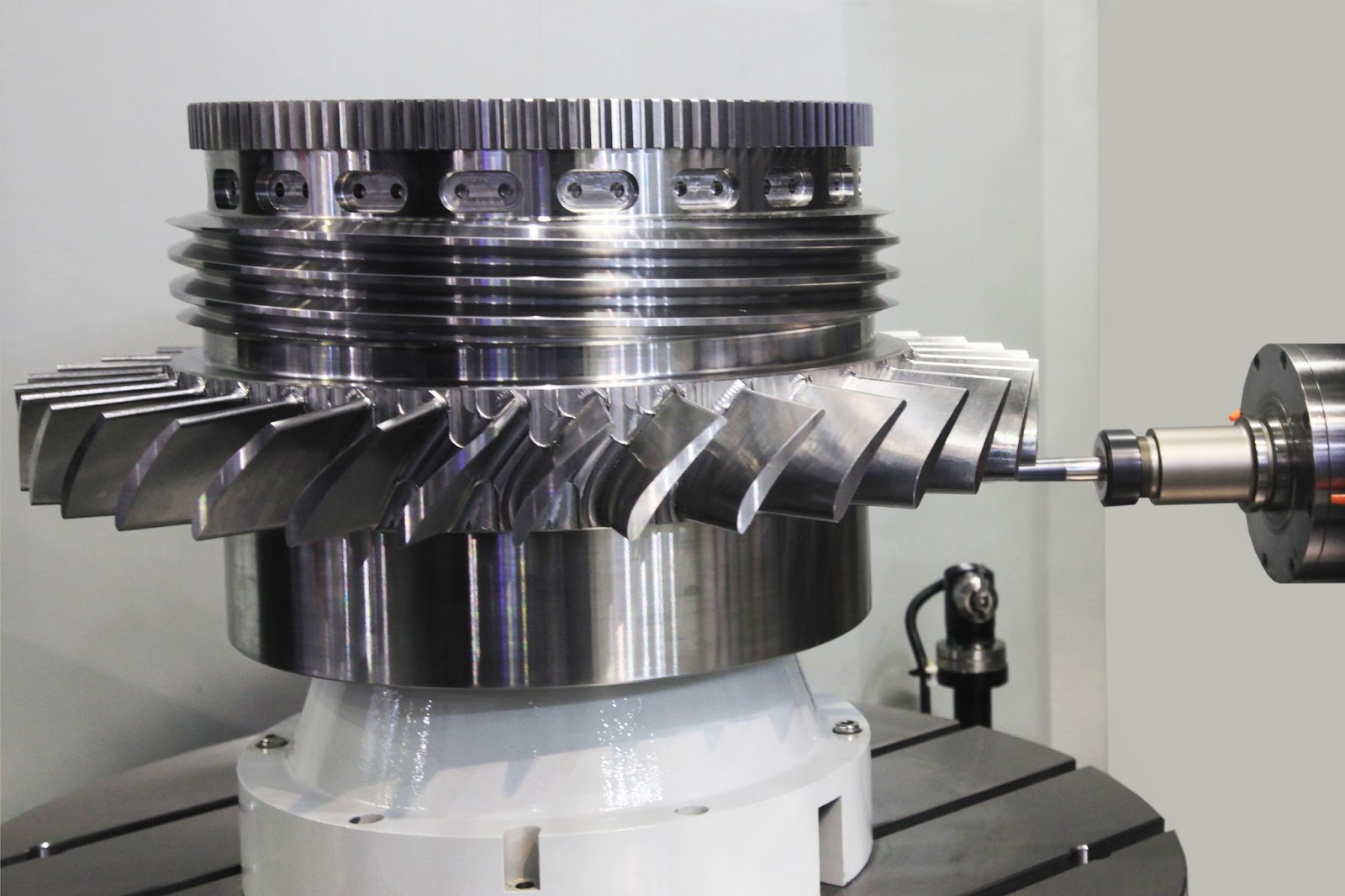

Accurate cost estimation for custom CNC machined components remains a critical challenge in precision manufacturing, directly impacting project timelines and budget allocation. At Honyo Prototype, we address this complexity through engineered solutions that balance dimensional accuracy, material efficiency, and rapid turnaround. Our CNC machining services leverage advanced 3-axis, 4-axis, and 5-axis milling and turning centers to produce complex geometries from metals, plastics, and composites, adhering to tight tolerances down to ±0.0002 inches. This technical capability ensures minimal waste and optimal cycle times, directly translating to predictable per-part costs for prototypes and low-volume production runs.

Transparency Through Technology

Honyo eliminates cost uncertainty with our proprietary Online Instant Quote system, designed specifically for engineering and procurement teams. By inputting part geometry, material specifications, quantity, and required certifications, manufacturers receive a validated price within seconds—not days. This system integrates real-time machine availability, material market pricing, and geometric complexity analysis, providing a granular breakdown of machining hours, setup costs, and finishing operations. Unlike generic quoting tools, our platform reflects actual shop-floor parameters, ensuring quotes align with production feasibility from the initial RFQ stage.

Strategic Cost Optimization

We recognize that part cost extends beyond raw material and machine time. Honyo’s engineering team collaborates early in the design phase to identify cost-saving opportunities through Design for Manufacturability (DFM) analysis, such as optimizing wall thicknesses, reducing secondary operations, or recommending alternative alloys without compromising performance. This proactive approach, combined with our instant quoting capability, empowers clients to make data-driven decisions that reduce total prototype costs by up to 30% while accelerating time-to-test. For engineering managers managing tight development cycles, this precision in cost forecasting is non-negotiable.

Technical Capabilities

Custom CNC machining costs for 3-axis, 4-axis, and 5-axis milling, as well as turning operations, depend on several technical factors including complexity, tolerance requirements, material type, setup time, and machine utilization. Tight tolerances (±0.0005″ to ±0.005″) significantly impact cost due to increased precision demands, tooling requirements, inspection time, and reduced machining speeds. Below is a comparative technical and cost overview for common materials used in prototyping and low-volume production at Honyo Prototype.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes |

|---|---|---|---|---|---|

| Typical Tolerance | ±0.005″ (standard), ±0.001″ (tight) | ±0.005″, down to ±0.0005″ | ±0.001″, down to ±0.0005″ | ±0.002″, down to ±0.0005″ | Tight tolerances increase inspection and process validation time |

| Setup Complexity | Low | Moderate | High | Low to moderate | 5-axis requires advanced fixturing and programming |

| Machining Time | Shortest | 10–25% longer than 3-axis | 20–40% longer than 3-axis | Fast for cylindrical parts | Higher axis count allows fewer setups but longer cycle per operation |

| Aluminum (6061, 7075) | $60–$100/hr | $75–$120/hr | $100–$180/hr | $50–$90/hr | Most cost-effective; excellent machinability |

| Steel (1018, 4140) | $70–$130/hr | $85–$150/hr | $120–$200/hr | $65–$110/hr | Higher tool wear; slower speeds; heat treatment may add cost |

| ABS (Plastic) | $50–$90/hr | $65–$110/hr | $90–$150/hr | $45–$80/hr | Lower cutting forces; risk of melting; tight tolerances challenging |

| Nylon (PA6, PA66) | $55–$95/hr | $70–$120/hr | $100–$160/hr | $50–$85/hr | Hygroscopic; requires drying; dimensional stability concerns |

| Tooling & Fixturing | Standard vise | Rotary indexer (4th axis) | Multi-axis trunnion or swivel | Collet or chuck | Custom fixtures increase NRE cost |

| Inspection Requirements | CMM or micrometer (basic) | CMM for angular features | Full CMM + GD&T analysis | OD/ID micrometers, bore gauges | Tight tolerance parts require full inspection reports |

| Lead Time (Typical) | 3–7 days | 5–10 days | 7–14 days | 3–6 days | Complex geometries and tight tolerances extend lead time |

Key Cost Drivers

Tight tolerance machining increases cost due to slower feed rates, specialized tooling (e.g., PCD or CBN for abrasives), temperature-controlled environments, and post-process metrology. Multi-axis milling reduces part handling but requires skilled programming (CAM) and longer validation. Materials like nylon and ABS, while lower in raw cost, can introduce variability due to moisture absorption, affecting dimensional accuracy and repeatability. Steel and hardened alloys increase tooling wear and cycle time, directly affecting hourly rates. For high-precision components, 5-axis CNC with in-process probing and thermal compensation delivers superior accuracy but at a premium.

From CAD to Part: The Process

Honyo Prototype Custom CNC Parts Cost Process Overview

Our streamlined workflow for custom CNC machining delivers transparent, accurate pricing from initial design to final shipment. This integrated process eliminates traditional quoting delays while ensuring manufacturability and cost efficiency.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or 2D drawings via our secure customer portal. The system automatically validates file integrity and extracts critical geometry data including part volume, feature complexity, tolerances, and material specifications. This structured data forms the technical foundation for immediate cost analysis without manual interpretation errors.

AI Quote Generation

Within 90 seconds, our proprietary AI engine processes the CAD data against dynamic cost parameters. The algorithm calculates machine time based on toolpath simulation, material consumption including waste factors, fixture requirements, and secondary operations. Real-time material market pricing and machine utilization rates are factored in, generating a firm quote with granular cost breakdowns. Clients receive instant visibility into cost drivers such as tolerance impacts or complex feature premiums before engineering engagement.

DFM Analysis and Collaboration

Upon quote acceptance, our manufacturing engineers conduct a formal Design for Manufacturability review. We identify opportunities to reduce costs while maintaining functional requirements—such as modifying non-critical radii, optimizing wall thicknesses, or consolidating features. Every suggested change includes a revised cost impact analysis visible in the client portal. This collaborative phase typically reduces final costs by 15-30% through actionable design refinements, with engineering approval required before production release.

Production Execution

Approved designs move to our climate-controlled machine floor with real-time scheduling visibility. We deploy the optimal equipment tier (3-axis, 5-axis, or mill-turn) based on part complexity, using only ISO-certified materials with full traceability. In-process inspections at critical stages verify dimensional compliance, while our ERP system tracks labor, machine hours, and material usage against the original quote. High-mix/low-volume capabilities allow efficient batch processing without setup cost penalties.

Delivery and Logistics

Finished parts undergo final CMM validation against original specifications, with inspection reports accessible in the portal. We manage consolidated shipping via pre-negotiated carrier rates with flat-fee domestic delivery. Clients receive automated shipment notifications with tracking and customs documentation for international orders. The entire process from CAD upload to delivery averages 5-7 business days for standard parts, with expedited options available.

This closed-loop system ensures cost predictability through algorithmic precision in quoting, engineering-driven optimization, and transparent production tracking—eliminating hidden fees and design rework common in traditional prototype machining services.

Start Your Project

Looking for accurate pricing on custom CNC parts? Contact Susan Leo at [email protected] for a fast, detailed quote tailored to your specifications. With our precision manufacturing facility located in Shenzhen, we deliver high-quality CNC machined components with quick turnaround times. Trust Honyo Prototype for cost-effective, reliable prototyping and low-volume production. Reach out today to streamline your next project.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.