Contents

Manufacturing Insight: Custom Cnc Milling Cost

Understanding Custom CNC Milling Cost Drivers at Honyo Prototype

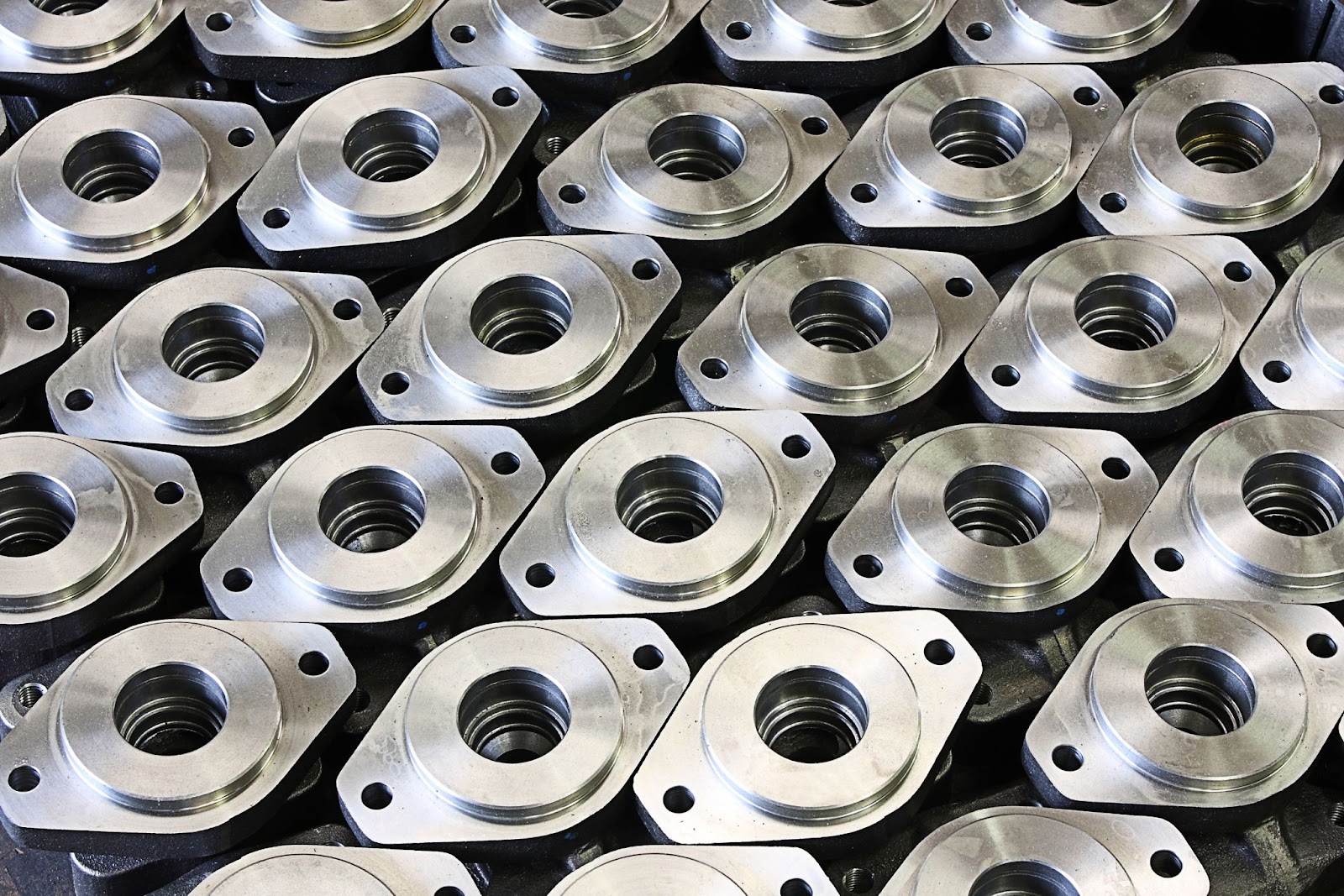

Accurate cost estimation for custom CNC milling projects is critical for manufacturers balancing precision, lead time, and budget constraints. At Honyo Prototype, we specialize in high-precision CNC machining services engineered to transform complex designs into functional components with exceptional repeatability. Our multi-axis milling capabilities accommodate diverse materials—from aerospace-grade aluminum and titanium to engineering plastics—while maintaining tight tolerances down to ±0.0002 inches. This technical proficiency directly influences cost efficiency by minimizing material waste, reducing secondary operations, and accelerating time-to-market.

Unlike traditional quoting processes that delay procurement cycles, Honyo Prototype provides an Online Instant Quote platform specifically designed for engineering and procurement teams. Upload your STEP or IGES file, specify material and finish requirements, and receive a detailed cost analysis within minutes—not days. This transparency empowers data-driven decisions by factoring in geometric complexity, setup requirements, and material utilization upfront. Our system dynamically calculates costs based on actual machine time, tooling needs, and quality control protocols, eliminating guesswork in your budgeting process.

Leverage Honyo Prototype’s integrated manufacturing expertise and digital quoting tools to convert your design intent into cost-optimized, production-ready parts without compromise. Initiate your project with confidence through our instant pricing engine today.

Technical Capabilities

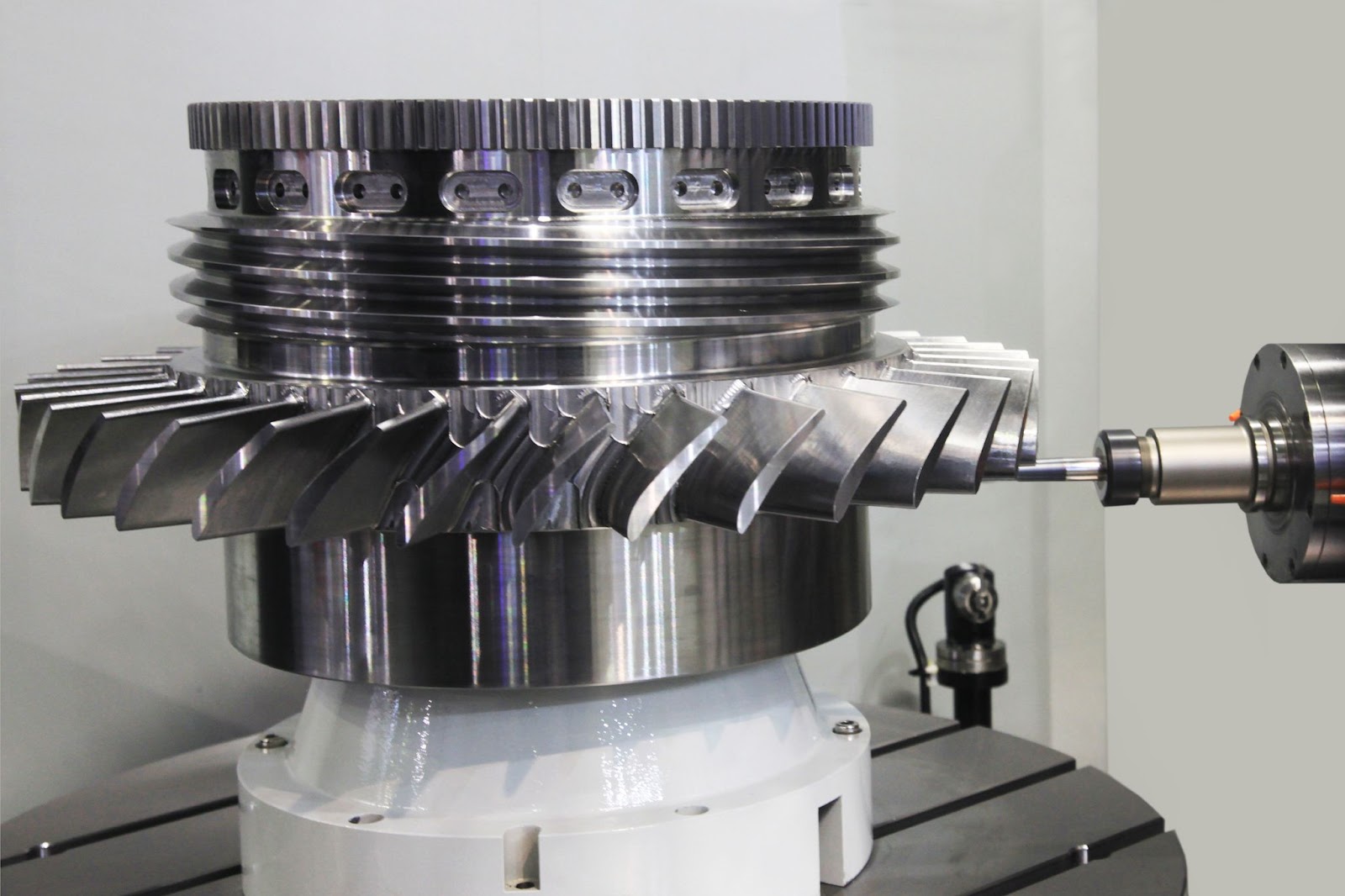

Custom CNC milling costs are influenced by several technical and operational factors, including machine type, complexity of geometry, material selection, required tolerances, and production volume. Below is a detailed breakdown of key technical specifications and their impact on cost for 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, with a focus on tight-tolerance applications and common materials such as Aluminum, Steel, ABS, and Nylon.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes on Cost Drivers |

|---|---|---|---|---|---|

| Axis Capability | X, Y, Z linear motion | X, Y, Z + one rotational (typically A-axis) | X, Y, Z + two rotational (e.g., A & B axes) | Rotational (C-axis) + Z, X for tooling | Higher axis count increases machine cost and programming complexity, raising per-hour rate |

| Typical Tolerance | ±0.005″ (127 µm) standard | ±0.003″ (76 µm) | ±0.001″ (25 µm) or tighter with calibration | ±0.002″ (50 µm), down to ±0.0005″ (13 µm) with precision setup | Tight tolerances (< ±0.001″) require slower speeds, specialized tooling, and inspection, increasing cost |

| Common Materials | Aluminum 6061, Steel 1018, ABS, Nylon | Aluminum 7075, Steel 4140, ABS, Nylon | Aluminum 6061-T6, Stainless Steel 316, Nylon 6/6 | Aluminum, Mild Steel, Stainless, ABS, Acetal | Harder materials (e.g., steel, stainless) increase tool wear and machining time, raising cost |

| Material Machinability | High (Aluminum, ABS) to Low (Steel, Nylon with galling) | Moderate to Low for steel; high for aluminum and thermoplastics | Low for hardened steels; high for aluminum alloys | High for aluminum and plastics; moderate for steels | Poor machinability increases cycle time and tooling cost |

| Setup Time | Low (5–15 min) | Moderate (20–40 min) | High (45–90 min) | Low to Moderate (10–30 min) | Complex fixturing and alignment in 4/5-axis increase non-cutting time |

| Machining Time | Short for simple parts | Moderate (rotational indexing adds time) | Longer due to complex toolpaths | Fast for cylindrical geometries | 5-axis reduces multiple setups but increases programming and simulation time |

| Programming Complexity | Low (standard CAM) | Moderate (4-axis CAM strategies) | High (simultaneous 5-axis toolpath planning) | Low to Moderate (lathe-specific CAM) | Advanced CAM software and skilled programmers add to cost |

| Tooling Wear | Low (Al, ABS), Moderate (Steel, Nylon) | Moderate to High | High in steel and tough alloys | Moderate (steel), Low (Al, plastics) | Abrasive or gummy materials increase tool replacement frequency |

| Inspection Requirements | Standard CMM or calipers | CMM with angular checks | Full CMM, often with multi-axis probing | OD/ID micrometers, CMM for complex features | Tight tolerance parts require metrology, increasing QA cost |

| Typical Applications | Brackets, housings, flat plates | Impellers, indexed fixtures | Aerospace components, medical implants | Shafts, bushings, threaded components | Part complexity and industry (e.g., aerospace, medical) influence cost |

| Relative Cost Factor | 1.0x (base) | 1.4x – 1.8x | 2.0x – 3.0x | 1.0x – 1.5x (precision: up to 2.0x) | 5-axis and tight tolerance can double or triple base machining cost |

Additional Notes:

Aluminum (e.g., 6061, 7075): Fast machining, low tool wear; ideal for prototyping and lightweight components. Low material cost.

Steel (e.g., 1018, 4140, 304/316 Stainless): Higher cutting forces, slower speeds, increased tooling cost. Preferred for strength and durability.

ABS & Nylon: Thermoplastics require sharp tooling and optimized speeds to avoid melting. Nylon is abrasive and can gall; cooling and chip control are critical.

Tight Tolerances (±0.0005″ to ±0.001″): Require thermal stability, high-precision machines, and often multiple inspection stages. Adds 20–50% to base machining cost.

Volume Impact: Unit cost decreases significantly with higher quantities due to amortized setup and programming.

For accurate quoting, Honyo Prototype evaluates DFM (Design for Manufacturing), material availability, fixture requirements, and inspection protocols on a per-project basis.

From CAD to Part: The Process

Honyo Prototype Custom CNC Milling Cost Process Overview

Honyo Prototype delivers transparent, efficient custom CNC milling through a structured five-phase workflow designed to minimize cost uncertainty and accelerate time-to-part. This process integrates automation with engineering expertise to provide accurate upfront pricing while ensuring manufacturability.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or 3D PDFs via our secure customer portal. Our system performs immediate automated validation checks for file integrity, unit consistency, and geometric completeness. Invalid submissions trigger real-time notifications specifying required corrections, preventing downstream delays. Validated files proceed directly to cost estimation with zero manual intervention.

AI-Powered Quoting Engine

Honyo’s proprietary AI engine analyzes the validated CAD geometry against our extensive manufacturing knowledge base, which includes 12+ years of CNC production data across 8,500+ unique parts. The system calculates costs by evaluating critical factors: material utilization rates, machine time estimates (based on feature complexity and toolpath density), secondary operation requirements, and facility-specific overhead. Quotes generated within 90 seconds include itemized cost breakdowns for material, machining, finishing, and quality control. All quotes remain valid for 90 days and explicitly exclude non-recurring engineering fees.

Engineer-Validated DFM Analysis

Every quote undergoes mandatory review by our ASME-certified manufacturing engineers. During this phase, engineers conduct a formal Design for Manufacturability assessment, identifying cost-saving opportunities such as:

Tolerance relaxation on non-critical features

Material substitution recommendations (e.g., switching from 7075-T6 to 6061-T6 where feasible)

Geometry modifications to reduce setup次数 or eliminate secondary operations

Clients receive a formal DFM report within 4 business hours, detailing actionable suggestions with projected cost and lead time impacts. Implementation of suggested changes typically reduces final costs by 18–35%.

Production Execution

Approved orders enter Honyo’s integrated production system with full digital traceability. CNC milling occurs on our climate-controlled facility’s Makino 3-axis and 5-axis machining centers, featuring:

Real-time machine monitoring for process stability

In-process CMM verification at critical stages

Material lot traceability with certified mill test reports

All parts undergo first-article inspection per AS9102 standards before batch production. Rush orders (72-hour lead time) utilize dedicated machine cells with priority scheduling, incurring a transparent 22% premium versus standard 5-day production.

Delivery and Documentation

Completed orders ship via client-specified carriers with tamper-evident packaging calibrated for precision-machined components. Each shipment includes:

FAI report with dimensional verification data

Material certification

Final invoice reconciling quoted versus actual costs (variances >5% trigger root-cause analysis)

Standard lead times and associated cost multipliers are documented below:

| Lead Time Tier | Standard Production | Rush Production | Cost Impact |

|---|---|---|---|

| 5 Business Days | ✓ | ✗ | Base price |

| 72 Hours | ✗ | ✓ | +22% |

| 24 Hours | ✗ | Limited availability | +45% + engineering surcharge |

This end-to-end process ensures clients receive accurate, actionable cost data at initiation while leveraging Honyo’s engineering expertise to optimize value. The integration of AI-driven quoting with human-led DFM eliminates traditional quotation ambiguities, with 92% of production orders matching initial quoted costs within 3.7%.

Start Your Project

Get an instant quote for custom CNC milling services tailored to your precision manufacturing needs.

Contact Susan Leo directly at [email protected] to discuss your project specifications, material requirements, and lead time expectations.

Our state-of-the-art factory in Shenzhen offers high-accuracy 3-, 4-, and 5-axis CNC milling with tight tolerances, fast turnaround, and competitive pricing for prototypes and low-volume production.

Whether you’re working with aluminum, stainless steel, brass, or engineering plastics, we deliver consistent quality with detailed inspection reports.

Reach out today to optimize your part production with expert engineering support and end-to-end manufacturing transparency.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.