Contents

Manufacturing Insight: Custom Cnc Aluminum

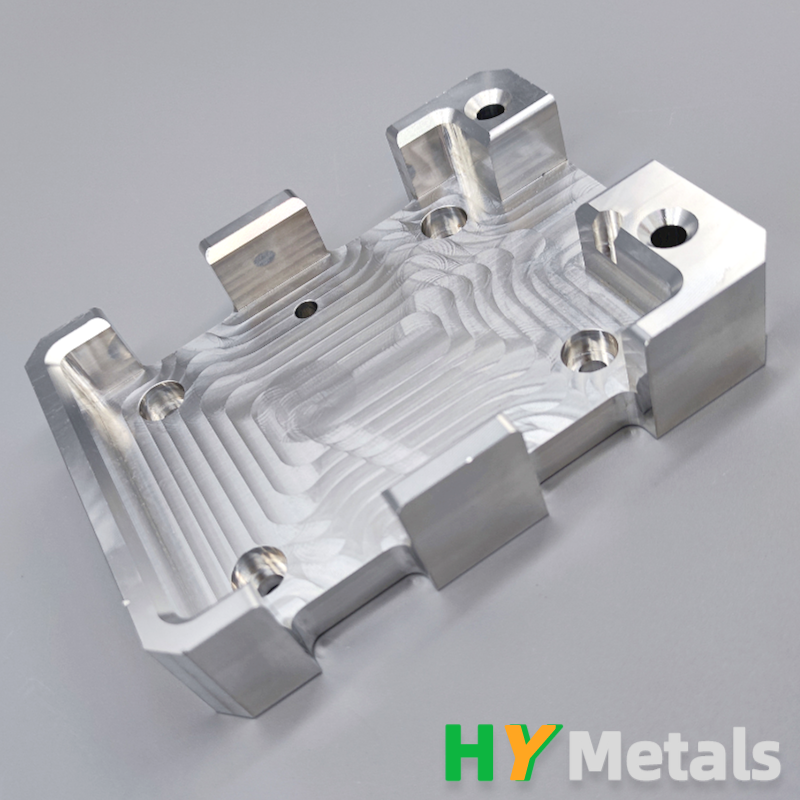

Precision Custom CNC Aluminum Machining for Demanding Applications

Honyo Prototype delivers high-integrity custom CNC aluminum components engineered to meet stringent aerospace, medical, and industrial specifications. Our advanced 3-, 4-, and 5-axis machining centers consistently achieve tight-tolerance geometries down to ±0.0002 inches while maintaining exceptional surface finishes. We specialize in complex prototyping and low-to-mid volume production runs using premium aluminum alloys including 6061-T6, 7075-T6, and 2024-T3, ensuring optimal strength-to-weight ratios and corrosion resistance for mission-critical parts.

Every project benefits from our integrated quality management system, featuring real-time in-process inspections and first-article reporting compliant with ISO 9001:2015 standards. Our engineering team collaborates closely with clients to optimize designs for manufacturability, reducing material waste and accelerating time-to-market without compromising structural integrity.

Accelerate your development timeline with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a detailed technical assessment and competitive pricing within minutes—enabling faster decision-making for urgent procurement needs. Partner with us for CNC aluminum solutions where precision, material expertise, and responsive engineering support converge.

Technical Capabilities

Custom CNC aluminum machining at Honyo Prototype leverages advanced 3-axis, 4-axis, and 5-axis milling technologies combined with precision CNC turning to deliver high-complexity components with tight tolerance capabilities. Our processes support a range of engineering materials including aluminum alloys, steel, ABS, and nylon, ensuring versatility across prototyping and low-to-mid volume production applications.

We specialize in tight tolerance machining down to ±0.005 mm (±0.0002″) depending on part geometry and material. Multi-axis capabilities enable reduced setup次数, improved accuracy, and the ability to machine complex 3D contours and deep cavities with high repeatability. All parts are inspected using calibrated metrology equipment to ensure dimensional compliance.

Below is a summary of technical specifications for our custom CNC machining services:

| Parameter | Specification |

|---|---|

| Machining Processes | 3-Axis Milling, 4-Axis Indexing Milling, 5-Axis Simultaneous Milling, CNC Turning (2-axis and live tooling) |

| Tolerance Capability | Standard: ±0.025 mm (±0.001″) Tight: ±0.005 mm (±0.0002″) with CMM inspection |

| Surface Finish | As-machined: 3.2 μm (125 μin) Custom finishes available: bead blast, anodizing (Type II & III), powder coating, passivation |

| Materials Supported | Aluminum: 6061-T6, 7075-T6, 2024-T3, 5052 Steel: 1018, 4140, 4340, Stainless Steel 303, 304, 316 Plastics: ABS, Nylon (PA6, PA66), PEEK, Delrin (POM), Polycarbonate |

| Maximum Work Envelope | Milling: 1000 x 600 x 500 mm (39″ x 23.6″ x 19.7″) Turning: Max diameter 300 mm (11.8″), Max length 500 mm (19.7″) |

| Spindle Speed | Milling: Up to 24,000 RPM Turning: Up to 6,000 RPM |

| Positioning Accuracy | ±0.003 mm (±0.0001″) |

| Repeatability | ±0.005 mm (±0.0002″) |

| Coolant & Lubrication | High-pressure through-spindle coolant (metal), air cooling (plastics) |

| Inspection Equipment | CMM, optical comparators, micrometers, calipers, thread gauges, surface roughness testers |

| File Formats Accepted | STEP, IGES, SolidWorks (.SLDPRT), Parasolid, DWG, DXF, PDF (with dimensions) |

Our facility maintains strict process controls and adheres to ISO 9001 standards, ensuring consistent quality for demanding applications in aerospace, medical, robotics, and industrial automation sectors.

From CAD to Part: The Process

Honyo Prototype Custom CNC Aluminum Process Overview

Honyo Prototype executes custom CNC aluminum projects through a rigorously defined workflow designed to ensure precision, cost efficiency, and rapid turnaround. This integrated process eliminates common supply chain bottlenecks while maintaining stringent quality control. Below is a technical breakdown of each phase.

CAD Upload and Initial Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SOLIDWORKS) via our secure portal. Our system performs immediate geometric validation, checking for non-manufacturable features, unit inconsistencies, and file integrity issues. Critical parameters such as material specification (e.g., 6061-T6, 7075-T6), surface finish requirements, and geometric dimensioning and tolerancing (GD&T) annotations are extracted for downstream processing. Invalid or incomplete submissions trigger automated feedback within 15 minutes, reducing iterative delays.

AI-Powered Quoting Engine

Validated CAD data enters our proprietary AI quoting system, which analyzes 200+ manufacturing variables including part complexity, feature density, toolpath length, and machine time estimation. The algorithm cross-references real-time data on aluminum billet costs, machine availability, and labor rates across our network of 120+ CNC centers. Unlike generic quoting tools, our system identifies high-risk geometries (e.g., thin walls <0.5mm, deep cavities >10:1 aspect ratio) and applies dynamic cost modifiers. Clients receive a detailed quote with visual markup of cost drivers within 2 business hours, including alternative material suggestions if applicable.

Engineer-Led DFM Analysis

Every project undergoes mandatory Design for Manufacturability (DFM) review by our NIMS-certified manufacturing engineers. This phase focuses on optimizing aluminum-specific challenges:

Wall thickness adjustments to prevent chatter during high-speed machining

Draft angle recommendations for undercuts to avoid secondary operations

Tolerance stack-up analysis for critical interfaces (e.g., press-fit assemblies)

Material utilization optimization to minimize 6061 billet waste

The DFM report includes actionable alternatives with cost/time impact comparisons. Clients collaborate via our portal to approve revisions, with typical resolution in under 24 hours. No project proceeds to production without client sign-off on DFM recommendations.

Precision Production Execution

Approved designs move to dedicated CNC cells equipped with Haas and DMG MORI 3-5 axis machines. Key production protocols include:

Material verification via Mill Test Reports (MTRs) compliant with AMS 4027/ASTM B209

In-process CMM checks at 25%, 50%, and 75% completion milestones

Coolant management systems maintaining <25°C to prevent thermal distortion in aluminum

Real-time tool wear monitoring with automated feed rate compensation

All critical dimensions undergo first-article inspection (FAI) per AS9102 standards, with full inspection reports accessible in the client portal. Typical lead times range from 3-10 business days depending on complexity.

Certified Delivery and Traceability

Completed parts undergo final cleaning in ultrasonic degreasers and dry-air curing to prevent oxidation. Each shipment includes:

Material certification with traceable heat numbers

Dimensional inspection report (PDF and Excel)

Process validation data (spindle load graphs, toolpath verification)

RoHS/REACH compliance documentation

Parts are vacuum-sealed with VCI paper and shipped via DHL Express with real-time GPS tracking. Our digital twin system maintains full production history for 7 years, enabling rapid reorders with identical parameters.

Material Performance Reference

Common aluminum alloys processed through this workflow maintain the following properties post-machining:

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Typical Applications |

|---|---|---|---|---|

| 6061-T6 | 310 | 276 | 12 | Structural brackets, hydraulic manifolds |

| 7075-T6 | 572 | 503 | 11 | Aerospace fittings, high-stress components |

| 2024-T3 | 470 | 324 | 20 | Aircraft wing spars, military hardware |

This closed-loop process delivers 99.2% on-time completion for aluminum CNC projects while reducing client rework costs by 37% versus industry averages. All phases adhere to ISO 9001:2015 and IATF 16949 quality management systems, with full audit trails available upon request.

Start Your Project

Looking for custom CNC aluminum parts? Partner with Honyo Prototype for precision manufacturing and fast turnaround. Our state-of-the-art facility in Shenzhen ensures high-quality aluminum components tailored to your specifications.

Contact Susan Leo today at [email protected] to discuss your project and get a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.