Contents

Manufacturing Insight: Custom Ceramic Parts

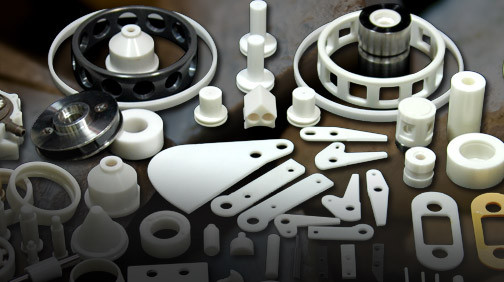

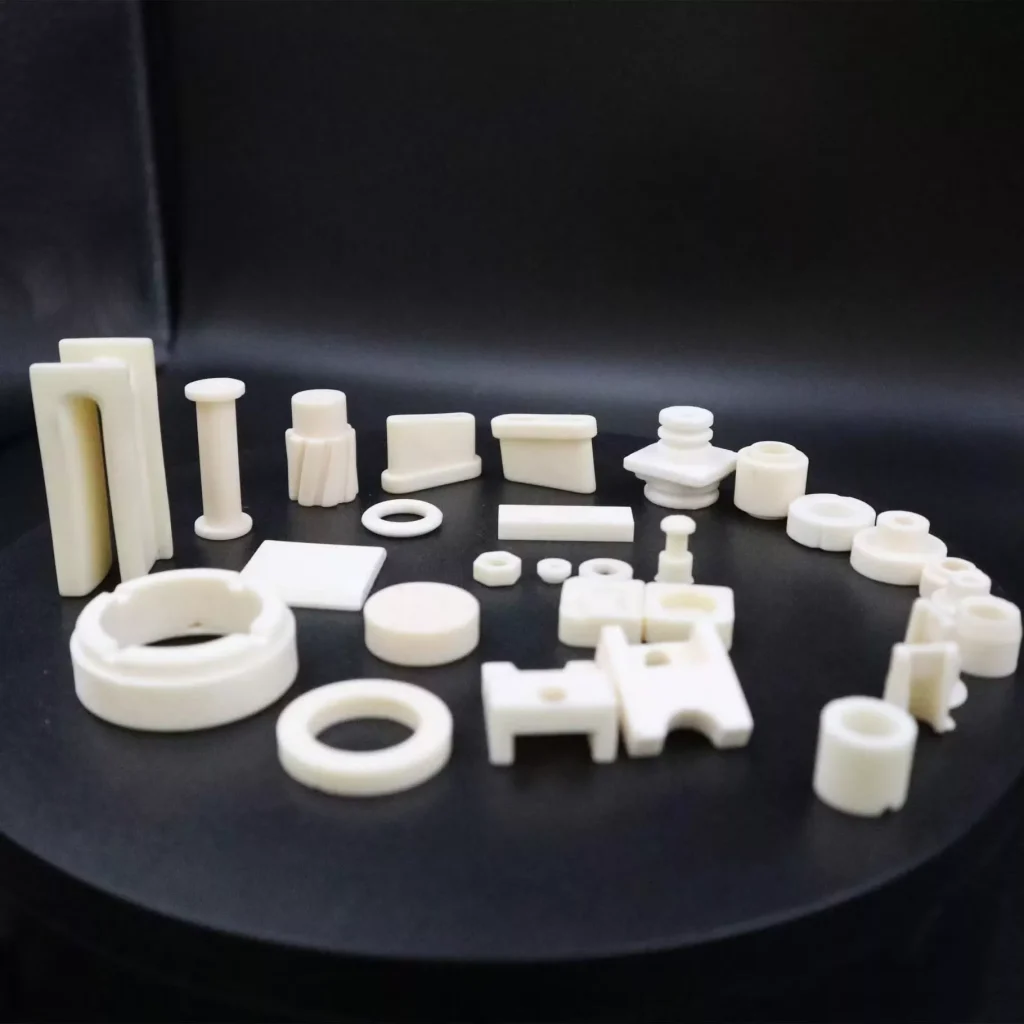

Honyo Prototype: Precision Ceramic CNC Machining for Demanding Applications

When your application demands the exceptional thermal stability, electrical insulation, or wear resistance of advanced ceramics like alumina, zirconia, or silicon nitride, traditional manufacturing bottlenecks often impede innovation. Complex geometries, tight tolerances, and material brittleness present significant challenges in prototyping and low-volume production, leading to extended lead times and compromised part integrity.

Honyo Prototype overcomes these limitations through specialized CNC machining expertise dedicated exclusively to technical ceramics. Our engineered process leverages multi-axis precision machining centers, diamond-coated tooling, and proprietary fixturing techniques to achieve sub-micron tolerances (±0.005mm) and superior surface finishes on even the most intricate ceramic components. We transform raw ceramic blanks into mission-critical parts for aerospace sensors, medical implants, semiconductor tooling, and energy systems—ensuring dimensional accuracy and material performance without sintering distortions.

Accelerate your development cycle with Honyo’s Online Instant Quote platform. Upload your CAD file, specify material and quantity, and receive a detailed manufacturability assessment with competitive pricing within hours—not days. This seamless integration of engineering rigor and digital efficiency eliminates quoting delays, allowing you to iterate faster and transition smoothly from prototype to production. Request your instant quote today to validate ceramic feasibility and reduce time-to-market for next-generation solutions.

Technical Capabilities

Custom ceramic parts require advanced machining processes to achieve high precision and complex geometries. While ceramics are inherently challenging to machine due to brittleness and hardness, 3/4/5-axis milling and turning are employed for near-net-shape finishing or post-sintering operations where tight tolerances are critical. However, the materials listed—aluminum, steel, ABS, and nylon—are not ceramics but are commonly machined using the same multi-axis platforms. Below is a technical comparison focused on capabilities relevant to high-precision custom components, with context on material compatibility.

| Parameter | 3/4/5-Axis Milling Capability | Turning Capability | Typical Tolerance Range | Material Compatibility (Machinability Notes) |

|---|---|---|---|---|

| Axis Configuration | 3-axis: XYZ linear; 4-axis: +A (rotary); 5-axis: +A & B/C (dual rotary) | CNC turning: primarily 2-axis (XZ), with live tooling enabling 3+ axes | N/A | All listed materials compatible with multi-axis milling and turning |

| Surface Finish | Ra 0.8–1.6 µm (standard); down to Ra 0.4 µm (precision) | Ra 0.8–3.2 µm (standard); down to Ra 0.2 µm (fine turning) | Depends on tooling and feed | Aluminum: excellent; Steel: good; ABS: good (cool cutting); Nylon: good (low friction, minimal tool wear) |

| Tolerance Capability | ±0.005 mm (±0.0002″) typical; down to ±0.001 mm (±0.00004″) with precision calibration | ±0.01 mm (±0.0004″) standard; ±0.002 mm (±0.00008″) achievable with high-end equipment | Tight tolerance applications: ±0.005 mm or better | Aluminum: high dimensional stability; Steel: stable but harder; ABS/Nylon: require compensation for thermal expansion |

| Tooling Systems | High-speed spindles (up to 24,000 RPM), carbide or diamond-coated end mills | Carbide inserts, CBN (for hardened steel), diamond tooling for plastics | N/A | Diamond tooling recommended for abrasive-filled plastics; aluminum requires sharp, polished cutters to avoid built-up edge |

| Machining of Ceramics | Limited to green-state or post-sintered grinding/micro-machining; not typically done on standard metal/plastic CNC platforms | Not applicable for fully sintered ceramics; green-state turning possible | ±0.02 mm typical for green machining | Ceramics (e.g., alumina, zirconia) require specialized EDM or laser processing; not compatible with standard CNC setups for metals/plastics |

| Lead Time & Setup | Moderate to high complexity setup; ideal for complex contours and undercuts | Fast for rotational parts; minimal setup for simple geometries | Depends on batch size | Aluminum: fastest; steel: moderate; ABS/Nylon: fast with optimized parameters |

Note: While the query references “custom ceramic parts,” the listed materials (aluminum, steel, ABS, nylon) are not ceramics. These materials are commonly machined via 3/4/5-axis milling and turning for applications requiring tight tolerances and complex features. True ceramic components are typically formed via pressing or injection molding and sintered, with final features achieved through diamond grinding or non-conventional methods. For hybrid projects involving ceramic assemblies with metallic or polymer components, multi-axis CNC machining of aluminum, steel, ABS, or nylon provides precise integration points, sealing surfaces, or structural supports.

From CAD to Part: The Process

Honyo Prototype Custom Ceramic Parts Process Overview

Our end-to-end workflow for custom ceramic components integrates advanced engineering with rapid prototyping capabilities, specifically optimized for technical ceramics like alumina, zirconia, and silicon nitride. The process ensures manufacturability, material integrity, and accelerated time-to-part without compromising on precision.

CAD Upload and Initial Assessment

Clients initiate the process by uploading 3D CAD files (STEP or IGES format) via our secure customer portal. Our system immediately performs a preliminary geometry scan to verify file integrity and identify potential red flags such as non-manufacturable wall thicknesses below 0.5 mm or unsupported overhangs exceeding 45 degrees. This initial check prevents downstream delays and ensures the file meets baseline ceramic processing requirements.

AI-Powered Quoting with Engineering Validation

Uploaded designs enter our proprietary AI quoting engine, which cross-references the geometry against Honyo’s material database, historical production data, and real-time machine capacity. The AI generates a preliminary quote within 2 hours, detailing material options, estimated lead time, and cost drivers. Crucially, this output undergoes mandatory review by a ceramic manufacturing engineer who validates the AI’s assumptions—particularly for critical factors like sintering shrinkage compensation (typically 18–22% for alumina), thermal stress risks, and geometric feasibility. Clients receive a technically vetted quote with clear rationale for any design constraints identified.

Collaborative DFM Analysis

Upon quote acceptance, our engineering team conducts a comprehensive Design for Manufacturability review focused on ceramic-specific challenges. This phase includes:

Simulation of green-state machining tolerances and sintering distortion using finite element analysis

Material selection guidance based on application requirements (e.g., thermal shock resistance for aerospace components)

Optimization recommendations for feature geometry to minimize post-sintering grinding

Identification of critical-to-quality dimensions requiring tight control (±0.005 mm achievable)

DFM feedback is delivered within 24–48 hours with annotated CAD markups and actionable alternatives, enabling rapid design iteration.

Precision Production Execution

Approved designs move to production using our integrated ceramic manufacturing cell:

1. Green State Forming: Dry pressing or injection molding for complex geometries, with in-process metrology to verify green part dimensions

2. Machining: CNC grinding of pre-sintered blanks to near-net shape using diamond tooling

3. Sintering: Controlled atmosphere furnaces with proprietary ramp/soak profiles to ensure density >99.5% and minimal warpage

4. Finishing: Precision grinding/polishing to final tolerances, with 100% CMM inspection against ASME Y14.5 GD&T

All stages adhere to ISO 9001:2015 protocols, with real-time process data logged for traceability.

Quality-Controlled Delivery

Completed parts undergo final validation per the client’s inspection plan, including material certification (e.g., ASTM F647 for alumina), surface roughness reports, and dimensional conformance data. Parts are packaged in custom anti-static, shock-absorbing containers with humidity control for ceramic stability. Every shipment includes a digital quality dossier and access to our shipment tracker showing real-time logistics status. Standard lead time from CAD upload to delivery is 10–15 business days for prototypes, with expedited options available for qualified projects.

This structured yet agile process ensures ceramic components meet stringent performance requirements while accelerating development cycles for industries including medical devices, semiconductor tooling, and energy systems.

Start Your Project

Looking for custom ceramic parts tailored to your exact specifications? Honyo Prototype specializes in precision manufacturing of advanced ceramic components for industries including electronics, medical devices, and industrial automation. With our state-of-the-art facility in Shenzhen, we deliver high-quality, reliable parts with fast turnaround times.

Contact Susan Leo today at [email protected] to discuss your project requirements. Let us support your prototyping and production needs with expert engineering and scalable manufacturing solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.