Contents

Manufacturing Insight: Custom Brass Parts

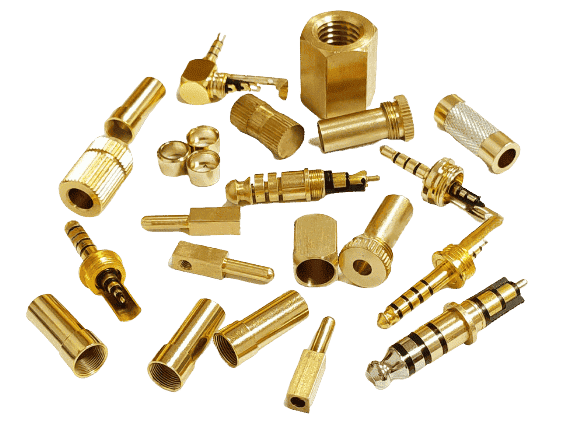

Precision Brass Components Engineered for Performance

Honyo Prototype delivers mission-critical custom brass parts through advanced CNC machining expertise, leveraging brass’s inherent properties of corrosion resistance, electrical conductivity, and exceptional machinability. Our multi-axis CNC machining centers achieve tight tolerances down to ±0.0002 inches, ensuring dimensional accuracy and surface finishes critical for hydraulic systems, electrical connectors, and precision instrumentation. We specialize in complex geometries—from intricate valve bodies to threaded fittings—using certified brass alloys including C36000, C26000, and C46400, with rigorous in-process inspection protocols to guarantee compliance with ISO 9001 standards.

Accelerate your prototyping or production timeline with Honyo’s Online Instant Quote system. Upload your 3D CAD file to receive a detailed, no-obligation cost analysis and lead time estimate within hours—not days—enabling faster design validation and procurement decisions.

Request your instant quote today to experience brass component manufacturing where precision meets speed.

Technical Capabilities

Custom brass parts manufactured via 3-axis, 4-axis, and 5-axis milling and turning processes are engineered for high precision and complex geometries across industries such as aerospace, medical, and industrial automation. These parts are typically held to tight tolerances, often within ±0.0005″ (±0.013 mm), depending on feature size and design complexity. While brass is the primary material focus, Honyo Prototype also supports precision machining of aluminum, steel, ABS, and nylon to meet diverse functional and environmental requirements.

Below is a summary of technical capabilities and material characteristics relevant to custom machined brass components:

| Parameter | Specification / Detail |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including multi-axis live tooling) |

| Tight Tolerance Capability | ±0.0005″ (±0.013 mm) typical; feature-dependent; held under controlled inspection |

| Surface Finish (Typical) | 32 to 125 µin RA; customizable with polishing, plating, or coating options |

| Feature Complexity | High – capable of deep pockets, undercuts, helical threading, micro-features |

| Primary Material | Brass (C36000 free-cutting brass standard); also C26000, C28000 upon request |

| Alternative Materials | Aluminum (6061-T6, 7075-T6), Steel (1018, 4140, 17-4 PH), ABS, Nylon (6 & 6/6) |

| Brass Material Properties | Excellent machinability, good corrosion resistance, electrical conductivity, low friction |

| Secondary Operations | Deburring, threading, knurling, anodizing (for Al), passivation, laser marking |

| Inspection & QA | First article inspection (FAI) reports, CMM, optical comparators, GD&T compliance |

| Max Work Envelope (Milling) | 24″ x 18″ x 12″ (600 x 450 x 300 mm); varies by machine configuration |

| Max Turning Diameter | 2.5″ to 6″ (63–152 mm) depending on bar feed and machine type |

| Lead Time (Typical) | 7–15 business days for prototypes; production runs quoted separately |

All custom brass parts are manufactured using high-speed CNC equipment with tool presetting and in-process probing to ensure dimensional accuracy. Multi-axis setups reduce part handling and improve repeatability, especially for complex contours and angled features. Material selection guides are available to assist in optimizing for strength, weight, conductivity, or chemical resistance.

From CAD to Part: The Process

Custom Brass Parts Workflow at Honyo Prototype

Honyo Prototype executes custom brass parts manufacturing through a rigorously defined five-stage process optimized for precision, speed, and technical validation. This workflow ensures brass-specific material properties—such as machinability, thermal conductivity, and corrosion resistance—are systematically addressed at every phase.

CAD Upload

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats preferred) via our secure customer portal. For brass components, we require geometrically complete models with critical tolerances, surface finish annotations, and alloy specifications (e.g., C36000 free-machining brass). Incomplete submissions trigger automated validation checks, notifying clients of missing datums or unsupported file types before proceeding.

AI-Powered Quoting

Uploaded CAD data feeds our proprietary AI quoting engine, which calculates real-time cost and lead time estimates. The algorithm factors brass-specific variables: material density (8.5 g/cm³ for C36000), current LME copper/zinc pricing volatility, machining complexity (e.g., thin walls prone to chatter), and secondary operations like plating. Quotes include material waste analysis and are human-reviewed by our engineering team within 2 business hours to validate AI output accuracy.

DFM Analysis

All brass designs undergo mandatory Design for Manufacturability review by certified manufacturing engineers. We focus on brass-specific risk mitigation: verifying adequate draft angles for casting, adjusting tolerances to account for brass’s 20.5 µm/m°C thermal expansion, and flagging features vulnerable to galling (e.g., fine threads without lubricity considerations). Clients receive a formal DFM report with actionable recommendations, such as modifying wall thicknesses to prevent sink marks in sand-cast brass or optimizing hole depth-to-diameter ratios for drilling stability.

Production Execution

Approved designs move to production in our ISO 9001-certified facility. Brass parts are manufactured using CNC milling/turning centers with carbide tooling optimized for brass’s high chip load rates. Key process controls include:

Material certification traceability (mill test reports for every brass billet)

In-process CMM verification at critical stages (e.g., after stress-relieving heat treatment)

Cleanroom assembly for fluid-handling components to prevent dezincification

Surface finishing via non-ferrous tumbling or electroless nickel plating per ASTM B733

The following table summarizes common brass alloys we machine and their typical applications:

| Alloy Designation | Common Name | Key Properties | Typical Applications |

|---|---|---|---|

| C36000 | Free-Cutting Brass | Highest machinability, good strength | Valves, fittings, screw machine parts |

| C26000 | Cartridge Brass | Excellent cold-forming, corrosion resistant | Electrical contacts, ammunition casings |

| C46400 | Naval Brass | Seawater corrosion resistance | Marine hardware, ship fittings |

Delivery Assurance

Final inspection includes first-article reporting (FAI) per AS9102 standards, material composition verification via XRF spectroscopy, and functional testing where applicable. All brass parts ship with full documentation: RoHS/REACH compliance certificates, dimensional inspection reports, and batch-specific material certifications. Standard lead time is 10–15 business days from DFM approval, with expedited options available. Every shipment includes anti-tarnish packaging and humidity indicators to maintain brass surface integrity during transit.

This integrated workflow reduces brass part development cycles by 30% compared to industry averages while ensuring metallurgical and dimensional compliance for mission-critical applications.

Start Your Project

Looking for high-precision custom brass parts manufactured to your exact specifications? Honyo Prototype delivers reliable, high-quality brass components for industrial, automotive, and OEM applications. With our advanced machining capabilities and strict quality control, we ensure consistent performance and fast turnaround.

Our manufacturing facility is based in Shenzhen, leveraging efficient production systems and strategic supply chain access for competitive pricing and timely delivery.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.