Contents

Manufacturing Insight: Custom Bracket Fabrication

Precision Custom Bracket Fabrication Through Advanced CNC Machining

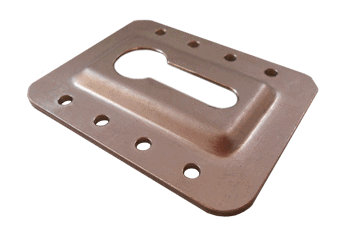

At Honyo Prototype, we transform complex bracket requirements into mission-critical components with uncompromising precision. Our CNC machining services deliver fully customized brackets engineered to exact structural and dimensional specifications, whether for aerospace assemblies, medical device frameworks, or industrial automation systems. Leveraging multi-axis milling and turning centers, we consistently achieve tight tolerances down to ±0.005 mm across diverse materials including aluminum alloys, stainless steel, titanium, and engineered plastics. This capability ensures optimal load distribution, vibration resistance, and seamless integration into your final assembly—eliminating field failures caused by off-the-shelf compromises.

What sets Honyo apart is our commitment to accelerating your prototyping and production timeline. Our streamlined workflow transitions digital designs directly into certified, ready-to-install brackets with rapid turnaround, supported by in-house metallurgical verification and first-article inspection reports. Crucially, we remove procurement friction through our Online Instant Quote platform, where engineers upload CAD files to receive detailed cost and lead-time estimates within seconds—no manual RFQ delays. This transparency empowers faster decision-making while maintaining the rigorous quality standards expected from a trusted manufacturing partner.

For brackets that perform under real-world demands, Honyo Prototype combines CNC precision with responsive engineering collaboration. Begin your project with confidence: validate feasibility and pricing instantly at honyoprototype.com/quote.

Technical Capabilities

Custom bracket fabrication at Honyo Prototype leverages advanced 3-, 4-, and 5-axis CNC milling along with precision turning to produce complex, high-integrity components for demanding industrial, aerospace, and automation applications. Our process is optimized for tight-tolerance requirements, typically holding ±0.0005″ (0.0127 mm) on critical features, with full first-article inspection and CMM reporting available. Multi-axis capabilities allow for reduced setup counts, improved part accuracy, and the ability to machine complex geometries in a single operation.

We support a range of engineering-grade materials including aluminum, steel, ABS, and nylon, enabling solutions from lightweight structural brackets to high-strength, wear-resistant components. Material selection is matched to functional requirements such as strength, weight, corrosion resistance, and environmental stability.

Below is a summary of technical capabilities for custom bracket fabrication:

| Parameter | Specification |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning |

| Tolerance Capability | ±0.0005″ (0.0127 mm) typical; tighter tolerances on request with SPC controls |

| Surface Finish | As-machined: 32–125 μin Ra; post-processed options available (e.g., anodizing, plating, coating) |

| Materials | Aluminum (6061-T6, 7075-T6), Steel (1018, 4140, Stainless 304/316), ABS (FDM-grade), Nylon (PA6, PA66) |

| Maximum Work Envelope | Milling: 24″ × 36″ × 20″ (610 × 914 × 508 mm); Turning: Ø16″ × 48″ (406 × 1219 mm) |

| Lead Time (Prototype) | 5–10 business days, depending on complexity and material |

| Quality Standards | ISO 9001-compliant processes; FAI reports, CMM inspection, GD&T support |

| Secondary Operations | Deburring, tapping, hardware insertion, heat treatment, surface finishing |

This capability ensures that custom brackets meet rigorous design and performance criteria, whether for rapid prototyping or low-volume production runs.

From CAD to Part: The Process

Honyo Prototype Custom Bracket Fabrication Process Overview

Honyo Prototype executes custom bracket fabrication through a rigorously defined five-stage workflow designed for speed, accuracy, and manufacturability. This process eliminates traditional quoting bottlenecks while ensuring engineering integrity from initial design to final shipment.

Step 1: CAD Upload via Secure Client Portal

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS/AutoCAD) through Honyo’s encrypted web portal. The system automatically validates file integrity and extracts critical geometric data, material specifications, and tolerance requirements. All uploads undergo immediate virus scanning and are assigned a unique project ID for traceability, with no manual intervention required at this stage.

Step 2: AI-Powered Instant Quoting

Uploaded designs enter Honyo’s proprietary AI quoting engine, which analyzes over 200 manufacturability parameters in under 90 seconds. The system cross-references real-time material costs, machine availability, labor rates, and historical production data to generate a fixed-price quote. Key outputs include cost breakdowns, lead time estimates (typically 3–7 business days for brackets), and preliminary feasibility flags. Clients receive downloadable PDF quotes with engineering notes, eliminating the 24–72 hour quoting delays common in traditional shops.

Step 3: Engineering-Driven DFM Analysis

Upon quote acceptance, Honyo’s manufacturing engineers conduct a collaborative Design for Manufacturability (DFM) review. Unlike automated-only checks, this phase combines algorithmic analysis with human expertise to address:

Material yield optimization and grain direction requirements for structural brackets

Tolerance stack-up validation against ASME Y14.5 standards

Feature manufacturability (e.g., minimum bend radii, hole spacing, flange heights)

Secondary operation sequencing (tapping, welding, finishing)

Engineers provide annotated CAD markups within 4 business hours, proposing actionable revisions that reduce costs by 15–30% while maintaining functional requirements. Client approval is mandatory before production launch.

Step 4: Precision Production Execution

Approved designs move to our climate-controlled fabrication floor using the following standardized workflow:

| Process Stage | Equipment Used | Key Capabilities |

|---|---|---|

| Cutting | Amada LC-2513 AJ fiber laser | ±0.1mm accuracy, 25mm max steel thickness |

| Forming | Trumpf TruBend 5000 press brakes | 130-ton capacity, 3D backgauge simulation |

| Machining | DMG MORI CTX beta 1250 | 5-axis milling, ±0.025mm tolerances |

| Finishing | Automated deburring + powder coat line | ISO 12944-compliant coatings |

All brackets undergo in-process CMM verification at critical stages, with first-article inspection reports (FAIRs) provided pre-shipment. High-mix production cells enable concurrent runs of dissimilar bracket designs without reconfiguration delays.

Step 5: Quality-Controlled Delivery

Final brackets receive full dimensional certification per ISO 9001:2015 protocols. Each shipment includes:

Batch-specific material certs (MTRs)

FAIRs with 3D deviation maps

Traceability logs linking to production timestamps

Protective packaging rated for international freight

Orders ship via DHL/FedEx with real-time logistics tracking, typically achieving 99.2% on-time delivery. Rush services (24–72 hour turnaround) are available for emergency prototypes through our dedicated express lane.

This integrated process reduces typical bracket prototyping cycles by 65% compared to industry averages while maintaining rigorous quality control. Clients gain full visibility via our client portal, which provides real-time production dashboards from DFM approval through shipment confirmation.

Start Your Project

Looking for custom bracket fabrication tailored to your exact specifications? Partner with Honyo Prototype for precision-engineered solutions manufactured at our Shenzhen facility. With advanced fabrication capabilities and strict quality control, we deliver durable, high-performance brackets for industrial, automotive, and electronics applications.

Contact Susan Leo today to discuss your project requirements. Email at [email protected] for fast, professional support and prototyping-to-production service.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.