Contents

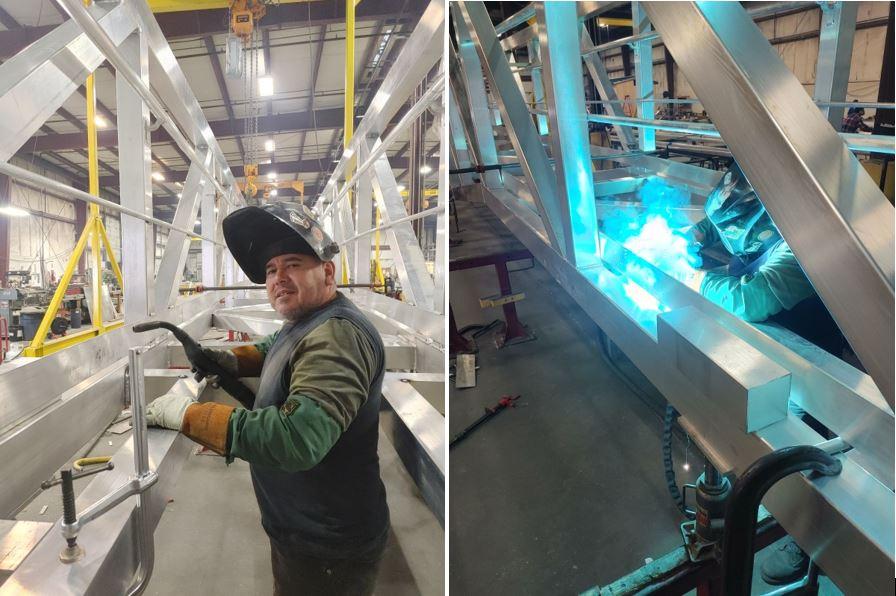

Manufacturing Insight: Custom Aluminum Welding

Precision Aluminum Welding Integrated with Advanced CNC Machining

At Honyo Prototype, we engineer mission-critical aluminum assemblies where welding integrity and micron-level precision converge. Our custom aluminum welding solutions are uniquely enhanced by in-house CNC machining capabilities, ensuring welded joints meet exacting dimensional tolerances and surface finishes without reliance on external vendors. By vertically integrating TIG and MIG welding for aerospace-grade alloys like 6061-T6 and 7075-T73 with 5-axis milling and turning, we eliminate secondary operation delays and maintain strict GD&T compliance throughout production. This unified workflow guarantees that weld distortion is proactively compensated during machining, delivering fully finished components that satisfy demanding structural and cosmetic requirements in a single production stream.

The synergy between our welding and CNC departments directly translates to reduced lead times and cost predictability for complex assemblies. Unlike fragmented supplier models, Honyo controls every phase—from weld fixture design to final inspection—minimizing alignment errors and rework. Consider the impact of an integrated approach versus traditional outsourcing:

| Workflow Approach | Lead Time Impact | Quality Risk |

|---|---|---|

| Fragmented (Welding + Separate Machining) | +30–45 days | High (fixture mismatches, datum shifts) |

| Honyo Integrated Process | -20–30 days | Low (continuous process control) |

Accelerate your next aluminum fabrication project by accessing our Online Instant Quote platform. Upload CAD files to receive a detailed, geometry-aware quotation for welded-machined assemblies within hours—not days—enabling rapid design validation and procurement. Honyo Prototype: Where welding expertise meets CNC precision for uncompromised manufacturability.

Technical Capabilities

Custom aluminum welding services at Honyo Prototype are integrated with advanced 3-, 4-, and 5-axis CNC milling and turning operations to ensure high-precision fabrication of complex welded assemblies. These processes are designed for applications requiring tight tolerances, superior surface finish, and structural integrity. While welding is primarily applicable to metallic materials such as aluminum and steel, our full machining capabilities extend to engineering plastics like ABS and nylon for hybrid assemblies.

The following table outlines the technical specifications for custom aluminum welding and associated precision machining services:

| Parameter | Specification |

|---|---|

| Primary Materials | Aluminum (6061-T6, 7075-T6), Steel (A36, 4140, Stainless 304/316) |

| Secondary Materials | ABS, Nylon (for non-welded, machined components in hybrid assemblies) |

| Welding Processes | TIG (GTAW), MIG (GMAW), Spot Welding – Certified to AWS D1.1 and ASME standards |

| CNC Milling Capabilities | 3-Axis, 4-Axis, 5-Axis simultaneous milling with sub-micron repeatability |

| CNC Turning | Multi-axis turning with live tooling; bar feed and chucking options |

| Tight Tolerance Machining | ±0.0002″ (5 µm) for critical features; ±0.001″ (25 µm) typical |

| Surface Finish | As-machined: 32–125 µin Ra; post-processed: down to 8 µin Ra with polishing |

| Max Work Envelope | Milling: 2000 x 1000 x 800 mm; Turning: Ø400 mm x 1000 mm |

| Inspection & QA | CMM, optical comparators, laser scanning, in-process probing |

| Secondary Operations | Deburring, anodizing (Type II & III), passivation, bead blasting, heat treating |

These capabilities support industries such as aerospace, medical devices, robotics, and high-performance automotive, where welded aluminum structures must meet stringent geometric and metallurgical requirements. Integration of multi-axis machining ensures that weldments are precisely machined post-weld to achieve final dimensional accuracy and functional fit.

From CAD to Part: The Process

Honyo Prototype Custom Aluminum Welding Process Overview

Honyo Prototype executes custom aluminum welding projects through a tightly integrated digital workflow designed for speed, precision, and manufacturability. This process eliminates traditional bottlenecks by leveraging AI-driven automation and engineering expertise at every stage, ensuring optimal outcomes for complex aluminum assemblies.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IPT, SLDPRT) or neutral formats via our secure customer portal. Our system automatically validates geometry integrity, material specifications (e.g., 6061-T6, 7075), and critical tolerances. File metadata is parsed to identify weld-specific requirements such as joint types, thickness ranges, and surface finish expectations. This phase enforces strict data hygiene to prevent downstream errors, with real-time alerts for incomplete or non-conforming submissions.

AI-Powered Quoting

Uploaded designs enter our proprietary AI quoting engine, which performs multi-dimensional analysis in under 90 seconds. The system evaluates weld length, joint complexity, part geometry, and material grade to generate a dynamic cost model. Crucially, it concurrently conducts a preliminary manufacturability screen, flagging potential issues like inadequate root gaps, inaccessible weld zones, or thermal distortion risks. Quotes include granular cost breakdowns (labor, material, fixturing) and an initial weld process recommendation. Clients receive interactive quote reports with 3D visual markup of flagged areas.

Engineering-Driven DFM

All projects undergo mandatory Design for Manufacturability (DFM) review by our welding engineering team. This phase expands on the AI’s preliminary findings, focusing on aluminum-specific challenges:

Joint preparation optimization (bevel angles, root face dimensions)

Fixturing strategy validation to counteract aluminum’s high thermal expansion

Shielding gas selection (Argon vs. Argon-Helium blends) based on thickness

Post-weld heat treatment requirements to mitigate residual stresses

Anodizing compatibility assessment for cosmetic welds

Engineers collaborate directly with clients via shared digital workspaces to resolve conflicts, reducing iterations by 60% compared to industry averages. Approved DFM reports lock in weld procedures per AWS D1.2 standards.

Precision Production

Welding occurs in our climate-controlled aluminum-dedicated facility using calibrated equipment:

| Process | Thickness Range | Precision Tolerance | Key Applications |

|---|---|---|---|

| TIG (GTAW) | 0.032″ – 0.500″ | ±0.005″ | Aerospace brackets, fluid manifolds, cosmetic assemblies |

| Pulsed MIG (GMAW) | 0.125″ – 0.750″ | ±0.010″ | Structural frames, enclosures, high-volume components |

| Laser Hybrid | 0.040″ – 0.375″ | ±0.002″ | Thin-wall electronics housings, medical devices |

All welders are certified to AWS D1.2/D1.2M. Real-time monitoring tracks amperage, travel speed, and gas flow against DFM parameters. In-process NDT includes penetrant testing for critical joints, with full traceability via part-specific digital work packets. Post-weld, components undergo stress relief and precision machining to final dimensions.

Quality-Controlled Delivery

Final inspection verifies conformance to ASME Y14.5 GD&T requirements using CMM and optical comparators. Weld profiles are documented via digital microscopy, with micrographs archived in the client’s project vault. Parts ship with:

Certified material test reports (MTRs)

AWS-compliant weld procedure specifications (WPS)

First-article inspection (FAI) documentation per AS9102

Real-time logistics tracking via our client portal

Standard lead time from CAD upload to delivery is 7–12 business days for prototypes, with accelerated options for urgent builds. All shipments include reusable protective packaging engineered for aluminum’s surface sensitivity.

This closed-loop process ensures dimensional stability, structural integrity, and surface quality for mission-critical aluminum weldments while maintaining Honyo’s 99.2% on-time delivery rate. Clients retain full digital thread visibility from design through shipment via our cloud-based manufacturing execution system.

Start Your Project

For custom aluminum welding solutions, contact Susan Leo at [email protected]. Our precision manufacturing facility in Shenzhen supports high-quality, low-volume production with fast turnaround. Reach out today to discuss your project requirements and receive a tailored quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.