Contents

Manufacturing Insight: Custom Aluminum Sheet Fabrication

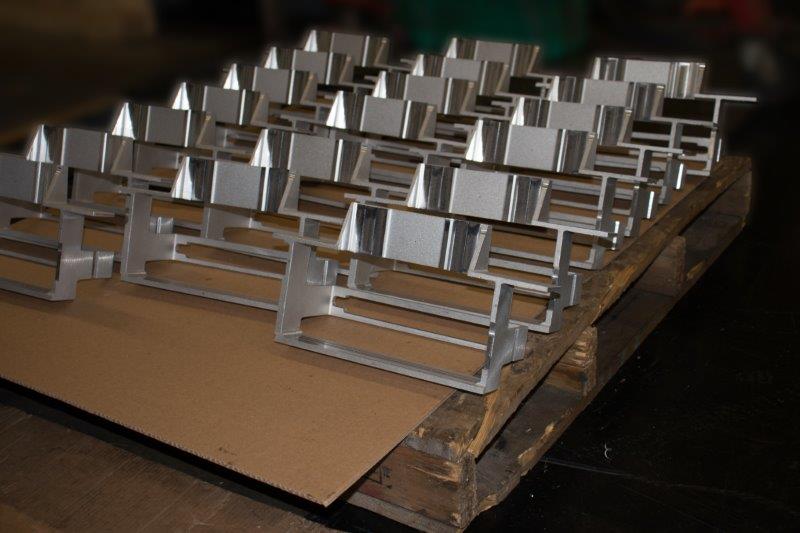

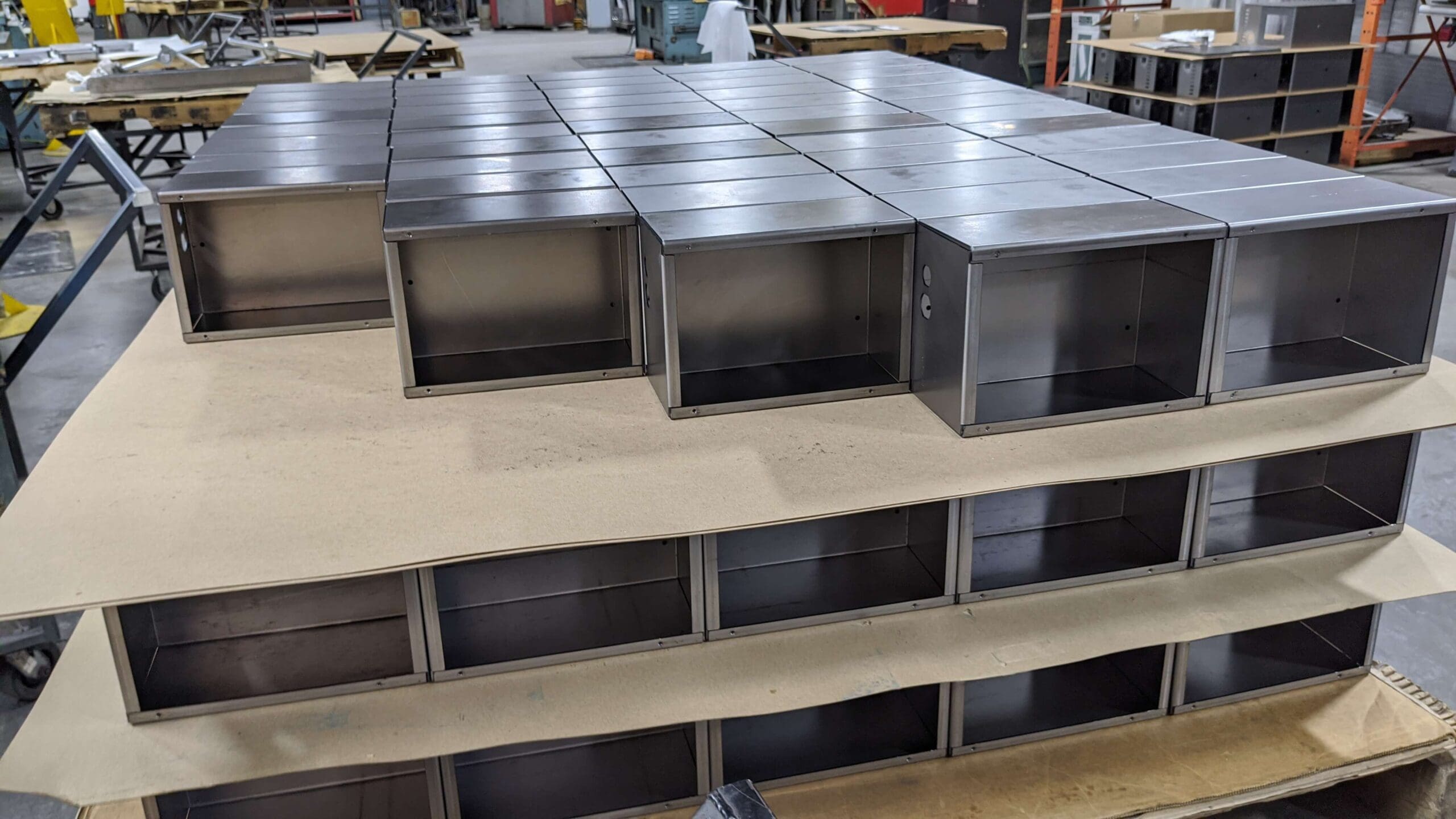

Precision Aluminum Sheet Fabrication for Demanding Industrial Applications

Honyo Prototype delivers end-to-end custom aluminum sheet fabrication engineered to meet stringent industrial requirements. Our advanced sheet metal capabilities encompass precision laser cutting, CNC bending, and comprehensive finishing processes—including anodizing, powder coating, and mechanical polishing—ensuring optimal performance for aerospace, medical, and automation sectors. We specialize in transforming 1060, 5052, 6061, and 7075 aluminum alloys into complex components with tolerances down to ±0.05mm, supporting both low-volume prototyping and high-volume production runs.

Leveraging state-of-the-art Amada and Trumpf equipment, we maintain rigorous quality control through in-process CMM validation and material traceability protocols. This technical rigor minimizes waste, accelerates time-to-market, and guarantees dimensional consistency across all project scales. For immediate project viability assessment, our Online Instant Quote system provides detailed manufacturing feedback and cost estimates within minutes—eliminating traditional quotation delays while validating design manufacturability against real-time production constraints. Partner with Honyo to convert your aluminum sheet specifications into certified, production-ready solutions.

Technical Capabilities

Custom aluminum sheet fabrication at Honyo Prototype integrates precision laser cutting, CNC bending, and expert welding to deliver high-tolerance metal components for industrial, automotive, and electronic applications. While aluminum is the primary material, our capabilities extend to steel, ABS, and nylon for hybrid assemblies or specialized requirements. Below is a detailed technical specification table outlining key process parameters and compatible materials.

| Process | Material Compatibility | Thickness Range | Tolerance | Tooling / Equipment | Notes |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum (6061-T6, 5052-H32), Mild Steel, Stainless Steel, ABS, Nylon (limited) | 0.5 mm – 12.0 mm (Aluminum), 0.5 mm – 10.0 mm (Steel), 0.5 mm – 6.0 mm (ABS/Nylon) | ±0.1 mm (standard) | 4 kW Fiber Laser, Nesting Software (AutoCAD/SolidWorks compatible) | High edge quality; minimal burr on aluminum; not recommended for thick nylon |

| CNC Bending | Aluminum (6061-T6, 5052-H32), Mild Steel, Stainless Steel | 0.8 mm – 6.0 mm | ±0.2° angular, ±0.1 mm linear | Amada CNC Press Brakes, V-dies with standard tool sets | Minimum flange: 2.5× material thickness; sharp bends may require special tooling |

| MIG/TIG Welding | Aluminum (6061, 5052), Mild Steel, Stainless Steel | 1.0 mm – 10.0 mm | ±0.5 mm (joint alignment) | ER319 filler (Al), ER70S-6 (Steel), Argon shielding | TIG preferred for thin aluminum; MIG for high-speed production |

| Material Notes | 6061-T6: High strength, weldable; 5052-H32: Excellent formability; Mild Steel: Low carbon, paintable; Stainless: Corrosion resistant; ABS/Nylon: Used for inserts or non-structural parts | — | — | — | ABS and nylon are machinable but not bendable; welding limited to ultrasonic or hot plate methods for plastics |

All fabricated components undergo in-process inspection and final dimensional verification. Secondary operations such as deburring, anodizing, powder coating, and hardware insertion are available upon request. Design for manufacturability (DFM) feedback is provided during quoting to optimize cost and performance.

From CAD to Part: The Process

Honyo Prototype delivers precision custom aluminum sheet fabrication through a tightly integrated five-stage workflow designed for speed, accuracy, and manufacturability. Our process begins with seamless digital onboarding and concludes with tracked global delivery, optimized specifically for aluminum’s unique material properties including grain direction sensitivity, springback behavior, and surface finish requirements.

CAD Upload and AI-Powered Quoting

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, DWG) via our secure customer portal. Our proprietary AI engine instantly analyzes geometric complexity, sheet thickness (0.5mm to 6.0mm), bend counts, hole patterns, and critical tolerances per ISO 2768-mK. The system cross-references real-time material costs, machine availability, and labor rates against our aluminum-specific production database—accounting for alloy types (6061-T6, 5052-H32, etc.), anodizing needs, and secondary operations—to generate a detailed quote within 90 seconds. This immediate feedback loop reduces RFQ turnaround from days to minutes while flagging potential data ambiguities like missing bend radii or conflicting datums.

Engineering-Validated DFM Analysis

Every project undergoes mandatory Design for Manufacturability validation by our senior aluminum fabrication engineers before production release. Unlike automated-only systems, our engineers perform deep-dive reviews focusing on aluminum-specific failure points: minimum bend radii relative to material thickness, hole-to-edge clearance to prevent distortion, grain orientation for critical bends, and thermal management during welding or heat treatment. We provide actionable revision suggestions via annotated 3D markups within 24 hours, ensuring designs align with our Amada CNC punch presses, Bystronic laser cutters, and precision press brakes. Key DFM checks include:

| Critical Parameter | Industry Standard Check | Honyo Enhanced Validation |

|---|---|---|

| Bend Radius | Minimum 1x material thickness | Adjusted for alloy temper (e.g., 0.8x for 5052-H32) |

| Hole Spacing | 2x hole diameter | 3x diameter for pierced holes near bends to prevent buckling |

| Grain Direction | Not typically verified | Explicitly confirmed for parts with >90° bends |

| Surface Finish | Basic requirement note | Masking strategy defined for anodized zones |

Precision Aluminum Production

Approved designs move to our climate-controlled fabrication floor where material traceability is maintained from raw sheet to finished part. Key production phases include:

Material staging with lot-controlled aluminum sheets from certified mills, laser cutting or CNC punching with kerf compensation for aluminum’s thermal expansion, precision air bending with real-time springback adjustment on 100-300 ton press brakes, and secondary operations like robotic MIG welding per AWS D1.2 standards. All critical dimensions undergo in-process CMM verification at defined hold points, with surface finishes ranging from #4 brushed to Type II anodized per MIL-A-8625. Our production cells are optimized for aluminum’s burr formation tendencies, employing specialized tooling coatings and deburring protocols to meet Ra ≤ 1.6μm requirements.

Quality-Controlled Delivery

Final inspection includes first-article reporting per AS9102, full FAI documentation, and material certification traceability to mill test reports. Parts are packaged with anti-corrosion VCI paper and rigid foam inserts to prevent transit marring of anodized surfaces. We provide real-time shipment tracking via our logistics portal with ETAs updated through DHL/FedEx APIs, supporting JIT delivery schedules with 99.2% on-time performance. Every shipment includes a digital quality dossier accessible via QR code, containing dimensional reports, process parameters, and non-conformance logs if applicable—ensuring full compliance for aerospace, medical, and industrial clients requiring ISO 9001:2015 and AS9100D traceability.

Start Your Project

For custom aluminum sheet fabrication solutions tailored to your specifications, contact Susan Leo at [email protected]. With precision engineering and rapid turnaround times, Honyo Prototype delivers high-quality fabricated aluminum components directly from our Shenzhen manufacturing facility.

Leverage our in-house capabilities for cutting, bending, welding, and finishing—all under strict quality control. Whether you need prototypes or low-volume production, we support your project with engineering expertise and cost-effective manufacturing.

Reach out today to request a quote or discuss your design requirements. Partner with a trusted manufacturer based in Shenzhen for reliable, responsive service.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.