Contents

Manufacturing Insight: Custom Aluminum Sheet

Precision Aluminum Solutions Engineered for Your Complex Builds

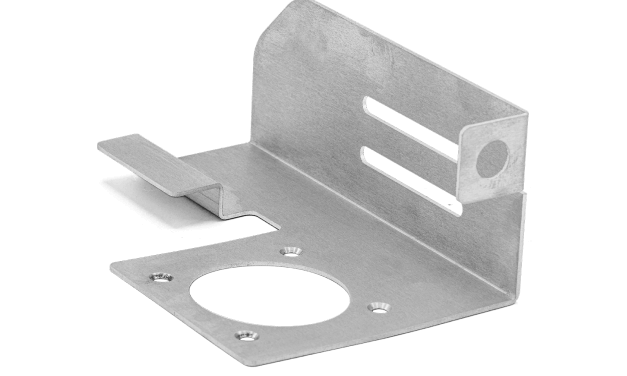

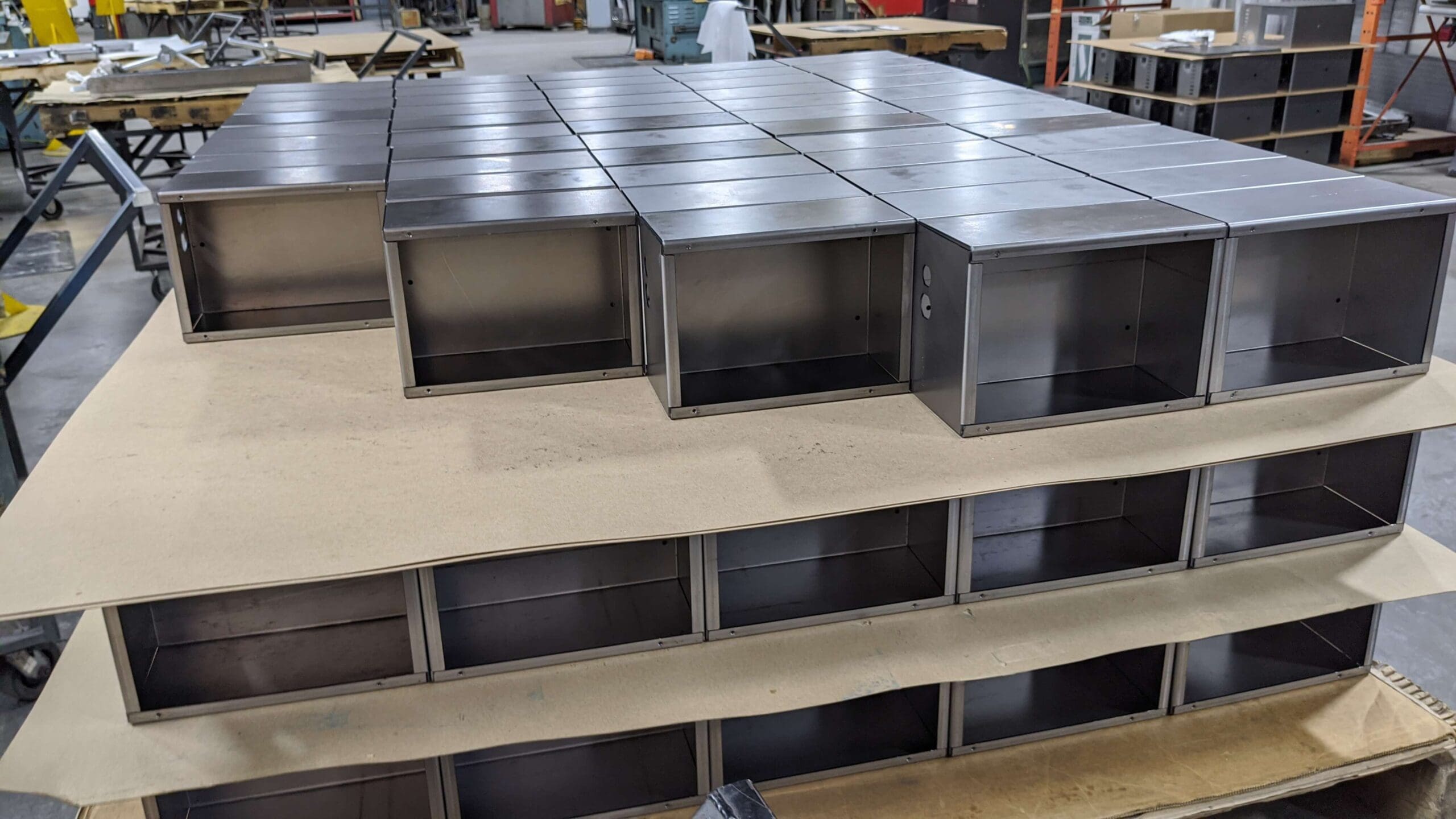

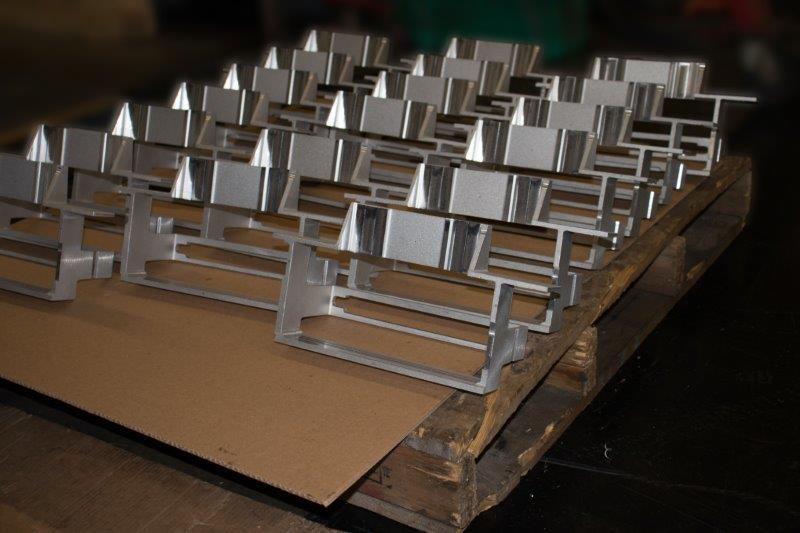

At Honyo Prototype, we transform raw aluminum sheet into mission-critical components with uncompromising precision and speed. Our integrated Sheet Metal Fabrication services specialize in custom aluminum solutions—from prototyping to low-volume production—leveraging advanced laser cutting, CNC bending, precision welding, and finishing capabilities. We consistently achieve tight tolerances of ±0.005 inches across complex geometries in aerospace-grade alloys like 6061-T6, 5052-H32, and 7075-T6, ensuring optimal strength-to-weight ratios, thermal management properties, and corrosion resistance for demanding applications in defense, medical, and industrial automation sectors.

Seamless Engineering Integration from CAD to Shipment

Our end-to-end workflow begins with DFM analysis to optimize your aluminum sheet design for manufacturability, minimizing material waste and accelerating time-to-market. Utilizing state-of-the-art Amada laser systems and CNC press brakes with 3D bending simulation, we handle thicknesses from 0.020″ to 0.250″ with burr-free edges and consistent flatness. Post-processing options include precision deburring, anodizing, powder coating, and robotic welding to MIL-STD-276A standards, all managed under ISO 9001:2015-certified quality protocols. This technical rigor ensures your aluminum components meet stringent functional and aesthetic requirements without secondary sourcing delays.

Accelerate Procurement with Real-Time Cost Transparency

Eliminate quoting bottlenecks with Honyo’s Online Instant Quote platform—engineered specifically for technical buyers. Simply upload your STEP or DXF file, specify material grade, finish, and quantity, and receive a detailed cost breakdown within 60 seconds. Our algorithm dynamically factors in laser path optimization, bend allowances, and finishing requirements to deliver accurate, no-estimation pricing. This transparency allows design teams to iterate rapidly during the feasibility phase while procurement secures validated costs before project kickoff, reducing lead time uncertainty by up to 72 hours versus traditional RFQ processes.

Material Performance Comparison for Critical Applications

| Aluminum Alloy | Typical Thickness Range | Key Mechanical Properties | Common Industry Use Cases |

|---|---|---|---|

| 6061-T6 | 0.040″ – 0.250″ | 45 ksi UTS, 40 ksi YS | Structural brackets, enclosures, robotics arms |

| 5052-H32 | 0.020″ – 0.188″ | 33 ksi UTS, 22 ksi YS | Marine components, fuel tanks, electronic housings |

| 7075-T6 | 0.060″ – 0.250″ | 83 ksi UTS, 73 ksi YS | Aerospace fittings, high-stress military hardware |

Partner with Honyo to convert your aluminum sheet specifications into validated, production-ready components—where engineering excellence meets procurement efficiency. Start your project with an instant quote today.

Technical Capabilities

Custom aluminum sheet fabrication at Honyo Prototype is optimized for high-precision laser cutting, CNC bending, and welding processes. While the primary focus is on aluminum alloys due to their lightweight and machinability, we also support steel, ABS, and nylon for comparative applications. Below are the technical specifications relevant to each material for fabrication processes.

| Material | Thickness Range | Tolerance (Laser Cutting) | Bending Minimum Radius | Welding Compatibility | Surface Finish | Common Alloy Grades |

|---|---|---|---|---|---|---|

| Aluminum | 0.5 mm – 12.0 mm | ±0.1 mm | 1× thickness | Excellent (TIG/MIG) | As-cut, anodized, or powder coated | 5052, 6061, 6082, 7075 |

| Steel (Mild) | 0.8 mm – 15.0 mm | ±0.15 mm | 1.5× thickness | Excellent (MIG/TIG/Spot) | Galvanized, painted, or powder coated | Q235, A36, SPCC |

| ABS | 1.0 mm – 10.0 mm | ±0.2 mm | 3× thickness | Limited (ultrasonic or adhesive) | As-machined or textured | Commercial grade ABS |

| Nylon (PA6/PA66) | 2.0 mm – 10.0 mm | ±0.2 mm | 4× thickness | Not recommended (adhesive or mechanical fastening) | As-machined | PA6, PA66, reinforced grades |

Notes:

Laser cutting is performed using fiber laser systems for metals and CO₂ lasers for plastics, ensuring clean edges with minimal heat-affected zones. Aluminum sheets are clamped securely to prevent warping during cutting. For bending, CNC press brakes with precision tooling achieve tight angular tolerances (±1°). Welding of aluminum requires controlled heat input and shielding gas (argon or Ar/He mix), with post-weld heat treatment available for stress relief.

Steel supports higher load applications but requires corrosion protection. ABS and nylon are suitable for non-structural, insulating, or prototype components where metal performance is not required. Material selection should consider mechanical loads, environmental exposure, and final application requirements.

From CAD to Part: The Process

Honyo Prototype Custom Aluminum Sheet Fabrication Process

Our streamlined workflow for custom aluminum sheet projects ensures technical precision and rapid turnaround from initial design to delivered part. The process integrates digital efficiency with hands-on manufacturing expertise specifically optimized for aluminum alloys including 5052, 6061-T6, and 7075-T6.

CAD Upload and Project Initiation

Clients submit native 3D CAD files (STEP, IGES, or native formats like SLDPRT, IPT, PRT) via our secure customer portal. The system validates file integrity and extracts critical geometry data including sheet thickness, bend radii, hole patterns, and flange dimensions. Material specification and required tolerances must be explicitly defined in the CAD model or accompanying documentation to ensure accurate processing.

AI-Powered Quoting Engine

Uploaded geometry triggers our proprietary AI quoting system trained on 15+ years of Honyo production data. The algorithm performs real-time analysis of manufacturability factors including minimum bend radii relative to sheet thickness, hole-to-edge distances, and complex feature nesting efficiency. It generates a formal quotation within 2 business hours detailing material cost (based on current LME rates), processing fees for operations like laser cutting, CNC bending, and finishing, and a preliminary lead time estimate. The AI flags potential cost drivers such as tight tolerances below ±0.1mm or complex multi-hit bends requiring secondary operations.

Automated DFM Analysis with Engineer Oversight

All quotes undergo mandatory Design for Manufacturability review. Our system runs automated checks against aluminum-specific constraints: grain direction requirements for bent parts, minimum flange lengths relative to material thickness, and avoidance of acute angles prone to cracking. A certified manufacturing engineer then validates the AI findings, focusing on aluminum-specific concerns like springback compensation in bending and thermal distortion risks during welding. Clients receive a formal DFM report within 24 hours of quote acceptance, highlighting actionable recommendations such as adjusting bend radii to standard tooling or modifying cutouts to prevent deformation. Client approval of the DFM report is required before production release.

Precision Production Execution

Approved designs move to our dedicated aluminum fabrication cell. Laser cutting utilizes nitrogen-assisted 4kW fiber lasers achieving ±0.1mm positional accuracy on sheets up to 3000mm x 1500mm. CNC press brakes with automatic tool changers handle bends up to 3000mm length with real-time springback compensation. All operators follow documented work instructions specifying alloy-specific parameters: brake tonnage calculations for 6061-T6 versus 5052, deburring protocols to prevent aluminum smearing, and clean handling procedures to avoid surface marring. In-process inspections verify critical dimensions after each major operation using calibrated CMMs and optical comparators. Secondary operations like anodizing or powder coating are performed by our certified partner network with full batch traceability.

Quality-Controlled Delivery

Final inspection includes first-article reporting per AS9102 where applicable, with full dimensional verification against the approved CAD model. Parts undergo visual inspection for surface defects common in aluminum processing such as micro-cracks at bend lines or laser cut edge oxidation. We provide material certification and process documentation with every shipment. Standard lead time is 5-7 business days post-DFM approval for quantities under 50 pieces, with expedited options available. All shipments include protective packaging tailored to aluminum’s susceptibility to scratching, with foam inserts and vapor corrosion inhibitors for extended storage requirements.

Start Your Project

Looking for custom aluminum sheet solutions? Partner with Honyo Prototype for precision fabrication and rapid turnaround. Our Shenzhen-based factory delivers high-quality, made-to-order aluminum sheets tailored to your specifications.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a personalized quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.