Contents

Manufacturing Insight: Custom Aluminum Pieces

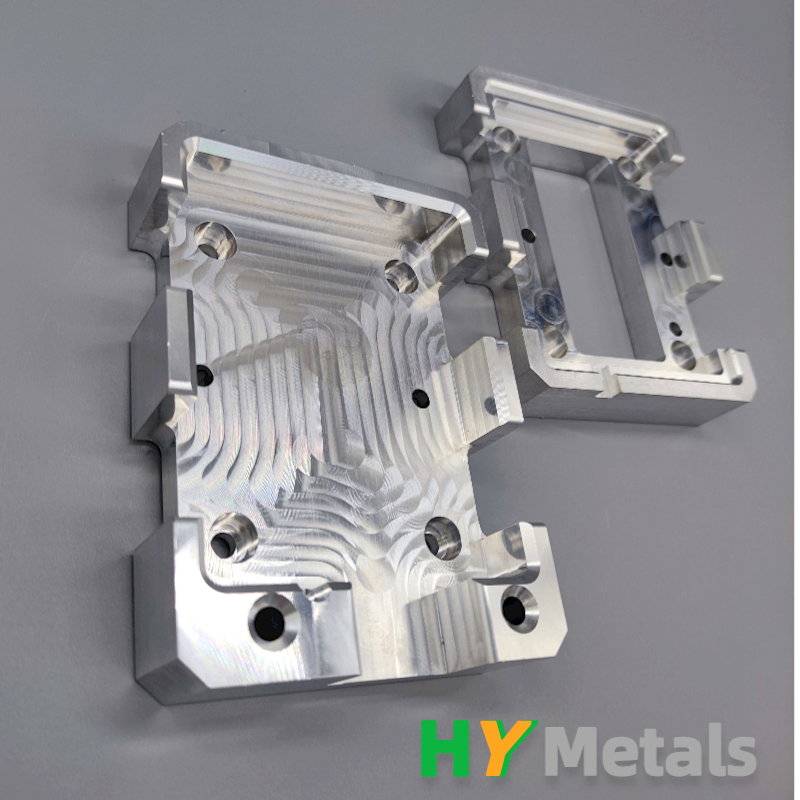

Precision Aluminum Components Engineered for Your Critical Applications

At Honyo Prototype, we transform complex aluminum designs into mission-ready components through advanced 3-, 4-, and 5-axis CNC machining. Our dedicated manufacturing cell for aluminum alloys—including 6061-T6, 7075-T6, and custom grades—delivers micron-level accuracy (±0.0005″), superior surface finishes, and full material traceability to meet aerospace, medical, and defense requirements. Every part undergoes rigorous in-process inspection using calibrated CMMs and optical comparators, ensuring dimensional integrity from prototype to production.

Unlike conventional suppliers, we eliminate quoting delays with our Online Instant Quote platform. Upload your STEP or IGES file, specify alloy, tolerances, and volume, and receive a detailed technical assessment and price within 90 seconds—no sales calls, no email tags. This accelerates your design-to-manufacturing workflow while providing transparent cost visibility at the earliest development stage.

Why Engineers Trust Honyo for Aluminum Machining

| Capability | Industry Standard | Honyo Prototype |

|—————————|——————-|—————–|

| Typical Lead Time (Prototype) | 7-10 business days | 3-5 business days |

| Max Tolerance Control | ±0.001″ | ±0.0005″ |

| Material Waste Reduction | Manual nesting | AI-optimized pathing |

| Quote Turnaround | 24-72 hours | Instant |

When your project demands repeatability, thermal stability, and structural performance in aluminum, our AS9100-certified process delivers certified components that perform. Start your next build with a quote that’s as precise as our toolpaths—upload your design today.

Technical Capabilities

Custom aluminum pieces manufactured via 3, 4, and 5-axis CNC milling and turning processes are engineered for high precision, complex geometry, and tight tolerance requirements. These components are commonly used in aerospace, medical, automotive, and industrial applications where dimensional accuracy and surface finish are critical. While aluminum is the primary material, Honyo Prototype also supports machining of steel, ABS, and nylon to meet diverse functional and environmental demands.

The following table outlines the technical specifications for custom machined parts across supported materials and processes:

| Specification Category | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes |

|---|---|---|---|---|---|

| Typical Tolerance | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | Can achieve ±0.0025 mm with special process controls |

| Surface Finish (Ra) | 1.6–3.2 µm (63–125 µin) | 1.6–3.2 µm (63–125 µin) | 0.8–1.6 µm (32–63 µin) | 0.8–3.2 µm (32–125 µin) | As-machined; polishing available |

| Max Work Envelope (mm) | 600 x 400 x 300 | 600 x 400 x 300 + rotary (±90°) | 500 x 400 x 400 (full 5-axis) | Ø300 x 500 L | Varies by machine capacity |

| Materials Supported | Aluminum 6061, 7075, 2024, Steel (1018, 4140, Stainless 303/316), ABS, Nylon (PA6, PA66) | Same as 3-axis | Same as 3-axis | Same as 3-axis | Material selection based on strength, corrosion resistance, machinability |

| Aluminum-Specific Notes | High MRR, excellent for structural components | Ideal for angled features with indexing | Best for complex contours, undercuts, and mold surfaces | Suitable for shafts, bushings, fittings | Anodizing, bead blasting, and plating available |

| Steel Applications | High-strength parts, tooling, wear components | Fixtures, durable housings | Aerospace brackets, engine components | Precision shafts, fasteners | Heat treatment available |

| ABS & Nylon Capabilities | Low-friction prototypes, enclosures | Jigs, lightweight fixtures | Complex non-metallic assemblies | Bushings, gears, insulators | Limited to non-structural loads |

| Secondary Operations | Deburring, tapping, threading, part marking, surface treatments | Same as 3-axis | Same as 3-axis | Parting, grooving, threading | Coordinate with inspection reports |

| Inspection Support | First Article Inspection (FAI), CMM, GD&T reporting, laser scanning | Available on request | Standard for tight-tolerance jobs | Optional per customer requirement | ISO 9001-compliant documentation |

Honyo Prototype maintains tight process control through calibrated equipment, in-process inspections, and experienced CNC programming (using CAM software such as Fusion 360, Mastercam). All custom aluminum and machined parts are produced to meet or exceed customer CAD and drawing specifications, with emphasis on repeatability and metrology validation.

From CAD to Part: The Process

Honyo Prototype Custom Aluminum Manufacturing Process

Our streamlined workflow for custom aluminum components ensures technical precision, rapid turnaround, and risk mitigation from concept to delivery. The process integrates AI-driven efficiency with hands-on engineering expertise, specifically optimized for aluminum alloys like 6061-T6, 7075-T6, and 5052-H32.

Upload CAD

Clients submit native CAD files (STEP, IGES, Parasolid) via our secure portal. Our system automatically validates file integrity, checks unit consistency, and identifies critical geometric features such as thin walls (<0.8mm), deep cavities (>3x diameter), or tight tolerances (±0.005mm). Unsupported formats trigger immediate client notification to prevent downstream delays.

AI-Powered Quoting

Within 90 seconds, our proprietary AI engine generates a preliminary quote by analyzing:

Material utilization efficiency (nesting optimization for plate stock)

Machine time estimation (3-axis vs. 5-axis CNC paths)

Secondary operation requirements (deburring, anodizing, bead blasting)

Real-time aluminum scrap rate adjustments (based on LME fluctuations)

The output includes cost drivers, lead time projections, and automated flags for potential manufacturability risks. Human engineers review all AI outputs before client submission.

Engineering-Driven DFM

Our manufacturing engineers conduct a rigorous Design for Manufacturability review within 4 business hours. This phase involves:

Converting nominal dimensions to production-friendly tolerances (e.g., suggesting ±0.05mm instead of ±0.01mm where functionally acceptable)

Recommending feature modifications to reduce CNC tool changes (e.g., standardizing radii to 0.5mm increments)

Validating thermal stability for critical dimensions during machining

Collaborating with clients via markup tools to resolve conflicts before toolpath generation

This step typically reduces production rework by 35–50% compared to direct-to-machine workflows.

Precision Production

Approved designs enter our climate-controlled production floor:

1. Material Prep: Aluminum plates undergo ultrasonic cleaning and stress-relief verification

2. CNC Machining: Haas and DMG MORI 5-axis centers execute validated toolpaths with in-process probing for dimensional stability

3. Secondary Ops: Anodizing (Type II/III), precision tapping, or laser engraving per spec

4. QA Protocol: CMM inspection (per ASME Y14.5), surface roughness testing (Ra ≤ 1.6μm standard), and first-article reporting

Certified Delivery

All shipments include:

Dimensional conformance report (GD&T verified)

Material certification (mill test reports traceable to heat number)

Anodizing thickness logs (where applicable)

Packing list with serialized part tracking

Standard lead time is 7–10 business days for quantities ≤50 units. Expedited 72-hour service available for simple geometries through our dedicated aluminum cell.

Critical Path Timeline Comparison

| Process Phase | Traditional Workflow | Honyo Prototype | Time Saved |

|———————|———————-|—————–|————|

| Quote Generation | 2–5 business days | <2 hours | 92% |

| DFM Resolution | 3–7 days | 1–2 days | 70% |

| First-Article QA | 1–3 days | 4–8 hours | 75% |

This integrated approach reduces time-to-prototype by 40–60% while maintaining ISO 9001:2015 compliance. We prioritize technical transparency at every stage to ensure your aluminum components meet functional requirements without cost overruns.

Start Your Project

Looking for custom aluminum pieces tailored to your exact specifications? Honyo Prototype delivers precision-manufactured aluminum components with fast turnaround times, supporting prototyping and low-volume production.

Our in-house CNC machining and fabrication capabilities are backed by rigorous quality control, ensuring consistent results for demanding industrial, automotive, and consumer applications.

With our factory located in Shenzhen, we offer competitive pricing and efficient logistics for global clients.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a personalized quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.