Contents

Manufacturing Insight: Custom Aluminum Machined Parts

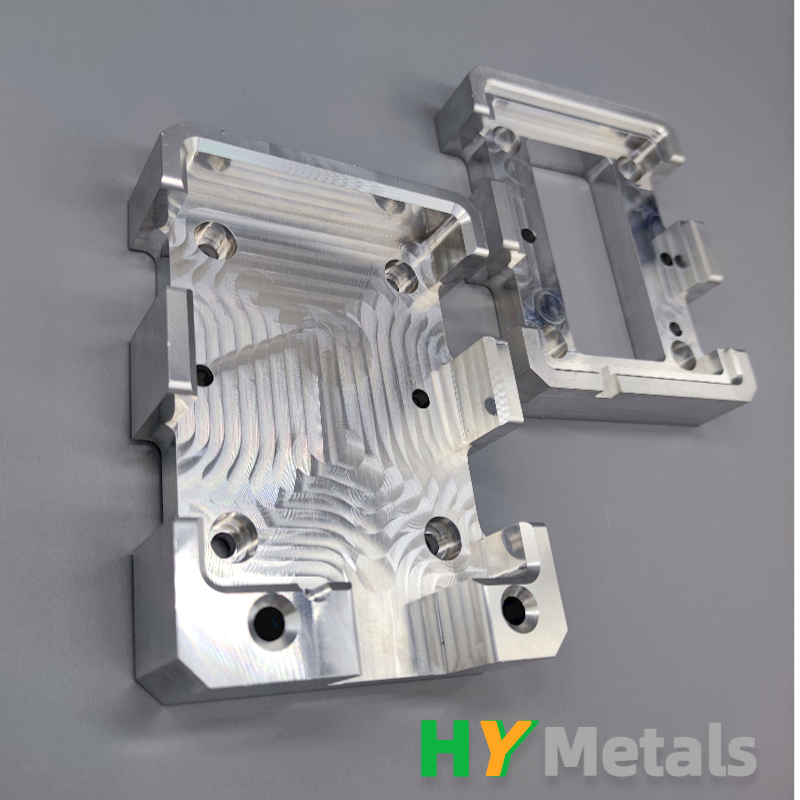

Precision Aluminum Components Engineered for Performance

Honyo Prototype delivers mission-critical custom aluminum machined parts through advanced CNC machining capabilities tailored for demanding industrial applications. Our expertise spans complex geometries in aerospace-grade alloys including 6061-T6, 7075-T73, and specialty tempers, ensuring optimal strength-to-weight ratios and thermal stability for structural, hydraulic, and high-precision components. Leveraging HAAS and DMG MORI multi-axis machining centers with sub-micron repeatability, we consistently achieve tight tolerances down to ±0.0002″ while maintaining stringent surface finish requirements critical for sealing interfaces and fatigue resistance.

Our integrated manufacturing ecosystem eliminates traditional prototyping bottlenecks by combining in-house material sourcing, first-article inspection via Zeiss CMM systems, and rapid iteration cycles—all backed by AS9100D and ISO 9001:2015 certified processes. For engineering teams requiring accelerated development timelines, Honyo’s Online Instant Quote platform provides validated pricing and lead times within 90 seconds for standard aluminum configurations, enabling immediate project progression without procurement delays. This seamless transition from digital model to certified hardware positions us as the strategic partner for OEMs facing compressed time-to-market windows in defense, medical device, and semiconductor equipment sectors.

Initiate your aluminum component project with real-time manufacturability feedback and transparent cost modeling—access the Online Instant Quote system directly through our technical portal to validate production feasibility before formal RFQ submission.

Technical Capabilities

Custom aluminum machined parts are precision components manufactured using advanced CNC machining techniques such as 3-axis, 4-axis, and 5-axis milling, as well as CNC turning. These processes enable the production of complex geometries with high accuracy and excellent surface finishes. Tight tolerance machining ensures dimensional consistency, often within ±0.0005″ (±0.013 mm), making these parts suitable for aerospace, medical, automotive, and industrial applications.

Below is a technical specifications overview for custom machined parts, covering key processes, material options, and capabilities:

| Feature | Specification |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including mill-turn) |

| Material Options | Aluminum (6061, 7075, 2024, etc.), Steel (1018, 4140, Stainless 303, 316), ABS, Nylon (6, 6/6, 12) |

| Tolerance Capabilities | Standard: ±0.001″ (±0.025 mm); Tight Tolerance: ±0.0005″ (±0.013 mm) |

| Surface Finish | As-machined: 125–250 μin Ra; Optional: 32–63 μin Ra with polishing or grinding |

| Maximum Work Envelope | Milling: Up to 24″ x 36″ x 20″; Turning: Up to 16″ diameter, 48″ length |

| Feature Accuracy | Hole positional accuracy: ±0.0002″; Angular tolerances: ±0.05° |

| Secondary Operations | Deburring, anodizing (Type II & III), passivation, bead blasting, laser marking, tapping, threading |

| Quality Standards | ISO 2768 (medium), ISO 1101 (geometric tolerances), GD&T compliant |

| Design Support | DFM analysis, CAD/CAM support (SolidWorks, STEP, IGES, DWG, DXF) |

These capabilities allow Honyo Prototype to deliver high-performance machined components with repeatable precision across a range of engineering-grade materials. Aluminum remains the most requested material due to its favorable strength-to-weight ratio and machinability, while steel variants are selected for higher strength and wear resistance. ABS and Nylon are used for non-metallic prototypes or low-friction, non-conductive components requiring tight tolerances.

From CAD to Part: The Process

Honyo Prototype delivers custom aluminum machined parts through a rigorously defined five-stage process designed for speed, precision, and manufacturability assurance. This integrated workflow eliminates traditional quoting bottlenecks while ensuring engineering excellence from digital design to physical part.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, SolidWorks, Fusion 360) via our secure customer portal. Our system validates file integrity and extracts critical geometric and material specifications. Aluminum alloy selection (e.g., 6061-T6, 7075-T6, 2024-T3) is confirmed during this phase, with material certification requirements documented for traceability.

AI Quote Generation

Proprietary AI analyzes the validated CAD geometry against real-time machine capacity, material costs, and historical production data. This generates an instant preliminary quote within 90 seconds, including estimated lead time and cost drivers. Crucially, the AI flags potential high-risk features (e.g., thin walls <0.5mm, deep cavities >10:1 aspect ratio) requiring engineering review. All AI outputs undergo validation by our manufacturing engineering team before client submission.

DFM Analysis and Collaboration

Our engineering team conducts a formal Design for Manufacturability review within 4 business hours of quote acceptance. This is not a rejection gate but a collaborative optimization phase. We provide specific, actionable feedback via annotated 3D models and written reports addressing:

Unmachinable geometries requiring design modification

Tolerance stack-up risks exceeding ±0.025mm capabilities

Cost-reduction opportunities through feature simplification

Material utilization efficiency improvements

Clients receive direct engineer access for rapid iteration until design approval is signed.

Precision Production

Approved designs move to our CNC machining center with strict adherence to documented parameters:

| Parameter | Specification | Verification Method |

|---|---|---|

| Machines | 3/4/5-axis Haas, DMG MORI | Machine logs |

| Tolerances | Standard: ±0.025mm; Precision: ±0.005mm | CMM, Optical Comparator |

| Surface Finish | As-machined: 3.2μm Ra; Polished: 0.8μm | Profilometer |

| In-Process Checks | First article + 10% batch sampling | SPC data tracking |

| Material Traceability | Full MTR documentation per lot | Certified mill test reports |

All aluminum parts undergo thermal stress relief where specified and are cleaned per ASTM B912 standards prior to final inspection.

Delivery and Documentation

Completed parts ship with comprehensive quality documentation including:

Dimensional inspection report (AS9102 format available)

Material test reports matching purchase order specifications

FAI documentation for critical aerospace/medical applications

Packing slip with serialized part tracking

Standard lead time is 7-12 business days from DFM sign-off. We provide real-time logistics updates via client portal with FedEx/DHL tracking. Every shipment includes a production summary highlighting process capabilities achieved for future design reference.

Start Your Project

Looking for high-precision custom aluminum machined parts? Partner with Honyo Prototype for reliable CNC machining services tailored to your specifications.

Our advanced manufacturing facility in Shenzhen ensures fast turnaround, strict quality control, and competitive pricing for low to medium volume production runs.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a personalized quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.