Introduction: Navigating the Global Market for custom aluminum boxes

In today’s competitive landscape, sourcing custom aluminum boxes can be a daunting challenge for international B2B buyers. With diverse applications ranging from industrial storage solutions to specialized transport needs, selecting the right aluminum box requires careful consideration. This guide aims to demystify the global market for custom aluminum boxes by providing an in-depth exploration of various types, their specific applications, and best practices for supplier vetting.

Throughout the guide, you will discover actionable insights into the cost factors influencing aluminum box procurement, helping you make informed purchasing decisions. From understanding the materials and construction options to evaluating warranties and service capabilities, this resource addresses the complexities faced by buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Saudi Arabia.

By equipping you with the knowledge to navigate this intricate market, we empower you to find the ideal custom aluminum boxes that meet your unique operational needs. Whether you are looking to enhance your supply chain efficiency or ensure the safety of transported goods, this comprehensive guide will serve as your trusted resource for making strategic, cost-effective decisions in the realm of custom aluminum boxes.

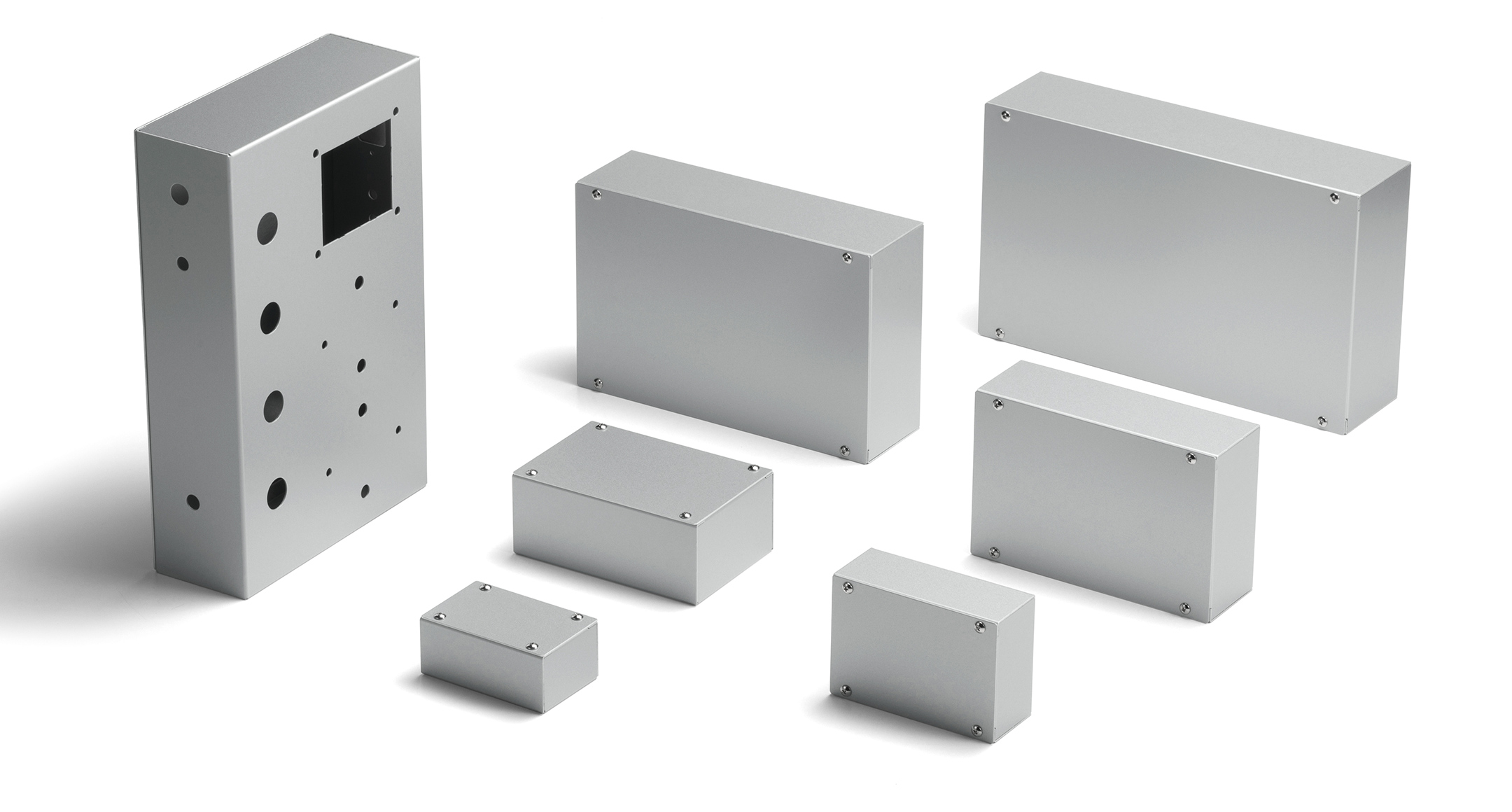

Understanding custom aluminum boxes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tool Boxes | Durable construction, customizable sizes, interlocking lids | Construction, maintenance, automotive | Pros: Strong, weather-resistant; Cons: Higher initial investment. |

| Storage Boxes | Watertight design, adjustable shelves, lightweight construction | Outdoor gear, RVs, commercial vehicles | Pros: Versatile, organized storage; Cons: May require additional accessories. |

| Utility Boxes | Heavy-duty aluminum, various locking mechanisms | Industrial applications, transportation | Pros: High security, robust; Cons: Limited aesthetic options. |

| Custom Cargo Boxes | Tailored dimensions, specialized mounting options | Logistics, overlanding, adventure sports | Pros: Maximizes space, tailored to needs; Cons: Longer lead times for customization. |

| Specialty Boxes | Specific designs for unique applications (e.g., medical, fire) | Emergency services, specialized industries | Pros: Meets niche requirements; Cons: Potentially higher costs. |

What Are the Key Characteristics of Tool Boxes for B2B Buyers?

Tool boxes are designed for durability and functionality, often constructed from high-grade aluminum. Their customizable sizes allow businesses to select the perfect fit for their equipment. Interlocking lids and various locking mechanisms enhance security, making them ideal for construction, maintenance, and automotive industries. When considering a tool box, buyers should evaluate the balance between initial investment and long-term durability, as these boxes can withstand rigorous use.

How Do Storage Boxes Enhance Organizational Efficiency?

Storage boxes are characterized by their watertight design and lightweight construction, making them suitable for outdoor applications and commercial vehicles. Many options come with adjustable shelves, allowing users to optimize internal space based on their specific needs. For businesses in sectors like RV manufacturing or outdoor equipment sales, these boxes provide a versatile solution. Buyers should consider the necessity of additional accessories for enhanced functionality, which can impact overall costs.

Why Choose Utility Boxes for Heavy-Duty Applications?

Utility boxes are built from heavy-duty aluminum, featuring various locking mechanisms to ensure security. They are commonly used in industrial applications and transportation sectors where equipment safety is paramount. Their robust construction can withstand harsh environments, appealing to businesses focused on longevity and reliability. However, buyers should be aware that aesthetic options may be limited, which could affect brand presentation.

What Advantages Do Custom Cargo Boxes Offer for Logistics?

Custom cargo boxes are tailored to specific dimensions and come with specialized mounting options, making them perfect for logistics companies and adventure sports. This customization allows businesses to maximize space efficiently, accommodating various equipment sizes and types. While the benefits of tailored solutions are significant, potential buyers should account for longer lead times in production and delivery, which can affect project timelines.

How Do Specialty Boxes Meet Unique Industry Needs?

Specialty boxes are designed for specific applications, such as medical or emergency services. These boxes often incorporate unique features tailored to niche requirements, making them indispensable in specialized industries. While they provide significant advantages in functionality, such as compliance with industry standards, buyers should be prepared for potentially higher costs and longer production times associated with these custom designs.

Key Industrial Applications of custom aluminum boxes

| Industry/Sector | Specific Application of custom aluminum boxes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Tool and equipment storage for service and repair shops | Durable, weather-resistant storage solutions | Custom dimensions, locking mechanisms, and weight capacity |

| Construction | Site storage for tools and materials | Enhanced organization and theft prevention | Size, mobility options, and resistance to harsh conditions |

| Logistics & Transport | Secure transport of sensitive equipment | Protection against damage and environmental factors | Compliance with international shipping standards, weight limits |

| Recreation & Adventure | Gear storage for overlanding and camping vehicles | Maximized space utilization and easy access | Compatibility with vehicle models, waterproofing features |

| Agriculture | Storage for farming tools and equipment | Improved efficiency and protection from elements | Customization for size, ease of transport, and durability |

How Are Custom Aluminum Boxes Used in the Automotive Industry?

In the automotive sector, custom aluminum boxes serve as essential storage solutions for tools and equipment in service and repair shops. These boxes are designed to withstand the rigors of daily use, providing a durable and weather-resistant option for organizing tools, preventing theft, and ensuring easy access. Buyers should consider specific requirements such as customized dimensions to fit their workspaces, secure locking mechanisms for safety, and weight capacity to accommodate heavy tools.

What Role Do Custom Aluminum Boxes Play in Construction Projects?

Custom aluminum boxes find significant application in construction, where they are used for site storage of tools and materials. Their robust construction helps keep valuable equipment organized and protected from theft and harsh weather conditions. For international buyers, it is crucial to assess the size and mobility options of these boxes, ensuring they can withstand the demanding environments of construction sites while providing easy transport and access.

How Do Custom Aluminum Boxes Enhance Logistics and Transport Operations?

In logistics and transport, custom aluminum boxes are utilized for securely transporting sensitive equipment. These boxes offer excellent protection against damage and environmental factors, which is vital for maintaining the integrity of goods during transit. Buyers must consider compliance with international shipping standards, weight limits, and the ability to customize the boxes to meet specific transport needs, ensuring they are fit for purpose in various regions.

Why Are Custom Aluminum Boxes Ideal for Recreational and Adventure Use?

For the recreation and adventure industry, particularly in overlanding and camping, custom aluminum boxes provide a practical solution for gear storage. These boxes maximize space utilization within vehicles, allowing easy access to equipment while keeping it organized and secure. Buyers should prioritize compatibility with specific vehicle models and look for waterproofing features to protect gear from the elements, ensuring a hassle-free adventure experience.

How Are Custom Aluminum Boxes Beneficial in Agriculture?

In agriculture, custom aluminum boxes are used to store farming tools and equipment, enhancing operational efficiency. Their durable design protects items from weather-related damage, ensuring they remain in optimal condition for use. When sourcing these boxes, buyers should focus on customization options for size and ease of transport, as well as the overall durability required for various farming applications, particularly in regions with challenging climates.

3 Common User Pain Points for ‘custom aluminum boxes’ & Their Solutions

Scenario 1: Compromised Durability in Harsh Environments

The Problem: B2B buyers often face challenges with the durability of aluminum boxes when used in rugged environments, such as construction sites or outdoor activities. These boxes may be subjected to extreme temperatures, moisture, or abrasive materials, leading to wear and tear that can compromise their integrity. Buyers may experience frustration when their products fail to perform as expected, resulting in costly replacements and disrupted operations.

The Solution: To ensure that custom aluminum boxes withstand harsh conditions, buyers should prioritize selecting high-grade materials and finishes. Look for options such as .100 aircraft-grade treadbrite aluminum or .125 diamond plate, which offer superior strength and resistance to corrosion. Additionally, consider investing in features such as interlocking lids with rubber gaskets and continuous aluminum hinges to enhance waterproofing and durability. It’s advisable to work closely with manufacturers to discuss specific environmental factors your boxes will encounter, allowing them to recommend the best materials and construction techniques tailored to your needs. Request samples or prototypes to test their performance under real-world conditions before making a bulk purchase.

Scenario 2: Inefficient Storage and Organization Solutions

The Problem: Many businesses struggle with inefficient storage solutions that lead to cluttered workspaces and wasted time searching for tools or equipment. Custom aluminum boxes that lack proper internal organization can exacerbate this issue, resulting in decreased productivity and increased frustration among team members. This is particularly true for industries such as construction, automotive, or logistics, where quick access to tools and materials is crucial for operational efficiency.

The Solution: To combat disorganization, buyers should consider custom aluminum boxes equipped with adjustable shelving, dividers, or modular compartments. Collaborate with manufacturers to design boxes that meet your specific storage needs, whether you require specialized compartments for tools, parts, or equipment. Additionally, consider investing in accessories such as mounting brackets or bolt-on rails that allow for further customization and expansion of storage capacity. Implementing a well-planned layout inside the box can streamline access to essential items, reducing time spent searching and enhancing overall workflow.

Scenario 3: Difficulty in Sourcing Custom Solutions

The Problem: International B2B buyers often encounter challenges when sourcing custom aluminum boxes, particularly when dealing with varying standards and regulations across regions. Language barriers, differing manufacturing practices, and logistical issues can complicate the procurement process, leading to delays and miscommunication. Buyers may feel overwhelmed by the complexities of ensuring that their custom orders meet local compliance requirements and quality standards.

The Solution: To navigate these sourcing difficulties, buyers should conduct thorough research to identify reputable manufacturers with experience in international trade and regional compliance. Engage in direct communication with potential suppliers to clarify specifications and expectations early in the process. Utilizing project management tools can help track progress, timelines, and quality checks throughout production. Additionally, consider partnering with a logistics provider familiar with cross-border shipments to streamline delivery and minimize potential delays. Establishing clear lines of communication and documentation will help mitigate misunderstandings, ensuring that the final product aligns with your initial requirements and regulatory standards.

Strategic Material Selection Guide for custom aluminum boxes

What Are the Key Properties of Common Materials Used in Custom Aluminum Boxes?

When selecting materials for custom aluminum boxes, several options are available, each with unique properties that influence performance, durability, and cost. Understanding these materials is crucial for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe.

1. Aircraft-Grade Aluminum

Key Properties: Aircraft-grade aluminum, often denoted as 6061 or 7075, is known for its high strength-to-weight ratio and excellent corrosion resistance. It can withstand extreme temperatures and pressures, making it suitable for various demanding applications.

Pros & Cons: The primary advantage of aircraft-grade aluminum is its durability and lightweight nature, which enhances portability. However, it is more expensive than standard aluminum alloys and may require specialized manufacturing processes, increasing lead times.

Impact on Application: This material is ideal for applications that require high strength and resistance to environmental factors, such as marine or aerospace uses. It is compatible with harsh media, making it suitable for outdoor storage solutions.

Considerations for International Buyers: Compliance with international standards, such as ASTM and JIS, is essential. Buyers in regions like Nigeria and Saudi Arabia should ensure that suppliers can provide certifications that meet local regulations.

2. Diamond Plate Aluminum

Key Properties: Diamond plate aluminum features a raised pattern that enhances grip and provides additional strength. It is typically available in thicknesses of .100 to .125 inches, offering good resistance to wear and tear.

Pros & Cons: The textured surface provides excellent slip resistance, making it suitable for high-traffic areas. However, diamond plate can be heavier than other aluminum types, potentially increasing shipping costs and complicating installation.

Impact on Application: This material is often used in industrial settings, such as construction sites or warehouses, where durability and safety are paramount. Its resistance to impact makes it suitable for heavy equipment storage.

Considerations for International Buyers: Buyers should be aware of the weight implications for shipping, especially in regions with high freight costs. Adherence to local safety standards is also crucial to ensure compliance with workplace regulations.

3. Smooth Aluminum

Key Properties: Smooth aluminum, typically available in .080 to .100 thickness, offers a sleek finish and is lightweight. It has moderate corrosion resistance and can be easily painted or anodized for aesthetic purposes.

Pros & Cons: The smooth surface allows for easy cleaning and customization, making it versatile for various applications. However, it may not be as durable as other options, particularly in rugged environments.

Impact on Application: This material is well-suited for applications requiring a more refined appearance, such as retail displays or office storage solutions. It is less ideal for environments exposed to harsh conditions.

Considerations for International Buyers: When sourcing smooth aluminum, buyers should consider the availability of customization options and whether the supplier can meet specific aesthetic requirements. Compliance with local environmental standards for coatings and finishes is also important.

4. Marine-Grade Aluminum

Key Properties: Marine-grade aluminum, typically classified as 5083 or 5086, is specifically formulated to resist corrosion in saltwater environments. It has excellent weldability and strength, making it suitable for demanding marine applications.

Pros & Cons: The primary advantage is its exceptional corrosion resistance, which extends the lifespan of the product in challenging conditions. However, it is often more costly than standard aluminum options and may require specialized welding techniques.

Impact on Application: Marine-grade aluminum is ideal for custom boxes used in boating, fishing, and other water-related activities. Its compatibility with marine environments makes it a preferred choice for coastal regions.

Considerations for International Buyers: Buyers in maritime regions should ensure that suppliers offer certifications for marine-grade materials and comply with international marine standards. Understanding local regulations regarding marine equipment is also essential.

Summary Table of Material Selection for Custom Aluminum Boxes

| Material | Typical Use Case for custom aluminum boxes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aircraft-Grade Aluminum | Aerospace and marine applications | High strength-to-weight ratio | Higher cost and manufacturing complexity | High |

| Diamond Plate Aluminum | Industrial settings and heavy equipment | Excellent slip resistance | Heavier, increasing shipping costs | Medium |

| Smooth Aluminum | Retail displays and office storage | Easy to clean and customize | Less durable in rugged environments | Low |

| Marine-Grade Aluminum | Boating and fishing gear | Exceptional corrosion resistance | Higher cost and specialized welding | High |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions when sourcing custom aluminum boxes tailored to their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for custom aluminum boxes

What Are the Key Stages in the Manufacturing Process of Custom Aluminum Boxes?

The manufacturing process for custom aluminum boxes typically involves several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages is vital for B2B buyers, as they directly affect product quality, durability, and suitability for various applications.

How is Material Prepared for Custom Aluminum Boxes?

The first step in manufacturing custom aluminum boxes is material preparation. High-quality aluminum sheets are selected based on specifications such as thickness and alloy type. Common choices include aircraft-grade aluminum, known for its strength and lightweight properties. Before use, the aluminum undergoes cleaning and surface treatment to remove any contaminants that could affect adhesion during later stages.

What Techniques Are Used in Forming Custom Aluminum Boxes?

Following material preparation, the forming process begins. Techniques such as CNC (Computer Numerical Control) machining, laser cutting, and stamping are commonly employed. CNC machining allows for precision shaping, ensuring that dimensions meet the exact requirements of the design. Laser cutting provides clean edges and intricate designs, while stamping is often used for bulk production due to its efficiency. Each technique has its advantages, and the choice depends on the specific design and volume of boxes required.

How Are Custom Aluminum Boxes Assembled?

Once the components are formed, the assembly stage commences. This involves joining the various parts, such as lids, bodies, and any additional features like latches or hinges. Welding is a prevalent method for creating strong, permanent joints, particularly in high-stress applications. For components that require disassembly or adjustment, bolting or riveting may be preferred. Quality assembly ensures that the final product is not only functional but also durable enough to withstand rugged use.

What Finishing Processes Enhance the Quality of Custom Aluminum Boxes?

The finishing stage is essential for both aesthetics and functionality. Common finishing techniques include anodizing, powder coating, and polishing. Anodizing increases corrosion resistance and can enhance the appearance of the aluminum. Powder coating provides a durable, colored finish that protects against scratches and UV damage. Polishing, on the other hand, gives the aluminum a reflective surface, which can be particularly appealing for consumer-facing products.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is crucial in the manufacturing of custom aluminum boxes. International standards such as ISO 9001 ensure that manufacturers adhere to consistent quality management practices. This certification indicates that a company has implemented systems for continuous improvement and customer satisfaction.

Which Industry-Specific Certifications Are Important?

In addition to ISO standards, industry-specific certifications may also apply. For example, CE marking is essential for products sold in Europe, demonstrating compliance with health, safety, and environmental protection standards. In the oil and gas sector, API (American Petroleum Institute) certifications may be required, particularly for boxes used in hazardous environments. Buyers should verify that suppliers possess relevant certifications to ensure product reliability.

What Are the Key Quality Control Checkpoints During Manufacturing?

A robust quality control (QC) system incorporates various checkpoints throughout the manufacturing process. Incoming Quality Control (IQC) focuses on the initial materials to ensure they meet specifications. In-Process Quality Control (IPQC) monitors production stages to catch any defects early. Finally, Final Quality Control (FQC) involves comprehensive testing of the finished product before shipment.

What Common Testing Methods Are Used?

Common testing methods include dimensional checks, tensile strength tests, and corrosion resistance evaluations. Dimensional checks ensure that the boxes meet specified measurements, while tensile strength tests assess the material’s ability to withstand stress. Corrosion resistance tests, such as salt spray testing, determine how well the aluminum can withstand environmental factors over time. These tests are critical for industries that require high durability and reliability.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of their suppliers. Conducting audits is one effective method, allowing buyers to assess the supplier’s manufacturing capabilities and QC protocols firsthand. Requesting quality reports and certificates can also provide insight into the supplier’s adherence to industry standards. Furthermore, engaging third-party inspection services can offer an unbiased evaluation of the manufacturing processes and product quality.

What QC and Certification Nuances Should International Buyers Consider?

For international buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding local regulations and certifications is crucial. Different regions may have specific requirements for product standards and safety certifications. Buyers should ensure that their suppliers are compliant with both international standards and local regulations to avoid potential legal and logistical challenges.

Conclusion: Why Quality Assurance is Essential for Custom Aluminum Boxes

In summary, the manufacturing processes and quality assurance measures for custom aluminum boxes are multifaceted and essential for ensuring product integrity and customer satisfaction. By understanding these processes and verifying supplier practices, B2B buyers can make informed decisions that align with their operational needs and compliance requirements. Investing time in assessing manufacturing quality not only enhances product reliability but also fosters long-term partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom aluminum boxes’

Introduction

Sourcing custom aluminum boxes requires careful planning and execution to ensure that you meet your specific needs while maintaining quality and cost-effectiveness. This guide offers a step-by-step checklist to help international B2B buyers streamline their procurement process, ensuring that they make informed decisions and choose the right suppliers for their custom aluminum box needs.

1. Define Your Technical Specifications

Clearly outline the requirements for your custom aluminum boxes, including dimensions, weight capacity, and design features. This step is crucial as it serves as the foundation for your procurement process. Consider factors such as:

– Material Thickness: Choose between options like .100 or .125 aluminum based on durability needs.

– Design Features: Specify features like interlocking lids, gas shock door hold backs, and mounting brackets.

2. Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in custom aluminum boxes. Look for companies that have a strong reputation in your target market regions, such as Africa, South America, the Middle East, and Europe. Important criteria include:

– Industry Experience: Favor suppliers with a proven track record in your specific industry.

– Customer Reviews: Check online reviews and testimonials to gauge customer satisfaction.

3. Evaluate Supplier Certifications

Before finalizing any supplier, verify their certifications and compliance with international standards. This step is vital to ensure product quality and reliability. Key certifications to look for include:

– ISO Certifications: Indicates adherence to quality management standards.

– Warranty Offers: Suppliers should provide warranties on their workmanship and materials, which can safeguard your investment.

4. Request Samples

Always request samples of the custom aluminum boxes before placing a bulk order. Samples allow you to assess the quality of materials and craftsmanship. When reviewing samples, pay attention to:

– Finish and Aesthetics: Ensure that the box meets your design expectations.

– Functionality: Test features such as latches and hinges to confirm they operate smoothly.

5. Discuss Customization Options

Engage with suppliers to explore available customization options that can enhance the functionality of your aluminum boxes. This discussion should include:

– Add-Ons and Accessories: Inquire about additional features such as adjustable shelves or mounting brackets.

– Design Flexibility: Ensure the supplier can accommodate specific design requests that align with your operational needs.

6. Negotiate Pricing and Terms

Once you have narrowed down your choices, initiate negotiations on pricing, lead times, and payment terms. This step is critical to securing a favorable deal that aligns with your budget constraints. Consider:

– Bulk Discounts: Ask about pricing adjustments for larger orders.

– Payment Flexibility: Explore options for payment schedules that can ease cash flow.

7. Finalize Your Order and Confirm Delivery

After agreeing on terms, finalize your order and confirm delivery timelines. Clear communication during this phase is essential to avoid misunderstandings. Make sure to:

– Review Contracts: Ensure all specifications and terms are documented clearly.

– Track Progress: Stay in touch with the supplier for updates on manufacturing and shipping to manage expectations effectively.

By following this checklist, B2B buyers can effectively navigate the process of sourcing custom aluminum boxes, ensuring they achieve both quality and value in their purchases.

Comprehensive Cost and Pricing Analysis for custom aluminum boxes Sourcing

What Are the Key Cost Components for Custom Aluminum Boxes?

When sourcing custom aluminum boxes, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of aluminum grade significantly impacts costs. Options like .100 aircraft-grade treadbrite aluminum or .125 diamond plate are common, with higher quality materials resulting in increased durability but also higher prices.

-

Labor: Skilled labor is essential for the customization and assembly of aluminum boxes. Costs may vary based on the complexity of the design and the labor market in the supplier’s region.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help minimize these overhead costs.

-

Tooling: Custom designs may require specialized tooling, which can be a significant upfront investment. However, once the tooling is created, the cost can be amortized over larger production runs.

-

Quality Control: Rigorous QC processes ensure that the products meet specified standards. This may involve additional inspections and testing, contributing to overall costs.

-

Logistics: Shipping and handling costs can vary widely, especially for international buyers. Factors such as distance, mode of transport, and freight terms (Incoterms) will influence logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure business viability. Margins can vary based on market competition and the uniqueness of the product.

How Do Pricing Influencers Affect Custom Aluminum Box Costs?

Several factors can influence the pricing of custom aluminum boxes:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in reduced per-unit costs due to economies of scale. Negotiating for lower MOQs may also be possible, especially with long-term suppliers.

-

Specifications and Customization: Custom features, such as unique sizes, finishes, or additional compartments, will increase costs. Clear communication of requirements will help suppliers provide accurate quotes.

-

Material Quality and Certifications: Higher quality materials or those with specific certifications (e.g., ISO) typically come at a premium. Buyers should weigh the benefits of these options against their budget.

-

Supplier Factors: The reputation, reliability, and location of the supplier can impact pricing. Suppliers in regions with lower production costs may offer more competitive pricing.

-

Incoterms: Understanding the agreed-upon Incoterms is vital for budgeting. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping costs and risks, affecting overall expenditure.

What Buyer Tips Can Optimize Sourcing Costs for International Markets?

B2B buyers, particularly in Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Negotiation: Engage in discussions with suppliers to negotiate better pricing or payment terms. Establishing a rapport can lead to more favorable conditions.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and logistics costs. A lower initial price may not always represent the best value if long-term expenses are higher.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and international tariffs that can affect pricing. Consider suppliers who can provide fixed pricing over a contract period to mitigate risks.

-

Supplier Diversification: Avoid dependency on a single supplier by exploring multiple options. This can provide leverage in negotiations and ensure competitive pricing.

-

Due Diligence: Conduct thorough research on potential suppliers, including reviews and certifications, to ensure quality and reliability, which can ultimately save costs related to defects or delays.

Disclaimer on Indicative Prices

Pricing for custom aluminum boxes can vary widely based on the aforementioned factors. While indicative prices may be provided by suppliers, actual costs will depend on specific requirements, market conditions, and negotiations. Buyers are encouraged to obtain multiple quotes and perform due diligence to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing custom aluminum boxes With Other Solutions

When considering storage and transport solutions for various industries, it’s crucial to evaluate different options that can meet specific needs effectively. Custom aluminum boxes are popular for their durability, versatility, and aesthetic appeal. However, several alternatives can also serve similar purposes, each with its unique advantages and disadvantages. This analysis will compare custom aluminum boxes with two viable alternatives: plastic storage containers and steel storage boxes.

| Comparison Aspect | Custom Aluminum Boxes | Plastic Storage Containers | Steel Storage Boxes |

|---|---|---|---|

| Performance | High durability; resistant to corrosion | Moderate durability; less resistant to extreme temperatures | Very durable; resistant to impact and weather |

| Cost | Higher initial investment | Generally lower cost | Mid-range cost |

| Ease of Implementation | Customizable but may require lead time | Easy to purchase and use | Installation may be complex |

| Maintenance | Low; simple cleaning required | Moderate; can degrade over time | Low; resistant to rust but may require painting |

| Best Use Case | Heavy-duty applications, long-term use | Lightweight, general storage needs | Heavy-duty industrial applications |

What Are the Advantages and Disadvantages of Plastic Storage Containers?

Plastic storage containers are widely used due to their affordability and lightweight nature. They are ideal for situations where weight is a concern, such as in shipping or moving goods. Additionally, they come in various sizes and configurations, making them versatile for different applications. However, plastic is generally less durable than aluminum and can degrade under extreme temperatures or UV exposure, making it less suitable for outdoor or heavy-duty applications.

How Do Steel Storage Boxes Compare to Custom Aluminum Boxes?

Steel storage boxes offer significant strength and durability, making them an excellent choice for industrial and construction environments. They can withstand harsh conditions and are less prone to damage from impacts compared to plastic. However, they are heavier and often more challenging to transport. Steel boxes may also require additional maintenance, such as rust prevention treatments, particularly in humid or coastal environments. While they can be cost-effective for long-term use, the initial investment might be higher than that of plastic containers but lower than custom aluminum boxes.

How Should B2B Buyers Choose the Right Solution?

When selecting between custom aluminum boxes and alternative solutions like plastic containers or steel boxes, B2B buyers should consider their specific operational needs and budget constraints. Custom aluminum boxes excel in performance and longevity, making them suitable for demanding applications where reliability is crucial. Conversely, if cost and weight are primary concerns, plastic containers may be the better option. Steel boxes are a solid choice for heavy-duty needs but may require more maintenance and offer less flexibility in customization.

In conclusion, the right choice depends on the unique requirements of each business, including the nature of the goods being stored or transported, environmental conditions, and budgetary limitations. Evaluating these factors will help international B2B buyers make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for custom aluminum boxes

What Are the Key Technical Properties of Custom Aluminum Boxes for B2B Buyers?

When considering custom aluminum boxes, several technical properties are crucial for ensuring durability, functionality, and compliance with industry standards. Here are some essential specifications to understand:

-

Material Grade

The material grade of aluminum used in custom boxes is a key determinant of strength and weight. Common grades include 6061 and 5052, with 6061 being highly versatile and suitable for structural applications. Understanding the material grade helps buyers assess the box’s resistance to corrosion and impact, which is vital for industries like construction and transportation. -

Thickness

The thickness of the aluminum, often measured in gauge or millimeters, directly influences the box’s durability and weight capacity. Typical thicknesses range from 0.080″ to 0.125″. Thicker materials may be necessary for applications requiring enhanced strength, such as heavy equipment transport, while thinner options may suffice for lighter uses. -

Tolerance

Tolerance refers to the permissible limit or limits of variation in a physical dimension. For custom aluminum boxes, tight tolerances ensure that parts fit together correctly and perform as intended. This specification is critical for OEM (Original Equipment Manufacturer) applications where precision is paramount. -

Finish Type

The finish applied to aluminum boxes affects both aesthetics and functionality. Options include anodized, powder-coated, or brushed finishes, each providing different levels of corrosion resistance and visual appeal. For B2B buyers, selecting the right finish can enhance the product’s longevity and brand image. -

Load Capacity

This specification indicates how much weight the box can securely carry. Load capacity is essential for determining whether a custom aluminum box meets the operational requirements of specific industries, such as automotive or construction. Buyers should always verify that the load capacity aligns with their intended use to avoid potential failures. -

Warranty Period

A warranty is an assurance of quality and durability. Custom aluminum boxes often come with warranties ranging from 5 to 10 years, covering workmanship and material defects. Understanding the warranty terms is crucial for B2B buyers as it reflects the manufacturer’s confidence in their product and provides protection against defects.

What Common Trade Terms Should B2B Buyers Know for Custom Aluminum Boxes?

In the world of custom aluminum boxes, several trade terms are frequently used that are essential for effective communication and negotiation. Here’s a breakdown of some of the most important terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers looking to procure custom boxes that fit into larger assembly systems or products. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest order quantity a supplier is willing to accept. This term is crucial for B2B buyers to know, as it directly affects purchasing decisions and inventory management. Buyers should ensure their order size meets the MOQ to avoid unnecessary costs. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers. It typically outlines the specifications and quantities required. For B2B buyers, using an RFQ ensures they receive competitive pricing and clear terms from multiple vendors. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international shipping. Knowledge of Incoterms is essential for B2B transactions, as they clarify who is responsible for shipping, insurance, and tariffs, thus reducing potential misunderstandings. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the product. For custom aluminum boxes, lead time can vary based on complexity and customization options. Understanding lead time helps buyers plan their operations and inventory effectively. -

Customization Options

This encompasses the various modifications that can be made to standard aluminum boxes, including size, color, and additional features like locks or shelving. Knowing the available customization options allows B2B buyers to tailor products to their specific needs, enhancing functionality and efficiency.

By familiarizing themselves with these technical properties and industry terms, B2B buyers can make informed decisions when sourcing custom aluminum boxes, ensuring they select the right products for their operational requirements.

Navigating Market Dynamics and Sourcing Trends in the custom aluminum boxes Sector

What Are the Current Market Dynamics and Key Trends Affecting Custom Aluminum Boxes?

The custom aluminum boxes market is experiencing robust growth driven by several global factors. The demand for lightweight, durable packaging solutions has surged, particularly in industries such as automotive, aerospace, and electronics. This trend is largely attributed to the increasing need for efficient logistics and transportation solutions in developing regions like Africa and South America, where infrastructure improvements are underway. In addition, the rise of e-commerce has led to a heightened requirement for secure and customizable packaging options, further propelling the demand for custom aluminum boxes.

Emerging B2B technologies are also reshaping sourcing trends. Innovations such as 3D printing and advanced CAD software enable manufacturers to produce highly customized aluminum boxes tailored to specific client needs. This technology not only enhances product quality but also reduces lead times, allowing businesses to respond more swiftly to market demands. International buyers, particularly from the Middle East and Europe, are increasingly leveraging digital platforms for sourcing, streamlining the procurement process while enhancing transparency and supplier collaboration.

In terms of market dynamics, the competitive landscape is evolving, with an increasing number of manufacturers focusing on specialization and customization. This shift is particularly relevant for B2B buyers in regions like Nigeria and Saudi Arabia, where unique specifications often dictate purchasing decisions. As competition intensifies, buyers are encouraged to engage in thorough supplier evaluations to ensure they partner with manufacturers who can deliver quality and reliability.

How Is Sustainability and Ethical Sourcing Reshaping the Custom Aluminum Boxes Market?

Sustainability has emerged as a pivotal consideration in the custom aluminum boxes sector. With growing environmental awareness, businesses are increasingly prioritizing eco-friendly practices. The production of aluminum itself is energy-intensive; however, its recyclability offers a significant advantage. B2B buyers are encouraged to seek suppliers who utilize recycled aluminum and adopt energy-efficient manufacturing processes, thereby minimizing their environmental footprint.

Ethical sourcing is also gaining traction, with buyers keen to ensure that their suppliers adhere to fair labor practices and responsible sourcing. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) can serve as indicators of a supplier’s commitment to sustainability. Buyers can benefit from asking potential suppliers about their sustainability certifications and practices, which can enhance their corporate responsibility profile.

Moreover, integrating ‘green’ materials into the design of custom aluminum boxes is becoming more prevalent. Features such as non-toxic finishes and sustainable packaging solutions are increasingly requested by end-users, reflecting a broader trend towards environmental responsibility. As B2B buyers from regions like Europe and the Middle East become more environmentally conscious, aligning with suppliers who prioritize sustainability can not only enhance brand reputation but also open up new market opportunities.

What Is the Historical Context of Custom Aluminum Boxes in the B2B Landscape?

The evolution of custom aluminum boxes can be traced back to the mid-20th century when aluminum began to gain popularity due to its lightweight and corrosion-resistant properties. Initially utilized primarily in the aerospace and automotive sectors, the versatility of aluminum led to its adoption across various industries, including construction and consumer goods.

As global trade expanded, the need for robust and customizable packaging solutions became evident. The introduction of advanced manufacturing techniques, such as welding and anodizing, has further enhanced the functionality and aesthetic appeal of aluminum boxes. Over time, these products have transitioned from simple storage solutions to sophisticated packaging options that cater to the specific requirements of diverse industries.

Today, custom aluminum boxes represent a vital element in logistics and supply chain management, reflecting the broader trends of globalization and technological advancement. As the market continues to evolve, B2B buyers are urged to stay abreast of emerging innovations and sustainability practices to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of custom aluminum boxes

-

How do I ensure the quality of custom aluminum boxes from suppliers?

To ensure quality, start by requesting samples from potential suppliers. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, verify their experience in manufacturing aluminum boxes, especially those tailored to your industry needs. Conduct factory visits if possible, or utilize third-party inspection services to assess production processes and materials used. Lastly, review customer testimonials and case studies to gauge satisfaction levels and product performance. -

What is the best way to customize aluminum boxes for specific applications?

The best way to customize aluminum boxes is to clearly define your requirements, including dimensions, load capacity, and intended use. Collaborate with your supplier during the design phase to explore options such as lid styles, lock types, and additional features like shelving or mounting brackets. Providing detailed specifications and visual references will help the manufacturer understand your vision. Engage in prototyping to test the design before full-scale production, ensuring it meets your operational needs. -

What are the minimum order quantities (MOQ) for custom aluminum boxes?

Minimum order quantities can vary significantly between suppliers. Generally, MOQs for custom aluminum boxes range from 50 to 200 units, depending on the complexity of the design and materials required. Smaller orders may incur higher per-unit costs due to setup and production inefficiencies. It’s advisable to discuss your specific requirements with the supplier to negotiate suitable MOQs that align with your budget and inventory strategy, particularly if you’re a new buyer. -

What payment terms should I expect when sourcing custom aluminum boxes internationally?

Payment terms can differ based on the supplier and your negotiation. Common terms include a 30% deposit upfront with the balance due upon shipment or a letter of credit for larger orders. Ensure clarity on the payment methods accepted, such as bank transfers or credit terms. It’s crucial to establish these terms early in negotiations to avoid disputes later. Additionally, consider the implications of currency fluctuations and international transaction fees when budgeting for your purchase. -

What should I consider regarding logistics and shipping when importing aluminum boxes?

When importing aluminum boxes, consider factors such as shipping methods, lead times, and customs regulations in your country. Determine whether you prefer air or sea freight based on urgency and cost. Collaborate with your supplier to ensure proper packaging and labeling to comply with international shipping standards. Also, factor in additional costs like duties, taxes, and insurance. Engaging a freight forwarder can simplify logistics and help navigate the complexities of customs clearance. -

How do I vet suppliers for custom aluminum boxes to ensure reliability?

To vet suppliers, start by researching their reputation through online reviews, industry forums, and references from previous clients. Assess their manufacturing capabilities, including technology and workforce expertise. Request financial statements or credit reports to evaluate stability. Additionally, check for compliance with international quality standards and certifications. Conducting site visits or audits can further enhance your confidence in their operations and ensure they can meet your quality and delivery expectations. -

What kind of warranties or guarantees should I expect for custom aluminum boxes?

Most reputable suppliers offer warranties that cover workmanship and material defects. Typical warranties range from one to ten years, depending on the manufacturer’s policies and the specific product. Ensure you receive clear documentation outlining the warranty terms, including what is covered and the process for filing claims. It’s also beneficial to inquire about post-sale support, such as replacement parts or maintenance services, to maximize the longevity of your investment. -

How can I ensure compliance with international trade regulations when purchasing aluminum boxes?

To ensure compliance, familiarize yourself with the import regulations in your country, including tariffs, import duties, and safety standards for aluminum products. Request necessary documentation from your supplier, such as certificates of origin and compliance with safety regulations. Engage with a customs broker to facilitate the import process and ensure all paperwork is in order. Staying informed about international trade agreements that may affect your purchase can also provide cost-saving opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Custom Aluminum Boxes Manufacturers & Suppliers List

1. Alum-Line – Custom Aluminum Boxes

Domain: alumline.com

Registered: 2000 (25 years)

Introduction: Alum-Line Aluminum Custom Boxes are built for a lifetime of use, offering customization to fit any space. They are made from .100 aircraft grade treadbrite aluminum, with options for .125 diamond plate and .080 diamond plate or .100 smooth for shorter lengths. The boxes come with a five-year workmanship warranty and a ten-year warranty on aluminum. Features include interlocking lids with rubber ga…

2. Mad Cow Metal Works – Aluminum Dry Boxes

Domain: madcowmetalworks.com

Registered: 2010 (15 years)

Introduction: Aluminum Dry Boxes for rafting, car camping, RVs, etc. Features include water resistance and durability. Product offerings: Standard Dry Boxes, Bear Resistant Boxes, Custom Boxes. Specific products include: The Molly Box ($345), The Hollywood ($370), 24″ IGBC Dry Box (13″h) ($510), 24″ IGBC Dry Box (18″h) ($595), 28″ to 44″ Dry Boxes, Custom Captain’s Boxes ($1,010), Kitchen Box ($990), Custom Dry…

3. Aluminess – Deluxe Box Explorer Edition

Domain: aluminess.com

Registered: 2003 (22 years)

Introduction: Aluminum Storage Boxes & Accessories from Aluminess include a variety of products designed for van owners. Key products include: 1. Deluxe Box Explorer Edition – $950.00 (originally $1,150.00) 2. Deluxe Box Classic – $850.00 (originally $995.00) 3. Slim Box With Side Door – $850.00 (originally $950.00), dimensions 30″x20″x12″ 4. Rear Door Bike Rack/Box Option Kit – $425.00 5. Rear Door Rack Bolt-O…

4. KDM Fab – Custom Aluminum Box Fabrication

Domain: kdmfab.com

Registered: 2022 (3 years)

Introduction: Custom aluminum box fabrication services including prototypes and mass production. Capabilities include 3D design and polishing. Various aluminum alloys used for custom features. Options for windows, louvers, locks, gaskets, etc. Versatile applications: electrical enclosures, mobile cabinets, tool storage. IP-rated and NEMA-rated boxes for outdoor, commercial, marine, and industrial use. Specific …

5. Takachi – Custom Sized Aluminium Box

Domain: takachi-enclosure.com

Registered: 2011 (14 years)

Introduction: CUSTOM SIZED ALUMINIUM BOX – TCF series

Category: Custom sized enclosure, Sheet metal enclosure, Project box, Aluminium chassis, Control box, Switch box

Key Features:

– Custom sized aluminium sheet metal box with an aluminium sheet cover.

– Detachable top cover for easy assembly and maintenance access.

– Internal surface unfinished for conductive and grounding possibilities.

– Suitable for vario…

6. Trebor Manufacturing – Aluminum Tool Boxes

Domain: trebormanufacturing.com

Registered: 2002 (23 years)

Introduction: Aluminum Tool Boxes from Trebor Manufacturing include various custom options such as Underbody Tool Boxes, Top Lid Tool Boxes, Cross Frame Tool Boxes, Step Tool Boxes, and Big Mouth Step Tool Boxes. The product range features different dimensions (depth, width, height, and length) and finishes (checker plate, extruded aluminum, smooth). Door options include single doors (various configurations) an…

7. Roam Built – Universal Aluminum Storage Box

Domain: roambuilt.com

Registered: 2015 (10 years)

Introduction: Universal Aluminum Storage Box – Rugged, Lightweight & Weather-Resistant. Heavy-duty, rust-proof aluminum storage box built for overlanding, camping, and off-grid adventures. Perfect for tools, gear, or generator storage. Lightweight, weather-sealed, and mounts easily to swing-outs or flat surfaces. Sale prices: $941.00 for Universal Aluminum Storage Box, $1,450.00 for ROAMBUILT Trail Box with opt…

8. 800Toolbox – Custom Tool Boxes for Trucks

Domain: 800toolbox.com

Registered: 1995 (30 years)

Introduction: Custom tool boxes for trucks including pickup trucks, semi tool boxes, cab guards, pickup headache racks, cargo slides, truck flatbeds, RV truck tow bodies, RV haulers, RV toters, trailer and flatbed underbody toolboxes. Customization available for any product to meet specific customer needs. Products include custom truck tool boxes, truck flatbeds, service bodies, truck slides, enclosures, and mo…

Strategic Sourcing Conclusion and Outlook for custom aluminum boxes

In conclusion, strategic sourcing of custom aluminum boxes presents a significant opportunity for international B2B buyers across diverse markets in Africa, South America, the Middle East, and Europe. By prioritizing quality, durability, and customization, businesses can enhance their operational efficiency and ensure that their products are stored and transported securely. The emphasis on sourcing from reputable manufacturers not only guarantees superior craftsmanship but also fosters long-term partnerships that can adapt to evolving market needs.

Investing in custom aluminum boxes can lead to improved organizational capabilities and increased safety during transport, essential for industries ranging from construction to automotive. The flexibility in design options allows companies to tailor solutions that meet specific requirements, maximizing utility and functionality.

As you consider your sourcing strategies, take the time to evaluate suppliers who align with your quality standards and business values. By doing so, you position your company for success in a competitive landscape. Embrace the future of storage and transport solutions—connect with trusted manufacturers today to explore how custom aluminum boxes can elevate your operations.