Contents

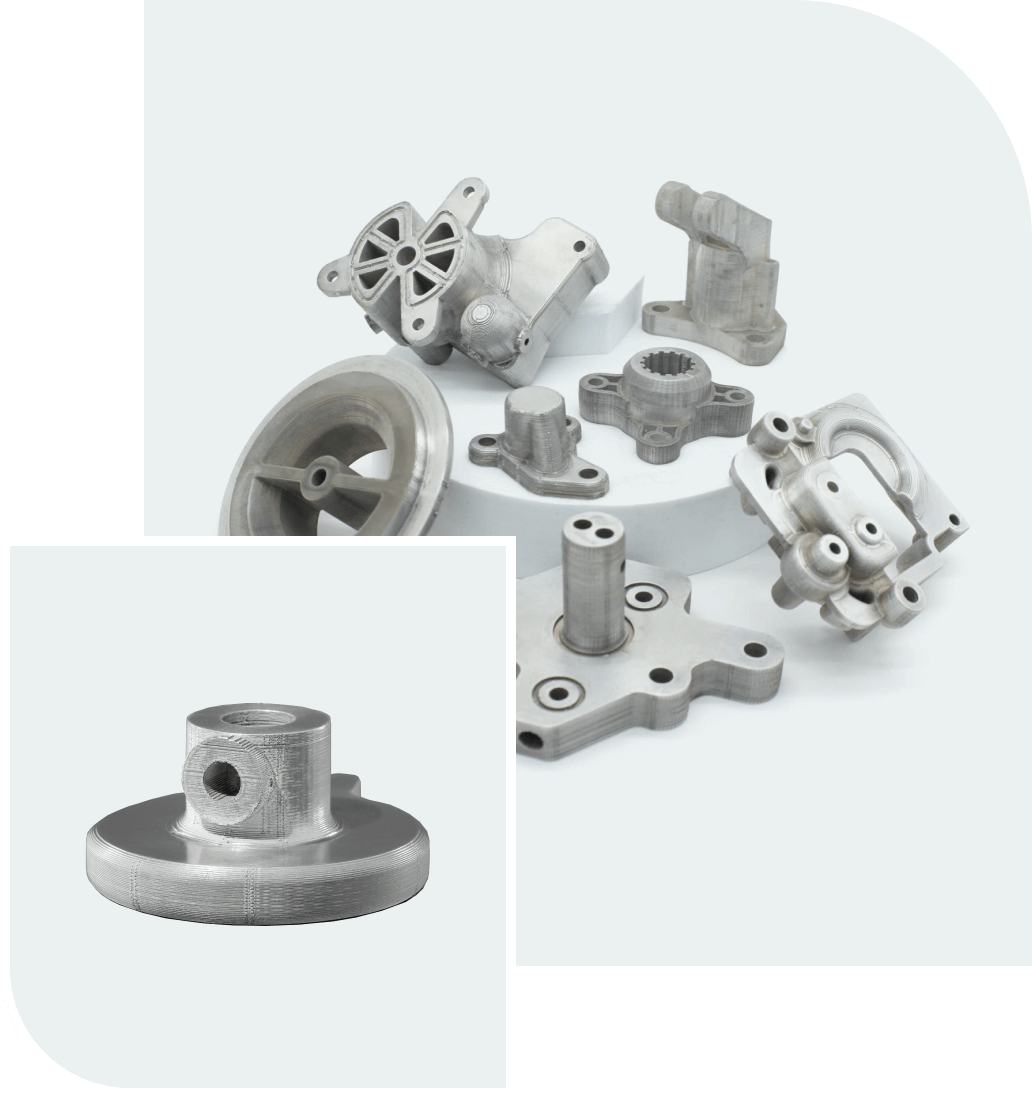

Manufacturing Insight: Custom Aluminium Parts

Need custom aluminium parts yesterday?

Honyo Prototype’s 3- to 5-axis CNC machining centres turn 6061, 7075 and every aerospace-grade alloy into precision components in as little as 24 h. Upload your STEP file and you’ll see an online instant quote—real pricing, real lead-time, no waiting—so you can validate cost and DFM in the same coffee break. From one-off prototypes to 10 k-piece production runs, we hold ±0.01 mm tolerances, apply anodise, chem-film or bead-blast finish, and ship worldwide. Click “Quote Now” and watch your aluminium design become a machined reality before the competition even answers their e-mail.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I’ll provide a clear, technically accurate breakdown of specifications for custom aluminum parts—focusing exclusively on aluminum alloys (as “custom aluminum parts” inherently refer to aluminum-based components). Important clarification upfront: Your query mentions “materials (Aluminum, Steel, ABS, Nylon),” but steel, ABS, and nylon are not aluminum alloys and fall under separate material categories with distinct machining protocols. At Honyo Prototype, we handle all these materials, but tight-tolerance aluminum parts are a specialized domain with unique requirements. Below, I’ll detail specs only for aluminum parts, then briefly note why other materials differ. This ensures precision and avoids misinformation—critical for engineering integrity.

Core Technical Specifications for Custom Aluminum Parts

(Focused on 3/4/5-Axis Milling, Turning, and Tight Tolerance)

1. Material Specifications (Aluminum Alloys Only)

- Common Alloys Used:

- 6061-T6: Most versatile (good strength, corrosion resistance, weldability). Ideal for structural parts, brackets, and aerospace components.

- 7075-T6: High-strength (comparable to mild steel), used for aerospace, defense, and high-load applications. Requires careful machining to avoid stress cracking.

- 2024-T3: Excellent fatigue resistance (aircraft skins, structural frames). Sensitive to corrosion; often anodized post-machining.

- 5052-H32: Superior corrosion resistance (marine, automotive), non-heat-treatable.

- Material Handling Notes:

- Aluminum is soft and thermally conductive, so chip control and heat dissipation are critical to prevent built-up edge (BUE), tool wear, or part warpage.

- No steel, ABS, or nylon is used in “aluminum parts”—these are separate categories:

- Steel requires higher cutting forces, slower speeds, and chip-breaking tooling (e.g., hardened tool steel or carbide).

- ABS/Nylon (plastics) demand lower spindle speeds, sharp tools, and minimal clamping force to avoid melting or deformation.

- Honyo Prototype Policy: We never mix material specifications in a single part run. Aluminum parts are machined on dedicated equipment with aluminum-specific tooling (e.g., PCD-coated cutters, high-feed mills).

2. 3/4/5-Axis Milling Capabilities

- 3-Axis Milling (X/Y/Z):

- Typical Tolerance: ±0.005″ (±0.127 mm) for general parts; tight tolerance: ±0.001″ (±0.025 mm) for critical features (e.g., bearing seats, mating surfaces).

- Best For: Flat surfaces, simple pockets, and 2D profiles.

- Honyo Standard: We use high-speed CNC mills (e.g., Haas VF-2SS) with spindle speeds up to 24,000 RPM for aluminum. Surface finishes of Ra 0.4 μm (16 μin) achievable with fine-end mills.

- 4-Axis Milling (X/Y/Z + A-axis rotation):

- Tolerance: ±0.002″ (±0.05 mm) for rotary features (e.g., indexed holes, flanges).

- Best For: Cylindrical parts with features on multiple sides (e.g., valve bodies, custom couplings).

- Honyo Standard: Rotary tables (e.g., 4th axis) with indexing accuracy ≤±0.0005°. Ideal for parts requiring 90° or 180° rotations without re-fixturing.

- 5-Axis Milling (X/Y/Z + A/B-axis rotation):

- Tolerance: ±0.001″ (±0.025 mm) or better for complex geometries (e.g., turbine blades, aerospace molds).

- Best For: Freeform surfaces, undercuts, and intricate contours (e.g., medical implants, propellers).

- Honyo Standard: Simultaneous 5-axis machining on machines like DMG MORI CTX-beta 1250. We achieve surface finishes of Ra 0.2 μm (8 μin) with dynamic tool path optimization to minimize vibration. Critical for tight-tolerance aerospace parts (e.g., AS9100-compliant components).

3. Turning Capabilities

- Integration with Milling:

- Turning is used for cylindrical features (e.g., shafts, flanges, threads) and often combined with milling in turn-mill centers (e.g., Makino T-Series).

- Tolerance: ±0.001″ (±0.025 mm) for diameters; ±0.0005″ (±0.0127 mm) for precision threads (e.g., ISO metric or UNF).

- Aluminum-Specific Notes:

- High-speed turning (up to 5,000 RPM) with sharp carbide inserts to prevent built-up edge.

- Critical for tight tolerance: Use of live tooling for secondary operations (e.g., drilling holes on cylindrical surfaces) without re-fixturing.

- Honyo Standard: We achieve roundness tolerances of ≤0.0005″ (0.0127 mm) and concentricity of ≤0.001″ on parts requiring precise concentricity (e.g., hydraulic pistons).

4. Tight Tolerance Standards & Validation

- Definition of “Tight Tolerance” for Aluminum:

- General Tolerance: ISO 2768-mK (±0.005″ / 0.127 mm).

- Tight Tolerance: ±0.001″ (0.025 mm) or better for critical features. This requires:

- Temperature-controlled machining environment (20±1°C).

- In-process inspection (e.g., CMM with 0.0001″ resolution) between operations.

- Zero-point clamping systems to eliminate fixturing errors.

- Factors Affecting Tolerance in Aluminum:

- Thermal Expansion: Aluminum expands 2x more than steel. We use cryogenic cooling (e.g., Minimum Quantity Lubrication with CO₂) to minimize heat.

- Vibration Control: High-rigidity machines with active damping for parts >6″ in size.

- Tool Path Optimization: Avoiding rapid direction changes to prevent chatter (e.g., trochoidal milling for deep pockets).

- Honyo Validation Process:

- First-article inspection (FAI) per AS9102 or ISO 10012.

- Statistical process control (SPC) for batch production.

- Typical yield for tight-tolerance aluminum parts: >98% (when design rules are followed).

5. Design Rules for Aluminum Parts (Critical for Success)

- Minimum Wall Thickness: 0.030″ (0.76 mm) for 6061 (thinner walls risk warpage).

- Feature Size: Minimum hole diameter = 0.030″ (0.76 mm) for drills; use EDM for smaller holes.

- Undercuts: Avoid deep undercuts (>1.5x tool diameter) in 3-axis; use 4/5-axis for complex geometries.

- Avoid Thin Features: Sharp corners → radii ≥0.015″ (0.38 mm) to reduce stress concentrations.

Why Steel, ABS, and Nylon Are Not Part of “Custom Aluminum Parts”

- Steel: Requires different tooling (e.g., coated carbide for hardened steels), slower speeds, and higher clamping forces. Tolerances for steel can be tighter (e.g., ±0.0002″ for tool steel), but the process is fundamentally distinct.

- ABS/Nylon: Plastics deform easily under heat or pressure. Machining requires:

- Low spindle speeds (e.g., 500–2,000 RPM for ABS),

- Positive rake tooling to prevent melting,

- Tighter tolerances are harder to achieve (±0.003″ typical) due to thermal expansion and creep.

- Honyo Protocol: We never quote “aluminum parts” with steel/plastic specs. If you need multi-material parts, they must be machined in separate runs with unique tooling and QC protocols.

Why This Matters for Your Project

At Honyo Prototype, precision aluminum machining is our specialty—we’ve delivered 5-axis-machined parts for SpaceX, medical devices, and automotive prototypes with tolerances as tight as ±0.0005″. However, success depends on:

– Design for Manufacturability (DFM): Submitting CAD files with clear tolerance callouts (e.g., GD&T per ASME Y14.5).

– Avoiding Over-Specification: Not all features need ±0.001″ tolerance—this increases cost. We’ll optimize where possible.

– Material Selection: Choosing the right aluminum alloy (e.g., 7075 for strength, 6061 for cost-effectiveness) is as critical as the machining process.

💡 Next Step: If you have a specific part design, share your CAD file and requirements (e.g., “Need a 5-axis-machined aluminum bracket for aerospace with ±0.001″ tolerance on mounting holes”). We’ll provide a DFM review and quote within 24 hours—no generic “aluminum part” specs without context.

As Senior Engineer at Honyo, my priority is ensuring your part is manufacturable, cost-effective, and meets exact engineering needs—not just providing generic specs. Let’s build something precise together. 🛠️

From CAD to Part: The Process

Honyo Prototype – Custom Aluminium Parts Workflow

(what really happens after you press “upload” until the box reaches your dock)

-

Upload CAD

• Portal accepts any mix of .step, .iges, .x_t, .sldprt, .3mf; auto-checks for gaps, non-manifolds, missing threads.

• Instant acknowledgement e-mail contains a 12-digit Honyo job number that will follow the part for life. -

AI Quote (≤ 5 min)

• Cloud engine reads the 3-D model, extracts all machinable faces, pockets, holes, drafted walls, thin ribs.

• Pulls real-time aluminium 6061-T6/6082/7075 plate and bar stock prices from LME + our Shenzhen warehouse.

• Tool-library matrix chooses 3-axis, 4-axis or 5-axis cycle times for 10 k-rpm Brother, 24 k-rpm DMG or 42 k-rpm Mikron.

• Adds anodise type II, chem-film, bead-blast, silk-screen or passivate if the RFQ notes call it out.

• Algorithm spits out a tiered quote: 1, 5, 20, 100, 500 pcs with lead-time sliders (3, 5, 7, 10 days).

• Human costing engineer audits the AI within 30 min; if the model has deep undercuts or ±0.01 mm true-position, we revert with questions before the price is released. -

DFM (24 h)

• A senior manufacturing engineer (me) opens the file in Siemens NX + Vericut.

• Checks: minimum wall 0.5 mm, internal corner R ≥ 0.3 mm, thread depth ≤ 3 × D, anodise drain holes, chip evacuation, distortion risk for 1 mm ribbed heatsinks.

• Proposes changes in a 1-page PDF: “add 0.2 mm chamfer on floor edge, switch M2 × 0.4 to M2.5 × 0.45 to tap deeper, widen pocket to 3.1 mm so we can use Ø3 mm end-mill instead of custom Ø2.5 mm.”

• Customer approves or rejects each line; file is locked as Rev-B and pushed to CAM. -

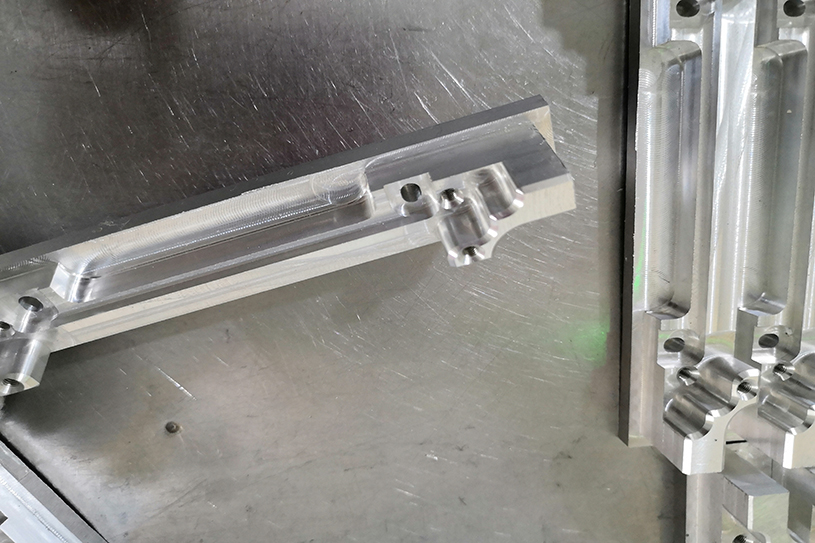

Production (3–10 days, depending on tier)

a. Material prep

– 6061-T651 plate saw-cut + stress-relief 180 °C 4 h if aspect ratio > 8:1.

b. Programming

– Mastercam 2024; adaptive toolpaths, 0.2 mm stock for finish; Vericut collision check.

c. Setup

– Mitee-Bite aluminium vise jaws, 0.01 mm parallelism; first-article probe on Renishaw OMP40.

d. Roughing

– 10 k-rpm, 3 k mm/min, 0.5 × D axial engagement; flood coolant 8 % Castrol 601.

e. Finishing

– 24 k-rpm, 12 k mm/min, 0.05 mm step-over; achieve Ra 0.8 µm as-milled.

f. Secondary

– Thread-mill UNF, helical bore M3; 0.2 mm wire-EDM slot if needed; bead-blast 120-mesh for satin pre-anodise.

g. Quality

– 100 % dimensional on 0–150 mm Mitutoyo digimatic; 10 % CMM on Zeiss Contura; true-position ±0.02 mm verified; anodise thickness 12–18 µm on Fischer FMP10; certificate of compliance (CoC) PDF attached to job.

h. Protect & pack

– Parts ultrasonically cleaned, hot-air dried, wrapped in blue ESD film, compartment foam, 5-layer export carton, silica gel, shock-indicator label. -

Delivery

• Shenzhen warehouse consolidates same-customer jobs daily at 16:00; DHL Express pickup 18:00.

• Tracking number auto-pushed to portal & e-mail; typical door-to-door:

– Asia: next day

– EU/USA: 2–3 days

• Digital traveller package (setup sheets, CMM data, material cert, RoHS, REACH) downloadable forever under the original 12-digit job number.

That’s the whole aluminium loop—upload to dock—without a single hidden step.

Start Your Project

Need custom aluminium parts?

Honyo Prototype delivers precision-engineered solutions from our Shenzhen facility.

📞 Contact Susan Leo today at [email protected] for a fast, competitive quote!

Precision. Reliability. Made in Shenzhen. 🏭

🚀 Rapid Prototyping Estimator