Contents

Manufacturing Insight: Custom Action Figure Parts

Precision CNC Machining for Action Figure Innovation

Honyo Prototype delivers engineered excellence for custom action figure components through advanced CNC machining capabilities. Our manufacturing process ensures micron-level accuracy essential for intricate figure articulation points, weapon accessories, and character-specific detailing where dimensional consistency directly impacts final product performance and aesthetics. Utilizing multi-axis milling and turning centers, we achieve tight tolerances down to ±0.005mm in engineering-grade thermoplastics, metals, and composites—enabling complex geometries that injection molding alone cannot replicate during prototyping or low-volume production phases.

This precision eliminates fitment issues in multi-part assemblies while maintaining material integrity for functional joints and snap-fit connections. Unlike additive methods, our CNC-machined prototypes provide true-to-production surface finishes and mechanical properties, accelerating validation cycles for licensing partners and toy developers. Honyo’s expertise spans from initial CAD file validation to finishing treatments including anodizing, plating, and custom texture application—all under ISO 9001-controlled workflows to guarantee repeatability across batches.

Accelerate your development timeline with immediate cost transparency. Our Online Instant Quote system provides validated pricing for custom action figure parts within 90 seconds, factoring in material selection, geometric complexity, and required tolerances. Simply upload your STEP or IGES file to receive a comprehensive manufacturing assessment and lead time estimate—no sales intermediary required. This digital efficiency allows engineering teams to iterate designs rapidly while maintaining strict budgetary control throughout the prototyping phase.

| Key CNC Advantages for Action Figure Parts |

|---|

| Tolerance Range: ±0.005mm to ±0.025mm |

| Material Compatibility: ABS, PC, Nylon, Aluminum 6061, Brass |

| Lead Time: As fast as 3 business days for prototypes |

| Volume Flexibility: 1–500+ units per order |

Access our Online Instant Quote platform directly at honyoprototype.com/quote to initiate production-ready custom action figure components with technical rigor and commercial agility.

Technical Capabilities

Custom action figure parts require high precision manufacturing due to intricate geometries, fine surface details, and tight dimensional tolerances. These components are commonly produced using advanced CNC machining methods such as 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, to achieve complex contours and repeatable accuracy. Applications include prototype development, limited-run collectible manufacturing, and functional joint systems in high-end figures.

The following table outlines the technical specifications and capabilities relevant to the production of custom action figure parts using CNC machining:

| Parameter | Specification Details |

|---|---|

| Machining Processes | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (for symmetrical joints, pegs, pins) |

| Tolerance | ±0.005 mm to ±0.025 mm (±0.0002″ to ±0.001″) typical; tight tolerance achievable on critical fit features |

| Surface Finish | Ra 0.8 µm to 3.2 µm (32–125 µin); post-processing available (polishing, bead blasting) |

| Feature Resolution | Capable of machining fine details such as facial textures, thread patterns, and snap-fit geometries |

| Minimum Wall Thickness | 0.5 mm (Aluminum, ABS), 0.8 mm (Steel), 0.6 mm (Nylon) – dependent on geometry and support |

| Materials Supported | Aluminum (6061, 7075): Lightweight, strong, good for metal prototypes and display bases Steel (17-4 PH, A2): High strength and wear resistance for durable joints and internal frames ABS: Impact-resistant thermoplastic; suitable for lightweight, detailed non-metal parts Nylon (PA6, PA66): Flexible, durable, and wear-resistant; ideal for living hinges and snap-fit connectors |

| Secondary Operations | Deburring, anodizing (Al), passivation (steel), painting, pad printing, assembly support |

| Typical Applications | Custom joints, skeletal frames, weapon accessories, head sculpts, armor pieces, interlocking components |

| Lead Time | 3–7 days for prototypes; 7–14 days for small production batches (10–100 units) |

Honyo Prototype leverages multi-axis CNC platforms to ensure high repeatability and micron-level precision, enabling the production of complex, fully functional action figure components in both metal and engineering-grade plastics.

From CAD to Part: The Process

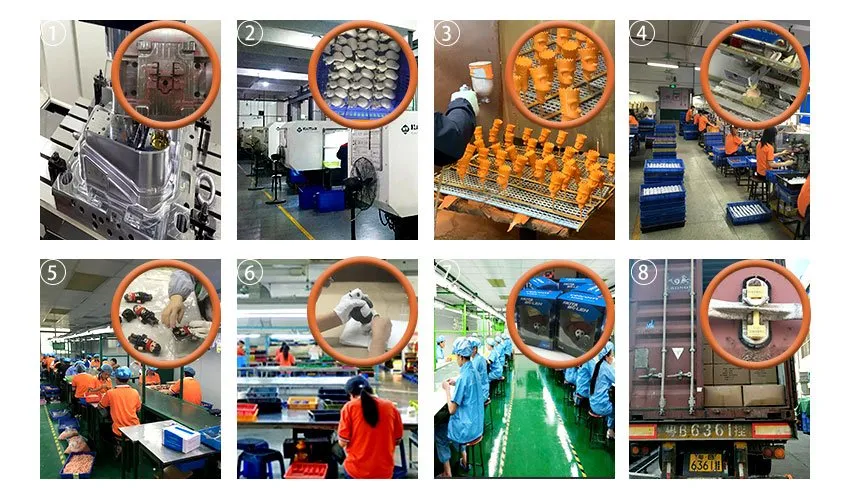

Honyo Prototype executes custom action figure part production through a rigorously defined technical workflow optimized for precision, speed, and manufacturability. This process ensures seamless transition from digital design to physical delivery while maintaining strict quality control at each phase.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or high-resolution mesh formats (STL, OBJ) via our secure customer portal. All submissions undergo automated validation for geometric integrity, watertightness, and unit consistency. Files failing minimum mesh resolution (0.05mm) or containing non-manifold edges trigger immediate notifications requiring client correction prior to processing. This stage establishes the foundational geometry for downstream analysis.

AI Quote Generation

Validated CAD data feeds into Honyo’s proprietary AI quoting engine, which performs real-time analysis of 17 geometric and material parameters. The system calculates machine time, material consumption, support structure requirements, and post-processing complexity against dynamic cost databases for engineering-grade polymers (e.g., PA12, ABS-like resins, photopolymers). Quotes include granular cost breakdowns for material, labor, and finishing, with turnaround typically under 90 minutes. Critical geometric constraints such as minimum wall thickness (1.2mm for SLS) or overhang limitations (>45° without supports) are flagged during this phase.

DFM Analysis

All quotes undergo mandatory Design for Manufacturing review by Honyo’s engineering team specializing in small-scale prototyping. This stage focuses on action figure-specific failure points: joint stability analysis, stress concentration mapping at articulation points, and demolding feasibility for undercuts. Engineers implement critical modifications including wall thickness optimization, strategic ribbing for thin limbs, draft angle adjustments (1°-3°), and split-line optimization for multipart assemblies. Clients receive annotated DFM reports with recommended changes and impact assessments on cost/timeline before approval.

Production Execution

Approved designs move to production using technology-matched processes:

SLS (Selective Laser Sintering) for durable nylon-based parts requiring snap-fit joints

SLA/DLP for high-detail resin components (e.g., facial features, accessories)

Multi Jet Fusion for larger batch quantities with consistent mechanical properties

Each build undergoes in-process monitoring via thermal imaging and layer adhesion sensors. Post-processing includes automated depowdering, ultrasonic cleaning, and manual finishing for critical surfaces. All parts receive dimensional verification against CAD nominal using coordinate measuring machines (CMM) with 10μm accuracy.

Delivery and Quality Assurance

Final inspection packages include first-article reports with critical dimension measurements, material certification, and surface finish analysis. Parts ship in custom anti-static packaging with compartmentalized trays for fragile components. Typical lead times from CAD approval are 5-7 business days for quantities under 100 units. Real-time shipment tracking integrates with client ERP systems via API.

Production timelines vary by technology and complexity as shown in the standard throughput table:

| Technology | Avg. Build Time per Unit | Max Batch Size | Typical Lead Time | Surface Finish (Ra) |

|---|---|---|---|---|

| SLS | 8-12 hours | 50-75 units | 5-7 days | 15-25 μm |

| SLA | 4-6 hours | 25-40 units | 4-6 days | 8-15 μm |

| MJF | 3-5 hours | 100+ units | 6-8 days | 12-20 μm |

This integrated workflow eliminates traditional prototyping bottlenecks through AI-driven quoting and specialized DFM for miniature geometries, ensuring action figure components meet both aesthetic requirements and functional durability standards for end-use application.

Start Your Project

Looking for custom action figure parts tailored to your design specifications? Honyo Prototype specializes in precision manufacturing of action figure components, from intricate limbs to detailed headsculpts, using high-quality materials and advanced prototyping techniques.

Our factory in Shenzhen offers scalable production, strict quality control, and fast turnaround times—ideal for both prototypes and bulk orders. Whether you’re developing a new collectible line or need replacement parts, we deliver consistent accuracy and finish.

Contact Susan Leo today at [email protected] to discuss your project, request a quote, or receive technical support. Let’s bring your vision to life with engineering precision and manufacturing excellence.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.