Contents

Manufacturing Insight: Cost To Cnc A Part

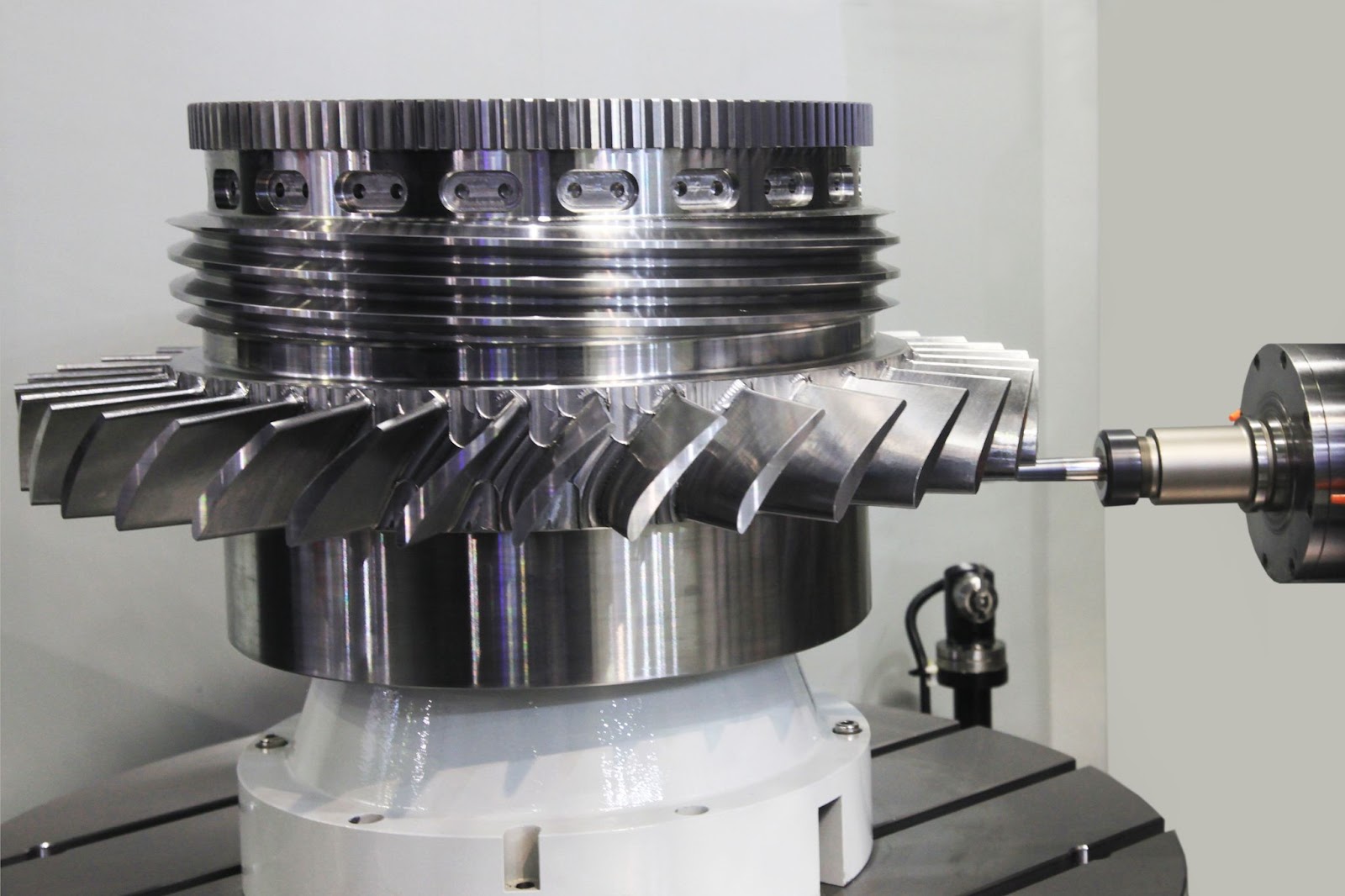

Understanding the true cost to CNC a part requires analyzing multiple engineering and production variables beyond basic material expenses. At Honyo Prototype, our precision CNC machining services encompass multi-axis milling, turning, and grinding capabilities for complex components in aluminum, steel, titanium, and engineering plastics, consistently holding tolerances to ±0.0002 inches. We recognize that accurate cost estimation hinges on geometric complexity, required tolerances, material selection, secondary operations, and order volume – factors our engineering team evaluates rigorously to avoid underquoting or design compromises.

Our Online Instant Quote platform directly addresses this challenge by providing transparent, data-driven cost projections within minutes. Upload your CAD file, specify materials and quantities, and receive a detailed breakdown reflecting real manufacturability insights – no generic pricing tiers. This eliminates estimation guesswork early in the design phase, allowing you to optimize part geometry for cost efficiency before committing to production. By integrating engineering expertise with automated quoting, Honyo ensures your CNC project achieves both technical precision and predictable budgeting from prototype to volume production.

Key cost drivers we evaluate include

Material type and block size requirements

Geometric complexity and feature density

Tolerance stringency across critical dimensions

Secondary processes like anodizing or precision tapping

Annual usage volume and delivery timeline constraints

Leverage our instant quoting system to transform cost uncertainty into actionable manufacturing intelligence for your next CNC project.

Technical Capabilities

Cost to CNC machine a part depends on several technical and operational factors, including machine type, complexity, material, tolerances, setup time, and volume. Below is a breakdown of key technical specifications influencing cost across 3-axis, 4-axis, and 5-axis milling, as well as turning operations. The analysis includes common materials such as Aluminum (6061-T6), Steel (1018 or 4140), ABS, and Nylon.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Machine Complexity | Standard 3 linear axes (X, Y, Z) | Adds one rotational axis (typically A-axis) for indexing | Full simultaneous motion on 3 linear and 2 rotational axes | Primarily 2-axis (X, Z) for cylindrical parts; optional C-axis for milling |

| Setup Time | Low (15–30 min typical) | Moderate (30–60 min) due to rotary alignment | High (60–90+ min) due to fixturing and probing | Low to moderate (15–45 min), depends on part geometry |

| Cycle Time Influence | Moderate – limited access may require multiple setups | Reduced setups for features on multiple sides | Minimal setups; complex geometries in single setup | Fast for high-length-to-diameter ratios; optimized for symmetry |

| Tight Tolerance Capability (±) | ±0.005″ (standard), ±0.001″ achievable with care | ±0.001″ with proper calibration | ±0.0005″ to ±0.001″ with high-precision machines | ±0.0005″ achievable on diameters and lengths with precision turning |

| Surface Finish (typical) | 32–125 μin Ra | 32–63 μin Ra | 16–32 μin Ra (with contouring) | 16–63 μin Ra depending on tooling and speed |

| Material Suitability | Aluminum: Excellent | Aluminum: Excellent | Aluminum: Optimal for complex aerospace parts | Aluminum: High machinability, low tool wear |

| Steel: Moderate (slower speeds, higher tool wear) | Steel: Good with rigid setups | Steel: Preferred for high-accuracy steel components | Steel: Suitable; requires rigid setup and proper coolant | |

| ABS: Good, but heat-sensitive | ABS: Limited due to fixturing challenges | ABS: Limited use; not typical for high-end 5-axis | ABS: Possible for prototypes; prone to burring | |

| Nylon: Fair (gummy, requires sharp tools) | Nylon: Challenging due to deformation | Nylon: Rarely used; fixturing difficult | Nylon: Machinable; needs sharp cutting edges and chip control | |

| Tooling Cost Impact | Low to moderate | Moderate (additional rotary-compatible tooling) | High (advanced cutters, frequent calibration) | Low to moderate (standard turning inserts) |

| Labor & Programming | Low (standard CAM) | Moderate (4-axis CAM and fixturing) | High (5-axis CAM, collision avoidance, verification) | Low (standard G-code for turning) |

| Typical Applications | Brackets, housings, flat plates | Index-rotated features (e.g., impellers) | Aerospace, medical, complex contours | Shafts, bushings, threaded components |

| Relative Cost Factor (Baseline = 1.0) | 1.0 | 1.4–1.8 | 2.0–3.5 | 1.0–1.3 (depending on complexity) |

Notes on Tight Tolerances (±0.001″ or tighter):

Requires thermal stability, high-precision spindles, and frequent in-process inspection.

Increases cost significantly due to slower feeds, specialized tooling, and metrology (e.g., CMM validation).

Materials like steel and stainless steel are more dimensionally stable than plastics (ABS, Nylon), making them better suited for tight tolerance work.

Plastics such as ABS and Nylon may require stress-relieved stock and controlled machining sequences to minimize warpage.

Material-Specific Observations:

Aluminum (6061-T6): Most cost-effective for all CNC processes; high material removal rates.

Steel (1018/4140): 2–3× more expensive than aluminum due to slower speeds, harder tooling, and higher machine load.

ABS: Low melting point; requires sharp tools and light cuts. Best for low-volume prototypes.

Nylon: Low friction but prone to dimensional change with moisture; pre-dry recommended. Machining cost higher than ABS due to deformation risks.

Overall, 5-axis milling and tight tolerance work significantly increase unit cost, especially in steel and challenging plastics. Turning remains the most economical method for rotational parts, while multi-axis milling justifies cost through reduced setups and access to complex geometries.

From CAD to Part: The Process

Honyo Prototype CNC Machining Cost Process Workflow

Our end-to-end CNC machining process is engineered for speed, accuracy, and cost transparency. Each phase integrates advanced technology with expert engineering oversight to eliminate surprises and optimize manufacturability. Below is a technical breakdown of the workflow from CAD upload to delivery.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid preferred) via our secure online portal. Our system performs an initial automated validation check for file integrity, unit consistency, and geometric completeness. This step ensures the model is suitable for downstream processing, reducing errors before quoting begins. File size limits and format requirements are enforced to maintain system efficiency.

AI-Powered Instant Quote

Upon CAD validation, our proprietary AI engine analyzes geometric complexity, material selection, tolerances, and surface finish requirements. The algorithm calculates estimated machine time using parametric models based on real-time shop floor data, including toolpath simulation, material removal rates, and machine utilization rates. Quotes are generated in under 90 seconds with cost breakdowns for setup, machining, material, and finishing. Critical parameters triggering cost variables include:

Feature complexity: Deep cavities, undercuts, or thin walls increasing toolpath length

Tolerance density: Number of tight tolerances (e.g., ±0.005mm vs. ±0.1mm) per part volume

Material grade: Premium alloys (e.g., Inconel 718) vs. standard aluminum 6061

Typical Cost Distribution for Mid-Complexity Aluminum Part

| Cost Category | Percentage | Key Drivers |

|—————|————|————-|

| Machine Time | 55-65% | Part volume, feature density, spindle utilization |

| Material | 15-20% | Raw stock size, scrap rate, alloy grade |

| Setup/Handling| 10-15% | Fixture complexity, secondary operations |

| Finishing | 8-12% | Surface roughness, anodizing, deburring level |

DFM Analysis and Optimization

Every quote is accompanied by a formal Design for Manufacturability (DFM) report generated through hybrid AI-engineer collaboration. Our system flags non-value-added features (e.g., unnecessary tight tolerances on non-critical surfaces), suggests optimal stock sizes to minimize waste, and identifies opportunities to reduce machine setups. Senior manufacturing engineers review high-risk elements, providing actionable recommendations such as:

Modifying internal corner radii to match standard tooling (e.g., 0.8mm instead of 0.5mm)

Consolidating features to enable single-setup machining

Substituting materials where functional requirements allow cost reduction

Client approval of DFM suggestions is required before production, ensuring alignment on cost/performance trade-offs.

Production Execution

Approved orders enter our dynamic scheduling system, which prioritizes jobs based on delivery deadlines, machine compatibility, and material availability. Production leverages:

Smart nesting: Grouping similar parts across multiple machines to amortize setup costs

Real-time monitoring: IoT-enabled machines track spindle load, tool wear, and cycle times

In-process inspection: Automated CMM checks at critical stages for high-tolerance features

All parts undergo first-article inspection (FAI) per AS9102 standards, with full dimensional reports available upon request. Material certifications and process documentation are maintained in our digital thread system.

Delivery and Logistics

Completed parts undergo final cleaning, protective packaging (vapor corrosion inhibitors for metals), and barcode tracking. Shipping options include:

Standard: 3-5 business days via DHL/FedEx (FOB Shenzhen)

Expedited: 24-48 hour air freight with real-time GPS tracking

Consolidated: Batched shipments for multi-part programs to reduce freight costs

Customs documentation, including HS codes and material origin certificates, is auto-generated. Delivery timelines include buffer days for surface finishing options (e.g., +2 days for Type II anodizing).

This integrated workflow reduces cost uncertainty by 70% compared to traditional quoting methods while maintaining rigorous quality controls. The AI-quote-to-DFM linkage ensures manufacturability is validated before commitment, preventing costly redesigns during production. For complex projects, our engineering team provides direct consultation to refine requirements against cost drivers.

Start Your Project

Looking to understand the cost to CNC a part? Get a fast, accurate quote from Honyo Prototype’s expert manufacturing team.

Contact Susan Leo directly at [email protected] to discuss your project specifications and receive a competitive pricing estimate.

With our advanced CNC machining capabilities and efficient production processes at our Shenzhen factory, we deliver high-quality precision parts on time and at a competitive cost.

Let’s get your next prototype or production run started—reach out today.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.