Introduction: Navigating the Global Market for cost of titanium vs steel

The choice between titanium and steel can significantly impact project budgets and operational efficiency, particularly for international B2B buyers navigating the complexities of material sourcing. As businesses in regions like Africa, South America, the Middle East, and Europe seek reliable materials for construction, manufacturing, and specialized applications, understanding the cost dynamics of titanium versus steel becomes critical. This guide delves into the various types of titanium and steel alloys, their applications across industries, and essential factors to consider when vetting suppliers.

With titanium often touted for its superior strength-to-weight ratio and corrosion resistance, while steel is recognized for its affordability and versatility, the decision isn’t straightforward. This comprehensive resource will empower B2B buyers to make informed purchasing decisions by providing insights into the pricing structures, performance characteristics, and suitability of each metal for specific applications.

Additionally, we will explore strategies for effective supplier evaluation and sourcing, ensuring that businesses can confidently navigate the global market landscape. By equipping decision-makers with actionable knowledge, this guide aims to alleviate the uncertainties associated with material selection, ultimately leading to enhanced project outcomes and cost-effectiveness.

Understanding cost of titanium vs steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Titanium Grade 5 | High strength-to-weight ratio, excellent corrosion resistance | Aerospace, marine, medical devices | Pros: Lightweight, durable, corrosion-resistant. Cons: High cost, difficult to machine. |

| Stainless Steel 304 | Good corrosion resistance, moderate strength, ease of fabrication | Food processing, construction, automotive | Pros: Cost-effective, versatile, easy to weld. Cons: Heavier than titanium, prone to rust without maintenance. |

| Titanium Grade 2 | Good ductility, moderate strength, excellent corrosion resistance | Chemical processing, marine applications | Pros: Strong, biocompatible, lightweight. Cons: Higher price, less strength than Grade 5. |

| Stainless Steel 316 | Excellent corrosion resistance, high tensile strength | Pharmaceutical, marine, food industries | Pros: Very durable, good for harsh environments. Cons: Higher cost than 304, heavier. |

| Titanium Alloys (e.g., Ti-6Al-4V) | Exceptional strength, lightweight, high melting point | Aerospace, automotive, high-performance machinery | Pros: Superior performance, lightweight. Cons: Expensive, complex processing requirements. |

What are the Characteristics and Suitability of Titanium Grade 5 for B2B Buyers?

Titanium Grade 5, also known as Ti-6Al-4V, is renowned for its high strength-to-weight ratio, making it ideal for applications in the aerospace and medical sectors. Its excellent corrosion resistance allows it to perform well in challenging environments, such as marine and chemical processing. B2B buyers should consider the high cost and machining difficulties associated with this grade, which may require specialized tools and processes. However, its long-term performance benefits often justify the initial investment.

How Does Stainless Steel 304 Compare in Cost and Applications?

Stainless Steel 304 is one of the most commonly used grades, appreciated for its balance of good corrosion resistance and moderate strength. It is widely utilized in food processing, construction, and automotive applications due to its ease of fabrication and cost-effectiveness. While it is more affordable than titanium, buyers should be aware of its susceptibility to rust if not properly maintained. Its versatility and availability make it a go-to choice for many industries, but the weight may be a factor in specific applications.

What Makes Titanium Grade 2 a Viable Option for Chemical Processing?

Titanium Grade 2 is characterized by its good ductility and moderate strength, making it suitable for various chemical processing applications. It offers excellent corrosion resistance, particularly in acidic environments, which is crucial for industries dealing with harsh chemicals. While its price point is higher than stainless steel, the long-term durability and reduced maintenance needs can lead to cost savings over time. Buyers should evaluate the specific requirements of their applications to determine if the benefits of Grade 2 outweigh the higher initial costs.

Why Choose Stainless Steel 316 for Harsh Environments?

Stainless Steel 316 is favored for its superior corrosion resistance, particularly in marine and pharmaceutical applications. Its high tensile strength makes it suitable for demanding environments, ensuring structural integrity under stress. Although it is more expensive than 304 stainless steel, its performance in corrosive settings often justifies the additional cost. Buyers must weigh the trade-offs between price and performance, particularly if their operations involve exposure to saltwater or harsh chemicals.

What are the Advantages of Titanium Alloys like Ti-6Al-4V for High-Performance Needs?

Titanium alloys, such as Ti-6Al-4V, are designed for high-performance applications, notably in aerospace and advanced automotive sectors. They offer exceptional strength and lightweight characteristics, making them ideal for components that require reduced weight without compromising structural integrity. The complexity of processing and higher costs are notable downsides, but the performance benefits often make them worth the investment for businesses focused on innovation and efficiency. B2B buyers should assess their specific performance needs and budget constraints when considering these alloys.

Key Industrial Applications of cost of titanium vs steel

| Industry/Sector | Specific Application of cost of titanium vs steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft components (e.g., fuselage frames) | Lightweight, high strength, and corrosion resistance reduce fuel costs and increase performance. | Ensure compliance with international aviation standards and certifications. |

| Medical Devices | Surgical instruments and implants | Titanium’s biocompatibility ensures patient safety and longevity of devices. | Verify supplier certifications and material traceability to meet regulatory requirements. |

| Marine Engineering | Ship hulls and propeller shafts | Titanium’s resistance to seawater corrosion enhances durability and reduces maintenance costs. | Assess local availability of titanium versus steel options to optimize logistics. |

| Automotive | Engine components and chassis parts | Weight reduction leads to improved fuel efficiency and performance in vehicles. | Evaluate cost implications in relation to performance benefits, especially for electric vehicles. |

| Construction | Structural components in high-stress environments | Titanium’s strength-to-weight ratio allows for innovative designs and reduced material usage. | Consider regional supply chains and potential tariffs affecting titanium sourcing. |

How Is the Cost of Titanium vs Steel Impacting Aerospace Applications?

In the aerospace industry, the cost of titanium versus steel plays a critical role in manufacturing aircraft components, such as fuselage frames and engine parts. Titanium’s lightweight nature and exceptional strength-to-weight ratio contribute to improved fuel efficiency and reduced operational costs. However, its higher cost can be a barrier for some manufacturers. International buyers must ensure that their suppliers comply with stringent aviation standards, as any failure in quality can lead to significant safety risks and financial losses.

What Are the Benefits of Using Titanium in Medical Devices?

The medical device sector frequently utilizes titanium due to its biocompatibility and corrosion resistance. Surgical instruments, implants, and prosthetics made from titanium have a longer lifespan and pose fewer risks to patients. While the cost of titanium is substantially higher than that of stainless steel, the benefits in terms of patient safety and product reliability can justify the investment. Buyers in this field should prioritize suppliers who can provide comprehensive certifications and traceability of materials to meet regulatory requirements.

Why Is Titanium Preferred in Marine Engineering?

In marine engineering, titanium is favored for applications such as ship hulls and propeller shafts because of its remarkable resistance to seawater corrosion. This property significantly reduces maintenance costs and prolongs the lifespan of marine vessels. Although titanium is more expensive than steel, the long-term savings on maintenance can make it a more viable option. Buyers should consider the logistical aspects of sourcing titanium, including local availability and potential tariffs, which can impact overall costs.

How Does the Cost of Titanium vs Steel Affect the Automotive Industry?

The automotive industry increasingly turns to titanium for engine components and chassis parts to enhance fuel efficiency and performance. While the initial cost of titanium is higher, its lightweight properties can lead to significant savings in fuel consumption over the vehicle’s lifespan. This is particularly relevant for the growing electric vehicle market, where weight reduction is crucial. Buyers should carefully evaluate the cost-benefit relationship and consider the long-term implications of material selection in their designs.

What Advantages Does Titanium Offer in Construction?

In construction, especially in high-stress environments, titanium’s strength-to-weight ratio allows for innovative structural designs while minimizing material usage. Although titanium is more costly than traditional steel, its durability and reduced maintenance needs can lead to lower overall project costs. International buyers should assess regional supply chains for titanium and consider the impact of tariffs and trade regulations on sourcing, as these factors can significantly influence project budgets and timelines.

3 Common User Pain Points for ‘cost of titanium vs steel’ & Their Solutions

Scenario 1: Balancing Cost and Performance in Aerospace Applications

The Problem: A purchasing manager at an aerospace company is tasked with sourcing materials for a new aircraft component. The team is considering titanium for its excellent strength-to-weight ratio and corrosion resistance but is concerned about the significantly higher costs compared to steel. The challenge lies in justifying the expense to stakeholders who prioritize budget constraints over performance, especially when steel can offer adequate strength for less critical components.

The Solution: To effectively address this challenge, the purchasing manager should conduct a thorough cost-benefit analysis that includes not only the upfront material costs but also the long-term performance benefits of titanium. By calculating potential savings from reduced fuel consumption due to weight savings and lower maintenance costs due to titanium’s corrosion resistance, the manager can present a compelling case. Engaging with titanium suppliers to obtain detailed performance data and case studies from similar aerospace applications can further strengthen the proposal. Additionally, exploring options for titanium alloys that offer a balance between cost and performance may provide a middle ground, ensuring that the company maintains its competitive edge without compromising financial stability.

Scenario 2: Understanding the Total Cost of Ownership for Industrial Machinery

The Problem: A factory manager is faced with the decision of whether to invest in titanium or steel components for a new production line. While steel is cheaper and more readily available, the manager is concerned about the long-term durability and maintenance costs associated with steel, especially in a high-temperature and corrosive environment. The uncertainty about the total cost of ownership (TCO) creates hesitation in making a decision, as initial costs do not reflect the potential lifetime costs of the materials.

The Solution: To navigate this dilemma, the factory manager should develop a comprehensive TCO model that evaluates all costs associated with both materials over their expected lifespan. This model should include initial purchase price, installation costs, maintenance expenses, and potential downtime due to repairs or replacements. It’s beneficial to consult with engineers who can provide insights on the performance of titanium versus steel under specific operating conditions. Additionally, considering the implementation of a pilot project using titanium components can allow the manager to gather real-world data on performance and maintenance, providing a clearer picture of the value proposition. This informed approach will enable a more strategic decision-making process that aligns with both operational goals and budgetary constraints.

Scenario 3: Navigating the Supply Chain Challenges in Emerging Markets

The Problem: A procurement officer in a South American manufacturing firm is exploring options for sourcing titanium and steel materials. They encounter significant supply chain challenges, including fluctuating prices, limited local availability of titanium, and the complexities of importing materials. These issues lead to frustration and uncertainty in planning production schedules and budgeting for projects, impacting the company’s competitiveness in a rapidly evolving market.

The Solution: To mitigate these supply chain challenges, the procurement officer should establish strong relationships with multiple suppliers for both titanium and steel, including local and international sources. Implementing a diversified sourcing strategy can help buffer against price fluctuations and availability issues. Additionally, leveraging technology such as supply chain management software can provide real-time insights into market trends and inventory levels, allowing for more agile decision-making. Engaging in negotiations for long-term contracts with suppliers can also stabilize costs and ensure consistent material availability. Finally, participating in industry conferences and trade shows can facilitate networking with suppliers and peers, providing valuable information on best practices and emerging trends in material sourcing. This proactive approach will enhance the firm’s resilience and operational efficiency in the face of supply chain challenges.

Strategic Material Selection Guide for cost of titanium vs steel

What are the Key Properties of Titanium and Steel for B2B Applications?

When comparing titanium and steel, several key properties dictate their suitability for various applications. Titanium is renowned for its excellent strength-to-weight ratio and exceptional corrosion resistance, making it ideal for aerospace, marine, and medical applications where weight and durability are critical. Its melting point is significantly higher than that of steel, allowing it to perform well under extreme temperatures. However, titanium’s lower hardness and elasticity can complicate manufacturing processes, particularly in high-volume production scenarios.

On the other hand, steel, particularly stainless steel, is favored for its hardness and elasticity, which facilitate easier machining and fabrication. Steel’s lower cost and widespread availability make it a go-to material for construction, automotive, and industrial applications. However, its susceptibility to corrosion necessitates protective coatings or treatments, especially in harsh environments.

What are the Pros and Cons of Using Titanium and Steel?

Titanium

Pros: Titanium’s primary advantages include its lightweight nature and high corrosion resistance, which make it suitable for applications in harsh environments, such as offshore drilling and aerospace. Its ability to withstand extreme temperatures without deforming is also a significant benefit.

Cons: The main drawbacks of titanium are its high cost and complex manufacturing requirements. Extracting and processing titanium is labor-intensive and time-consuming, resulting in higher prices compared to steel. Additionally, its lower modulus of elasticity can lead to deformation under certain conditions.

Steel

Pros: Steel’s advantages lie in its cost-effectiveness and versatility. It is widely available and can be easily welded and machined, making it suitable for a broad range of applications. Its durability and structural integrity are well-suited for construction and heavy machinery.

Cons: The primary disadvantage of steel is its vulnerability to corrosion, which can lead to maintenance challenges. Additionally, its heavier weight can be a limiting factor in applications where weight savings are critical.

How Do Material Properties Impact Application Suitability?

The choice between titanium and steel often hinges on the specific requirements of the application. For example, titanium is often used in aerospace components where weight reduction is crucial, while steel is preferred in construction due to its strength and cost efficiency. In industries such as oil and gas, titanium’s corrosion resistance makes it ideal for offshore environments, while stainless steel is commonly used in pipelines and storage tanks due to its durability and lower cost.

What Should International B2B Buyers Consider When Choosing Between Titanium and Steel?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider compliance with local and international standards such as ASTM, DIN, or JIS. Understanding the specific material properties that align with local environmental conditions and regulatory requirements is essential. For instance, buyers in coastal areas may prioritize corrosion resistance, while those in construction may focus on cost and availability. Additionally, the logistical aspects of sourcing and transporting materials should be factored into the decision-making process.

Summary Table of Material Comparison

| Material | Typical Use Case for cost of titanium vs steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Aerospace components, medical implants | Excellent strength-to-weight ratio | High cost and complex manufacturing | High |

| Stainless Steel | Construction, automotive parts | Cost-effective and widely available | Susceptible to corrosion | Low |

| Alloy Steel | Heavy machinery, industrial applications | High tensile strength | Heavier, less corrosion-resistant | Medium |

| Titanium Alloys | Marine applications, high-performance engines | Superior corrosion resistance | Difficult to machine and process | High |

This analysis provides a comprehensive overview of the cost implications and performance characteristics of titanium versus steel, enabling B2B buyers to make informed decisions based on their specific application needs and regional market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for cost of titanium vs steel

What are the Key Stages in the Manufacturing Process of Titanium and Steel?

The manufacturing processes for titanium and steel involve several critical stages, each tailored to the specific properties of the material. Understanding these stages is essential for B2B buyers looking to evaluate costs effectively.

Material Preparation: How is Titanium and Steel Prepared for Manufacturing?

For titanium, the first step is sourcing the raw material, which is usually obtained through the Kroll process or the Hunter process. These methods extract titanium from its ores, typically rutile or ilmenite, using chemical reactions to produce titanium sponge. The sponge is then melted in vacuum arc remelting (VAR) furnaces to produce titanium ingots.

In contrast, steel manufacturing begins with iron ore, which is smelted in a blast furnace. The molten iron is mixed with carbon and other alloying elements to produce various steel grades. This process often involves refining to remove impurities and achieve desired properties.

Forming Techniques: What Methods are Used to Shape Titanium and Steel?

The forming processes differ significantly due to the material characteristics. Titanium is often shaped using techniques like CNC machining, forging, and hydroforming. These methods are essential due to titanium’s strength and lower machinability, which necessitate precise, controlled processes.

Steel, being more versatile and easier to work with, can be processed through a range of techniques including stamping, bending, and welding. These methods allow for greater flexibility in manufacturing complex shapes and structures, making steel a cost-effective choice for many applications.

Assembly and Finishing: How are Titanium and Steel Products Assembled and Finished?

In the assembly phase, titanium components often require specialized welding techniques, such as gas tungsten arc welding (GTAW), to maintain structural integrity. Due to titanium’s reactivity, it is critical to perform these processes in an inert atmosphere to prevent contamination.

For steel, welding is more straightforward, with various techniques like MIG and TIG welding being employed based on the specific requirements of the project. Finishing processes for both materials may include anodizing for titanium, which enhances its corrosion resistance, and galvanizing for steel, which protects against rust.

What International Quality Standards Should B2B Buyers Know?

Quality assurance is paramount in the manufacturing of titanium and steel. International standards such as ISO 9001, which outlines requirements for a quality management system, are essential for ensuring consistent quality across suppliers.

Which Industry-Specific Certifications are Important?

In addition to general quality standards, industry-specific certifications are critical. For example, the CE mark is mandatory for products sold within the European Economic Area, while the American Petroleum Institute (API) certification is vital for oil and gas applications. Understanding these certifications can help B2B buyers assess the credibility of their suppliers.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integral to maintaining product integrity throughout the manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): Assessing raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring processes during manufacturing to identify any deviations from quality standards.

- Final Quality Control (FQC): Conducting comprehensive tests on finished products before they are shipped to customers.

What Testing Methods Are Commonly Used in Quality Assurance?

B2B buyers should be aware of the various testing methods used to verify the quality of titanium and steel products. Common tests include:

- Tensile Testing: Measures the strength and ductility of materials.

- Hardness Testing: Evaluates the material’s resistance to deformation.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing and radiography to detect internal flaws without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is crucial for B2B buyers. Here are some strategies:

- Supplier Audits: Conducting on-site audits to assess the manufacturer’s adherence to quality standards and processes.

- Quality Reports: Requesting detailed quality assurance reports that outline testing results and compliance with international standards.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate the quality of the products before they are shipped.

What Are the Quality Control and Certification Nuances for International Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is vital. Different countries may have varying regulations regarding material specifications and certifications. Therefore, it is crucial for buyers to:

- Research Local Regulations: Familiarize themselves with the specific compliance requirements in their region.

- Engage Local Experts: Collaborate with local consultants or legal experts to navigate complex regulatory environments.

- Establish Clear Communication: Maintain open lines of communication with suppliers to ensure that all quality expectations are understood and met.

Conclusion: Making Informed Decisions on Titanium vs. Steel

B2B buyers must carefully consider the manufacturing processes and quality assurance measures associated with titanium and steel. By understanding the nuances of material preparation, forming techniques, assembly, and finishing processes, as well as the critical quality control checkpoints and certifications, buyers can make informed decisions that align with their project requirements and budget constraints.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cost of titanium vs steel’

Introduction

This guide serves as a practical checklist for B2B buyers who are evaluating the costs and benefits of titanium versus steel for their procurement needs. Understanding the nuances of these two materials is crucial for making informed decisions that align with your project requirements, budget constraints, and application specifications.

Step 1: Define Your Technical Specifications

Clearly articulate the technical requirements for your project. Consider factors such as strength, weight, corrosion resistance, and temperature tolerance. Having precise specifications will help you determine whether titanium or steel is more suitable for your application, ultimately influencing your cost analysis.

Step 2: Analyze Cost Implications

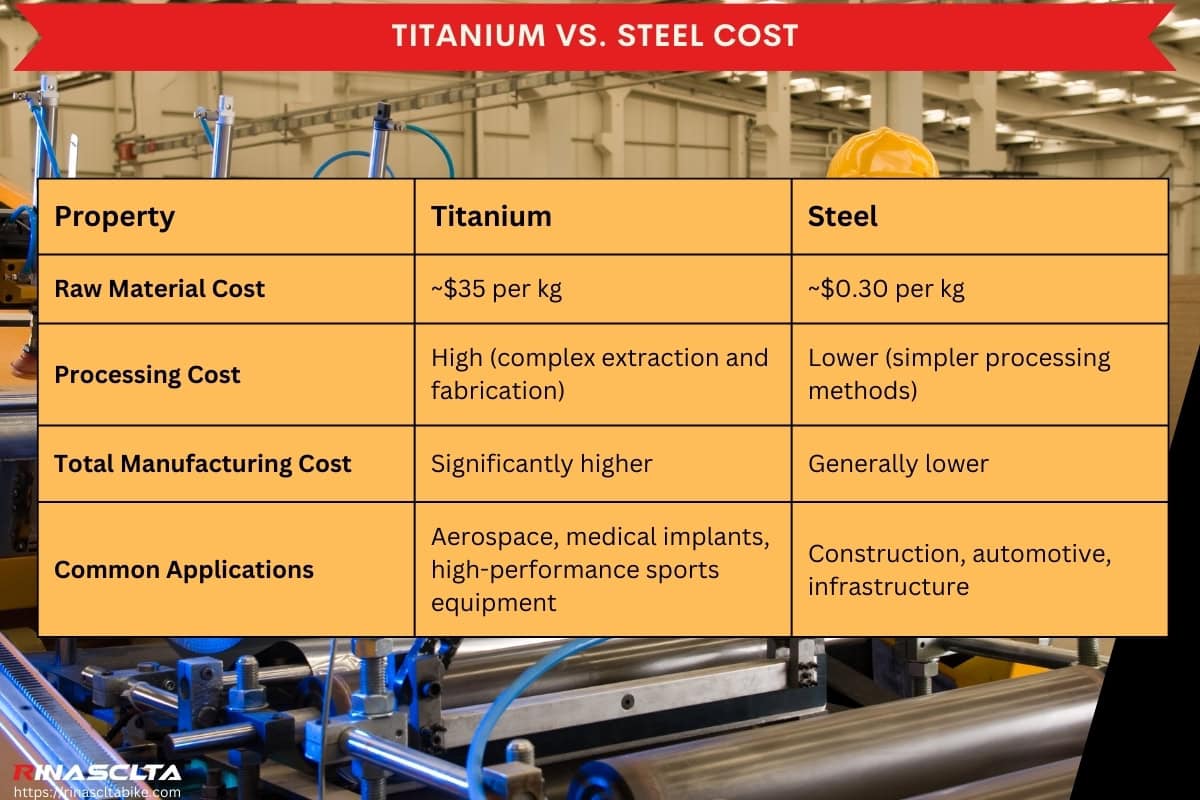

Conduct a thorough comparison of the costs associated with both materials. Titanium typically ranges from $35 to $50 per kg, while stainless steel is significantly less expensive, ranging from $1 to $1.50 per kg. Understanding these price differentials will help you assess the financial viability of each option in relation to your project budget.

Step 3: Evaluate Application Requirements

Identify the specific application for which you are sourcing the material. Titanium excels in high-performance environments, such as aerospace and medical applications, due to its superior strength-to-weight ratio and corrosion resistance. Conversely, stainless steel is often preferred for construction and industrial uses due to its cost-effectiveness and ease of fabrication.

Step 4: Research Supplier Credentials

Before making a purchase, vet potential suppliers thoroughly. Look for certifications, industry experience, and customer reviews. Ensure that the suppliers you consider have a proven track record in providing high-quality materials that meet international standards, particularly if you are operating in diverse markets across Africa, South America, the Middle East, and Europe.

Step 5: Request Sample Materials

Before finalizing your order, request samples of both titanium and stainless steel from your shortlisted suppliers. This will allow you to assess the physical properties and performance of the materials in real-world conditions. Testing samples can provide valuable insights that may influence your final decision.

Step 6: Understand Processing and Fabrication Costs

Inquire about the processing and fabrication costs associated with each material. Titanium may require specialized machining due to its unique properties, which can increase overall expenses. Compare these costs against those of stainless steel, which is generally easier to work with and may offer more flexible fabrication options.

Step 7: Plan for Long-Term Maintenance and Durability

Consider the long-term implications of your material choice in terms of maintenance and durability. While titanium offers exceptional corrosion resistance, it may require more careful handling during installation. Stainless steel, while more affordable, may need regular maintenance to prevent rust and degradation, which can lead to additional costs over time.

By following this checklist, B2B buyers can make well-informed decisions when sourcing materials for their projects, ensuring alignment with both technical requirements and budget considerations.

Comprehensive Cost and Pricing Analysis for cost of titanium vs steel Sourcing

What Are the Key Cost Components for Sourcing Titanium and Steel?

When evaluating the cost of titanium versus steel, various components contribute to the overall pricing structure. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: Titanium is significantly more expensive than steel, with prices ranging from $35 to $50 per kilogram compared to $1 to $1.50 for stainless steel. The high cost of titanium is attributed to its extraction and processing complexities. Buyers should consider the specific alloy requirements, as different grades can vary widely in price.

-

Labor: The labor costs associated with machining titanium are generally higher due to its difficult workability. Skilled labor is often required to handle titanium processing, which increases overall labor costs. In contrast, steel can be machined more easily, leading to lower labor expenses.

-

Manufacturing Overhead: Overhead costs for titanium production can be elevated due to the advanced technology and facilities required to process the metal. Steel manufacturing typically involves less stringent overhead due to the more established processes and equipment.

-

Tooling: The tooling costs for titanium are higher as specialized tools are often needed to cut and shape it. Steel tooling is typically less expensive and more readily available, which can reduce initial investment costs for steel projects.

-

Quality Control (QC): Both materials require stringent QC measures, but titanium often demands more extensive testing due to its applications in high-performance sectors like aerospace and medical. These additional QC measures can add to the overall cost.

-

Logistics: Transporting titanium can incur higher logistics costs, especially when shipping to international markets due to its weight and handling requirements. Steel, being denser and more commonly used, often has more established logistics channels, leading to lower transport costs.

-

Margin: Supplier margins can vary significantly based on the material. Titanium suppliers may charge a higher margin due to the complexities involved in sourcing and processing, while steel suppliers often have more competitive pricing due to the abundance of the material.

How Do Price Influencers Affect Sourcing Decisions for Titanium and Steel?

Several factors influence the price of titanium and steel, which buyers should consider when sourcing these materials:

-

Volume/MOQ: Larger orders typically lead to better pricing. Suppliers may offer discounts for bulk purchases, which can significantly lower the overall cost per unit.

-

Specifications and Customization: Custom specifications can increase costs. Buyers should clarify their requirements upfront to avoid unexpected price hikes during production.

-

Material Quality and Certifications: Higher quality materials and specific certifications (such as ISO or ASTM) can increase costs. Buyers in industries with stringent regulations must factor in these costs when selecting materials.

-

Supplier Factors: The reliability and reputation of the supplier can also impact pricing. Established suppliers may charge more, but they often provide better quality assurance and service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They determine who bears the costs and risks at each stage of transportation, which can affect the total landed cost of the materials.

What Are the Best Practices for Negotiating Prices in International Sourcing?

B2B buyers should adopt several strategies to enhance cost-efficiency when sourcing titanium and steel:

-

Negotiate Effectively: Leverage volume commitments and long-term contracts to negotiate better prices. Building a good relationship with suppliers can also yield favorable terms.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, lifespan, and potential failure costs associated with each material. Titanium may have higher upfront costs but can offer savings in longevity and reduced maintenance.

-

Be Aware of Pricing Nuances: International buyers should be cognizant of currency fluctuations, local market conditions, and import tariffs that could impact the final costs. Understanding these factors is essential for accurate budgeting.

Disclaimer on Indicative Prices

The prices mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific project requirements. Buyers should conduct thorough market research and engage with multiple suppliers to obtain accurate and current pricing information tailored to their needs.

Alternatives Analysis: Comparing cost of titanium vs steel With Other Solutions

Understanding Alternative Solutions to Titanium and Steel Costs

In the quest for materials that balance performance and cost, businesses often find themselves weighing the merits of titanium and steel against alternative solutions. The choice of material significantly impacts manufacturing processes, product longevity, and overall project costs. Below, we explore how titanium and steel compare to alternative materials and methods, providing B2B buyers with actionable insights for informed decision-making.

Comparison Table

| Comparison Aspect | Cost of Titanium Vs Steel | Alternative 1: Aluminum Alloys | Alternative 2: Carbon Fiber |

|---|---|---|---|

| Performance | High strength-to-weight ratio; excellent corrosion resistance; suitable for extreme conditions. | Good strength-to-weight ratio; less corrosion resistance than titanium. | Exceptional strength-to-weight ratio; fatigue resistance; poor impact resistance. |

| Cost | Titanium: $35-$50/kg; Steel: $1-$1.50/kg. | $2-$5/kg, depending on alloy. | $20-$50/kg, depending on type. |

| Ease of Implementation | Requires specialized machining and welding techniques. | Easy to machine and weld; widely available. | Requires specialized handling and curing processes. |

| Maintenance | Low maintenance due to high corrosion resistance. | Moderate maintenance; prone to corrosion without protection. | Low maintenance but may require careful handling to avoid damage. |

| Best Use Case | Aerospace, medical implants, marine applications. | Automotive, construction, consumer goods. | Aerospace, high-performance sporting goods, automotive. |

In-Depth Analysis of Alternatives

Aluminum Alloys: A Cost-Effective Solution

Aluminum alloys represent a viable alternative, particularly in industries where weight savings are critical, but budget constraints are tighter. Priced between $2 and $5 per kilogram, aluminum alloys are easier to machine and weld compared to titanium. However, they lack the corrosion resistance and strength of titanium, which may limit their application in harsh environments. For construction and automotive industries, where moderate performance is acceptable, aluminum alloys provide a compelling balance between cost and functionality.

Carbon Fiber: Superior Performance with Caveats

Carbon fiber is another alternative, offering an impressive strength-to-weight ratio that often surpasses both titanium and steel. However, its cost ranges from $20 to $50 per kilogram, making it a more expensive option. Carbon fiber is particularly advantageous in applications requiring lightweight materials, such as aerospace and high-performance sporting goods. Nevertheless, it is less durable under impact and requires specialized handling during manufacturing and installation. This can lead to increased labor costs and complexity in production.

Choosing the Right Solution for Your Needs

When selecting between titanium, steel, and alternative materials, B2B buyers should consider several factors, including the specific application, budget constraints, and the required performance characteristics. Titanium offers unmatched strength and corrosion resistance for critical applications, while steel remains the economical choice for general use. Alternatives like aluminum and carbon fiber can serve specific needs but come with their own set of trade-offs in terms of cost and performance. Ultimately, the right choice will depend on the unique requirements of each project, ensuring that the selected material aligns with both operational goals and financial realities.

Essential Technical Properties and Trade Terminology for cost of titanium vs steel

When considering the cost of titanium versus steel, it is essential to understand the technical properties and trade terminology that influence decision-making in B2B transactions. The following sections outline critical specifications and common industry terms that can guide international buyers, especially in emerging markets.

What Are the Key Technical Properties Affecting the Cost of Titanium and Steel?

-

Material Grade

Material grade refers to the specific classification of titanium or steel based on its composition and properties. For instance, titanium alloys like Ti-6Al-4V are known for their high strength-to-weight ratio, while stainless steel grades such as 304 and 316 are favored for corrosion resistance. Understanding material grades helps buyers select the right product for their application, ensuring performance and durability. -

Yield Strength

Yield strength is the amount of stress a material can withstand before it begins to deform permanently. Titanium typically has a higher yield strength compared to many stainless steel grades, making it suitable for high-performance applications. This property is crucial for industries such as aerospace and automotive, where material failure could have catastrophic consequences. -

Corrosion Resistance

Corrosion resistance is a critical property, especially for applications exposed to harsh environments. Titanium naturally forms a protective oxide layer, making it highly resistant to corrosion, while stainless steel, although generally resistant, can still suffer from rusting if not properly maintained. Buyers should consider the operating environment when selecting materials to minimize long-term costs related to maintenance and replacement. -

Weight and Density

The weight and density of materials affect transportation costs and structural efficiency. Titanium is significantly lighter than steel, which can lead to reduced shipping costs and improved fuel efficiency in applications like aerospace. Understanding the weight implications is vital for buyers looking to optimize operational costs. -

Machinability

Machinability refers to how easily a material can be cut and shaped. Steel is generally easier to machine than titanium due to its lower hardness. For manufacturers, this can affect production timelines and costs, making it an important consideration when choosing between these metals. -

Thermal Conductivity

Thermal conductivity indicates how well a material conducts heat. Stainless steel typically has higher thermal conductivity than titanium, which is crucial in applications involving heat exchange. Buyers in industries such as chemical processing should evaluate this property to ensure efficient design and operation.

What Are Common Trade Terms Related to Titanium and Steel Procurement?

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers to ensure quality and compatibility of materials in their applications. -

MOQ (Minimum Order Quantity)

MOQ signifies the minimum number of units a supplier is willing to sell. This term is crucial for buyers, especially in international trade, as it can affect inventory management and cash flow. Buyers should negotiate MOQs that align with their operational needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific quantities and types of materials. This process is essential for obtaining competitive pricing and ensuring that all suppliers are evaluated on the same criteria. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and manage risks associated with cross-border procurement. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is crucial for supply chain planning and can affect project timelines significantly. -

Certification

Certification indicates that materials meet specific industry standards or regulations. For sectors like aerospace or medical devices, ensuring that titanium or steel is certified can be a prerequisite for compliance and safety.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and budget constraints, ultimately leading to successful procurement strategies in the titanium versus steel market.

Navigating Market Dynamics and Sourcing Trends in the cost of titanium vs steel Sector

What Are the Current Market Dynamics Affecting the Cost of Titanium vs Steel?

The cost dynamics of titanium versus steel are influenced by various global drivers, including demand fluctuations, production challenges, and geopolitical factors. Titanium, known for its superior strength-to-weight ratio and corrosion resistance, is increasingly favored in high-performance applications like aerospace and medical devices. Conversely, steel remains the preferred choice for construction and automotive sectors due to its lower cost and robust properties.

Recent trends indicate a growing demand for titanium in emerging markets across Africa and South America, driven by infrastructural development and industrialization. In the Middle East and Europe, the focus on lightweight materials in automotive and aerospace industries is propelling titanium usage. Technological advancements in extraction and processing are also making titanium more accessible, potentially narrowing the price gap with steel.

International B2B buyers need to stay abreast of these trends to optimize sourcing strategies. Understanding local market conditions, such as currency fluctuations and regional manufacturing capabilities, is essential. For instance, buyers in Nigeria and Vietnam may experience different pricing structures due to local economic conditions and supply chain efficiencies.

How Is Sustainability Shaping Sourcing Decisions in the Titanium vs Steel Market?

Sustainability is becoming a critical factor in sourcing decisions for B2B buyers in the titanium and steel sectors. Titanium is often viewed as a more sustainable option due to its long lifespan and resistance to corrosion, which reduces the need for frequent replacements. Additionally, its lightweight nature contributes to fuel efficiency in transportation applications, further minimizing environmental impact.

Ethical sourcing is gaining traction, with buyers increasingly demanding transparency in supply chains. This encompasses not only the environmental footprint of materials but also the social impacts of mining and processing operations. Certifications such as ISO 14001 for environmental management systems and the Responsible Steel certification are becoming vital in assessing suppliers’ commitment to sustainable practices.

As companies strive to meet corporate social responsibility (CSR) goals, integrating sustainability into procurement strategies is essential. B2B buyers should prioritize suppliers who can demonstrate compliance with environmental standards and ethical sourcing practices, ensuring that their supply chains align with broader sustainability objectives.

What Is the Historical Context of Titanium and Steel in Industrial Applications?

The use of titanium and steel has evolved significantly over the years, shaped by technological advancements and changing industrial needs. Steel has been a foundational material since the Industrial Revolution, valued for its strength, durability, and cost-effectiveness. Its versatility has made it a staple in construction, manufacturing, and transportation.

Titanium, discovered in the late 18th century, emerged as a significant industrial material in the mid-20th century, primarily due to its unique properties. Initially utilized in aerospace applications, its use has expanded into medical, automotive, and marine sectors. The ongoing evolution of alloy compositions and processing techniques continues to enhance titanium’s appeal, particularly in high-performance applications.

Understanding the historical context of these materials helps B2B buyers appreciate their current market dynamics and make informed sourcing decisions. As industries evolve, so too do the applications and availability of titanium and steel, underscoring the importance of continuous market analysis.

Frequently Asked Questions (FAQs) for B2B Buyers of cost of titanium vs steel

-

How do I determine the cost-effectiveness of titanium versus steel for my project?

To assess cost-effectiveness, consider both the initial material costs and the long-term performance benefits. Titanium typically ranges from $35 to $50 per kg, while stainless steel is significantly cheaper, costing about $1 to $1.50 per kg. However, titanium offers superior corrosion resistance, a higher strength-to-weight ratio, and lower maintenance costs, which may justify its higher upfront price in specific applications, particularly in aerospace, marine, and medical sectors. Conduct a total cost of ownership analysis that includes maintenance, longevity, and potential downtime costs to make an informed decision. -

What factors should I consider when choosing between titanium and steel?

When selecting between titanium and steel, consider factors such as application requirements, environmental conditions, weight restrictions, and budget constraints. Titanium excels in applications requiring high strength with low weight and excellent corrosion resistance, while steel is more cost-effective and offers better hardness and elasticity. Evaluate the specific performance characteristics required for your project and consider long-term operational costs, including maintenance and durability, to select the most suitable material. -

What are the common applications for titanium compared to steel?

Titanium is widely used in aerospace, medical devices, and high-performance automotive applications due to its strength-to-weight ratio and corrosion resistance. In contrast, steel is prevalent in construction, infrastructure, and manufacturing due to its durability, cost-effectiveness, and ease of fabrication. Understanding the specific requirements of your project will help you choose the right material based on performance needs and economic viability. -

How do I vet suppliers for titanium and steel materials?

Vetting suppliers involves assessing their experience, certifications, and quality assurance processes. Look for suppliers with a proven track record in your industry, and consider their ability to provide detailed material specifications, test reports, and compliance with international standards. Request references and conduct site visits if possible to verify their operational capabilities. Additionally, evaluate their responsiveness and customer service to ensure they can meet your supply chain needs. -

What are the typical minimum order quantities (MOQ) for titanium and steel?

MOQs can vary significantly based on the supplier and the specific product. Generally, titanium suppliers may have higher MOQs due to the costly extraction and processing of the material, often ranging from 100 kg to several tons. In contrast, steel suppliers may offer lower MOQs, sometimes as low as 10 kg, depending on the product type and specifications. Always confirm MOQs with suppliers to align your purchasing strategy with your project requirements. -

What payment terms should I negotiate with titanium and steel suppliers?

Negotiating favorable payment terms is crucial for managing cash flow. Common terms include net 30 or net 60 days, but you may also consider options such as partial upfront payments or letters of credit for larger orders. It’s essential to establish clear terms regarding payment schedules, late fees, and any discounts for early payments. Ensure that the terms align with your financial capabilities and project timelines to maintain a smooth procurement process. -

How can I ensure quality assurance for titanium and steel products?

Quality assurance can be ensured through rigorous supplier audits and by requesting detailed documentation, such as certificates of compliance, material test reports, and inspection records. Establish clear quality specifications and standards upfront, and consider implementing third-party inspections for critical components. Collaborating closely with suppliers on quality control processes will help mitigate risks and ensure that the materials meet your project requirements. -

What logistics considerations should I keep in mind when sourcing titanium and steel internationally?

When sourcing internationally, consider factors such as shipping costs, lead times, and import regulations. Ensure that your suppliers can provide reliable shipping options and understand the customs clearance process in your country. Evaluate the total landed cost, which includes product price, shipping, tariffs, and taxes. Additionally, plan for potential delays in transit and ensure that your supply chain is flexible enough to accommodate any unforeseen challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cost Of Titanium Vs Steel Manufacturers & Suppliers List

1. Metal Supermarkets – Titanium

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Titanium is an elemental earth metal, known for its high melting point and is often alloyed with metals like iron and aluminum. It offers high corrosion resistance, impact absorption, and an exceptional strength-to-weight ratio, making it suitable for high-performance industries such as aerospace, automotive, and marine applications. Common titanium applications include surgical tools, prosthetics…

2. Reddit – Lightweight Backpacker Stoves

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Titanium is lightweight and suitable for backpacker stoves, while stainless steel is heavier but cheaper and easier to work with. Aluminum is not recommended as it will melt during use. Titanium is more difficult to bend than stainless steel. A titanium stove can weigh between 5-6 lbs, which is ideal for backpacking.

3. Timeless – Matte Stainless Steel & Titanium Razors

Domain: badgerandblade.com

Registered: 2005 (20 years)

Introduction: Timeless razors pricing: Matte stainless steel open comb razor with scalloped top cap – $230; Titanium version of the same razor – $260. Titanium alloy used by Timeless is Titanium Grade 5 / 6Al4V, known for excellent performance but more difficult to process than 316 stainless steel. Timeless uses WEDM (Wire Electrical Discharge Machining) for cutting the razor head, which reduces friction during…

4. VMT CNC – Titanium Pricing Insights

Domain: vmtcnc.com

Registered: 2019 (6 years)

Introduction: The cost of titanium per pound varies significantly based on its grade and market conditions. Key price ranges include:

– Commercially Pure Titanium (Grade 1 and 2): $6–$9 per pound, used in applications like chemical processing and heat exchangers.

– Titanium 6-4 Alloy (Grade 5): $10–$15 per pound, known for high strength and corrosion resistance, commonly used in aerospace and medical applicati…

5. Huaxiao Metal – Titanium Solutions

Domain: huaxiaometal.com

Registered: 2014 (11 years)

Introduction: Titanium is known for its excellent performance and wide range of applications, but it is expensive due to several factors: 1. Scarcity of titanium ore and complex extraction process: Titanium mostly exists in the form of minerals like rutile and ilmenite, and refining these into pure titanium is complicated and energy-consuming. The main extraction method is the Kroll Process, which involves conv…

6. Titanium vs Carbon Steel – Offshore Pipework Solutions

Domain: azom.com

Registered: 1999 (26 years)

Introduction: Titanium vs Carbon Steel for Offshore Pipework:

– Titanium offers lower costs due to its strength, lower density, and good corrosion resistance.

– Case Study: Elf Petroleum Norge evaluated a 6-inch carbon steel pipe system for seawater, replaced due to corrosion, with titanium.

– Carbon Steel Cost Considerations: Included purchase, pre-fabrication, installation, and transport costs.

– Titanium…

7. DTG Machining – Titanium and Steel Solutions

Domain: dtg-machining.com

Registered: 2020 (5 years)

Introduction: Titanium is generally more expensive than steel, with costs ranging from $20 to $50 per kilogram, and high-performance alloys costing even more. Steel is more affordable, with prices typically ranging from $1 to $3 per kilogram, depending on the type and market conditions. Titanium offers superior strength and corrosion resistance.

Strategic Sourcing Conclusion and Outlook for cost of titanium vs steel

In summary, the choice between titanium and steel hinges on several critical factors, including application requirements, budget constraints, and performance characteristics. Titanium, while offering superior strength-to-weight ratios and corrosion resistance, comes with a significantly higher price tag, ranging from $35 to $50 per kg. In contrast, stainless steel presents a more cost-effective solution at approximately $1 to $1.50 per kg, making it a practical option for many industries, particularly where budget considerations are paramount.

Strategic sourcing remains essential for international B2B buyers, especially in emerging markets like Africa, South America, the Middle East, and Europe. Understanding the unique properties and costs associated with these metals enables businesses to make informed decisions that align with their operational needs and financial goals.

As global supply chains evolve, staying abreast of market trends and pricing fluctuations will be crucial for optimizing procurement strategies. We encourage international buyers to leverage this knowledge to negotiate better terms and explore innovative sourcing solutions that enhance their competitiveness in the marketplace. Embrace the opportunity to refine your sourcing strategies and position your business for success in a dynamic global environment.