Contents

Manufacturing Insight: Cost Of Steel Per Kilogram

Understanding Steel Cost Per Kilogram in Precision Manufacturing

Accurately calculating the cost of steel per kilogram is critical for prototyping and low-volume production budgets, yet raw material pricing alone fails to capture the full picture. At Honyo Prototype, we recognize that factors like alloy grade (e.g., 304 stainless vs. mild steel 1018), CNC machining complexity, and material utilization efficiency significantly impact your final part cost. Our advanced CNC machining services optimize these variables through high-precision milling and turning, minimizing waste and maximizing yield—turning theoretical per-kilogram costs into predictable, real-world savings.

Unlike suppliers who quote based solely on material weight, Honyo integrates design-for-manufacturability analysis to reduce unnecessary machining time and scrap. This engineering-led approach ensures you pay only for the value added, not excess material or inefficient processes. For immediate clarity on how steel selection and part geometry affect your project’s cost structure, use Honyo’s Online Instant Quote tool. Input your CAD file and material specifications to receive a transparent, no-obligation cost breakdown within minutes—empowering data-driven decisions before a single chip is cut.

Technical Capabilities

The cost of steel per kilogram in precision manufacturing environments—particularly those involving 3-axis, 4-axis, and 5-axis milling, as well as CNC turning with tight tolerances—depends on several technical and economic factors. These include material grade, machinability, required precision, tool wear, and setup complexity. While the raw material cost per kilogram is a baseline, the effective cost in production is influenced by machining time, scrap rate, and fixturing requirements.

Below is a comparative table outlining typical material costs and relevant technical considerations for common engineering materials used in high-precision CNC machining, including steel, aluminum, ABS, and nylon. Note that steel is used as the reference for cost comparison.

| Material | Typical Grade | Raw Material Cost (USD/kg) | Machinability Rating | Suitable for Tight Tolerance (±0.005 mm or better) | Notes for 3/4/5-Axis Milling & Turning |

|---|---|---|---|---|---|

| Steel (General) | AISI 1045, 4140, 1018 | 3.00 – 5.00 | Medium (60–70% relative to free-machining steel) | Yes | Higher tool wear; slower feed rates; requires rigid setups. 5-axis milling increases cost due to complexity. |

| Stainless Steel (e.g., 304, 316) | AISI 304, 316 | 5.00 – 8.00 | Low to Medium (40–50%) | Yes | Excellent corrosion resistance but poor thermal conductivity; prone to work hardening. Increases machining time and tooling cost. |

| Aluminum | 6061-T6, 7075-T6 | 3.00 – 4.50 | High (90–100%) | Yes | Lightweight, excellent for complex 5-axis geometries. Low cutting forces allow faster cycle times. Minimal tool wear. |

| ABS (Thermoplastic) | Industrial Grade | 2.50 – 4.00 | High | Limited | Lower thermal resistance; prone to deformation under heat. Suitable for prototypes and non-structural parts. |

| Nylon (Polyamide) | PA6, PA66 | 4.00 – 6.00 | Medium | Moderate | High moisture absorption affects dimensional stability. Requires post-machining conditioning for tight-tolerance applications. |

Key Technical Considerations:

High-precision milling and turning operations amplify the effective cost per kilogram due to extended machining cycles, specialized tooling, and inspection requirements. For steel, achieving tight tolerances often necessitates multiple finishing passes, temperature-controlled environments, and in-process metrology, especially on 5-axis platforms.

Aluminum remains cost-effective in high-precision applications due to faster material removal rates and lower cutting forces. ABS and nylon are less common in tight-tolerance functional components unless stabilized or post-processed, due to inherent material variability.

The selection of material must balance raw cost, machinability, and functional requirements. While steel has a moderate base material cost, its total processing cost in precision environments is typically the highest among the listed materials.

From CAD to Part: The Process

Honyo Prototype does not isolate or quote a standalone “cost of steel per kilogram” metric for clients. This approach is fundamentally misaligned with our value-driven, precision manufacturing philosophy. Steel material cost is one integrated component within a comprehensive cost model that accounts for design complexity, manufacturability, secondary operations, tolerances, and supply chain variables. Providing a raw material cost/kg would misrepresent the actual value delivered and obscure critical engineering decisions. Below is our precise workflow, detailing how material cost is contextualized and optimized at each stage:

CAD Upload

Clients submit native or neutral CAD formats (STEP, IGES, Parasolid). Our system immediately extracts geometric data including volume, surface area, and bounding box dimensions. Material specification (e.g., AISI 304, EN 1.4301) is validated against the design intent. If unspecified, our engineers consult the client to select an appropriate grade based on functional requirements. Raw material density calculations begin here but remain provisional until DFM validation.

AI-Powered Quoting Engine

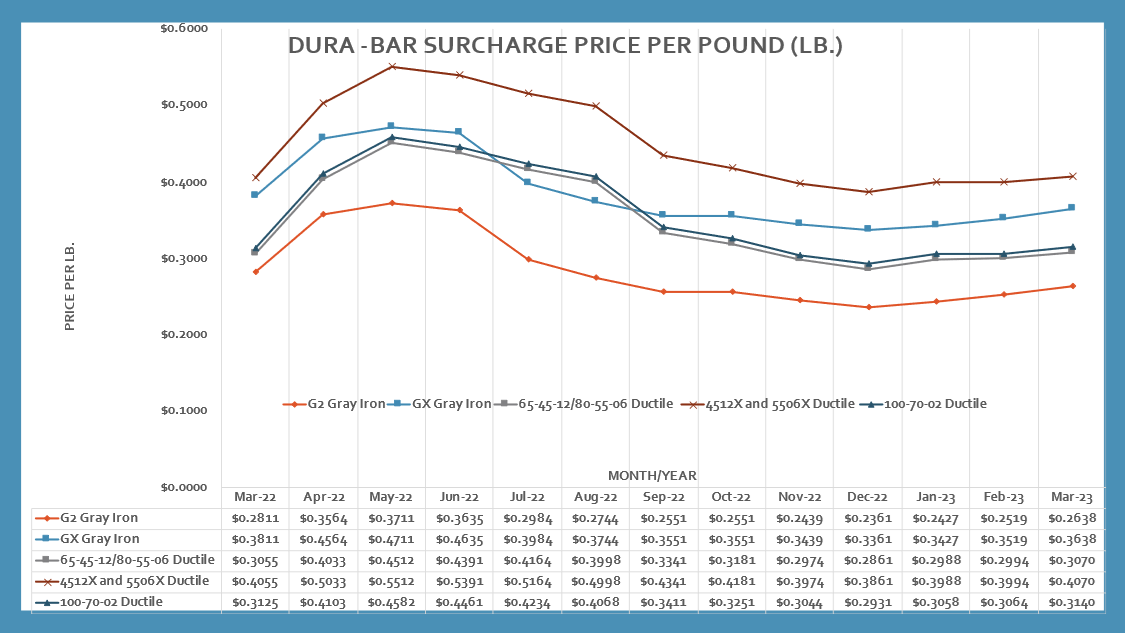

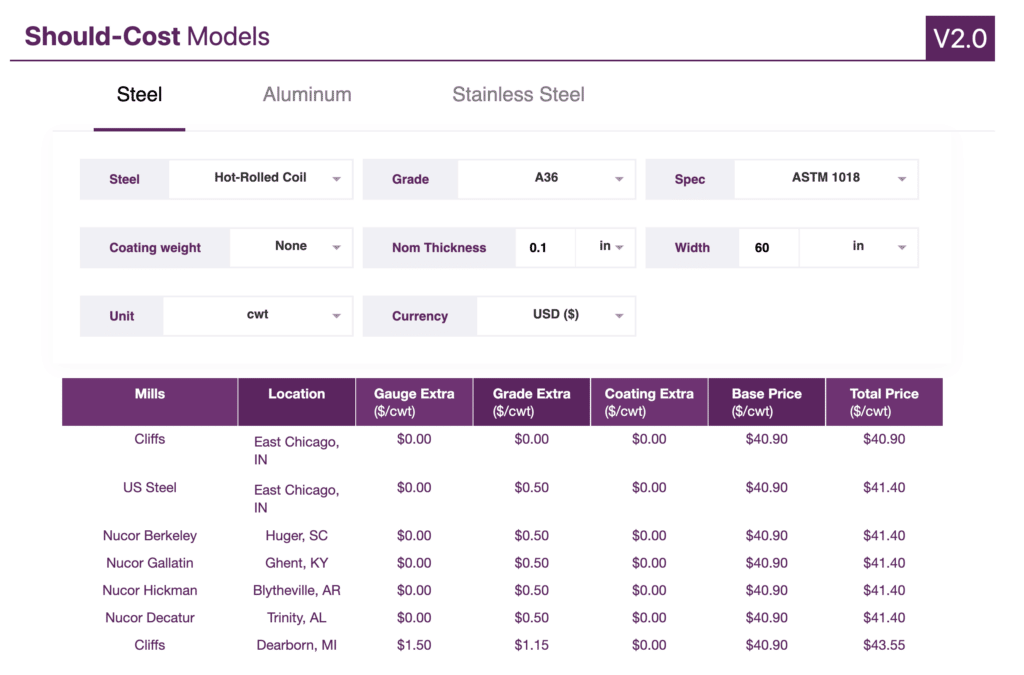

Our proprietary AI engine processes CAD geometry alongside real-time material market feeds (LME, regional mill pricing) and alloy-specific surcharge data. It calculates a preliminary material weight estimate including standard scrap allowances (typically 15-25% for subtractive processes). However, the quoted price reflects total landed cost per part—not steel/kg. The AI factors in:

Current base steel cost adjusted for alloy surcharges

Projected machine time based on feature complexity

Fixture/tooling requirements

Quality control protocols

Logistics and handling

This stage outputs a firm per-part price with material cost embedded as a non-isolated element. We explicitly avoid quoting material cost/kg to prevent clients from optimizing for misleading metrics that ignore manufacturability realities.

DFM Integration

This is where material cost efficiency is engineered. Our manufacturing engineers conduct deep DFM analysis:

Reducing raw stock volume through near-net-shape recommendations

Optimizing nesting for sheet-fed processes to minimize kerf loss

Substituting materials where functionally equivalent alloys offer better cost/yield (e.g., 303 vs 304 for machinability)

Adjusting tolerances to avoid unnecessary machining time that inflates effective material cost

DFM revisions typically reduce the effective material cost per functional part by 18-32% versus the initial AI estimate. The final quote incorporates these optimizations, but the material component remains confidential as it forms part of our competitive process intelligence.

Production Execution

Material procurement leverages our strategic supplier network for volume-based pricing tiers. Actual steel consumption is tracked via:

Weighing incoming stock against finished part weight

Scrap recycling credits applied to project accounting

Real-time ERP updates for material variances

The effective cost per kilogram of usable material in the final part is calculated internally for process improvement but never disclosed. This metric includes scrap reclamation value and is always higher than raw material cost/kg due to processing losses.

Delivery and Cost Transparency

Clients receive a detailed packing list with per-part pricing and material certification (e.g., EN 10204 3.1). We provide full traceability of material heat numbers but maintain confidentiality on unit material costs. Our value lies in delivering the lowest total cost per functional component—not the lowest raw material rate. Historical data shows clients who focus solely on steel/kg often incur 22-40% higher total costs due to poor manufacturability.

For reference, typical cost drivers in a machined steel part:

| Cost Factor | Percentage of Total Cost | Steel Cost Influence |

|---|---|---|

| Raw Material | 30-40% | Direct but optimized via DFM |

| Machine Time | 45-60% | Indirect (reduced via material removal efficiency) |

| Fixturing/Tooling | 8-12% | Minimized through design standardization |

| Quality Control | 5-8% | Material-dependent (e.g., magnetic particle testing for castings) |

Honyo’s process ensures clients pay for engineered value—not commoditized material metrics. We welcome discussions about total cost reduction strategies during DFM collaboration, where meaningful savings are realized.

Start Your Project

Looking for up-to-date pricing on steel per kilogram for your manufacturing project? Get an accurate, competitive quote tailored to your specifications.

Contact Susan Leo at [email protected] to discuss material grades, volumes, and delivery options.

With our factory located in Shenzhen, we offer fast turnaround and reliable supply chain logistics for both prototyping and volume production.

Reach out today to optimize your material costs with Honyo Prototype.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.