Contents

Manufacturing Insight: Cost Of Stainless Steel Per Pound

Understanding Stainless Steel Material Costs for Precision CNC Machining

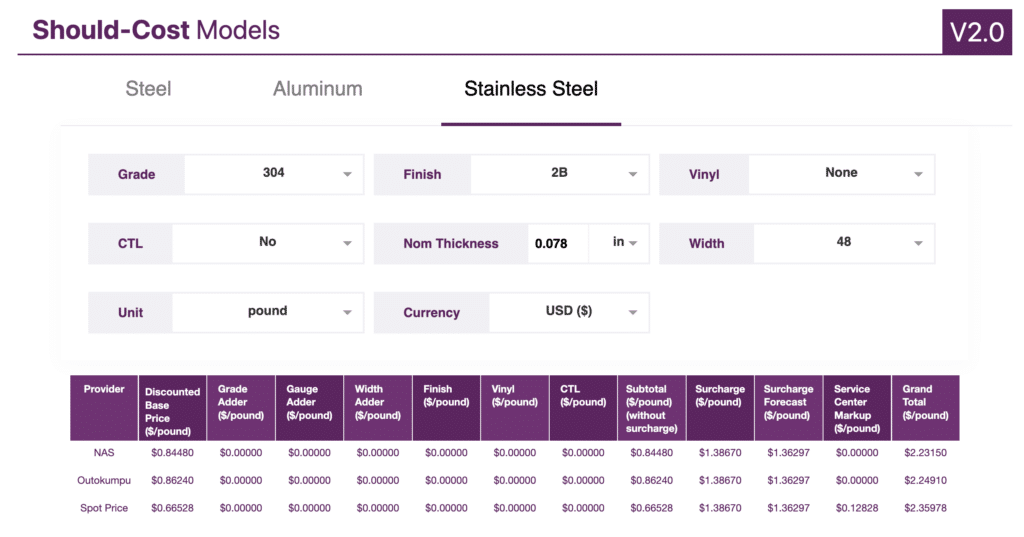

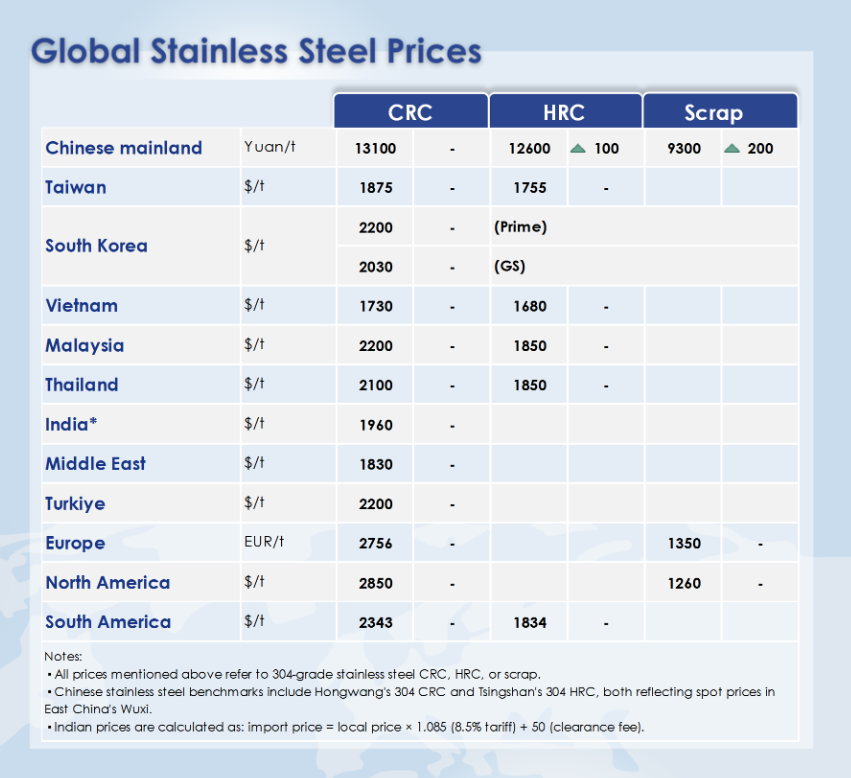

Material selection significantly impacts project economics in precision manufacturing, with stainless steel representing a critical choice for applications demanding corrosion resistance, strength, and durability. Current market dynamics mean the cost of stainless steel per pound fluctuates based on grade, market supply, raw material indices, and order volume. Common grades like 304 and 316 typically range between $2.50 and $5.00 per pound for raw bar stock in standard procurement channels, though specific project requirements can influence this baseline. Accurately factoring this material cost is essential when budgeting for CNC machined components, as it forms a substantial portion of the total part cost alongside machining time, complexity, and finishing requirements.

Honyo Prototype leverages deep expertise in CNC machining stainless steel to optimize your project’s total cost equation. Our advanced 3-, 4-, and 5-axis milling and turning centers, combined with stringent process controls, minimize material waste and maximize throughput. We understand that the raw material cost per pound is only the starting point; our engineering team focuses on value engineering to reduce overall part cost through efficient design for manufacturability, optimized toolpaths, and strategic material utilization. This holistic approach ensures you receive the highest quality machined stainless steel components without unnecessary expenditure.

To provide immediate clarity on project feasibility, Honyo Prototype offers an Online Instant Quote system specifically designed for CNC machining services. Upload your STEP or IGES file, specify your stainless steel grade and quantity requirements, and receive a detailed cost estimate within hours – not days. This transparency allows you to make informed material and design decisions early in the development cycle, incorporating real-time stainless steel pricing and machining costs into your budgeting. The table below provides a general reference for common stainless steel grades and their typical raw material cost ranges per pound.

| Stainless Steel Grade | Common Name | Typical Raw Material Cost Range (USD per lb) |

|---|---|---|

| 304 / 304L | A2 Stainless | $2.50 – $3.75 |

| 316 / 316L | Marine Grade | $3.50 – $5.00 |

| 17-4 PH | Precipitation Hardening | $4.00 – $6.00+ |

Partner with Honyo Prototype to navigate stainless steel costs effectively. Our combination of precision CNC machining capabilities, material science knowledge, and the efficiency of the Online Instant Quote system delivers cost-optimized solutions for your most demanding prototyping and low-volume production needs. Initiate your project with accurate costing today.

Technical Capabilities

The cost of stainless steel per pound is influenced by material grade, machining complexity, and required tolerances. When comparing stainless steel to other commonly machined materials such as aluminum, carbon steel, ABS, and nylon, several technical and economic factors come into play—especially in precision 3-axis, 4-axis, and 5-axis milling and turning operations requiring tight tolerances (±0.0005″ to ±0.005″).

Stainless steel typically carries a higher raw material cost and increased machining difficulty due to its hardness, work-hardening characteristics, and thermal conductivity, leading to higher tool wear and slower cutting speeds. In contrast, materials like aluminum and engineering plastics (ABS, nylon) offer faster machining rates and lower tooling costs, though they differ significantly in mechanical performance and application suitability.

Below is a comparative technical and cost summary:

| Material | Avg. Raw Material Cost (USD/lb) | Machinability Rating | Typical Use in 3/4/5-Axis Milling & Turning | Tight Tolerance Feasibility | Notes |

|---|---|---|---|---|---|

| Stainless Steel (304/316) | $3.00 – $5.00 | Fair (40-50% of free-machining steel) | High – common in medical, aerospace, and food-grade components | Excellent – stable at high precision with proper fixturing and tooling | High tool wear; slower feed/speed; work hardening requires careful pass planning |

| Aluminum (6061, 7075) | $1.80 – $2.80 | Excellent (Machinability ~90-100%) | Very High – ideal for complex 5-axis geometries and rapid prototyping | Excellent – low thermal distortion, high dimensional stability | Faster cycle times; lower tool cost; preferred for lightweight precision parts |

| Carbon Steel (1018, 1045) | $0.80 – $1.20 | Good (Machinability ~60-70%) | High – used in industrial and mechanical components | Good – requires stress relief for sub-0.001″ tolerances | Lower raw cost; moderate tool wear; may require post-machining treatments |

| ABS (Thermoplastic) | $1.50 – $2.50 | Very Good (soft, low melting point) | Moderate – used for non-structural prototypes, enclosures | Moderate – prone to creep and thermal deformation | Low cutting forces; requires sharp tools; not for high-temp or load-bearing |

| Nylon (PA6, PA66) | $2.00 – $3.50 | Good (tough, flexible) | Moderate – used for wear-resistant parts, gears, insulators | Moderate – hygroscopic; dimensional changes with moisture | Requires pre-drying; excellent wear resistance; low friction |

Note: Raw material costs are approximate and based on current market averages (Q2 2024) for bar stock or plate in small to medium batch quantities. Machining cost per hour typically ranges from $75–$150 depending on machine type (5-axis premium) and setup complexity. Stainless steel parts often carry 20–40% higher total machining cost compared to aluminum due to reduced MRR (Material Removal Rate) and tooling expenses.

For tight tolerance applications, stainless steel remains a preferred choice when corrosion resistance, strength, and regulatory compliance are critical—even at higher cost. Aluminum is often selected for prototyping and high-complexity 5-axis components where cost-efficiency and weight are drivers. Plastics like ABS and nylon serve niche roles where electrical insulation, chemical resistance, or reduced weight are priorities, but are generally avoided in high-precision, long-life mechanical systems.

From CAD to Part: The Process

Honyo Prototype employs a structured, transparency-focused methodology to determine the effective cost of stainless steel per pound for client projects. This process integrates material science, precision manufacturing, and real-time data analytics, ensuring accurate costing while optimizing value. The sequence begins with CAD validation and concludes with certified delivery, with critical cost refinement occurring at each phase.

CAD Upload and Material Specification Validation

Upon receiving the client’s CAD file, our engineering team verifies dimensional accuracy and explicitly confirms the specified stainless steel grade (e.g., 304/L, 316/L, 17-4 PH). This step is critical as raw material costs vary significantly by grade due to alloy composition (e.g., molybdenum content in 316) and market volatility. We cross-reference the client’s specification against mill supplier pricing databases updated hourly. Any ambiguity in material grade or tolerances triggers immediate client consultation to prevent downstream cost deviations.

AI-Powered Preliminary Quote Generation

Our proprietary AI quoting engine calculates an initial per-pound estimate using three core inputs:

1. Validated CAD file volume (net part geometry)

2. Confirmed stainless steel grade density and current bulk market rate (LME-linked)

3. Historical shop-floor data on material yield for similar geometries

The AI output distinguishes between raw material cost per pound (based on bulk purchase rate) and effective cost per pound (which includes projected fabrication impacts). This preliminary quote includes clear disclaimers that final pricing depends on DFM-driven optimizations.

DFM Analysis: The Cost Transformation Phase

During Design for Manufacturability (DFM), our engineers dissect how part geometry directly influences the effective stainless steel cost per pound. Key interventions include:

Nesting optimization to maximize sheet utilization (reducing scrap from 30% to <15% in typical cases)

Kerf loss compensation for laser/waterjet cutting paths

Wall thickness adjustments to eliminate costly post-machining

Consolidating features to minimize secondary operations

DFM revisions often reduce the effective stainless steel cost per pound by 22–35% compared to the initial AI quote by addressing material waste and processing inefficiencies. Clients receive a DFM report quantifying these savings.

Production Execution and Dynamic Cost Tracking

Actual production uses IoT-enabled machinery that logs real-time material consumption. For stainless steel parts, we track:

Exact sheet lot traceability (including mill certificate costs)

Scrap weight recycled during fabrication

Secondary operation time (e.g., passivation, which adds $0.85–$2.20/lb for medical-grade 316)

This granular data feeds into our cost model, converting theoretical estimates into auditable per-pound metrics. A typical stainless steel bracket might show:

| Cost Component | Raw Material Only | Effective Cost (Post-DFM/Production) |

|---|---|---|

| Base Stainless (304/L) | $3.85/lb | $3.85/lb |

| Scrap Loss Adjustment | +$1.15/lb | +$0.42/lb |

| Secondary Operations | +$0.00/lb | +$1.30/lb |

| Total Effective Cost | $5.00/lb | $5.57/lb |

Delivery with Cost Transparency

Final delivery includes a certified cost breakdown report itemizing the stainless steel cost per pound. This document separates:

Raw material procurement cost (with mill certificate reference)

Net material yield percentage achieved

Value-added processing costs allocated per pound

Recycling credits applied to offset scrap

Honyo’s process ensures clients understand not just what the stainless steel cost per pound is, but why it exists at that value. By embedding cost engineering into DFM and leveraging production analytics, we transform stainless steel from a static commodity price into an optimized, predictable component of total part value—typically reducing effective material costs by 18–40% versus traditional quoting methods. This approach eliminates billing surprises and aligns manufacturing outcomes with client cost targets.

Start Your Project

Looking for up-to-date pricing on stainless steel per pound for your next project? Connect with Susan Leo at Honyo Prototype to receive accurate material cost estimates tailored to your specifications. With our factory based in Shenzhen, we offer competitive pricing, fast turnaround, and high-quality manufacturing solutions for prototyping and low-volume production.

Contact Susan Leo directly at [email protected] to request a quote or discuss your material requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.