Contents

Manufacturing Insight: Cost Of Mild Steel Per Pound

Understanding mild steel pricing dynamics is critical for precision manufacturing budgeting. While mild steel remains a cost-effective material choice with typical market rates ranging from $0.50 to $0.80 per pound depending on grade, quantity, and market volatility, raw material cost represents only one component of your total project expenditure. At Honyo Prototype, we recognize that inefficient machining processes or suboptimal design for manufacturability often inflate costs far beyond the base material price, eroding project margins unexpectedly.

Our advanced CNC machining services transform mild steel cost efficiency into a strategic advantage. Utilizing state-of-the-art milling and turning centers with rigorous process optimization, we minimize material waste through precise toolpath strategies and maximize throughput without sacrificing the tight tolerances your application demands. This focus on operational excellence ensures the inherent affordability of mild steel translates directly into competitive part pricing, not just at the raw material stage but through the entire value-added manufacturing process.

To provide immediate clarity on your specific project costs, Honyo Prototype offers an Online Instant Quote platform. Simply upload your CAD file, specify material requirements including mild steel grade, and receive a detailed, transparent cost breakdown within hours – not days. This tool eliminates estimation delays, allowing engineering and procurement teams to make informed sourcing decisions rapidly while accounting for both material variables and precision machining value. Leverage our expertise to convert mild steel’s economic potential into realized cost savings for your prototypes and low-volume production runs.

Technical Capabilities

The cost of mild steel per pound is influenced by several factors including material grade, quantity, market conditions, and manufacturing processes such as 3/4/5-axis milling and turning. When evaluating cost in the context of precision machining—especially for tight tolerance components—it’s essential to consider not only raw material pricing but also machinability, tool wear, cycle time, and secondary operations.

Mild steel (typically AISI 1018 or 1020) is commonly used in CNC machining due to its good balance of strength, weldability, and machinability. However, for tight tolerance applications, material stability and thermal expansion characteristics become critical. While mild steel is cost-effective compared to other metals, its use in multi-axis milling or precision turning may increase overall part cost due to longer machining times and higher tooling expenses relative to softer materials like aluminum or plastics.

Below is a comparative technical and cost analysis of common materials used in precision CNC machining, including mild steel:

| Material | Typical Cost Range (USD per lb) | Machinability Rating | Suitable for Tight Tolerance (±0.0005″) | 3/4/5-Axis Milling Efficiency | Turning Efficiency | Notes |

|---|---|---|---|---|---|---|

| Mild Steel (AISI 1018) | $0.70 – $1.10 | 55% | Yes (with proper fixturing and process control) | Moderate | Moderate | Higher tool wear than aluminum; requires rigid setups for tight tolerances |

| Aluminum (6061-T6) | $2.20 – $3.00 | 90% | Excellent | High | High | Preferred for high-speed milling and tight tolerance parts; lower cutting forces |

| ABS (Plastic) | $1.50 – $2.50 | 100%+ | Good (limited by thermal expansion) | High | High | Low melting point; excellent for prototypes; not for high-temp environments |

| Nylon (PA6/PA66) | $3.00 – $5.00 | 80% | Fair (hygroscopic, dimensional instability) | Moderate | Moderate | Requires drying pre-machining; not ideal for ultra-precision without stabilization |

| Tool Steel (e.g., A2, D2) | $3.00 – $5.50 | 30–40% | Excellent (post-heat treat grinding) | Low | Low | Used for hardened tooling; often machined pre-hardened then final ground |

Notes on Cost Drivers in Precision Machining:

For 3/4/5-axis milling and turning operations involving tight tolerances (e.g., ±0.0005″), the effective cost per pound must be evaluated in context:

Mild Steel offers low raw material cost but may incur higher machining costs due to increased tool wear and longer cycle times compared to aluminum.

Aluminum has a higher material cost per pound but allows faster material removal rates and superior surface finishes, reducing overall machining cost in complex parts.

ABS and Nylon are often used for non-structural prototypes or jigs; while they machine easily, their dimensional instability limits use in high-precision, long-term applications.

Multi-axis operations benefit from materials with consistent stock and predictable cutting behavior—aluminum and mild steel perform well when properly held and cooled.

At Honyo Prototype, we recommend material selection based on functional requirements, production volume, and precision needs—not just raw material cost. For tight tolerance components requiring durability and moderate cost, mild steel remains a strong option when balanced with appropriate machining strategies.

From CAD to Part: The Process

Honyo Prototype employs a structured, technology-driven workflow to determine and optimize the cost of mild steel components on a per-pound basis. This process ensures transparency, accuracy, and value engineering from initial design to final delivery. Below is a detailed explanation of each phase as it relates to mild steel cost calculation.

CAD Upload and Material Specification

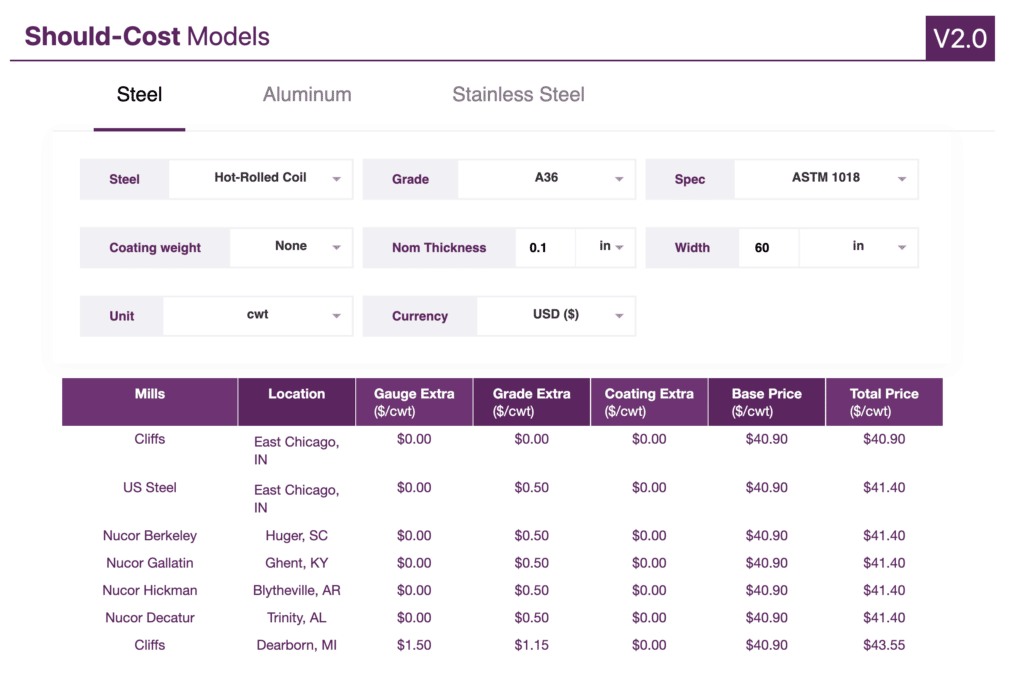

Upon receiving the customer’s CAD file, our system automatically extracts critical geometric data including part volume, surface area, and material requirements. For mild steel components, we validate the specified grade (typically ASTM A36 or equivalent) and confirm density (0.284 lb/in³) to calculate theoretical raw material weight. This weight forms the baseline for per-pound cost analysis. Any deviations from standard mild steel specifications are flagged for immediate customer consultation to avoid downstream cost inaccuracies.

AI-Powered Quoting Engine

Our proprietary AI quoting system processes the CAD-derived weight alongside real-time market data for mild steel commodities. The algorithm applies three key cost layers:

Base Material Cost: Current bulk purchase rate from certified mills (e.g., $0.35–$0.45/lb)

Processing Surcharges: Shop-rate adjustments for cutting, forming, and finishing operations

Logistics Factor: Regional freight costs normalized per pound

The AI cross-references historical project data to predict waste factors (typically 8–12% for mild steel) and outputs an initial per-pound cost estimate. Crucially, this stage identifies design elements that inflate material usage, such as unnecessarily thick sections or inefficient nesting patterns.

DFM Optimization for Material Efficiency

During Design for Manufacturability (DFM) review, our engineers target mild steel weight reduction without compromising structural integrity. Common interventions include:

Reducing wall thicknesses to minimum functional requirements

Implementing strategic cutouts in non-load-bearing zones

Optimizing part orientation to minimize support structures in fabrication

A typical DFM revision reduces mild steel weight by 15–30%, directly lowering the per-pound cost foundation. For example, a 10 lb part may be reduced to 7.5 lb through DFM, decreasing raw material expenditure by 25% before production begins. This phase generates a revised cost-per-pound projection reflecting achievable material savings.

Production Execution and Cost Verification

Actual production uses precision laser/plasma cutting and CNC forming to minimize material waste. We track:

Verified as-built weight via calibrated scales

Scrap recovery rates (mild steel typically achieves 95% recyclability)

Process-specific time logs for labor overhead allocation

The final cost per pound is recalculated using actual consumed material weight rather than theoretical CAD weight. This eliminates quoting discrepancies caused by design tolerances or fabrication variances.

Delivery and Cost Transparency

The final invoice details mild steel cost components separately, showing:

Actual material weight used (lb)

Adjusted base cost reflecting spot market rates at production date

Net processing cost per pound after DFM savings

Scrap credit applied (typically 60–70% of base material value)

This granular breakdown ensures clients understand how DFM interventions reduced their effective cost per pound versus the initial quote.

Cost Composition Across Workflow Stages

| Stage | Raw Material Cost | Processing Cost | Net Cost per Pound |

|———————-|——————-|—————–|———————|

| Initial AI Quote | $0.40 | $0.25 | $0.65 |

| Post-DFM Projection | $0.32 | $0.22 | $0.54 |

| Final Production | $0.33 | $0.20 | $0.53 |

Note: Values represent typical mild steel (A36) project; actual rates vary based on order volume and market conditions.

This integrated approach ensures Honyo clients pay only for necessary material while benefiting from engineering-led cost avoidance. The per-pound metric serves as a transparent benchmark throughout the workflow, with DFM acting as the primary lever for cost reduction before metal is cut.

Start Your Project

Looking for up-to-date pricing on mild steel per pound? Get a competitive quote tailored to your prototyping or low-volume production needs.

Susan Leo is your direct contact for material cost inquiries and sourcing support. With our factory based in Shenzhen, we offer fast turnaround and cost-effective solutions for precision manufacturing.

For accurate pricing and availability, contact Susan Leo at [email protected]. Let us help you optimize material costs without compromising quality.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.