Contents

Manufacturing Insight: Cost Of Carbon Steel Per Kg

Understanding Carbon Steel Cost Per Kilogram in Precision Manufacturing

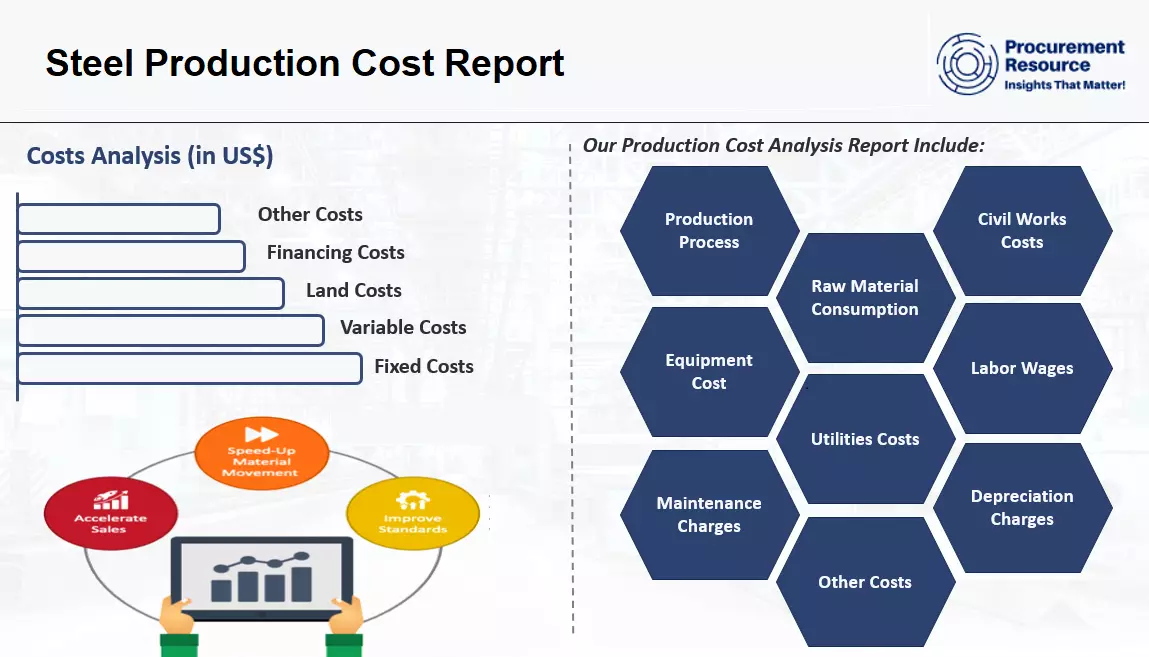

Material selection significantly impacts project economics, and carbon steel remains a cornerstone for its strength, machinability, and cost-effectiveness across industrial applications. While global market dynamics influence raw material pricing—typically ranging from $0.50 to $1.20 USD per kilogram for common grades like 1018 or 1045—the true cost efficiency of your components hinges on how that material is transformed. At Honyo Prototype, we recognize that minimizing waste and maximizing yield during CNC machining is where substantial savings are realized, far beyond the base material rate.

Our advanced CNC machining services optimize every phase of production, from strategic nesting of parts to reduce scrap to precision toolpath programming that ensures minimal material removal without compromising tolerances. This focus on process efficiency directly translates to lower per-part costs, even when accounting for volatile steel markets. By leveraging high-speed machining centers and rigorous quality control, we consistently deliver near-net-shape components that reduce secondary operations and accelerate time-to-market.

For immediate clarity on project economics, utilize Honyo Prototype’s Online Instant Quote platform. Input your CAD file and specifications to receive a detailed cost breakdown—including material, machining, and finishing—within minutes. This transparency empowers engineering and procurement teams to make data-driven decisions without delays, ensuring your carbon steel components meet both budgetary and performance targets. Partner with us to transform material cost challenges into competitive advantages.

Technical Capabilities

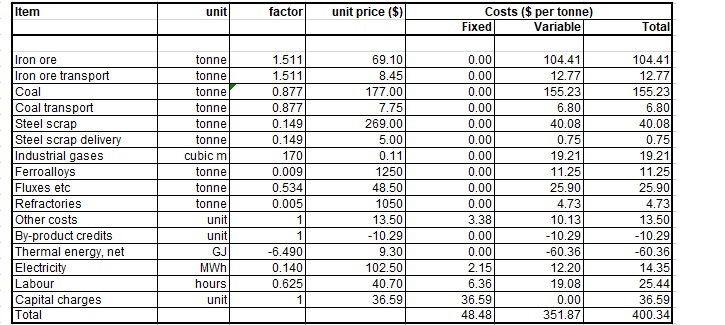

The cost of carbon steel per kilogram is influenced by several factors including raw material market pricing, machinability characteristics, and manufacturing complexity—particularly when applying high-precision processes such as 3/4/5-axis milling and turning with tight tolerances (typically ±0.005 mm to ±0.025 mm). While carbon steel is generally more expensive than plastics like ABS or Nylon, it is typically less costly than alloy steels or stainless steels. However, its higher density and harder structure increase machining time and tool wear, affecting overall production cost.

Below is a comparative technical and cost analysis across common engineering materials used in precision CNC machining:

| Material | Density (g/cm³) | Typical Cost per kg (USD) | Machinability Rating | Suitable for 3/4/5-Axis Milling | Suitable for Precision Turning | Tight Tolerance Feasibility (±0.01 mm) | Notes |

|---|---|---|---|---|---|---|---|

| Carbon Steel (e.g., 1045) | 7.85 | $0.80 – $1.20 | 60% (Moderate) | Yes | Yes | Yes | Higher tool wear; requires coolant and rigid setups; good dimensional stability |

| Aluminum (e.g., 6061-T6) | 2.70 | $2.50 – $3.50 | 90% (Excellent) | Yes | Yes | Yes | Lightweight; high MRR; ideal for complex 5-axis parts; lower tool wear |

| ABS (Plastic) | 1.04 | $1.80 – $2.50 | 80% (Good) | Yes | Yes | Moderate | Lower rigidity; prone to deflection; suitable for prototypes and non-structural parts |

| Nylon (Polyamide) | 1.15 | $3.00 – $5.00 | 50% (Fair) | Limited | Yes | No (hygroscopic, poor dimensional stability) | Requires dry machining; absorbs moisture; not ideal for tight tolerance production |

Notes on Cost Drivers in Precision Machining:

For carbon steel, while the base material cost per kg is relatively low, the total machining cost increases significantly under tight tolerance requirements due to slower cutting speeds, enhanced fixturing needs, and post-process inspections. Multi-axis milling operations further amplify costs due to programming complexity and longer cycle times.

Aluminum remains the preferred choice for high-complexity, tight-tolerance components where weight and machinability are critical. Plastics like ABS and Nylon offer lower density and corrosion resistance but are generally unsuitable for applications requiring long-term dimensional stability under precision constraints.

Material selection should balance part function, production volume, tolerance requirements, and total cost of ownership—not just raw material price per kilogram.

From CAD to Part: The Process

CAD Upload Phase

Upon receiving the customer’s CAD file, Honyo’s system extracts the geometric volume of the carbon steel component. This volume is multiplied by the standardized density of carbon steel (7.85 g/cm³) to calculate the theoretical net weight. This step establishes the baseline material quantity but does not yet reflect manufacturable weight due to unaccounted design features like undercuts or thin walls that may require additional material during production.

AI Quote Generation

The theoretical net weight feeds into Honyo’s AI quoting engine, which applies real-time market rates for carbon steel (e.g., AISI 1018 or 1045 grades) sourced from verified suppliers. The engine factors in standard scrap allowances (typically 8-12% for machined parts) and converts the adjusted weight into a preliminary material cost. Crucially, this quote remains provisional—actual costs will be refined during DFM as the AI cannot yet assess manufacturability-driven material waste.

DFM Analysis and Cost Refinement

During Design for Manufacturing (DFM) review, Honyo’s engineering team identifies opportunities to reduce material consumption. Examples include modifying fillet radii to minimize milling time (reducing tool wear on steel stock) or adjusting wall thicknesses to avoid secondary operations. The DFM report quantifies revised scrap rates and net weight, updating the material cost. For instance:

| Parameter | Pre-DFM | Post-DFM | Impact on Cost/kg |

|---|---|---|---|

| Net Part Weight | 1.8 kg | 1.6 kg | -11.1% |

| Scrap Allowance | 12% | 9% | -3% absolute |

| Effective Cost/kg | $1.85 | $1.62 | -12.4% |

This phase ensures the final cost/kg reflects optimized material usage, not just theoretical mass.

Production Execution

Actual carbon steel cost per kg is finalized during production using granular shop-floor data. Raw material batch certifications confirm exact steel grade pricing, while CNC machine sensors track real-time scrap generation (e.g., chips, rejected parts). Overhead costs—including energy for machining hardened steel and tooling depreciation—are allocated proportionally to the steel mass processed. A production dashboard dynamically updates the cost/kg as batches complete.

Delivery and Cost Reconciliation

Before shipment, Honyo reconciles the final cost/kg against the DFM-adjusted quote. Customers receive a detailed breakdown showing:

Verified raw material invoice cost per kg

Actual scrap rate from production logs

Allocated overhead (energy, labor, quality control)

Total cost/kg variance analysis

This transparency ensures the delivered part’s steel cost is traceable to physical consumption metrics, not estimates. Honyo’s process guarantees that the quoted cost/kg evolves from theoretical projection to auditable reality through engineering validation and production data.

Start Your Project

For accurate and up-to-date pricing on carbon steel per kilogram, contact Susan Leo at [email protected]. As a trusted manufacturing partner based in Shenzhen, Honyo Prototype offers competitive material rates with fast turnaround for prototypes and production runs. Reach out today to request a quote or discuss your project specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.