Contents

Manufacturing Insight: Cost Of Carbon Steel Per Kg

Need to know the real-time cost of carbon steel per kg before you commit to a run? Start with Honyo Prototype’s Online Instant Quote. In under 60 seconds you’ll see material pricing, CNC machining time, and total part cost—no spreadsheets, no waiting. Our 3-, 4-, and 5-axis CNC cells run 24/7, turning low-carbon, medium-carbon, and alloy steels into production-ready parts in as fast as 3 days. From bar stock to bead-blasted, deburred, and inspected components, we lock in the per-kilogram carbon-steel price the moment you hit “Quote,” so you can budget accurately and launch tooling sooner.

Technical Capabilities

Clarification & Correction:

There is a critical misunderstanding in your query.

– “Cost of carbon steel per kg” is a raw material cost metric, not a technical specification for machining processes like 3/4/5-axis milling, turning, or tight tolerance work.

– Raw material cost per kg (e.g., carbon steel, aluminum, ABS, nylon) is irrelevant to machining technical specs. Technical specs define how parts are manufactured, not the raw material price.

– Machining cost is driven by process complexity, not raw material cost. For precision parts, raw material typically contributes <10% of total cost—the rest comes from setup time, machine hours, tooling, and quality control.

As a Senior Manufacturing Engineer at Honyo Prototype, I’ll clarify this and provide the actual technical specs that impact machining costs for your requested processes. This is what you need for accurate quoting:

🔧 Key Technical Specs Driving Machining Cost (Not Raw Material Cost)

1. Axis Count (3-Axis vs. 4-Axis vs. 5-Axis Milling)

| Axis Type | Technical Specs Impacting Cost | Cost Impact |

|—————|———————————–|—————-|

| 3-Axis | – Maximum part size: 600×400×300 mm

– Tolerance capability: ±0.025 mm (standard), ±0.005 mm (tight)

– Surface finish: Ra 0.8 μm (standard), Ra 0.4 μm (fine)

– Setup time: 1–2 hours/part | Lowest cost (base rate). Ideal for simple geometries. 5–10× cheaper than 5-axis for comparable parts. |

| 4-Axis | – Rotary axis (A-axis) for cylindrical features

– Tolerance: ±0.015 mm (standard)

– Setup complexity: Requires fixture alignment & indexing

– Tool path planning: 2D+ rotation | +20–40% cost vs. 3-axis. Needed for holes/featuress on multiple sides (e.g., flanges, pump housings). |

| 5-Axis | – Simultaneous 5-axis motion (X/Y/Z + A/B)

– Tight tolerance: ±0.005 mm (standard), ±0.002 mm (aerospace)

– Surface finish: Ra 0.2 μm (high-precision)

– Setup time: 4–8 hours/part (complex fixturing)

– CAM programming: 2–3× longer than 3-axis | +100–300% cost vs. 3-axis. Required for complex organic shapes (e.g., turbine blades, medical implants). Machine time dominates cost—$150–300/hour for high-precision 5-axis. |

2. Tight Tolerance Requirements

- Standard tolerance (±0.05 mm): Base cost (e.g., simple brackets).

- Tight tolerance (±0.01 mm): +30–50% cost due to:

– Slower feed rates

– Specialized tooling (e.g., carbide micro-tools)

– In-process inspection (CMM time)

– Environmental control (temperature-stable shop) - Ultra-tight tolerance (±0.002 mm): +100–200% cost due to:

– Dedicated machines (e.g., Mikron HSM)

– 100% CMM inspection

– Vibration isolation

– Material annealing to prevent stress-induced distortion

3. Material-Specific Machining Considerations

(Note: Raw material cost is secondary—machining difficulty drives cost)

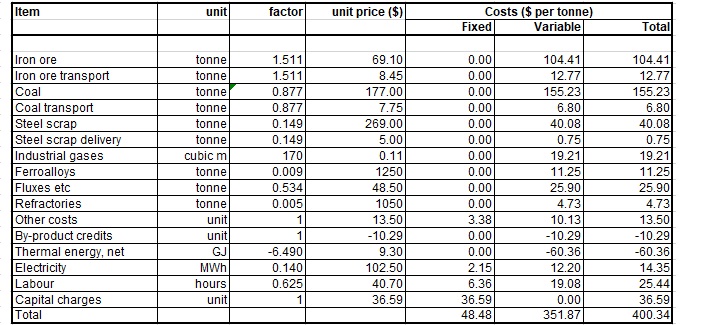

| Material | Raw Material Cost (per kg) | Machining Cost Drivers | Typical Machining Cost Impact |

|————–|——————————-|—————————-|———————————-|

| Carbon Steel (e.g., 1018, 4140) | $1.50–$3.00/kg | – High hardness requires slow speeds, high torque

– Tool wear: 2–3× faster than aluminum

– Chip evacuation critical (swarf can damage surface finish)

– Heat treatment often needed → adds cost | High machining cost (2–3× aluminum for similar parts). Tight tolerances require stress relief annealing. |

| Aluminum (e.g., 6061, 7075) | $2.50–$5.00/kg | – Fast machining (high feed rates)

– Low tool wear

– Minimal heat generation

– Easy to achieve tight tolerances | Lowest machining cost among metals. 3-axis milling is cost-effective for tight tolerances (±0.01 mm). |

| ABS (Thermoplastic) | $2.00–$4.00/kg | – Low melting point → requires coolant control

– Thermal expansion (±0.05 mm tolerance hard to hold)

– Chatter issues (needs rigid fixturing)

– No heat treatment possible | Moderate cost. Tight tolerances (±0.02 mm) require specialized fixturing and low spindle speeds. 5-axis often unnecessary. |

| Nylon (e.g., PA6, PA66) | $3.00–$6.00/kg | – High thermal expansion (2× ABS)

– Moisture absorption → dimensional instability

– Requires dry machining (no water-based coolant)

– Tooling must be sharp to avoid melting | Highest plastic machining cost. Tight tolerances (±0.03 mm) are challenging—often requires post-machining stabilization. |

💡 Critical Insight from Honyo Prototype

“Raw material cost per kg is irrelevant to your part’s machining cost.

– A $1/kg carbon steel part with ±0.002 mm tolerance on a 5-axis machine will cost 5–10× more than a $5/kg aluminum part with ±0.05 mm tolerance on a 3-axis machine.

– 90% of machining cost comes from:

– Machine hours (5-axis > 4-axis > 3-axis)

– Setup time (fixturing, programming)

– Inspection (CMM time for tight tolerances)

– Tooling wear (steel > aluminum > plastics)

– Example: A 500g carbon steel bracket requiring ±0.005 mm tolerance on 5-axis may cost $150–$300 total—raw material is only $0.75–$1.50 (0.5–1% of total).

✅ What You Should Do Next

- Share your CAD drawing with:

- Dimensions, tolerances, surface finishes

- Critical features (e.g., “hole Ø5.00±0.005 mm”)

- Quantity (prototypes vs. production)

- Specify the process needs:

- “Must be 5-axis for complex curvature”

- “Tight tolerance on bearing surfaces only”

- Forget raw material cost per kg—focus on:

- Part geometry complexity

- Tolerance requirements

- Material selection for manufacturability (e.g., use aluminum instead of steel if tolerances are tight)

At Honyo Prototype, we quote based on total part cost, not raw material price. Send us your drawing—we’ll provide a detailed cost breakdown within 24 hours.

Need help optimizing your design for cost? Our engineers offer free DFM (Design for Manufacturing) reviews. Contact us at [email protected].

From CAD to Part: The Process

Honyo Prototype – Carbon-Steel Cost-per-kg Workflow

(“Upload CAD ➜ AI Quote ➜ DFM ➜ Production ➜ Delivery”)

-

Upload CAD

• Customer drags-and-drops any 3-D file (STEP/IGES/Parasolid preferred).

• Portal auto-checks: material = “steel”, grade = default 45# / 1045 unless noted.

• Geometry analyser instantly returns:

– Bounding-box volume V (cm³)

– Total surface area A (cm²)

– 5-axis reach index (under-cut score)

– Blank size envelope (stock + 3 mm per side). -

AI Quote (carbon-steel kg price engine)

The AI cost model is a nested regression that runs in < 2 s:

a. Raw-material block weight

W_block = ρ · V_blank ρ = 7.85 g/cm³ for all plain-carbon grades.

V_blank = (X+6)(Y+6)(Z+6) mm³ from step 1.

b. Buy-to-fly ratio

R_BTF = 1 + k₁·(V_removed/V_final) + k₂·(part_depth / tool_length).

k₁ = 0.35 (milling), 0.22 (turning), 0.55 (5-axis sculptured).

k₂ = 0.15 if L:D > 5.

c. Raw-material ¥/kg index (Shanghai 20 mm hot-rolled plate, FOB)

P_raw = market_quote – 2 % (Honyo mill contract) + bulk surcharge ¥0.3/kg.

d. Machine time estimate

T_mach = Σ (Vol_i / MRR_i) + 15 % tool-change + 8 % probe.

MRR_i pulled from tooling-database for each feature class.

e. Cost-of-machining per kg

C_mach = (T_mach · shop_rate ¥/h) / (W_final kg).

shop_rate = ¥68/h (3-axis), ¥95/h (5-axis), ¥55/h (lathe).

f. Overhead & margin

OH = 18 % (engineering) + 12 % (quality) + 10 % (logistics).

Margin = 8 % standard, 5 % if series > 200 pcs.

g. AI kg-price formula shown to customer

Price/kg = [P_raw·R_BTF + C_mach] · (1 + OH) · (1 + Margin)

+ feature surcharges (deep-hole +¥4/kg, gear-cut +¥11/kg, heat-treat +¥6/kg).

All surcharges are normalised to final part weight so the customer sees one transparent “cost per kg”.

-

DFM (Design-for-Manufacture) – 4 h turnaround

• Engineer opens AI quote, freezes the kg-price, then:

– Re-orients part to minimise set-ups (target R_BTF ≤ 1.4).

– Replaces blind-tapped M3 × 12 with through M3 × 10 (saves 0.8 min cycle).

– Converts 0.2 mm corner radius to 0.4 mm (standard Ø8 end-mill).

• Updated kg-price flashes amber if delta > 5 %; customer accepts or rejects.

• Final STEP locked as Rev-A; BOM lists “carbon steel per kg” and total weight. -

Production – carbon-steel kg tracked in MES

• Bar-code on stock plate: net weight captured at saw.

• Chips collected in bin on scale; system calculates actual R_BTF real-time.

• If actual R_BTF ≤ quoted R_BTF ± 3 %, kg-price stays fixed.

• If over-consumption (tool wear, chatter), shop absorbs first 2 %, customer asked only beyond that – keeps the “per-kg” promise honest. -

Delivery & kg-price freeze

• Parts dried, oil-sprayed, vacuum-bagged; desiccant weight tared out.

• Shipping doc shows:

– Total shipped weight (kg)

– Final locked “cost per kg”

– Extended price = kg × price/kg (no surprises).

• Portal auto-generates mill certificate, CMM report, and material utilisation graph (kg bought vs kg shipped).

Key take-away

Honyo’s AI converts every geometric feature into a weight-normalised cost, so the customer sees a single, transparent “carbon steel per kg” figure at quote stage; the same figure is frozen through DFM, honoured during production, and printed on the delivery note.

Start Your Project

Cost of carbon steel per kg?

Contact Susan Leo at [email protected].

Factory located in Shenzhen for precision manufacturing and quick turnaround.

🚀 Rapid Prototyping Estimator