Contents

Manufacturing Insight: Cost Of 316 Stainless Steel Per Pound

Understanding 316 Stainless Steel Cost Per Pound in Precision Manufacturing

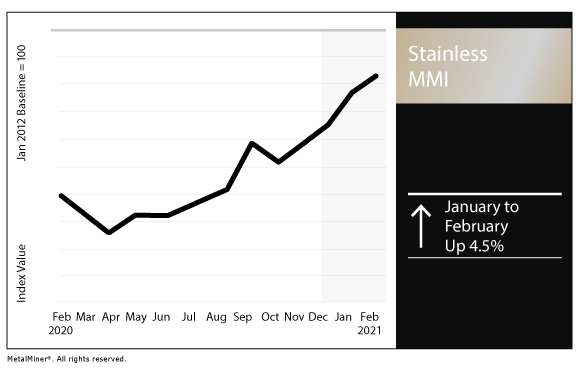

Material selection is a critical driver of both performance and project economics in precision component manufacturing. 316 stainless steel, with its superior corrosion resistance, particularly against chlorides and acids, high-temperature strength, and excellent weldability, remains a preferred choice for demanding applications across aerospace, medical, marine, and chemical processing industries. While the base market price for 316 stainless steel per pound fluctuates based on global commodity markets, form factor (bar, sheet, plate), and order volume, it serves as a foundational element in total part cost calculation. Current typical base material ranges are illustrated below.

| Form Factor | Typical Base Price Range (USD per Pound) | Key Influencing Factors |

|---|---|---|

| Hot Rolled Bar | $2.50 – $3.50 | Mill surcharges, lead times, minimum order |

| Cold Drawn Bar | $3.00 – $4.00+ | Tolerance precision, surface finish, alloy |

| Sheet/Plate | $3.25 – $4.25+ | Thickness, width, ASTM/AMS specifications |

However, focusing solely on the raw material cost per pound provides an incomplete picture for machined components. The true cost efficiency is significantly determined by the machining process itself. Material utilization rate, machining complexity, required tolerances, secondary operations, and overall production yield directly impact the final cost per finished part. Suboptimal machining practices can dramatically increase waste and labor, negating any minor savings from the base material price.

Honyo Prototype leverages advanced CNC machining capabilities and deep material science expertise to maximize cost efficiency for 316 stainless steel components. Our engineering team optimizes toolpaths, selects specialized cutting tools for stainless alloys, and implements rigorous process controls to minimize cycle times, reduce scrap, and ensure first-time quality. This focus on machining efficiency translates the base material cost into the most economical finished part possible, delivering superior value beyond the initial pound price.

Gain immediate clarity on the total cost for your specific 316 stainless steel CNC machining project. Honyo Prototype’s Online Instant Quote system provides rapid, accurate pricing based on your detailed CAD model and requirements, factoring in material, machining complexity, and our optimized processes. Submit your design today to receive a precise cost assessment reflecting the true value of precision manufacturing with Honyo.

Technical Capabilities

The cost of 316 stainless steel per pound is influenced by several technical and manufacturing factors, particularly when used in precision machining processes such as 3/4/5-axis milling and turning with tight tolerance requirements. Below is a comparative technical overview of 316 stainless steel in relation to other commonly machined materials—aluminum, general steel, ABS, and nylon—highlighting key properties that impact machining cost, tool wear, cycle time, and overall part economics.

| Material | Density (lb/in³) | Tensile Strength (psi) | Hardness (Rockwell B) | Machinability Rating (%) | Typical Cost per Pound (USD) | Notes on Machining in 3/4/5-Axis Milling & Turning |

|---|---|---|---|---|---|---|

| 316 Stainless Steel | 0.29 | 80,000 – 90,000 | 79 – 85 HRB | 45% | $3.50 – $5.00 | High corrosion resistance; generates significant heat during machining; requires rigid setups, sharp carbide tooling, and lower cutting speeds. High work-hardening rate increases cycle time and tool wear, especially in tight tolerance applications. |

| Aluminum (6061) | 0.098 | 45,000 | 30 – 40 HRB | 90% | $1.20 – $1.80 | Lightweight and highly machinable; allows high spindle speeds and feed rates in multi-axis operations. Minimal tool wear. Ideal for rapid prototyping and low-weight components. |

| Mild Steel (1018) | 0.284 | 60,000 – 70,000 | 70 – 80 HRB | 60% | $0.70 – $1.00 | Moderate strength and machinability. Generates more heat than aluminum but less than stainless. Suitable for general-purpose turned and milled parts with tolerances down to ±0.001″. |

| ABS (Thermoplastic) | 0.036 | 6,000 | — | 100% | $1.50 – $2.20 | Easily machined with high precision; low melting point requires careful speed control. Minimal tool wear. Used for prototypes and non-structural components. |

| Nylon (PA 6/66) | 0.041 | 9,000 – 11,000 | — | 95% | $2.00 – $3.00 | Low stiffness and high elasticity require stable fixturing. Susceptible to dimensional changes due to moisture absorption. Suitable for low-friction parts but challenging in tight tolerance scenarios. |

Note on Cost Drivers for 316 Stainless Steel in Precision Machining

The effective cost per pound of 316 stainless steel extends beyond raw material pricing. When machining complex geometries on 3/4/5-axis CNC systems with tight tolerances (e.g., ±0.0005″), the combination of high machine hour rates, specialized tooling, and reduced tool life significantly increases total part cost. Compared to aluminum or plastics like ABS and nylon, 316 stainless steel demands more frequent tool changes, lower material removal rates, and enhanced cooling strategies—factors that amplify the effective cost per finished component despite the base material cost being moderate to high.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined process to determine the final cost contribution of 316 stainless steel per pound within a customer’s project, moving beyond simple material weight calculations to incorporate fabrication complexity and process efficiency. This integrated approach ensures accurate, transparent costing aligned with actual production requirements.

Upload CAD

Upon receiving the customer’s CAD model, our system extracts precise geometric data including total volume, surface area, and bounding box dimensions. For 316 stainless steel projects, we immediately identify material-specific requirements such as corrosion resistance certifications or surface finish specifications that may influence sourcing costs. The initial raw material weight is calculated using the industry-standard density of 316 SS (0.29 lb/in³), but this serves only as a baseline input—final cost per pound is dynamically adjusted in subsequent stages based on manufacturability.

AI Quote Engine

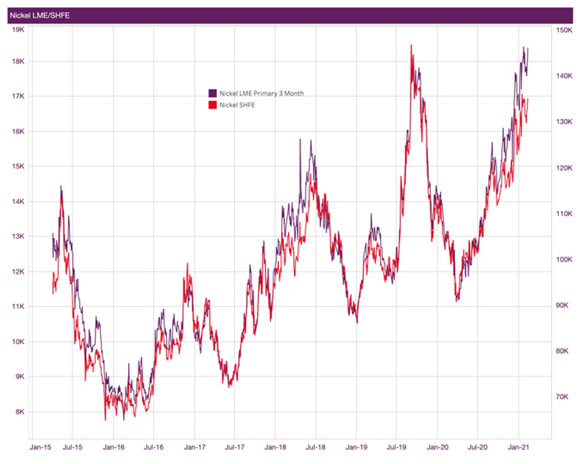

Our proprietary AI engine ingests the CAD-derived weight alongside real-time variables: current LME nickel/chromium differentials, mill surcharges for 316L versus standard 316, and regional scrap recovery rates. Crucially, it applies predictive waste factors based on the part’s geometry. For example, a complex bracket may show 1.8x the theoretical weight due to kerf loss in laser cutting or fixture requirements. The AI outputs a preliminary material cost per pound reflecting these adjusted consumption metrics, not just net part weight. Key parameters considered include:

| Parameter | Typical Range for 316 SS | Impact on Cost/lb |

|---|---|---|

| Material Surcharge | $1.20 – $2.80/lb | Direct adder to base metal cost |

| Net-to-Gross Weight Ratio | 0.45 – 0.75 | Lower ratio = higher effective cost/lb |

| Minimum Order Value Adjustment | $0 – $150 | Applied to small runs <5 lbs |

DFM Analysis

This phase critically refines the cost-per-pound calculation. Our manufacturing engineers conduct a granular review focusing on material utilization efficiency. We identify opportunities to: reduce raw stock size through nesting optimization, eliminate unnecessary thickness in non-structural zones, or suggest alternative geometries that minimize machining time (thus lowering the burdened cost allocation per pound). A DFM-revised design might reduce effective material cost by 18-32% through yield improvements, directly altering the pounds consumed per finished part. We provide customers with a revised cost-per-pound metric reflecting these optimized material consumption scenarios before approval.

Production Execution

During machining, we track actual material consumption via shop floor IoT systems. For 316 SS, we monitor: bar stock usage against cutoff waste, sheet nesting efficiency, and scrap segregation for premium recycling credits. High-performance CNC operations on 316 SS incur specific tooling wear costs that get apportioned into the burdened rate. The final material cost per pound is recalculated using actual consumed weight (including verified scrap), not theoretical CAD weight. Typical production variables affecting the final figure include:

Coolant and tooling amortization costs specific to 316 SS machining ($0.35 – $0.65/lb)

Scrap recovery value offset (-$0.10 – -$0.25/lb based on current scrap market)

Heat treatment or passivation surcharges (when applicable)

Delivery & Cost Finalization

The invoice reflects a consolidated material cost derived from actual consumed 316 SS weight multiplied by the burdened rate established during production. This final cost per pound encompasses all process-specific variables—not merely the raw metal price. Customers receive a detailed breakdown showing theoretical weight versus actual consumption, scrap recovery credits, and process-specific surcharges. For time-sensitive projects, we may apply expedited material sourcing premiums (typically $0.75 – $1.25/lb) which are explicitly called out.

This closed-loop methodology ensures the stated cost per pound of 316 stainless steel accurately represents the true production economics, eliminating common pitfalls of quoting based solely on CAD weight. The DFM phase remains the highest leverage point for cost optimization, where design adjustments can fundamentally alter material efficiency metrics before metal is cut.

Start Your Project

For accurate pricing on 316 stainless steel per pound, contact Susan Leo directly at [email protected]. As a trusted manufacturing partner based in Shenzhen, Honyo Prototype offers competitive material rates backed by in-house production capabilities and stringent quality control.

Our Shenzhen facility ensures efficient processing and fast turnaround for both prototype and production orders. Pricing is influenced by order volume, finishing requirements, and current raw material market conditions—Susan will provide a detailed quote tailored to your specifications.

Reach out today to discuss your project requirements and receive a precise cost analysis for 316 stainless steel components.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.