Contents

Manufacturing Insight: Copper Cnc Machining

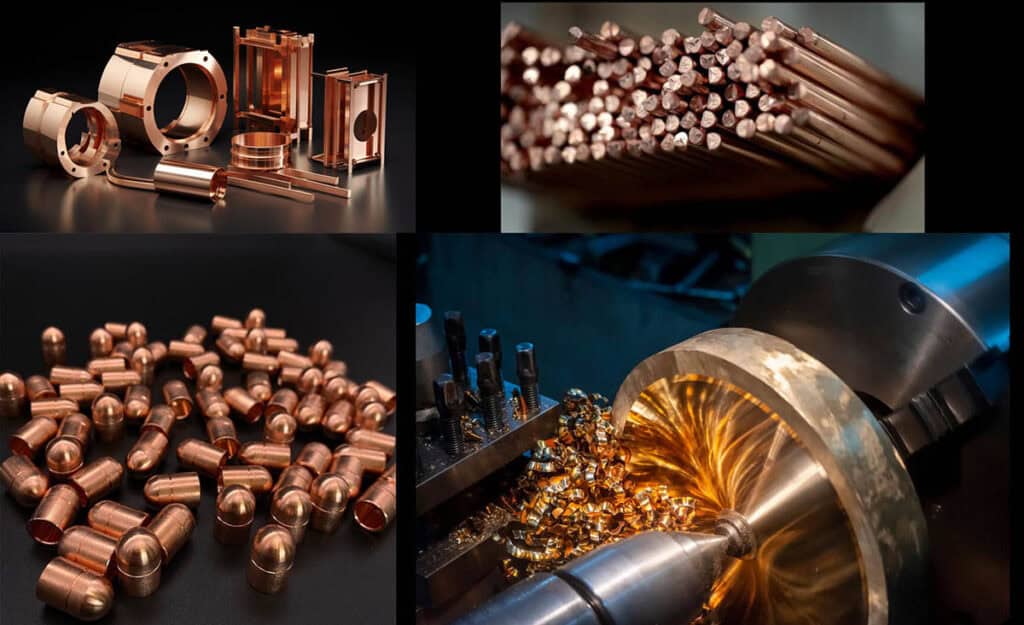

Precision Copper CNC Machining Expertise at Honyo Prototype

Copper and its alloys present unique challenges in precision manufacturing due to high thermal conductivity, material galling tendencies, and stringent surface finish requirements. At Honyo Prototype, we specialize in high-accuracy CNC machining of copper, brass, and beryllium-copper components for demanding applications in thermal management, electrical engineering, and RF shielding. Our ISO 9001-certified processes leverage advanced 3- to 5-axis CNC milling and turning centers with optimized toolpaths, specialized coatings, and coolant strategies to mitigate work hardening and achieve micron-level tolerances down to ±0.0002″.

We understand that copper projects demand both material science expertise and agile production capabilities. Honyo Prototype delivers certified copper alloys including C11000 EC, C10100 OFE, C26000 Cartridge Brass, and C17200 Beryllium-Copper, supporting complex geometries with surface finishes as fine as Ra 0.8 µm. Our engineering team collaborates with clients to address thermal distortion risks during machining and ensures seamless transition from prototype to low-volume production.

Material grade selection significantly impacts performance in copper machining. Key properties we optimize for include:

| Alloy Type | Typical Applications | Machinability Notes |

|---|---|---|

| C11000 (ETP) | Busbars, electrical contacts | Prone to galling; requires sharp tooling |

| C17200 (BeCu) | Springs, connectors | Toxic dust control; high hardness |

| C26000 (Cartridge Brass) | Valves, fittings | Excellent chip control; low lead content |

Accelerate your copper component development with Honyo Prototype’s Online Instant Quote system. Upload CAD files in STEP, IGES, or native formats to receive detailed manufacturability feedback and a formal quotation within hours—not days. Our platform provides transparent cost breakdowns, lead time estimates, and material sourcing options, enabling faster iteration for RF components, heat sinks, and custom electrical hardware. Partner with us for technically rigorous copper machining where thermal performance and dimensional integrity are non-negotiable.

Technical Capabilities

Copper CNC machining involves precision manufacturing processes tailored to the unique thermal and mechanical properties of copper and copper alloys. Due to copper’s high thermal conductivity, excellent electrical properties, and relative softness, specialized tooling, cutting parameters, and fixturing are required to maintain tight tolerances and surface integrity. The following table outlines key technical specifications for 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, with emphasis on tight tolerance capabilities and compatibility with copper, aluminum, steel, ABS, and nylon.

| Process | Axis Configuration | Typical Tolerance (Standard) | Tight Tolerance Capability | Spindle Speed Range (RPM) | Feed Rate Range (mm/min) | Compatible Materials (Primary) | Tooling Recommendations | Notes |

|---|---|---|---|---|---|---|---|---|

| 3-Axis Milling | X, Y, Z | ±0.005″ (0.127 mm) | ±0.001″ (0.025 mm) | 8,000–15,000 | 200–1,200 | Copper, Aluminum, Steel, ABS | Carbide end mills with polished flutes, high rake angles | Ideal for flat, prismatic copper parts; chip evacuation critical due to galling |

| 4-Axis Milling | X, Y, Z + Rotary (A) | ±0.003″ (0.076 mm) | ±0.0008″ (0.020 mm) | 6,000–12,000 | 150–1,000 | Copper, Aluminum, Steel, Nylon | Polished carbide or diamond-coated tools | Enables machining of cylindrical copper features; indexing required for multi-face work |

| 5-Axis Milling | X, Y, Z + Two Rotary (A/B or B/C) | ±0.002″ (0.051 mm) | ±0.0005″ (0.013 mm) | 5,000–10,000 | 100–800 | Copper, Aluminum, Steel | High-precision ball nose or end mills with PVD coating | Continuous contouring for complex copper electrodes or RF components; reduced setups |

| CNC Turning | X, Z (rotating workpiece) | ±0.002″ (0.051 mm) | ±0.0005″ (0.013 mm) | 500–5,000 (variable by diameter) | 50–500 | Copper, Aluminum, Steel, ABS, Nylon | CBN or carbide inserts with sharp edge, positive rake | Ideal for high-precision cylindrical copper bushings, connectors; peck drilling for deep holes |

Material Notes:

Copper: Requires low cutting speeds and high feed rates to avoid work hardening. Flood coolant is essential to manage heat and improve surface finish. Free-machining copper (C14500) is preferred over pure copper (C11000) for better chip control.

Aluminum: Easily machined at high speeds; compatible with all axis configurations. Use sharp tools to prevent built-up edge.

Steel: Requires rigid setups and lower speeds; ideal for hardened components. Tight tolerances achievable with proper tool wear monitoring.

ABS & Nylon: Thermoplastics that require sharp cutting tools and optimized chip removal to prevent melting. Best suited for lower spindle speeds with air blast cooling.

Tight Tolerance Considerations:

Achieving tolerances below ±0.001″ requires thermal stabilization, precision calibration, and in-process metrology.

Workholding must minimize deformation, especially for thin-walled copper parts.

Post-process inspection using CMM or optical comparators is standard for validation.

This technical framework supports high-precision component production across industries including aerospace, electronics, and medical devices, where copper’s conductivity and machinability are critical.

From CAD to Part: The Process

Honyo Prototype Copper CNC Machining Process Overview

Honyo Prototype executes precision copper CNC machining through a streamlined five-stage workflow designed for speed, accuracy, and material-specific optimization. Copper presents unique challenges—including high thermal conductivity, gummy chip formation, and susceptibility to work hardening—requiring specialized process controls. Our end-to-end methodology ensures consistent quality while minimizing lead times.

Stage 1: CAD Upload & Validation

Clients submit native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system performs automated geometry validation, verifying unit consistency, tolerance callouts, and manufacturability flags. For copper components, we specifically check for features prone to deformation (e.g., thin walls, deep cavities) and confirm material grade specifications (e.g., C11000 ETP, C10100 OFHC). Invalid submissions trigger immediate feedback with correction guidelines.

Stage 2: AI-Powered Quoting

Validated CAD files enter our proprietary AI quoting engine, which analyzes 30+ parameters: part volume, feature complexity, required tolerances (±0.005mm typical for copper), secondary operations, and material cost volatility. The AI cross-references real-time copper market pricing and machine utilization data to generate a binding quote within 2 business hours. Critical for copper machining, the quote explicitly itemizes costs for specialized tooling (e.g., polished carbide end mills), coolant requirements, and thermal management protocols.

Stage 3: DFM Analysis & Optimization

Engineers conduct a copper-specific Design for Manufacturability review, focusing on:

Chip evacuation strategies to prevent built-up edge (recommending variable-helix tools)

Thermal distortion mitigation (adjusting stepovers/feed rates to minimize heat retention)

Fixture design for soft-material stability (using low-clamp-force vises)

Annealing cycle integration for complex geometries

Clients receive a DFM report with actionable suggestions—such as adding relief grooves in high-stress areas—within 24 hours. Approval locks the production-ready workflow.

Stage 4: Precision Production

Copper machining occurs in climate-controlled cells with dedicated machines to avoid cross-contamination from other metals. Key process controls include:

| Parameter | Copper-Specific Setting | Purpose |

|---|---|---|

| Spindle Speed | 60-70% of aluminum rate | Reduces heat generation |

| Coolant | Non-chlorinated soluble oil | Prevents oxidation, improves chip break |

| Feed Rate | 20-30% higher than steel | Minimizes work hardening |

| Tool Geometry | Positive rake, polished flutes | Eliminates galling |

Parts undergo in-process CMM checks at critical stages, with thermal stabilization protocols between operations. All copper components receive post-machining de-burring and conductivity verification per ASTM B193.

Stage 5: Logistics & Delivery

Finished parts are individually wrapped in anti-tarnish VCI paper, placed in static-dissipative containers, and shipped with full traceability documentation—including material certs, first-article inspection reports, and surface roughness validation. Standard lead time is 7-10 business days from DFM approval, with real-time shipment tracking via our client portal. Expedited options include same-day dispatch for qualified projects.

This integrated approach leverages material science expertise and digital workflow automation to overcome copper’s machining challenges, delivering components that meet stringent electrical/thermal performance requirements for aerospace, semiconductor, and power transmission applications.

Start Your Project

Looking for precision copper CNC machining services? Partner with Honyo Prototype for high-quality, efficient manufacturing solutions tailored to your specifications. Our state-of-the-art facility in Shenzhen ensures tight tolerances, fast turnaround, and consistent quality for copper components across industries including electronics, automotive, and industrial equipment.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Factory Location: Shenzhen, China

Leverage our expertise in copper CNC machining for prototypes and low-to-mid volume production runs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.