Guide Contents

Project Insight: Copper Cnc Machining

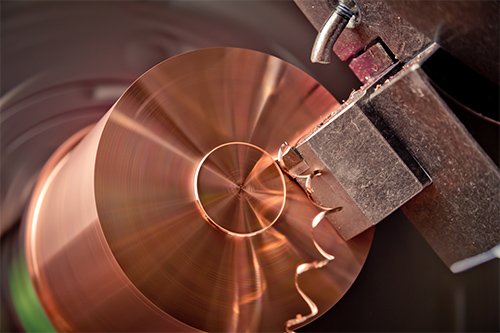

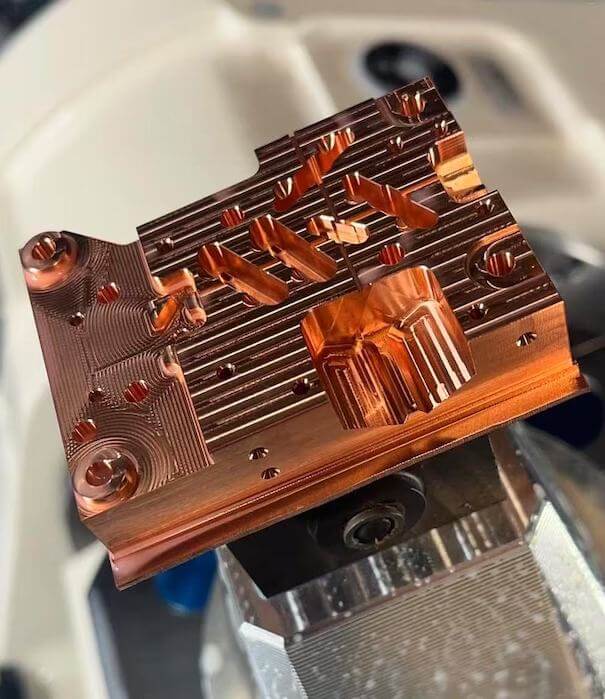

Manufacturing Insight: Copper CNC Machining – Precision Meets Speed for Next-Gen Hardware

Why Speed and Precision Are Critical for Copper Components

Performance-Critical Tolerances: Copper’s exceptional thermal and electrical conductivity demands micron-level accuracy (±0.01mm). Even minor deviations in heat sinks, electrical contacts, or RF components can disrupt functionality in high-stakes applications.

Accelerated Time-to-Market: Hardware startups operate on razor-thin innovation cycles. Delays in copper part delivery stall prototyping, testing, and investor validation – directly impacting competitive advantage.

Cost Efficiency Through Precision: Eliminate costly secondary operations (e.g., hand-finishing or rework) by achieving “first-time-right” parts, reducing total project costs by up to 30% compared to traditional workflows.

Honyo Prototype: Engineered for Copper Excellence

Online Instant Quote: Upload your CAD file in seconds to receive real-time pricing, lead times, and DFM feedback – no manual quotes, no delays.

AI-Powered Optimization: Proprietary algorithms analyze copper’s unique challenges (thermal expansion, galling, chip control) to auto-optimize toolpaths, cutting speeds, and fixturing for flawless surface finishes and dimensional stability.

Fast Turnaround Guarantee: Deliver functional prototypes in 24–48 hours with ±0.01mm tolerances across 3/4/5-axis capabilities – from simple heat sinks to complex multi-feature assemblies for end-use production.

At Honyo Prototype, we transform copper designs into precision-engineered realities – so you can innovate faster, with confidence.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Precision Copper Machining Technology

3/4/5-Axis CNC Machining: Execute complex geometries for heat sinks, electrical connectors, and thermal interfaces with unparalleled flexibility.

Copper-Specific Tooling Strategies: Advanced carbide cutters and cryogenic cooling systems eliminate galling and maintain surface integrity.

Real-Time Process Optimization: AI-driven sensors dynamically adjust spindle speed, feed rates, and tool paths for zero-defect output.

Micron-Level Tolerance Control

±0.01mm Accuracy: Achieved through thermal compensation systems and vibration-dampened spindles for critical electrical and thermal components.

Ra 0.4μm Surface Finish: Precision grinding for high-conductivity surfaces in RF shields and busbar applications.

In-Process Metrology: Integrated CMM checks during machining to ensure compliance with AS9100/ISO standards.

Scalable Production Capacity

1 to 10,000+ Parts: Seamlessly transition from single prototypes to high-volume production without retooling or delays.

Dedicated Copper Production Lines: Isolated workflows prevent cross-contamination and ensure material purity for sensitive applications.

Just-in-Time Manufacturing: Agile scheduling to align with your product development cycles or supply chain demands.

ISO 9001:2015 Certified Quality Assurance

100% Dimensional Inspection: Every part verified against engineering drawings using laser scanners and optical comparators.

Full Material Traceability: Certifications for each copper batch (C11000, C10100, etc.) from raw material to finished part.

Proactive Defect Prevention: Root cause analysis and statistical process control (SPC) to eliminate failures before they occur.

Digital-First Service Experience

AI-Powered Instant Quote Engine: Upload your CAD file and receive a detailed cost breakdown with DFM feedback in under 60 seconds.

Real-Time Production Tracking: Monitor machining progress, quality checkpoints, and shipping status through our client portal.

Industry-Leading Lead Times: Prototypes delivered in 3–5 days (standard) or 24 hours (expedited) for urgent hardware development cycles.

Materials & Surface Finishes

Material Options & Finishes

Precision Materials for Your Design Needs

Copper (C11000, C10100): Exceptional electrical (58 MS/m) and thermal conductivity (401 W/m·K), ideal for heat sinks, electrical contacts, and RF shielding. Cost-effective at $9–$15/kg. Our 5-axis machining ensures ±0.01mm tolerances for high-performance applications.

Aluminum 6061: Balanced strength, corrosion resistance, and machinability. Perfect for structural prototypes and lightweight components.

Aluminum 7075: Aerospace-grade strength (572 MPa tensile), ideal for high-stress applications where weight savings matter.

Stainless Steel 304/316: Superior corrosion resistance for medical, marine, and food-grade parts. 316 offers enhanced chloride resistance.

Brass (C11000): Excellent machinability and acoustic properties, commonly used for decorative fittings and electrical connectors.

PEEK: High-temp resistance (250°C+), chemical inertness, and biocompatibility for medical and aerospace components.

Tailored Surface Finishes

Copper-Specific:

Mirror Polishing: Achieve reflective, low-resistance surfaces for electrical contacts.

Electroplating (Gold/Nickel): Enhance conductivity, wear resistance, and corrosion protection.

Anti-Tarnish Coatings: Prevent oxidation while maintaining thermal performance.

General Finishes:

Anodizing (Aluminum): Custom colors with 20–50μm thickness for durability.

Powder Coating: Durable, matte/gloss finishes for steel and aluminum.

Passivation (Stainless Steel): Removes surface iron, boosting corrosion resistance.

Brushed Finish: Matte texture for architectural and aesthetic applications.

Smart Material Selection with AI-Powered Tools

Instant Quote Calculator: Upload your CAD file and get real-time pricing for copper CNC machining in seconds—no manual estimates needed.

AI-Optimized Recommendations: Our platform analyzes your design requirements (conductivity, strength, environment) to suggest the optimal material and finish combination.

Fast Turnaround Guarantee: Most copper prototypes ship in 3–5 business days. Our proprietary toolpath optimization cuts machining time by 20% while maintaining ±0.01mm precision.

Why Honyo? As pioneers in precision copper machining, we combine Susan Leo’s engineering expertise with cutting-edge AI to deliver functional prototypes and end-use parts faster than industry standards.

From Quote to Part: Our Process

How It Works: From CAD to Part

Seamless, transparent, and optimized for speed—your copper CNC machining journey starts here.

1. Upload CAD File

Submit your design files (STEP, STL, IGES, etc.) via our secure, user-friendly portal—no technical expertise required.

Our system automatically validates file integrity and compatibility for instant processing.

2. Get Instant Quote via AI-Powered Cost Calculator

Receive a real-time, transparent quote within seconds—no waiting, no manual quotes.

Detailed breakdown includes material costs (copper: $9–$15/kg), machining time, setup fees, and volume discounts.

Free cost calculator ensures zero hidden charges—only what you see is what you pay.

3. DFM Analysis & Optimization

AI-driven Design for Manufacturability (DFM) review identifies opportunities to optimize geometry, tolerances (+/- 0.01mm), and features for copper-specific machining challenges.

Receive actionable feedback to reduce costs, minimize material waste, and accelerate production—without compromising functionality.

4. Precision Production & Fast Delivery

Leverage our 3/4/5-axis CNC capabilities and strict quality controls to deliver micron-level precision for functional prototypes and end-use parts (e.g., electrical components, heat sinks, plumbing fittings).

Shenzhen-based manufacturing hub ensures rapid turnaround—prototypes in 24 hours, production runs scaled to your timeline.

End-to-end tracking with real-time updates and rigorous quality assurance at every stage.

Ready to transform your design into precision copper parts? Upload your CAD file now and get an instant quote in seconds.

Start Your Project with Honyo

Start Your Project with Honyo: Precision Copper Machining, Simplified

AI-Powered Instant Quote System

Free Online Cost Calculator: Get real-time pricing for copper CNC machining in seconds—no obligations, no delays.

Design Optimization: AI analyzes your CAD files to suggest cost-saving modifications without compromising precision.

Transparent Pricing: View material, setup, and machining costs broken down clearly—no surprises.

Precision Engineering Excellence

Tight Tolerances (+/- 0.01mm): Critical for functional prototypes and end-use parts in electrical, thermal, and RF applications.

Multi-Axis Mastery: 3/4/5-axis machining for complex geometries—optimized for copper’s thermal conductivity and softness.

Material-Specific Expertise: Specialized tooling and processes to prevent deformation, ensuring flawless surface finish and dimensional accuracy.

Rapid Turnaround, Zero Compromise

48-Hour Prototypes: Shenzhen/Dongguan facilities enable lightning-fast production cycles for urgent projects.

Seamless Scaling: From first article to high-volume runs—consistent quality without retooling delays.

Dedicated Project Management: Your single point of contact ensures on-time delivery and technical support at every stage.

Ready to Build with Precision?

Founder Susan Leo and our expert team are standing by to transform your copper designs into reality.

📧 Email: [email protected]

📞 Call: +86 139 2843 8620

📍 Visit: Shenzhen & Dongguan manufacturing hubs

Let’s engineer the future—faster, smarter, and with unmatched precision.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.