Contents

Manufacturing Insight: Coolant Nozzles For Cnc Machines

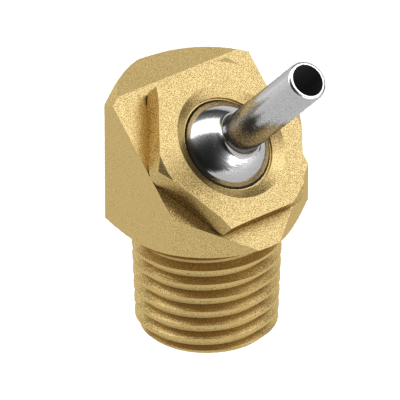

Precision Coolant Nozzle Solutions for Optimized CNC Machining Performance

In high-precision CNC operations, effective coolant delivery is non-negotiable for maximizing tool life, maintaining dimensional accuracy, and ensuring consistent surface finishes. Substandard nozzles lead to thermal distortion, accelerated tool wear, and unplanned downtime—directly impacting throughput and part quality. At Honyo Prototype, we engineer mission-critical coolant nozzles using advanced CNC machining processes designed to meet the most demanding industrial specifications. Our in-house capabilities span multi-axis milling, turning, and micro-machining, enabling tight tolerances down to ±0.005 mm and flawless surface integrity across materials like stainless steel, brass, aluminum, and engineered plastics. Every nozzle undergoes rigorous metrology validation to guarantee optimal flow dynamics, pressure resistance, and leak-free performance under continuous operational stress.

Leveraging decades of precision manufacturing expertise, Honyo transforms complex nozzle geometries—from articulated multi-jet systems to compact high-pressure variants—into reliable production assets. We prioritize rapid iteration and scalability, ensuring your coolant delivery system aligns precisely with spindle configurations, cutting strategies, and thermal management requirements. For engineering teams requiring accelerated procurement cycles, our Online Instant Quote platform delivers binding pricing and lead times in under 60 seconds. Simply upload your STEP or IGES file to receive a detailed manufacturability assessment alongside competitive pricing—no forms, no delays. Partner with Honyo to convert coolant delivery from a maintenance challenge into a strategic advantage for your CNC workflow.

Technical Capabilities

Coolant nozzles for CNC machines used in 3/4/5-axis milling, turning, and tight-tolerance applications are engineered to deliver precise, high-velocity coolant flow directly to the cutting interface. This ensures optimal chip evacuation, thermal management, and tool life—critical in high-precision and complex geometry machining. Nozzles must offer rigidity, chemical resistance, and flexibility in positioning to accommodate multi-axis tool paths and confined work envelopes.

The choice of nozzle material impacts performance based on pressure requirements, environmental exposure, and required durability. Common materials include aluminum for lightweight rigidity, steel for high-pressure and high-wear environments, and engineered polymers like ABS and nylon for corrosion resistance and reduced weight.

Below is a technical specification table summarizing key attributes of coolant nozzles by material and application:

| Parameter | Aluminum Nozzles | Steel Nozzles | ABS Plastic Nozzles | Nylon (Polyamide) Nozzles |

|---|---|---|---|---|

| Typical Applications | 3/4/5-axis milling, turning | High-pressure turning, heavy milling | Light-duty CNC, prototyping | General CNC, wet environments |

| Coolant Pressure Rating | Up to 70 bar (1000 psi) | Up to 100+ bar (1450+ psi) | Up to 35 bar (500 psi) | Up to 50 bar (725 psi) |

| Temperature Resistance | -50°C to +150°C | -50°C to +200°C | -20°C to +80°C | -40°C to +120°C |

| Chemical Resistance | Moderate (prone to corrosion) | High (stainless variants) | Good (resists water-based coolants) | Excellent (resists oils, coolants) |

| Mechanical Strength | High (rigid, vibration resistant) | Very High (wear-resistant) | Moderate (brittle at low T) | High (impact and abrasion resistant) |

| Weight | Lightweight | Heavy | Very lightweight | Lightweight |

| Adjustability | Manual or pneumatic swivel | Manual or robotic integration | Manual positioning | Manual or flexible hose feed |

| Mounting Interface | ISO 228/1, NPT, or custom CNC mounts | ISO 228/1, DIN 3852 | Push-fit or threaded adapters | Push-fit, threaded, modular |

| Flow Control | Adjustable orifice, laminar flow design | Precision orifice, multi-jet | Fixed or basic adjustment | Adjustable deflector tips |

| Tolerance Suitability | High (stable positioning) | Very High (minimal deflection) | Medium (flex under pressure) | High (dimensional stability) |

| Lifespan (Typical) | 2–5 years | 5–10+ years | 1–3 years | 3–6 years |

| Common Standards | ISO 1127, DIN 2353 | ISO 1127, ASTM A269 | ASTM D638, ISO 527 | ISO 18830, UL94 V-0 (flame) |

Notes:

For tight-tolerance machining, steel and aluminum nozzles are preferred due to minimal deflection under high coolant pressure and thermal stability.

Nylon and ABS are suitable for applications requiring corrosion resistance and electrical insulation, especially in environments with aggressive coolants.

Multi-axis systems often use articulated or robotic-compatible nozzles with quick-adjust features to maintain optimal coolant delivery across complex tool paths.

Nozzles must be compatible with through-spindle or high-pressure internal coolant systems when used in precision milling and deep turning operations.

From CAD to Part: The Process

Honyo Prototype Coolant Nozzle Manufacturing Process for CNC Machines

Our streamlined workflow ensures precision, efficiency, and reliability for coolant nozzle production. The process begins when a client uploads their CAD model through our secure online portal. We accept native formats including STEP, IGES, Parasolid, and SolidWorks files to maintain geometric accuracy. File validation occurs immediately, confirming dimensional completeness and identifying any missing metadata critical for manufacturing.

AI-Powered Quoting System

Upon CAD validation, our proprietary AI engine analyzes the model to generate an instant preliminary quote within 24 hours. The system evaluates key parameters such as part complexity, material requirements, tolerances, and surface finish specifications. For coolant nozzles, it specifically assesses internal flow path geometry, thread types (e.g., NPT, BSPP), and mounting interface criticality. While AI provides speed, all quotes undergo review by our applications engineering team to verify feasibility and address nuances like pressure ratings or corrosion resistance.

Engineering-Led DFM Analysis

Every design enters mandatory Design for Manufacturability (DFM) review by our senior manufacturing engineers. For coolant nozzles, we focus on:

Verifying thread engagement depth to prevent leakage under high-pressure coolant flow

Optimizing internal radii in fluid channels to minimize turbulence and erosion

Confirming material suitability against coolant chemistry (e.g., 303SS for standard coolants, 17-4PH for aggressive fluids)

Assessing thin-wall sections for deflection during clamping

Clients receive a detailed DFM report with actionable recommendations, typically within 48 hours. Common adjustments include modifying exit orifice chamfers for improved flow dynamics or suggesting standardized thread forms to reduce lead time.

Precision Production Execution

Approved designs move to production in our ISO 9001-certified facility. Coolant nozzles are manufactured using:

Swiss-type CNC lathes for complex geometries with tight tolerances (±0.005mm typical)

Multi-axis milling for non-rotational features like mounting flats or coolant distribution ports

In-process CMM verification of critical dimensions including thread pitch diameter and concentricity

All nozzles undergo 100% pressure testing to 1.5x operational rating with calibrated flow meters. Standard material options include:

| Material | Typical Application | Max Pressure Rating | Corrosion Resistance |

|---|---|---|---|

| 303 Stainless | General-purpose coolant | 1000 PSI | Moderate |

| 17-4 PH SS | High-pressure systems | 1500 PSI | High |

| Brass C36000 | Non-ferrous coolant lines | 750 PSI | Low |

Quality-Controlled Delivery

Final inspection includes surface roughness validation (Ra ≤ 0.8µm for sealing surfaces) and traceability documentation. Nozzles are packaged in anti-corrosion VCI bags with individual pressure test certificates. We offer consolidated shipping with real-time logistics tracking, typically delivering within 5-7 business days post-approval. Rush services are available for critical path components.

This integrated approach ensures coolant nozzles meet rigorous CNC operational demands while minimizing time-to-installation. For complex multi-nozzle manifolds or custom flow requirements, we recommend initiating the process with a pre-CAD engineering consultation to optimize performance parameters. Contact our applications engineering team to discuss specific coolant delivery challenges.

Start Your Project

Upgrade your CNC machining performance with precision-engineered coolant nozzles designed for optimal chip removal and tool cooling. Manufactured at our Shenzhen factory, our nozzles ensure durability, precise flow control, and seamless integration with your existing systems.

For inquiries or to request samples, contact Susan Leo at [email protected].

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.