Contents

Manufacturing Insight: Coolant Nozzle For Cnc Machine

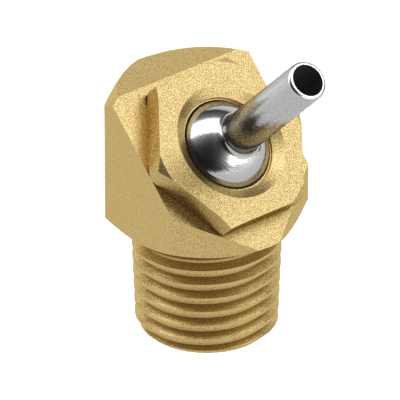

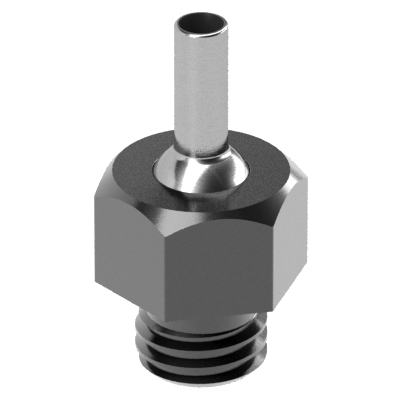

Precision Coolant Nozzles: Optimizing CNC Performance Through Expert Machining

Effective coolant delivery is non-negotiable for maximizing CNC machine uptime, tool life, and part quality. Standard nozzles often fail to maintain consistent flow under high-pressure conditions, leading to premature tool wear, thermal distortion, and subpar surface finishes. At Honyo Prototype, we engineer mission-critical coolant nozzles using advanced CNC machining processes that ensure micron-level accuracy in complex internal geometries and sealing surfaces. Our ISO 9001-certified facility leverages multi-axis milling and turning centers to produce nozzles from demanding materials like stainless steel 316, brass C36000, and PEEK, all held to tolerances as tight as ±0.005 mm. This precision guarantees optimal coolant trajectory and pressure stability, directly reducing scrap rates and extending spindle longevity in your production environment.

Honyo’s end-to-end CNC machining services integrate design validation, rapid prototyping, and high-volume production under one roof. We specialize in transforming conceptual nozzle designs into field-proven components through rigorous material selection, thermal analysis, and flow testing. Unlike generic suppliers, our engineers collaborate with clients to address specific application challenges—from micro-bore drilling for Swiss-type lathes to corrosion-resistant configurations for abrasive coolant mixtures.

Technical Comparison: Standard vs. Honyo-Engineered Nozzles

| Feature | Generic Nozzles | Honyo Precision Nozzles |

|————————|————————-|—————————-|

| Flow Consistency | ±15% variation | ±3% variation (verified) |

| Pressure Rating | Up to 50 bar | Up to 100 bar |

| Surface Finish (Ra) | 1.6–3.2 μm | 0.4–0.8 μm |

| Lead Time (Prototype) | 4–6 weeks | 7–10 business days |

Accelerate your CNC optimization with Honyo’s Online Instant Quote platform. Upload your STEP or IGES files to receive a detailed manufacturability analysis and competitive pricing within 2 hours—no sales calls required. Our digital workflow ensures rapid turnaround from quotation to first-article inspection, keeping your machine tools running at peak efficiency. Request your quote today and experience coolant delivery engineered for uncompromised performance.

Technical Capabilities

Coolant Nozzle for CNC Machine – Technical Specifications

The coolant nozzle is a critical component in CNC machining environments, especially in high-precision 3/4/5-axis milling and turning operations where tight tolerances are required. Proper coolant delivery ensures effective chip evacuation, reduced tool wear, and improved dimensional accuracy by minimizing thermal distortion. These nozzles must be durable, precisely adjustable, and chemically resistant to coolants and cutting fluids.

Below are the technical specifications and material considerations for coolant nozzles used in demanding CNC applications.

| Parameter | Specification |

|---|---|

| Application | 3/4/5-axis CNC milling, CNC turning centers, high-precision machining |

| Operating Pressure | 30 – 120 psi (2 – 8 bar), compatible with high-pressure through-spindle systems |

| Flow Rate | 5 – 40 liters per minute (adjustable based on nozzle orifice and pressure) |

| Nozzle Orifice Diameter | 1.5 mm to 6.0 mm (interchangeable tips available for focused or wide spray) |

| Adjustability | 360° swivel with locking mechanism; multi-axis articulation for precise aiming |

| Mounting Interface | Standard M8, M10, or 1/8″ NPT threads; modular brackets for tool holder proximity |

| Temperature Range | -20°C to +120°C (-4°F to +248°F) |

| Chemical Resistance | Resistant to water-soluble coolants, oil-based fluids, and synthetic emulsions |

| Precision Alignment | Laser-guided positioning options available for micron-level targeting |

| Material Options | Aluminum, Steel, ABS, Nylon – selected based on durability, weight, and cost |

Material Properties and Use Cases:

Aluminum (e.g., 6061-T6)

Lightweight and corrosion-resistant, anodized aluminum offers excellent strength-to-weight ratio. Ideal for articulated arms and adjustable mounts where rigidity and low inertia are important. Suitable for environments with moderate chemical exposure.

Steel (e.g., 304/316 Stainless)

Provides superior durability and resistance to high pressure and mechanical impact. Used in high-wear zones or near the cutting zone where robustness is critical. 316 stainless offers enhanced corrosion resistance to chlorinated coolants.

ABS (Acrylonitrile Butadiene Styrene)

A rigid thermoplastic used for low-cost, non-load-bearing nozzle bodies. Offers good machinability and chemical resistance but limited to lower temperature and pressure applications. Common in prototype or light-duty setups.

Nylon (e.g., PA6 or PA66)

Highly resistant to abrasion and chemicals, nylon is used for nozzle tips and liners. It maintains performance under continuous coolant flow and resists clogging. Ideal for high-cycle operations with aggressive fluid dynamics.

Each material is selected based on the operational demands of tight-tolerance machining, where consistent coolant delivery directly influences surface finish, tool life, and dimensional repeatability.

From CAD to Part: The Process

Honyo Prototype executes coolant nozzle manufacturing for CNC machines through a rigorously defined five-stage workflow optimized for precision, speed, and manufacturability. This process ensures components meet stringent requirements for flow dynamics, thread integrity, and thermal stability under high-pressure coolant conditions.

CAD Upload

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system validates geometric completeness, including critical features such as internal taper angles, thread profiles per ISO 228/1 standards, and mounting interface dimensions. Incomplete models trigger immediate automated notifications specifying required revisions to prevent downstream delays.

AI-Powered Quotation

Uploaded geometry undergoes automated analysis by our proprietary AI engine which evaluates 12+ manufacturability parameters including minimum wall thickness, aspect ratios, and feature accessibility for Swiss-type turning. The system cross-references material databases (common alloys: 303/304/17-4 PH stainless steel, brass C360) and generates a binding quote within 2 business hours. Quotes explicitly detail cost drivers such as secondary operations for micro-bore drilling (<1.5mm) or precision honing requirements.

Engineering DFM Review

All quotes include a comprehensive Design for Manufacturability report authored by our CNC process engineers. This phase identifies high-risk geometries such as unsupported overhangs in multi-nozzle manifolds or inadequate draft angles for internal coolant channels. Typical resolutions include suggesting chamfer adjustments to prevent burr formation during thread cutting or modifying internal radii to accommodate tool nose radius compensation. Client approval of DFM recommendations is mandatory prior to production release.

Precision Production

Approved designs enter production on dedicated Swiss automatic lathes (Tornos Deco 2000, Star SR-20) with real-time coolant pressure monitoring. Key process controls include:

In-process probing for thread pitch diameter verification per ASME B1.20.1

100% flow testing at 70 bar using calibrated flow meters

Surface roughness validation (Ra ≤ 0.8 µm) on critical sealing surfaces

Secondary operations like laser marking of part numbers occur only after first-article inspection clearance.

Quality-Controlled Delivery

Each shipment includes first-article inspection reports with CMM data for critical dimensions and flow test certificates. Parts are vacuum-sealed with corrosion inhibitors and kitted with mounting hardware where specified. Real-time logistics tracking is provided from our Shenzhen facility, with standard lead times of 7-10 business days for quantities under 500 units. Expedited delivery options include DHL Express with temperature-controlled packaging for sensitive materials.

Start Your Project

Upgrade your CNC machining performance with our precision-engineered coolant nozzles, designed for optimal chip removal and tool cooling. Manufactured in Shenzhen with strict quality control, our nozzles ensure durability and consistent performance under demanding conditions.

For inquiries or to request a sample, contact Susan Leo at [email protected]. We provide reliable, high-quality fluid delivery solutions tailored to your CNC application needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.